Sound-absorbing environmentally-friendly recycled asphalt concrete and preparation process thereof

A technology of recycled asphalt and preparation process, which is applied in the field of sound-absorbing and environmentally friendly recycled asphalt concrete and its preparation process, can solve the problems of inability to effectively reduce urban noise, poor stability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

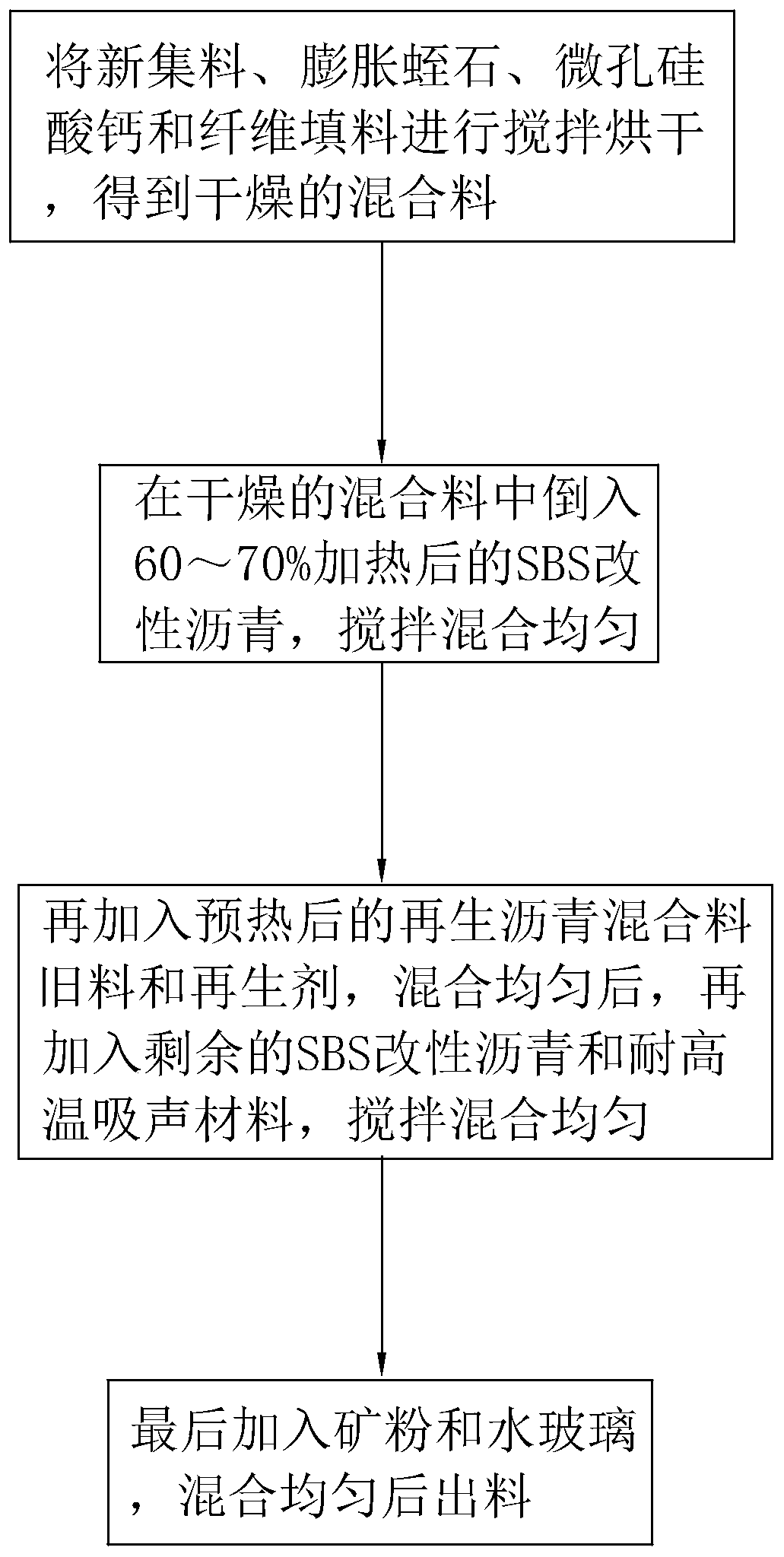

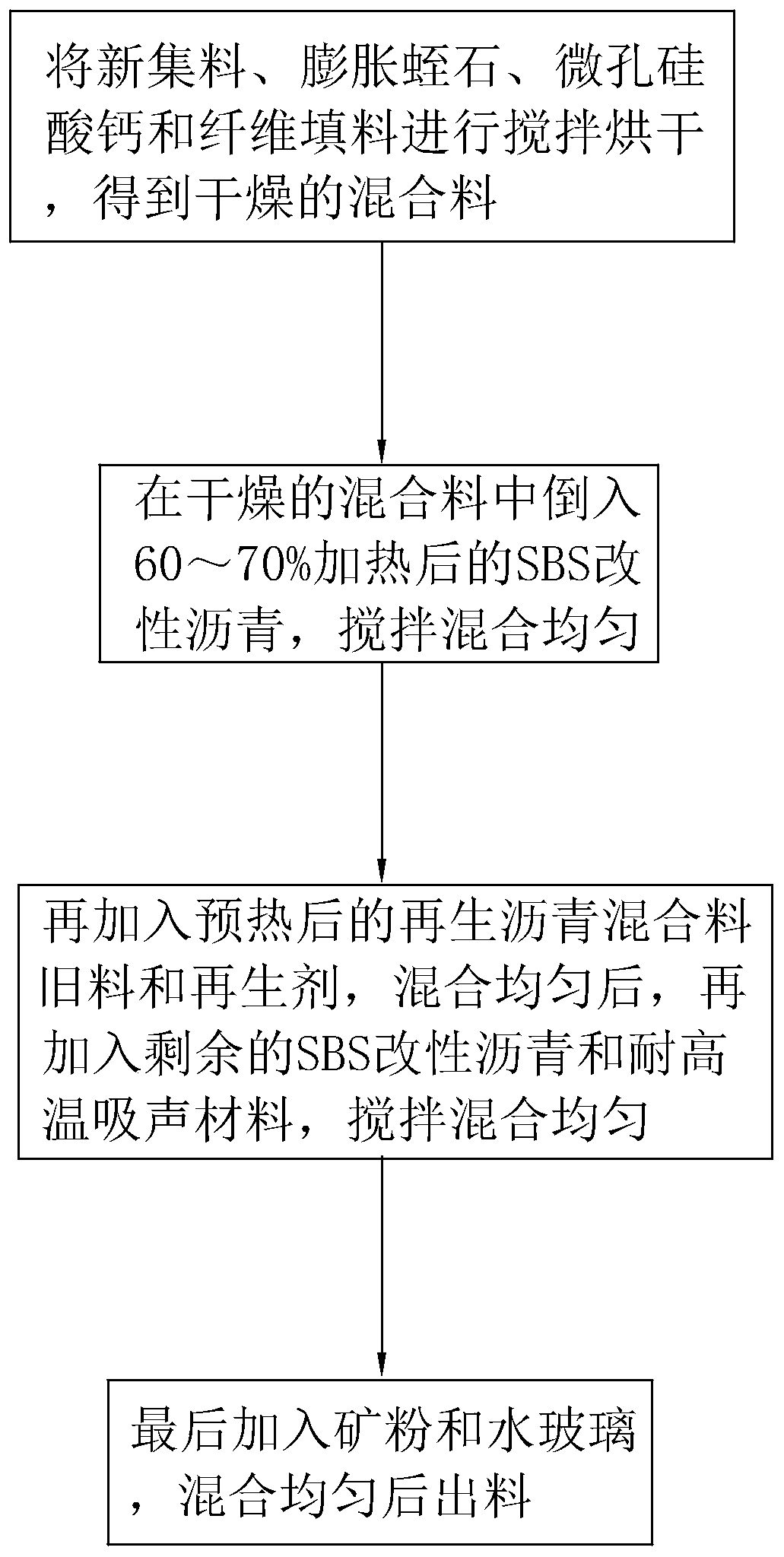

[0048] Example 1: A sound-absorbing and environmentally friendly recycled asphalt concrete, the components and their corresponding parts by weight are shown in Table 1, and were prepared through the following steps:

[0049] Step 1: Stir and dry the new aggregate, expanded vermiculite, microporous calcium silicate and polyester fiber in the drying barrel with the corresponding weight parts, the temperature is controlled at 110°C, the time is 20min, and the stirring speed is 900rpm , to obtain a dry mixture;

[0050] Step 2, put the dry mixture into the mixing tank, heat 60% by weight of SBS modified asphalt to 160°C, add it into the mixing tank evenly within 30s, and stir at a stirring speed of 1200rpm for 20min;

[0051] Step 3: Preheat the regenerated asphalt mixed old material to 80°C and add it together with the regeneration agent into the above mixing tank for stirring. The temperature in the mixing tank is maintained at 170°C, the stirring speed is 1100rpm, and the time...

Embodiment 2-8

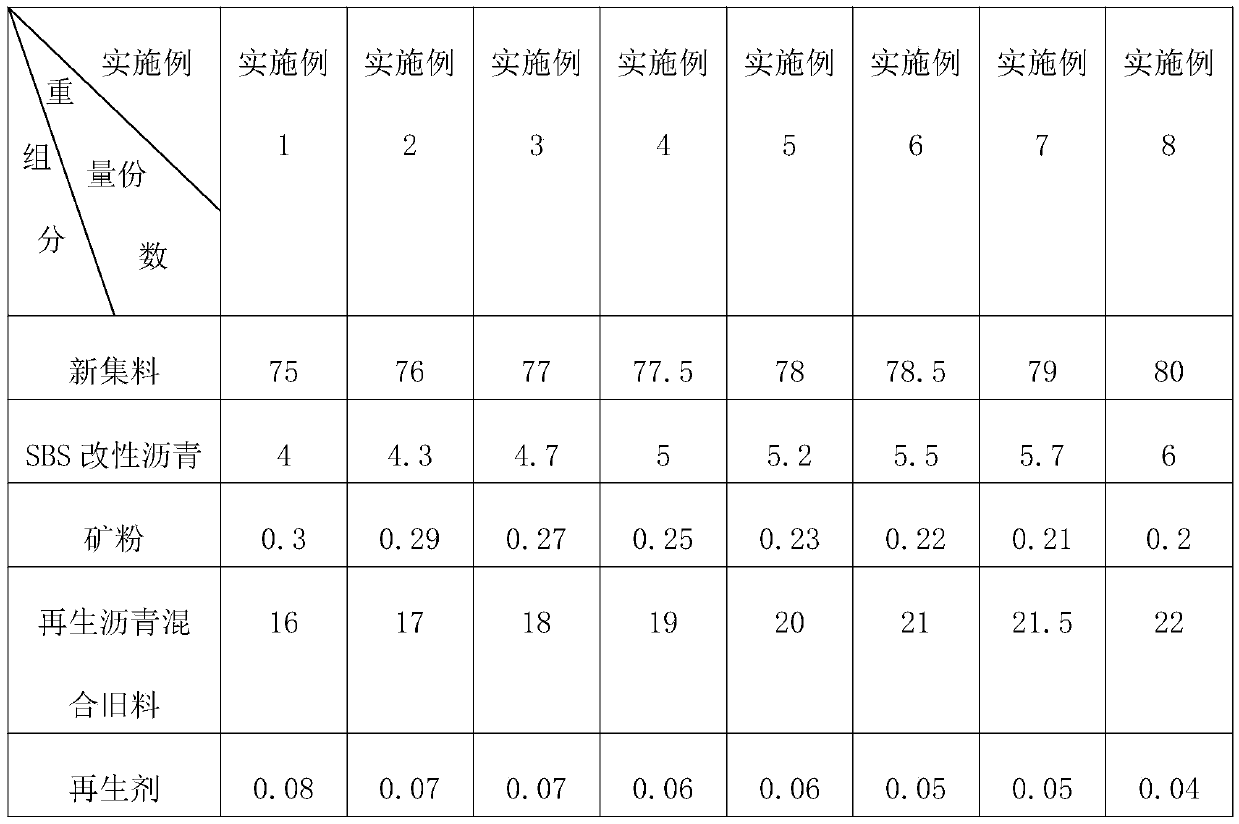

[0054] Example 2-8: A sound-absorbing and environment-friendly recycled asphalt concrete. The difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0055] Each component and parts by weight thereof in table 1 embodiment 1-8

[0056]

[0057]

Embodiment 9

[0058] Example 9: A sound-absorbing and environmentally friendly recycled asphalt concrete. The difference from Example 1 is that the new aggregate mainly has a particle size range of 0-3mm, 3-5mm, 5-13mm, 13-20mm, 20- The 25mm limestone is composed of 1.4:2.6:7.6:1:3.5 in parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com