Pulse type micro-jet gas nozzle control device

A technology of gas nozzles and control devices, which is applied to burners, combustion types, combustion methods, etc., can solve the problems of low combustion efficiency, inability to adjust the flame size, and flame instability, and achieve the effect of high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

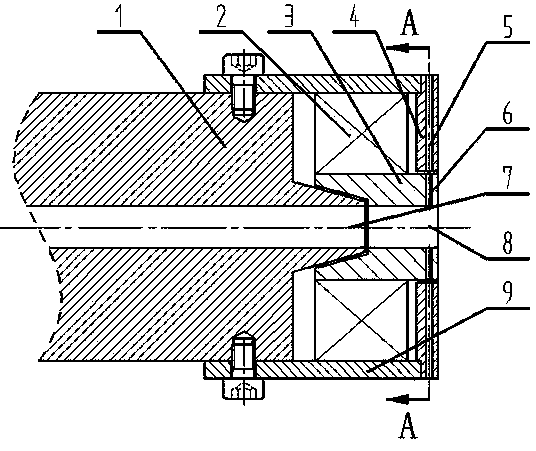

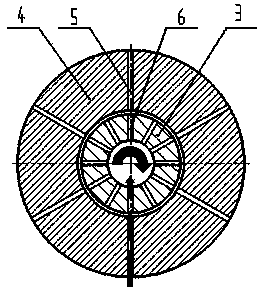

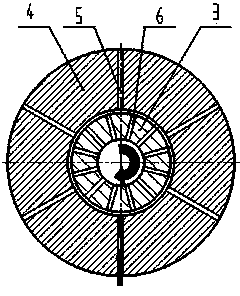

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0029] Figure 1 to Figure 10 The reference numerals in the figure are: gas nozzle 1; motor 2; rotating disc 3; fixed disc 4; fixed radial through hole 5; rotating radial through hole 6; gas injection through hole 7; 9; outer surface 10; threaded hole 11; boss 12; conical surface 13; top 14; conical surface 15; groove 16; outer surface 17; inner surface 18; inner surface 19; installation groove 20; installation hole 21; Medial side 22.

[0030] The present invention provides a pulse type micro-jet flow gas nozzle control device, which uses a method based on pulse injection to improve the mixing effect of gas and supporting gas, and adjusts the incident frequency, mass flow rate and the number of radial through holes of the supporting gas. Control the size of the flame to achieve full combustion of the gas to achieve the highest combustion eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com