Nozzle for gas stove and gas stove using nozzle

A technology of gas stoves and nozzles, which is applied in the field of household kitchen utensils, and can solve the problems of small contact area between gas source and air, limited air for one-shot injection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

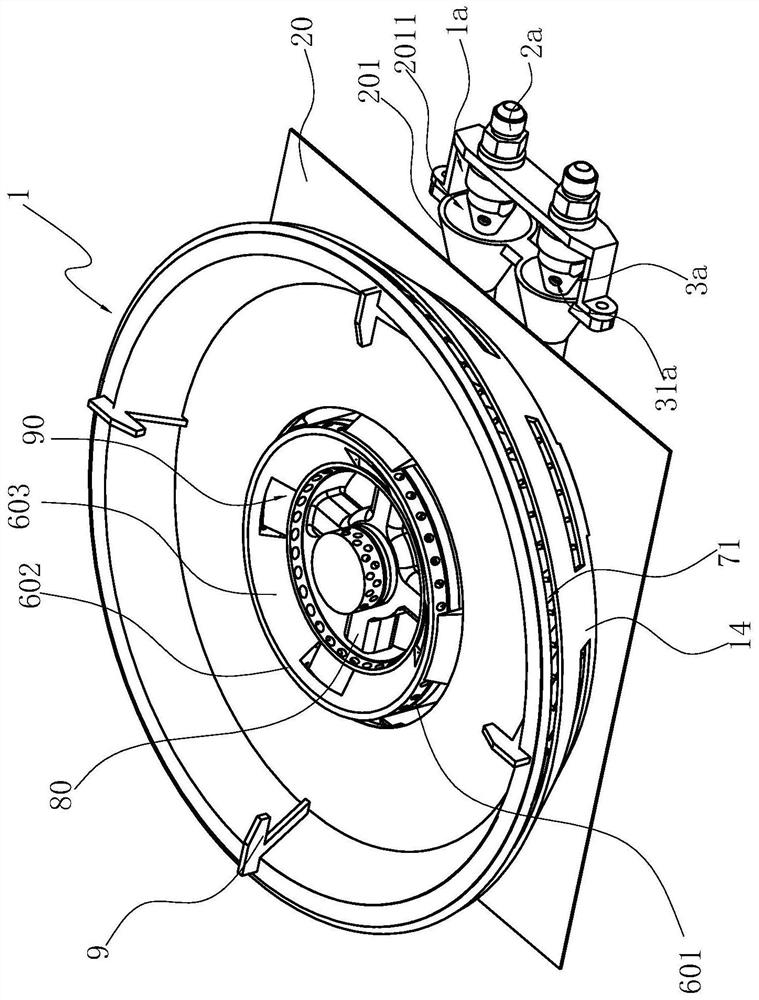

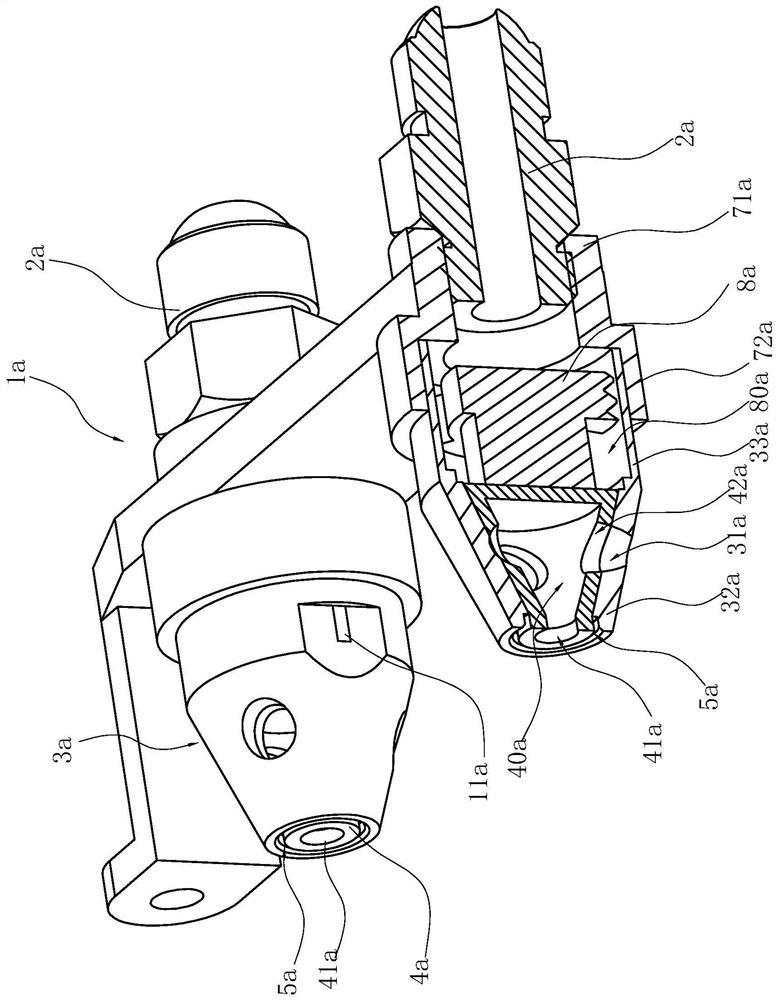

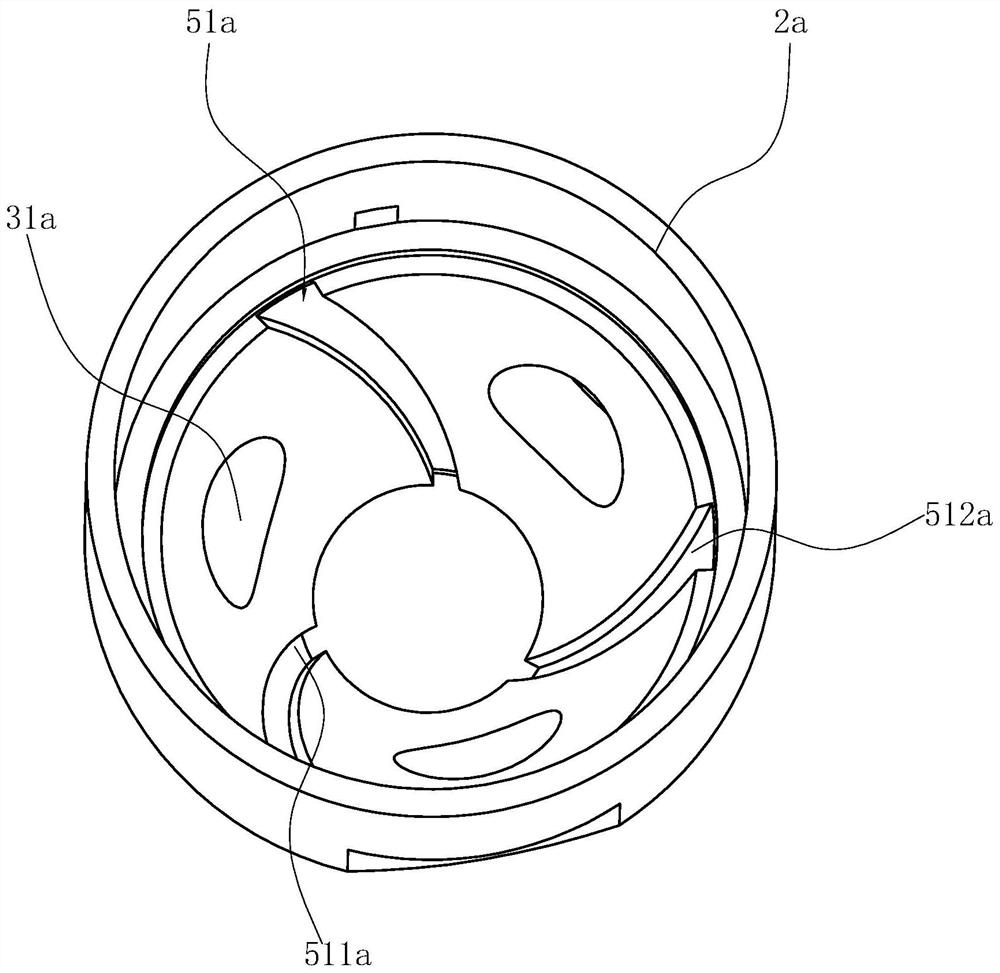

[0066] like Figure 1-14As shown, the nozzle for a gas stove in this embodiment includes a body 1a, the body 1a includes a nozzle portion 2a located at the tail of the body 1a for injecting gas into the body 1a, and a head portion of the body 1a, which is tubular and an air chamber 4a provided in the outlet portion 3a and isolated from the nozzle portion 2a, the air chamber 4a includes a head wall 401a, a tail wall 402a and a peripheral wall 403a connecting the head wall 401a and the tail wall 402a The head of the air chamber 4a has an air outflow hole 41a which is in fluid communication with the outlet portion 3a for primary air to flow out, and the tail wall of the air chamber is isolated from the nozzle portion 2a and has an inner surface of the pipe wall corresponding to the outlet portion 3a An inflow port for the inflow of gas injected into the main body 1a is formed, and the peripheral wall 403a of the air chamber 4a has an air inflow hole 42a in fluid communication wit...

Embodiment 2

[0075] The structure is basically the same as that of Embodiment 1. The only difference is that the cavity 13 is a semi-closed cavity 13 with only the second gap 5 and no air dividing cavity, such as Figure 15 and 16 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com