Vortex tube for mass spectrometry reaction acceleration and signal enhancement and its realization method

A vortex tube and mass spectrometry technology, applied in the field of ion optical device fabrication, can solve the problems of low ion mixing contact efficiency, difficult to adjust reaction time, low ion transmission efficiency, etc. The effect of improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

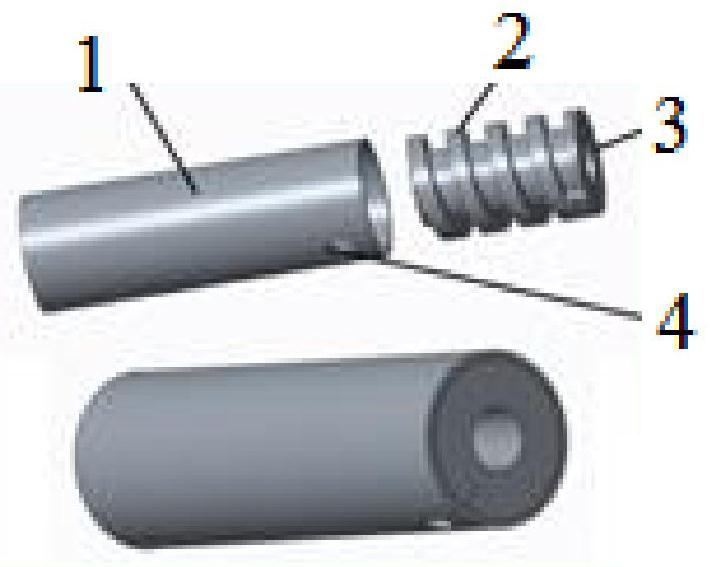

[0055] The vortex tube provided in this embodiment consists of two parts: a sealed tube and a threaded tube. The total length of the threaded pipe is 15.0mm, the maximum outer diameter is 10.0mm, the cross section of the thread is a rectangle of 2.0mm×1.5mm, and the pitch is 3.5mm. There is an ion channel with a diameter of 4.0mm in the center of the threaded tube. The length of the sealed tube is 30.0mm, the inner diameter is 10.1mm, and the outer diameter is 11.0mm, and a small hole with a diameter of 2.5mm is left at one end to introduce gas into the vortex tube. The threaded pipe is sleeved into the sealing pipe, and the two are tightly slidable, and one end of the threaded pipe is aligned with the end where the small air inlet hole on the sealing pipe is located. Gas is introduced through small holes and into the threaded grooves. Under the diversion action of the thread, the gas spirals forward, and after 15mm, it breaks away from the thread at the end of the threaded ...

Embodiment 2

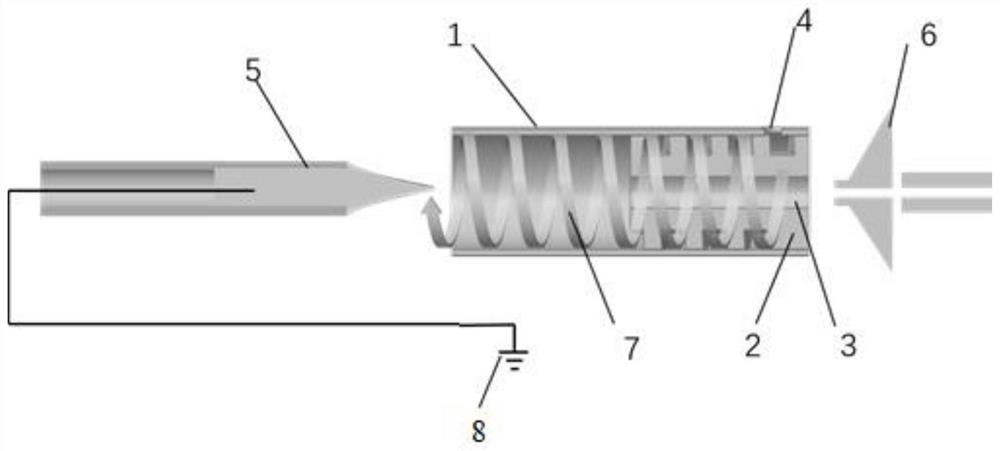

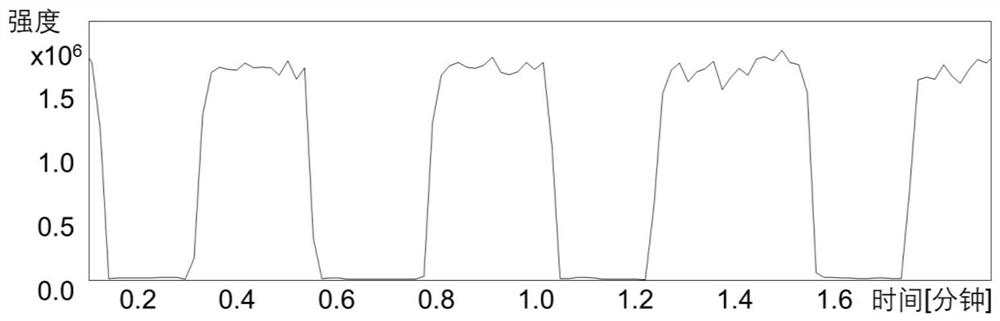

[0057] This embodiment provides a usage of the vortex tube of the present invention. Such as figure 2 As shown, the Nano-ESI ion source is placed on the front side of the vortex tube with its tip flush with the vortex tube outlet. The vortex tube is placed between the ion source and the MS inlet. After the sample is injected and a high voltage of 1000-5000V is provided by the high-voltage power supply 8, the tip of the Nano-ESI will generate many charged small droplets. Under the action of the vortex gas 7 for these small droplets, the solvent evaporates rapidly, and the volume of the droplets decreases. The reactants inside the droplet continue to accumulate on the surface of the droplet. When the surface tension of the droplet is exceeded, a "Coulomb explosion" occurs, and the droplet further becomes a smaller droplet. After several rounds of this process, charged ions are formed one by one in the vortex tube and finally enter the mass spectrometer to be detected. Durin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com