Catalyst injection method and catalyst injection device

A technology for injection devices and catalysts, applied in chemical instruments and methods, catalytic cracking, cracking, etc., can solve problems such as easy wear, unfavorable mixing, and inability to run for a long period of time, and achieve the goals of reducing wear, increasing reaction temperature, and reducing olefin content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

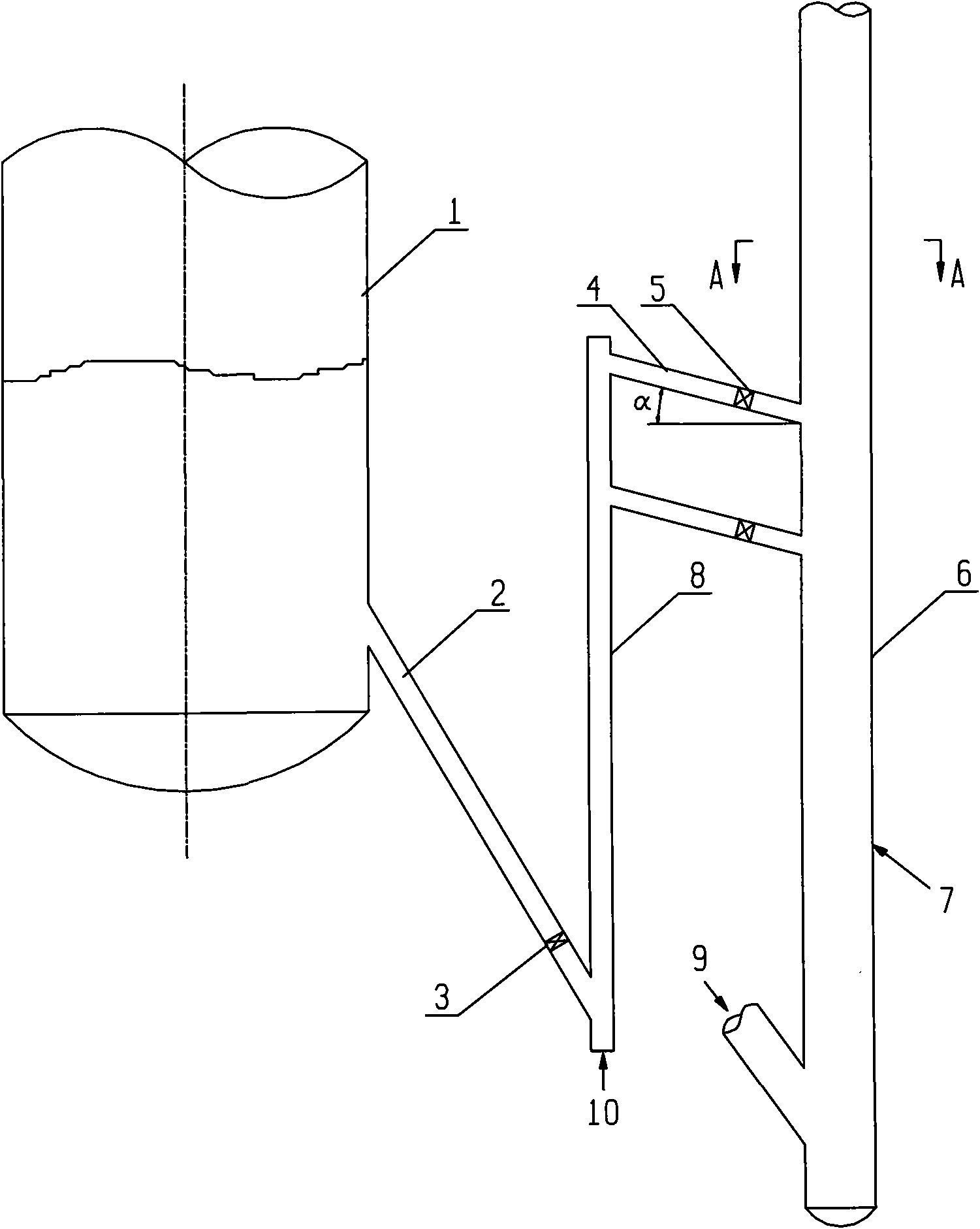

[0026] Such as figure 1 , a catalyst injection method, the catalytic cracking catalyst is injected into the container 1, through the inclined pipe 2 to the bottom of the standpipe 8, and then under the action of the lift gas 10, the catalyst is sent from the standpipe 8 to the injection pipe 4, under control It enters the FCC riser reactor 6 under the control of valve 5.

[0027] Such as figure 1 , a catalyst injection device, the bottom of the container 1 is connected to the inlet of the inclined catalyst tube 2, the outlet of the inclined catalyst tube 2 is connected to the inlet of the standpipe 8, the outlet of the standpipe 8 is connected to the inlet of the injection pipe 4, and the angle between the injection pipe 4 and the horizontal direction is For 30 °, there are 2 injection pipes 4.

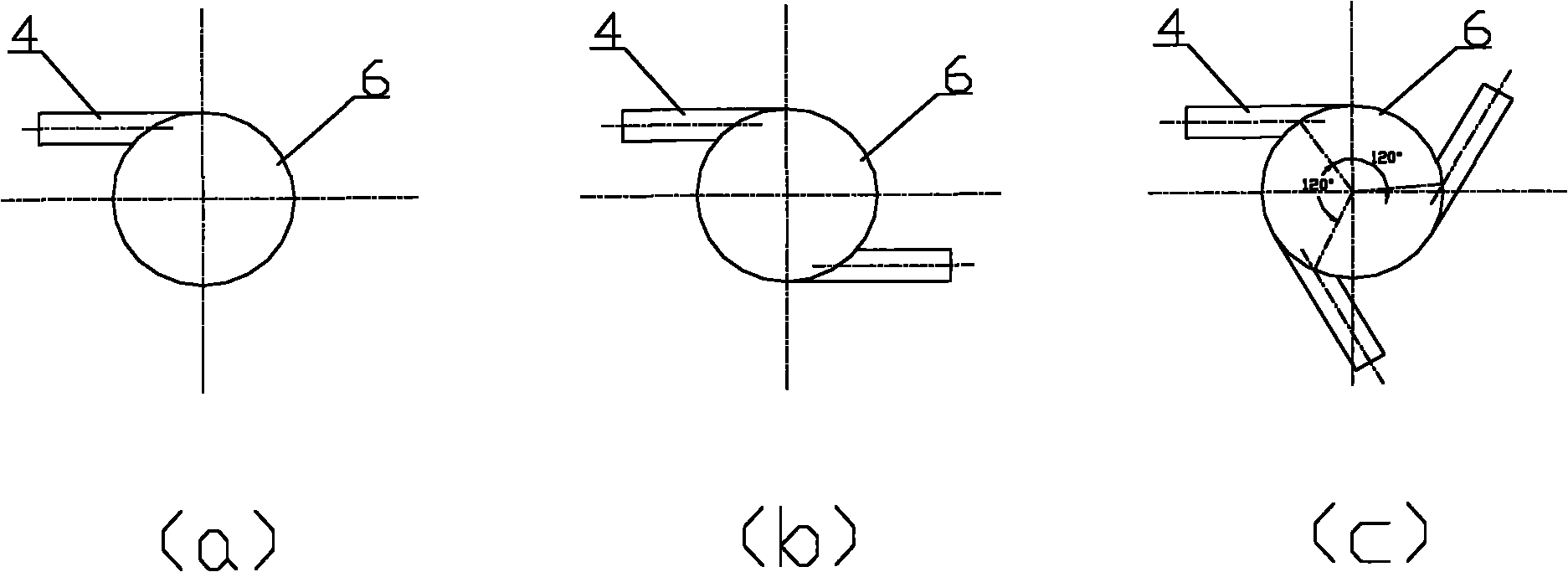

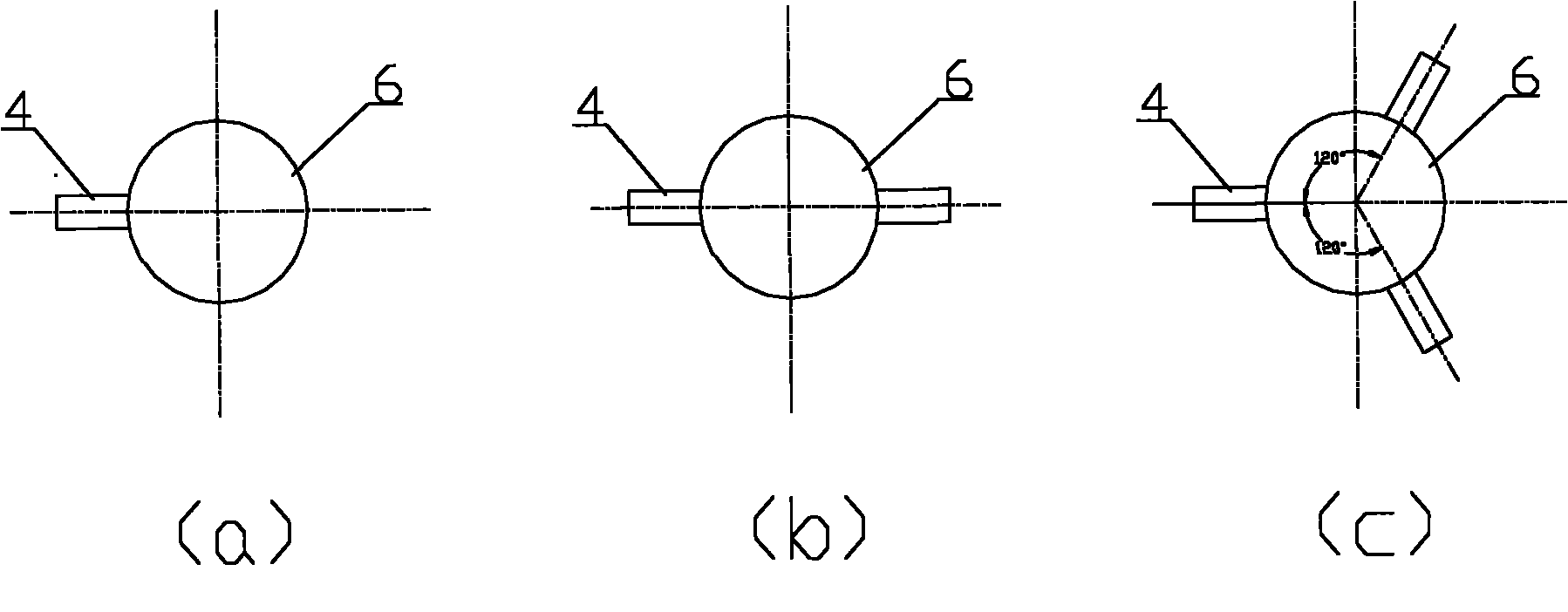

[0028] figure 2 , image 3 for figure 1 In the cross-sectional view of A-A, two-way or three-way methods are generally used to ensure that the catalysts at each injection port a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com