Continuous dry digestion device and processing method for wastes

A waste and dry technology, applied in biochemical cleaning devices, biochemical equipment and methods, biomass post-processing, etc. Element enrichment and other problems, to avoid the use of a large amount of water, reduce operating costs, and relieve the effect of inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

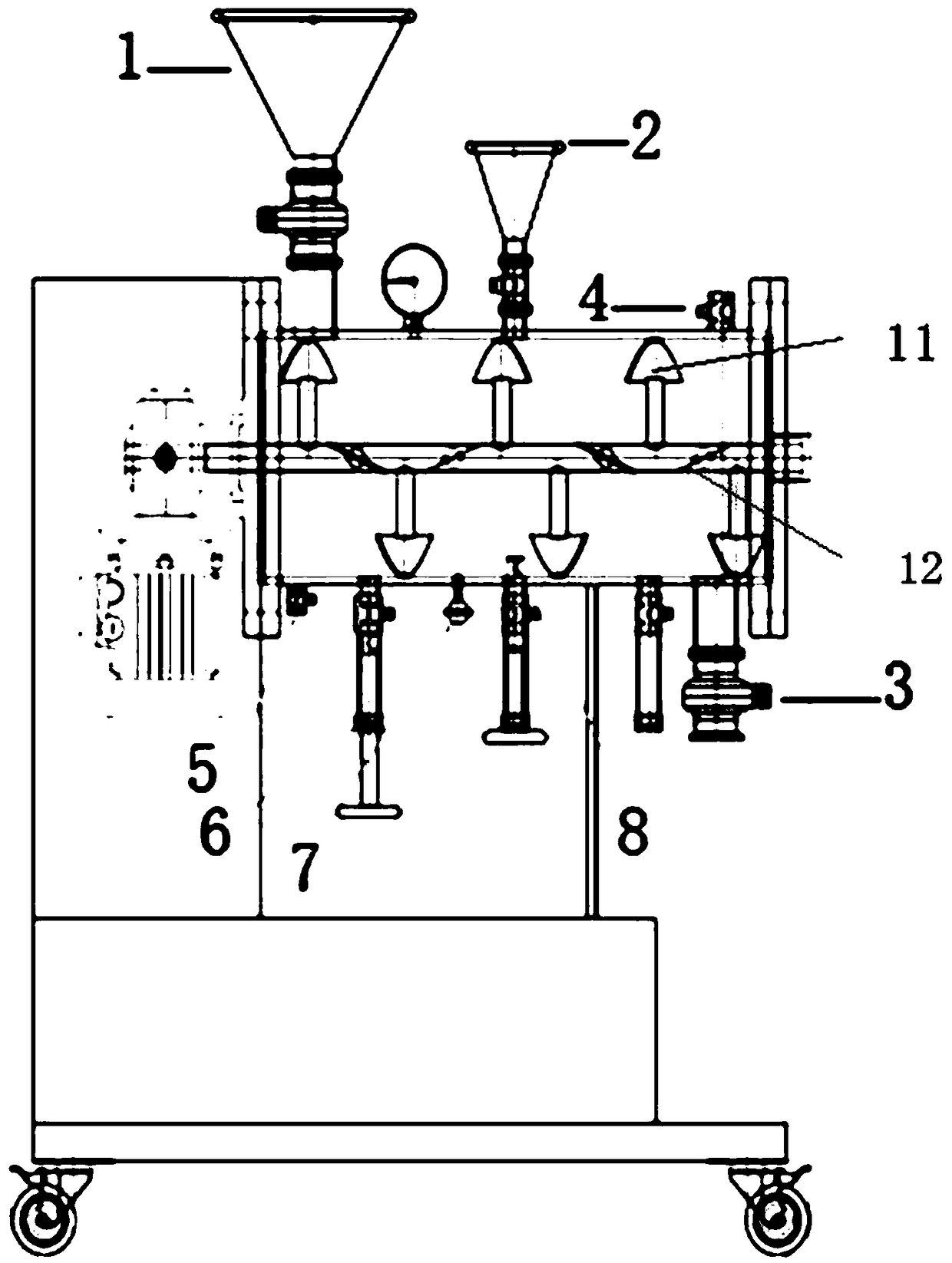

[0071] Example 1: Microbial anaerobic treatment of kitchen waste to produce biogas

[0072] First, the collected kitchen waste is squeezed to remove most of the water, and then input into the reactor through the deep bucket feed hopper 1; the anaerobic activated sludge is input into the reactor through the strain injection port 2, and in the reactor with 5kg of extruded kitchen waste is fully mixed by a compound mixing system. The dry weight ratio of activated sludge to kitchen waste is 2:1. The reaction is carried out in a reactor with a fermentation temperature of 37°C and a fermentation time of 18 days. The pressure is normal pressure; the fermentation product is separated to produce 502.3 liters of biogas, which is discharged through the biogas outlet 4, and the reaction residue is discharged through the tailing outlet 3.

Embodiment 2

[0073] Example 2: Anaerobic fermentation of municipal waste organic components to produce biogas

[0074] The anaerobic activated sludge is mixed with the pulverized urban refuse organic components, and is input into the reactor through a deep bucket feed hopper 1; the amount of the urban refuse organic components is 10kg, and the anaerobic activated sludge and the municipal refuse organic components The ratio is 3:1; in the reactor, it is mixed evenly by the compound stirring system, the fermentation temperature is 37°C, the fermentation time is 38 days, the fermentation pressure is normal pressure, the fermentation product is separated, the collected gas volume is 2050L, and the gas is discharged through the biogas outlet 4 Discharge, finally obtain the dry weight of the fermentation product with a mass of 7.7kg, realize volume reduction, and the reaction residue is discharged through the tailing discharge port 3.

Embodiment 3

[0075] Example 3: Mixed solid-state fermentation of kitchen waste and municipal solid waste

[0076] First, squeeze the collected kitchen waste to remove most of the water, mix the squeezed kitchen waste and municipal solid waste evenly in a ratio of 1:1 in the mixing tank, and input them through the deep bucket feeding hopper 1 Reactor; fully mix the anaerobic activated sludge with the above-mentioned organic mixture, and stir through the composite stirring system, so that the microbial catalyst and the 10kg extruded kitchen waste and domestic waste mixture are stirred evenly, the stirring speed is 30 rpm, and the stirring The direction is to stir clockwise for 3 hours, stop for 5 hours, and counterclockwise for 3 hours, and so forth; ferment in the reactor, the fermentation temperature is 30°C, the fermentation time is 20 days, the pressure of the fermentation is normal pressure, and the fermentation product is separated. The fermentation gas is collected and discharged thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com