Coal tar hydrogenating modified method by two-stage method

A technology of hydrogenation upgrading and coal tar, which is applied in the fields of hydrogenation treatment process, petroleum industry, and hydrocarbon oil treatment, which can solve the problems of cost increase and achieve the effects of reducing content, long service life, and reducing aromatics content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

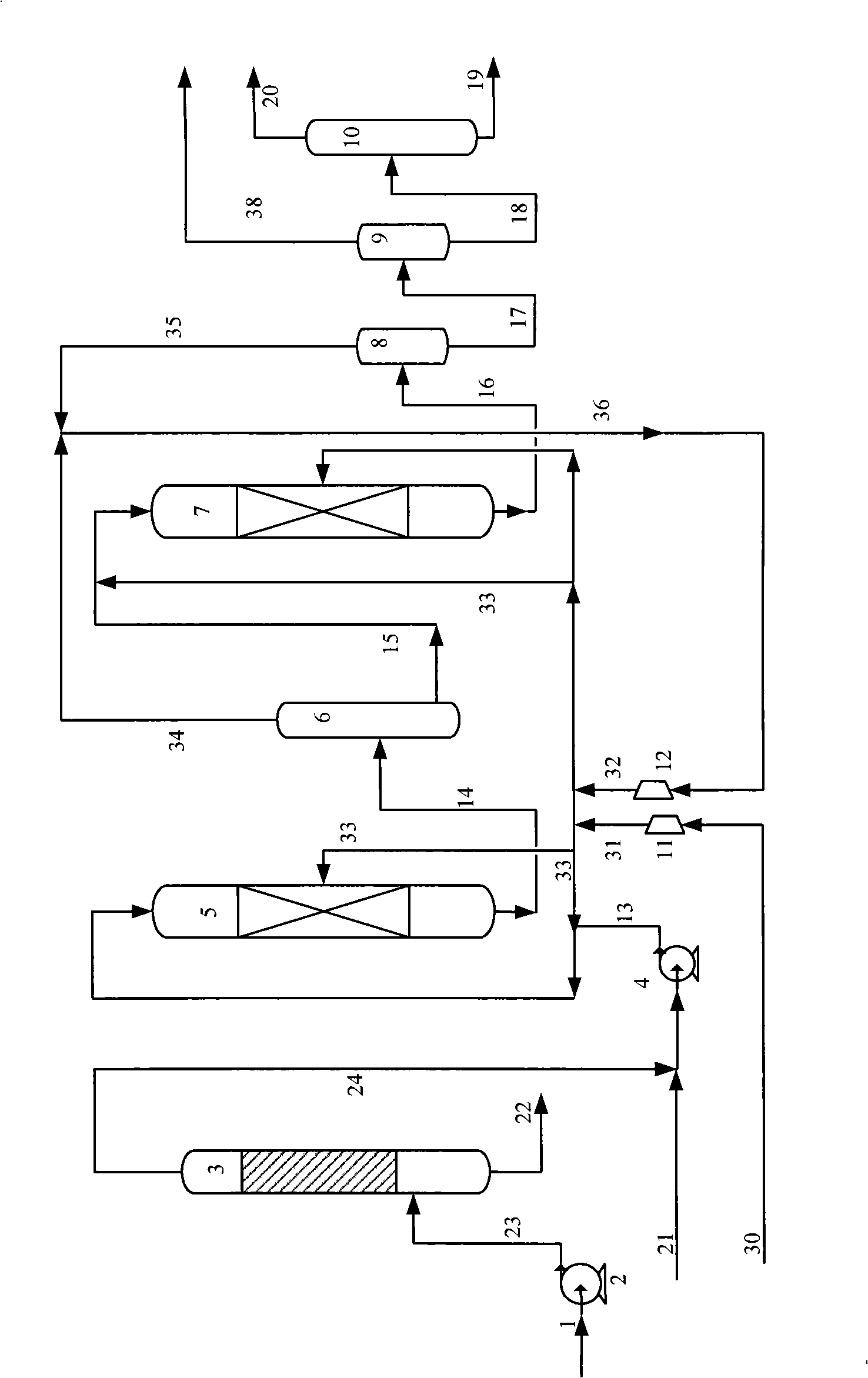

Image

Examples

Embodiment 1

[0041] A kind of high-temperature coal tar is used as raw material oil, its properties are shown in Table 1, continuous distillation under normal pressure is separated into 365 ° C coal tar heavy fraction, in addition, the < 365 ° C coal tar light fraction is tested Boiling point distillation removes the naphthalene-rich fraction at 210-230°C to obtain a light fraction of coal tar with naphthalene removal <365°C. The basic properties of the above fractions are shown in Table 2.

Embodiment 2

[0043] The naphthalene-removed coal tar light fraction obtained in Example 1 was blended with a catalytic cracking diesel oil A at a mass ratio of 1:3 to obtain a mixed feedstock oil B. The basic properties of the catalytic cracked diesel oil A and the mixed feedstock oil B are shown in Table 3. The raw material oil B is mixed with hydrogen and enters the first hydrogenation reaction zone to contact and react with the hydrofining catalyst E. The reaction effluent enters the second hydrogenation reaction zone after hydrogen sulfide and ammonia are removed in the intermediate flash tower The hydrocracking catalyst G is contacted to react, and the effluent after the reaction is cooled, separated and fractionated to obtain a diesel fraction and a small amount of naphtha fraction. The loading volume ratio of the hydrofinishing catalyst E and the hydrocracking catalyst G is 3:2. The specific reaction conditions are shown in Table 4, and the main product properties are shown in Table ...

Embodiment 3

[0046] The coal tar light fraction obtained in Example 1 was blended with a catalytic cracking diesel oil A at a mass ratio of 1:3 to obtain a mixed feedstock oil C. The basic properties of the catalytic cracked diesel oil A and the mixed feedstock oil C are shown in Table 3. The raw material oil C is mixed with hydrogen and enters the first hydrogenation reaction zone to contact and react with the hydrofining catalyst E. After the hydrogen sulfide and ammonia are removed in the high-pressure stripping tower, the reaction effluent enters the second hydrogenation reaction zone and The hydrocracking catalyst G contacts and reacts, and the loading volume ratio of the hydrofinishing catalyst E and the hydrocracking catalyst G is 1:1. The specific reaction conditions are shown in Table 4, and the main product properties are shown in Table 5.

[0047] It can be seen from Table 5 that the density of the diesel fraction is 0.8466g / cm 3 , the sulfur content is 26 μg / g, the polycyclic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com