High-efficiency chemical fertilizer processing device

A processing device and high-efficiency technology, applied in transportation and packaging, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of difficult mixing, affecting the quality of fertilizers, and hard lumps of fertilizers, etc., to achieve high work efficiency and mixing materials Rapid and uniform, avoid condensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

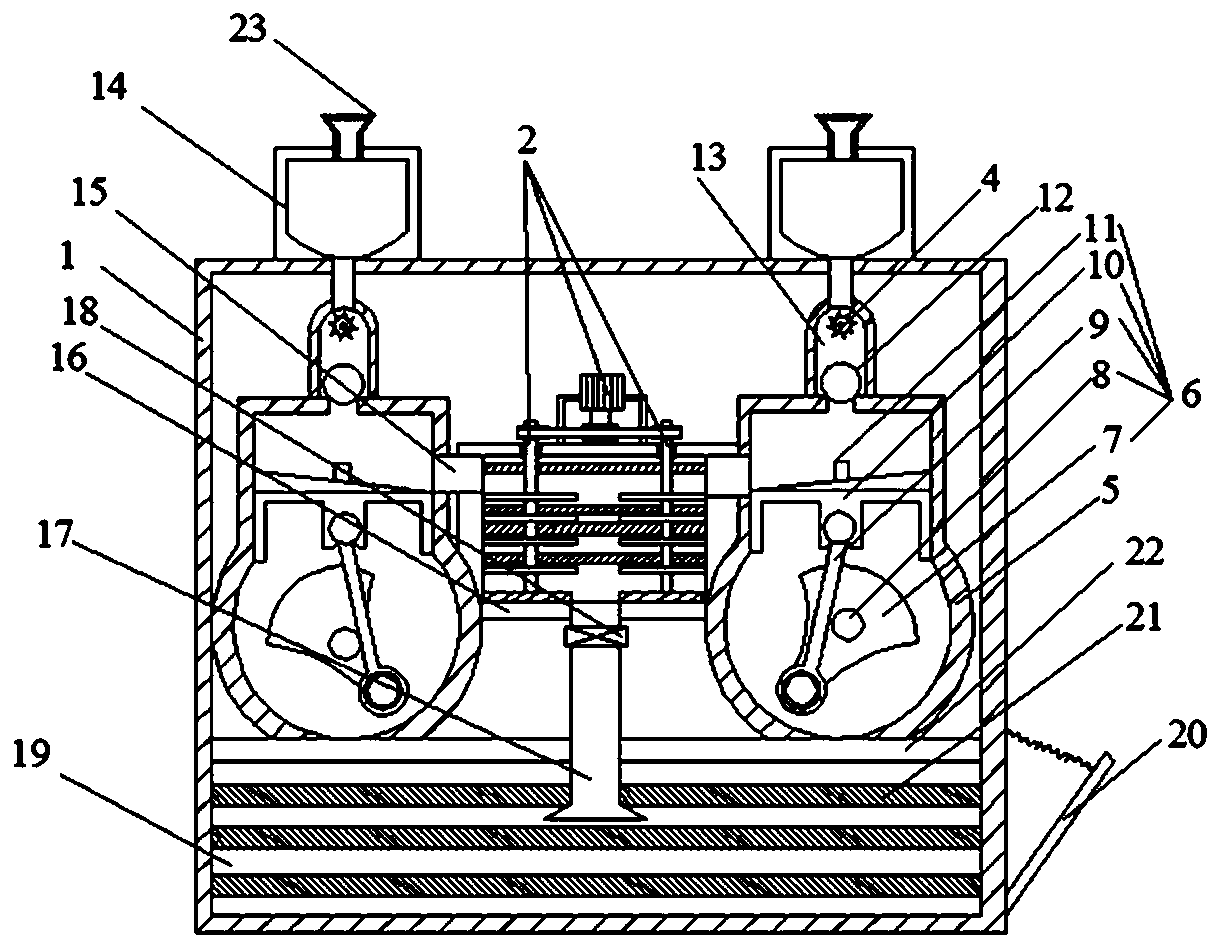

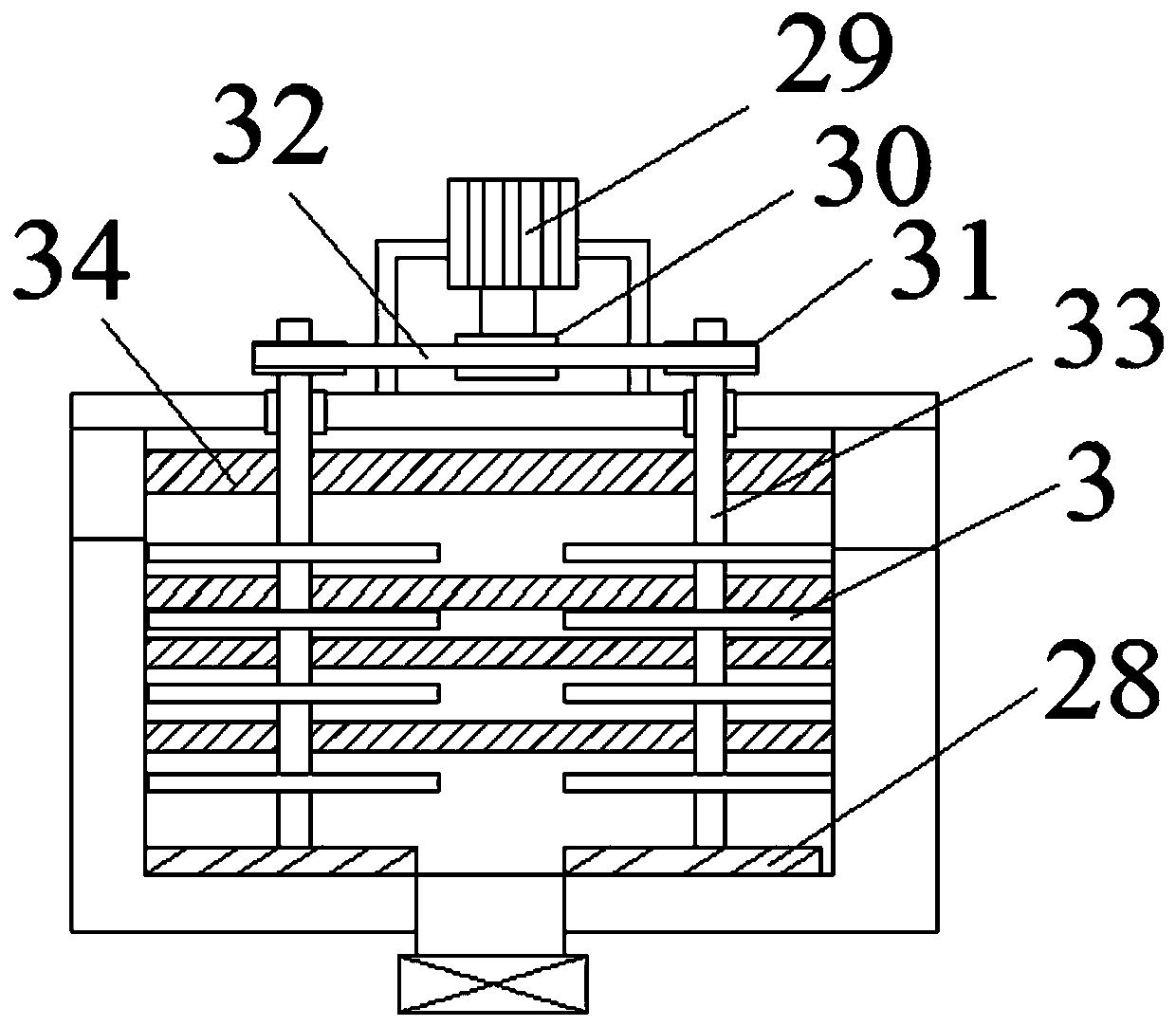

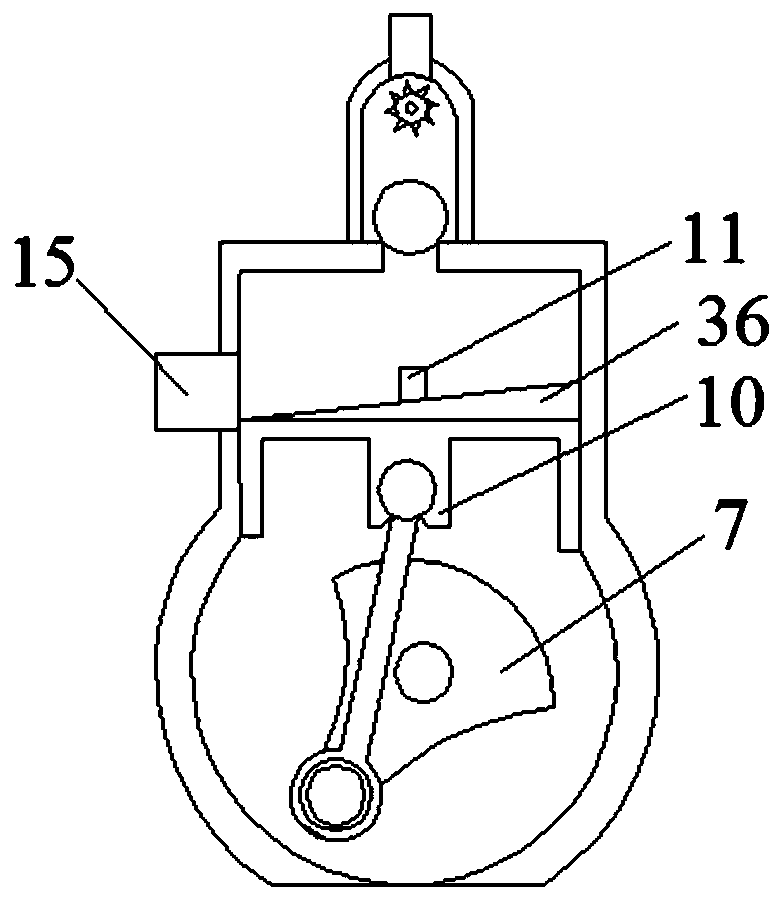

[0027] see Figure 1-7 , a high-efficiency fertilizer processing device according to an embodiment of the present invention, comprising an outer box 1, a mixing box 16, a mixing driving mechanism 2, a flying disc 3, a crushing mechanism 4, a feeding box 5 and a feeding mechanism 6, The inside of the outer box body 1 is provided with a dividing plate 22, the bottom of the dividing plate 22 is provided with a material storage chamber 19, and the top of the dividing plate 22 is fixed with a mixing box 16, and the two sides of the mixing box 16 Both sides are fixed with feeding box 5, the top of described feeding box 5 is provided with inverted U-shaped cavity 13 and is provided with the material inlet 15 that is communicated with mixing box 16 below inverted U-shaped cavity 13, described inverted The top of the U-shaped cavity 13 communicates with the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com