Polyurethane foaming method by combining and using carbon dioxide and organic amine

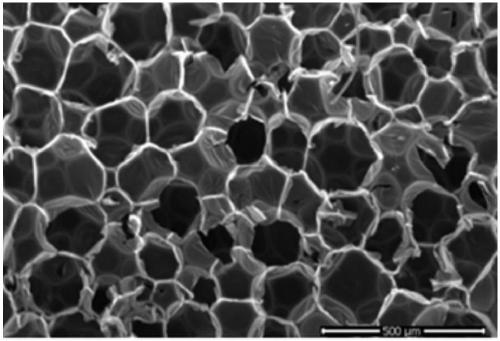

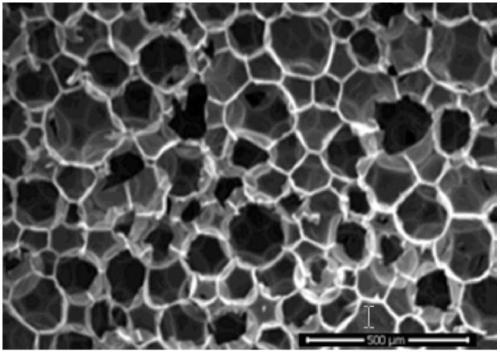

A carbon dioxide and polyurethane technology, applied in the field of polyurethane foam materials, can solve the problems of uneven cell size, high equipment pressure, uneven cell distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] With the polyether polyol SA460 of 40 weight parts (produced by Binhua Group in Binzhou City, Shandong Province), the toluenediamine polyether of 10 weight parts (by Shandong Bluestar Dongda Chemical Co., Ltd.), 5 weight parts of B Amine (being organic amine), the water of 1 weight part, the foam stabilizer DC3201 of 1 weight part (U.S. Air Chemical Company produces), the ammoniacal liquor (27% concentration) of 1 weight part, the flame retardant TCPP of 12.5 weight parts (Jiangsu Jacques Chemical Co., Ltd.) and 2 parts by weight of catalyst A33 (33LV, produced by American Air Chemicals) were evenly mixed to obtain a transparent foaming composition, that is, "white material", or called a combined polyether polyol. The "white material" is then transported to a pressure vessel for storage.

[0076] 80 parts of isocyanate MDI (PM200, Yantai Wanhua Chemical Group Co., Ltd.) was transported as isocyanate raw material (ie "black material") to a pressure vessel for storage.

...

Embodiment 2

[0079] With 40 parts by weight of polyether polyol 2010 (produced by Binhua Group in Binzhou City, Shandong Province), 10 parts by weight of toluenediamine polyether (by Shandong Bluestar Dongda Chemical Co., Ltd.), 6.5 parts by weight of a single Propanolamine (ie organic amine), 1 weight part of water, 1 weight part of foam stabilizer DC3201 (produced by U.S. Air Chemical Company), 1 weight part of ammonia (27% concentration), 12.5 weight parts of flame retardant TCPP (produced by Jiangsu Yake Chemical Co., Ltd.) and 2 parts by weight of catalyst A33 (33LV, produced by American Air Chemical Company) were evenly mixed to obtain a transparent foaming composition, that is, "white material", or called a combined polyether polyol. The "white material" is then transported to a pressure vessel for storage.

[0080] 80 parts of isocyanate MDI (PM200, Yantai Wanhua Chemical Group Co., Ltd.) was transported as isocyanate raw material (ie "black material") to a pressure vessel for stor...

Embodiment 3

[0083] Simultaneously feed supercritical CO into white material and black material 2 .

[0084] With 40 parts by weight of polyether polyol SA460 (produced by the Binhua Group in Binzhou City, Shandong Province), 10 parts by weight of toluenediamine polyether (by Shandong Bluestar Dongda Chemical Co., Ltd.), 6 parts by weight of single Ethanolamine (ie organic amine), 1 weight part of water, 1 weight part of foam stabilizer DC3201 (produced by U.S. Air Chemicals), 0.3 parts by weight of N, N-dimethylcyclohexylamine (U.S. Air Chemicals), 1.5 The potassium octanoate of weight part, the ammoniacal liquor (27% concentration) of 1 weight part, the flame retardant TCEP (trichloroethyl phosphate) of 12 weight parts and the flame retardant DMMP (dimethyl methyl phosphonate) of 2 weight parts ) to obtain a transparent foaming composition after mixing evenly, that is, "white material", or called a combined polyether polyol.

[0085] 80 parts of isocyanate MDI (PM200, Yantai Wanhua Che...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com