Emulsion paint stirring device for indoor buildings

A stirring device and latex paint technology, which is applied in the field of building material decoration, can solve the problems of partial accumulation of materials, uneven mixing, unfavorable mixing of latex paint, etc., and achieve the effect of uniform mixing and good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

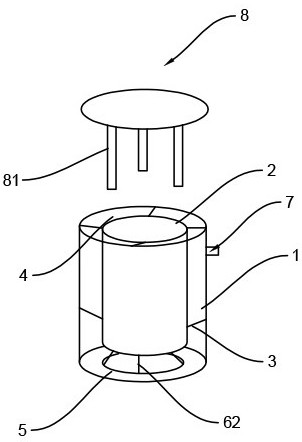

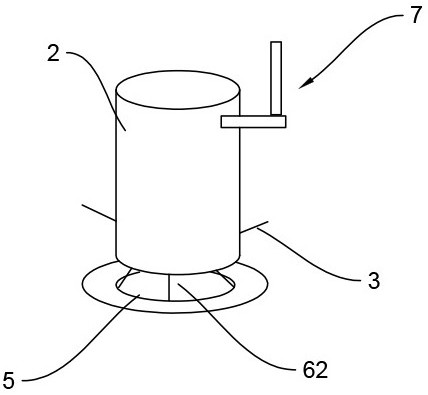

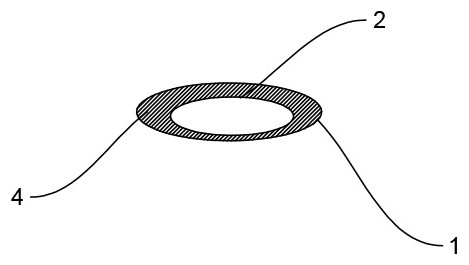

[0042] see Figure 1 to Figure 6, a latex paint stirring device for indoor architecture, comprising a fixed shell 1, a stirring cavity 2 built in the fixed shell 1, a plurality of first elastic members 3, A second elastic member 4 is connected, and the bottom of the fixed housing 1 is provided with an annular rail groove 5, and the stirring device also includes a plurality of stabilizing members 6, and the stabilizing member 6 includes a rail groove accommodated in the rail groove 5 Rolling ball 61, one end is fixedly connected to the bottom of the stirring chamber 2, and the other end is fixedly connected to the elastic connecting piece 62 of the rolling ball 61. When the stirring chamber 2 is not shaking, the elastic connecting piece 62 is in the Compressed state, the stirring device also includes a stirring part 7 for stirring the stirring chamber 2, and the stirring part 7 includes a through hole passing through the fixed shell 1 and a hole of the stirring chamber 2 The t...

Embodiment 2

[0052] see Figure 1 to Figure 5 , Figure 7 , a latex paint stirring device for indoor architecture, comprising a fixed shell 1, a stirring cavity 2 built in the fixed shell 1, a plurality of first elastic members 3, A second elastic member 4 is connected, and the bottom of the fixed housing 1 is provided with an annular rail groove 5, and the stirring device also includes a plurality of stabilizing members 6, and the stabilizing member 6 includes a rail groove accommodated in the rail groove 5 Rolling ball 61, one end is fixedly connected to the bottom of the stirring chamber 2, and the other end is fixedly connected to the elastic connecting piece 62 of the rolling ball 61. When the stirring chamber 2 is not shaking, the elastic connecting piece 62 is in the Compressed state, the stirring device also includes a stirring part 7 for stirring the stirring chamber 2, and the stirring part 7 includes a through hole passing through the fixed shell 1 and a hole of the stirring ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com