Method for synthesis of beta-zeolite

A synthesis method, the technology of zeolite beta, which is applied in the field of synthesis of zeolite beta, can solve the problems such as difficulty in obtaining nano-silicon-alumina ratio of zeolite beta, and achieve good selectivity and cracking activity, high acid strength, and high hydrothermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

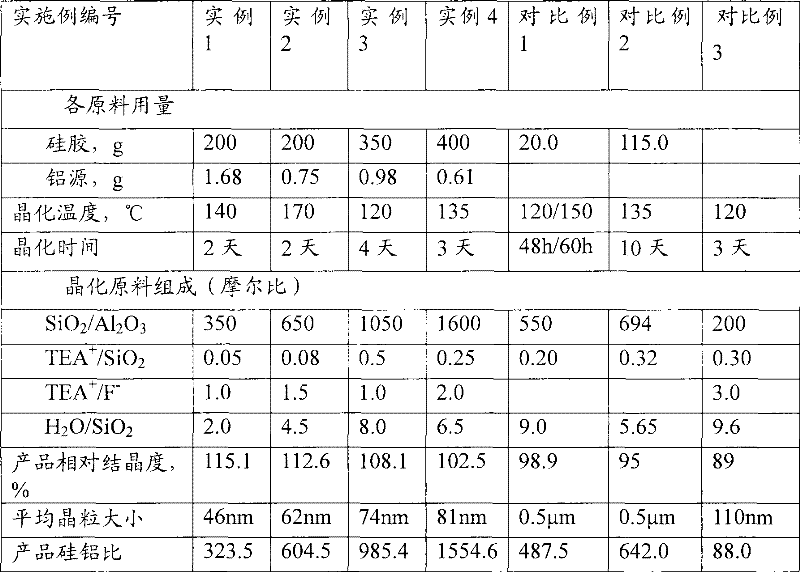

Embodiment 1

[0033] (1) Aluminum trihydrate (containing Al 2 o 3 56.5% by weight, produced by Shandong Aluminum Works) mixed with water, hydrochloric acid (analytically pure, concentration 37% by weight), acidified to form a sol, HCl:Al 2 o 3 =0.25 (molar ratio); then add 80-120 mesh coarse-porous silica gel (produced by Qingdao Ocean Chemical Factory), and then use ultrasonic waves to fully mix the silica gel and acidified peptized pseudo-boehmite at room temperature to obtain a silica-alumina gel. where nH in the above mixture 2 O / (nSiO 2 +nAl 2 o 3 )=10.0 (molar ratio), the consumption of silica gel and aluminum oxide trihydrate makes the SiO of the obtained silica-alumina gel 2 / Al 2 o 3 The molar ratio is 350;

[0034] (2) drying the silica-alumina gel obtained in step (1) at a temperature of 120° C. for 48 hours, and grinding it into 40-200 mesh silica-alumina gel particles;

[0035] (3) the silica-alumina colloid particle (with SiO2) gained in step (2) 2 meter), template ...

Embodiment 2

[0037] (1) Pseudoboehmite (containing Al 2 o 3 68.21% by weight, produced by Shandong Aluminum Works) mixed with water, acidified with acetic acid (Beijing Chemical Reagent Company, analytically pure), to form a sol, acetic acid and Al 2 o 3 The molar ratio of the silica gel to pseudo-boehmite is 0.35; then add 80-120 mesh fine-pore silica gel (produced by Qingdao Ocean Chemical Factory), the molar ratio of silica gel to pseudo-boehmite (based on SiO 2 / Al 2 o 3 ) is 650, and then use ultrasonic dispersion to fully mix silica gel and acidified peptized pseudo-boehmite at room temperature to obtain silica-alumina gel, wherein nH in the above mixture 2 O / (nSiO 2 +nAl 2 o 3 )=12.0 (molar ratio);

[0038] (2) drying the silica-alumina gel obtained in step (1) at a temperature of 120° C. for 48 hours, and grinding it into 40-200 mesh silica-alumina gel particles;

[0039] (3) the silica-alumina colloidal particle of step (2) gained is used as the raw material of synthesizi...

Embodiment 3

[0041] (1) aluminum hydroxide (containing Al 2 o 3 56.8% by weight, produced by Shandong Aluminum Works) as aluminum source, mix with water, acidify with formic acid (Beijing Chemical Reagent Company, analytically pure, concentration 40.0% by weight), form sol, formic acid: Al 2 o 3 =0.55; Add 120~200 meshes of mesoporous silica gel (produced by Qingdao Ocean Chemical Factory) afterwards, the mol ratio of silica gel and aluminum hydroxide is SiO 2 / Al 2 o 3 It is calculated as 1050, and then dispersed by ultrasonic wave, so that the silica gel and the acidified peptized pseudo-boehmite are fully mixed at room temperature to obtain a silica-alumina gel, wherein the nH in the above mixture 2 O / (nSiO 2 +nAl 2 o 3 )=16.0 (molar ratio).

[0042] (2) Dry the silica-alumina gel obtained in step (1) at 80°C for 24 hours, then dry at 120°C for 24 hours, and then grind it into 40-200 mesh silica-alumina gel particles;

[0043] (3) the silica-alumina colloid particle of step (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com