Efficient ammonia mixing and spraying device for flue gas denitration system

A technology of mixed spraying and denitrification, which is applied in the field of flue gas denitrification system, can solve the problems of large amount of installation work, and achieve the effect of compact layout, simple structure, and no nozzle clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

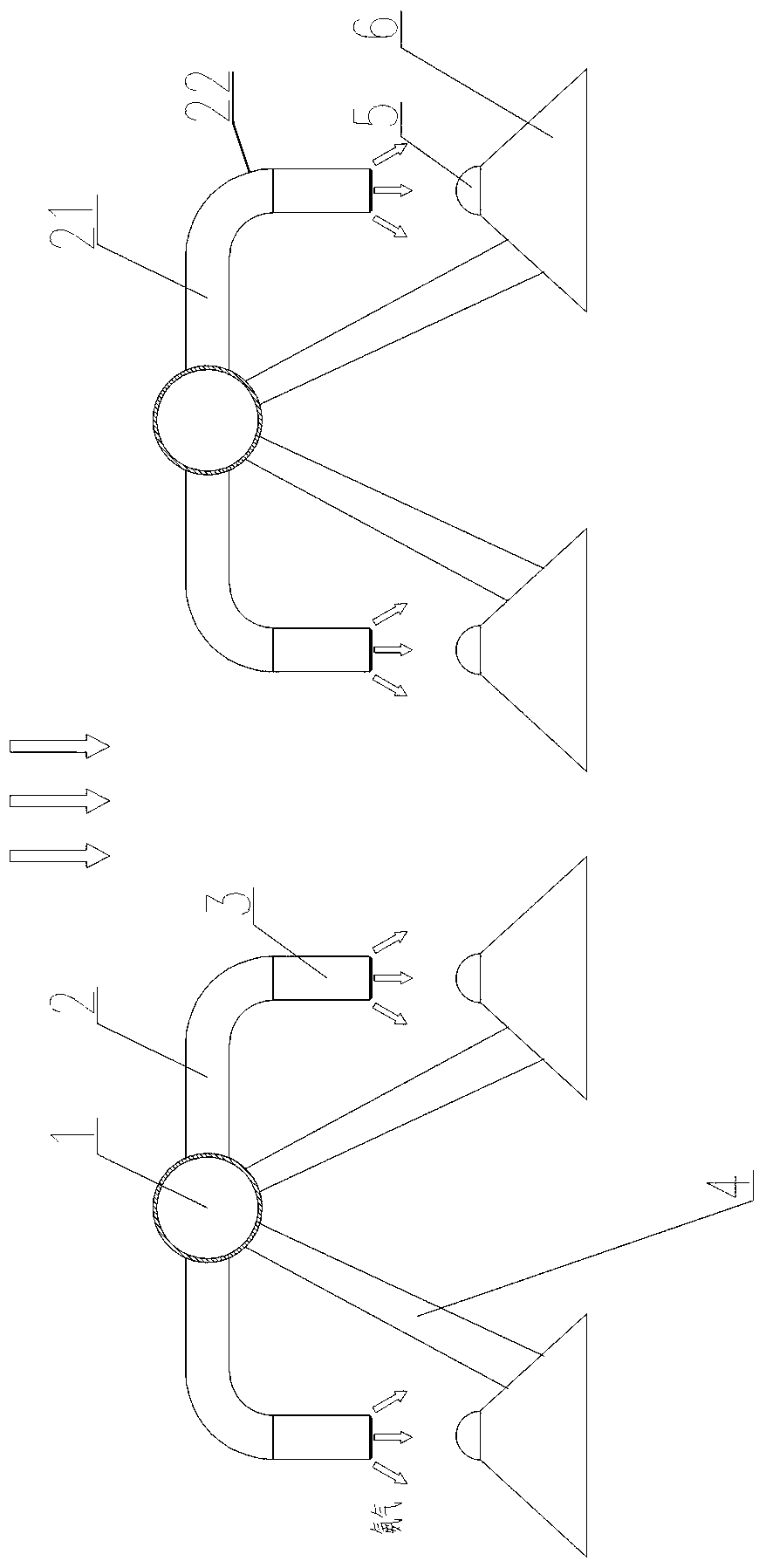

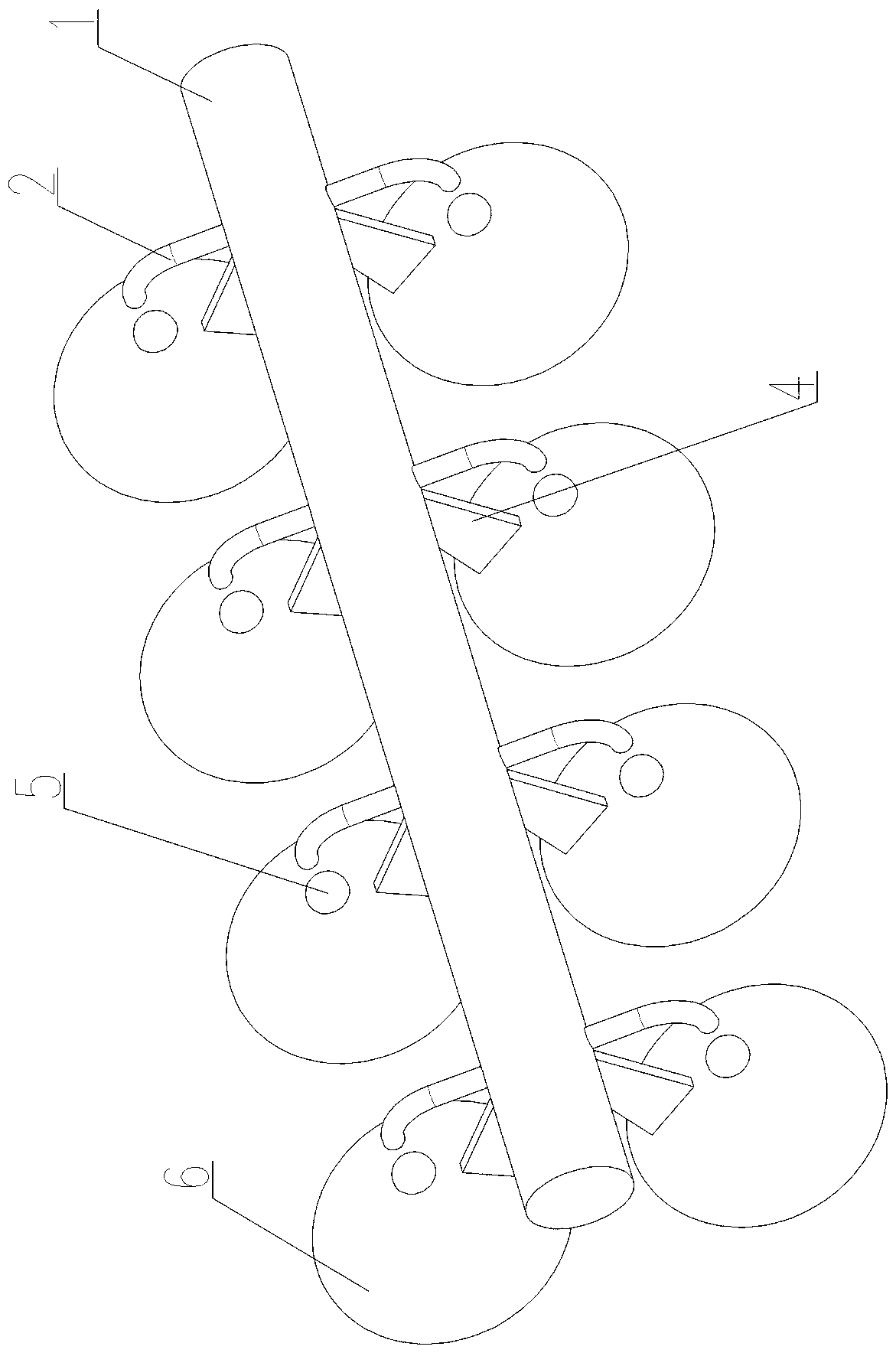

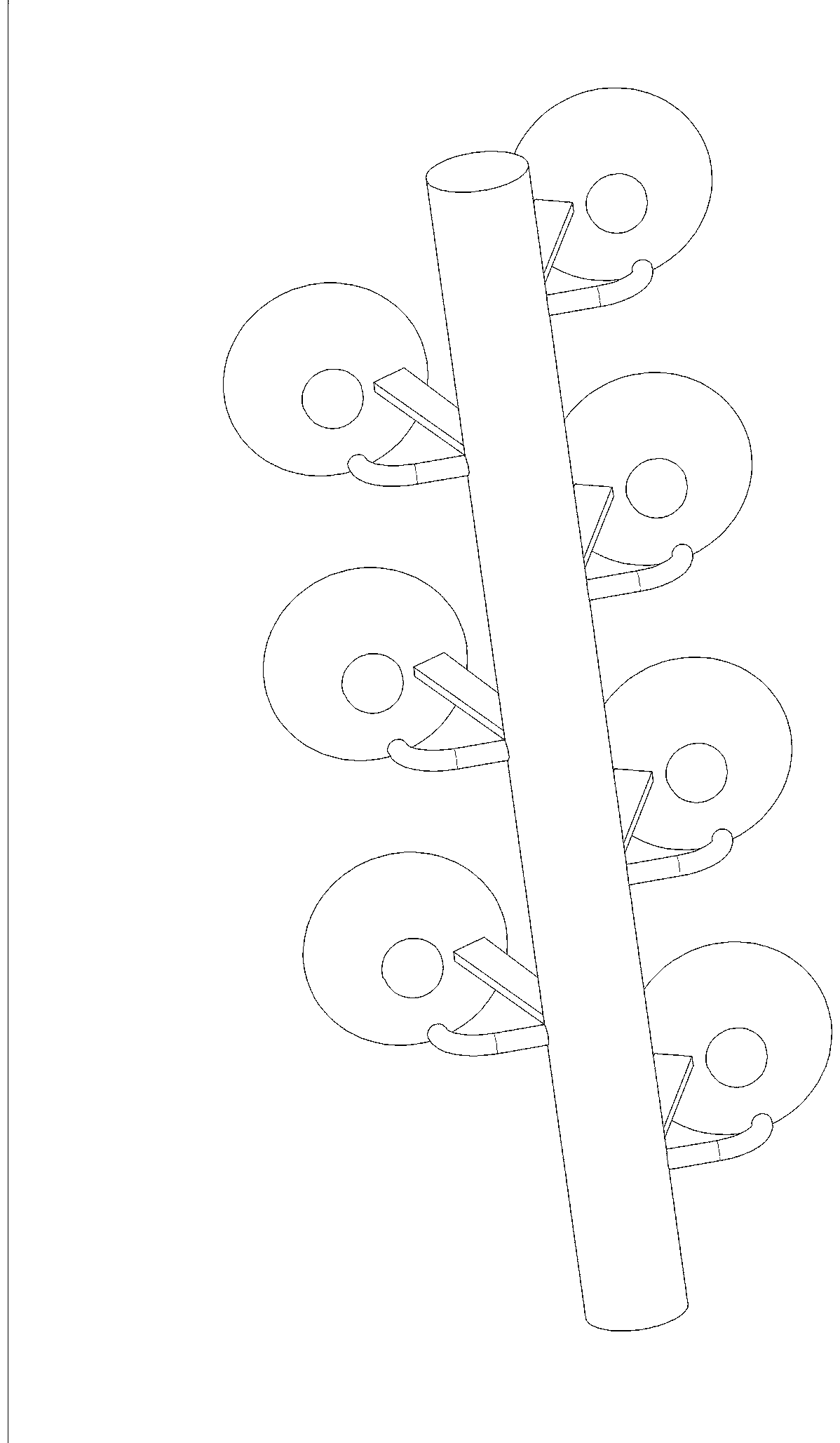

[0050] Such as Figure 1 to Figure 6 As shown, a high-efficiency mixing ammonia injection device for a flue gas denitrification system of the present invention includes an ammonia injection tube bundle with an ammonia injection port 3 and a static rapid mixing unit.

[0051] The ammonia injection tube bundle with the ammonia injection port 3 includes an ammonia injection tube, the ammonia injection tube leads into the denitration flue, and communicates with the ammonia injection port 3 in the denitration flue, and ammonia is sprayed through the ammonia injection port 3 The orientation of the ammonia injection port 3 is the same as the flue gas flow in the denitration flue;

[0052] The ammonia injection pipe includes a connected ammonia injection main pipe 1, and a plurality of ammonia injection branch pipes 2 connected to the ammonia injection main pipe 1;

[0053] The ammonia injection main pipe 1 is radially distributed with multiple ammonia injection branch pipes 2 in par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com