Pulse detonation pushing device based on regenerative cooling structure

A technology of regenerative cooling and pulse detonation, which is applied to jet propulsion devices, intermittent jet devices, rocket engine devices, etc., can solve the problems of inability to solve the cooling problem of hot-end components, thermal protection of hot-end components, and long detonation time. Achieve improved overall propulsion performance, fast blending, low quality and low hazard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings.

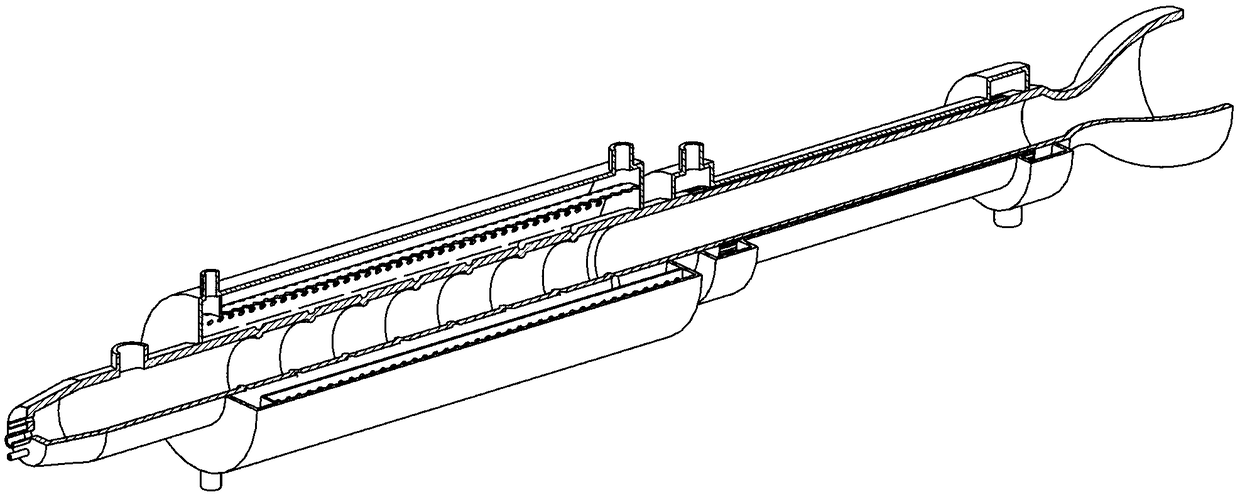

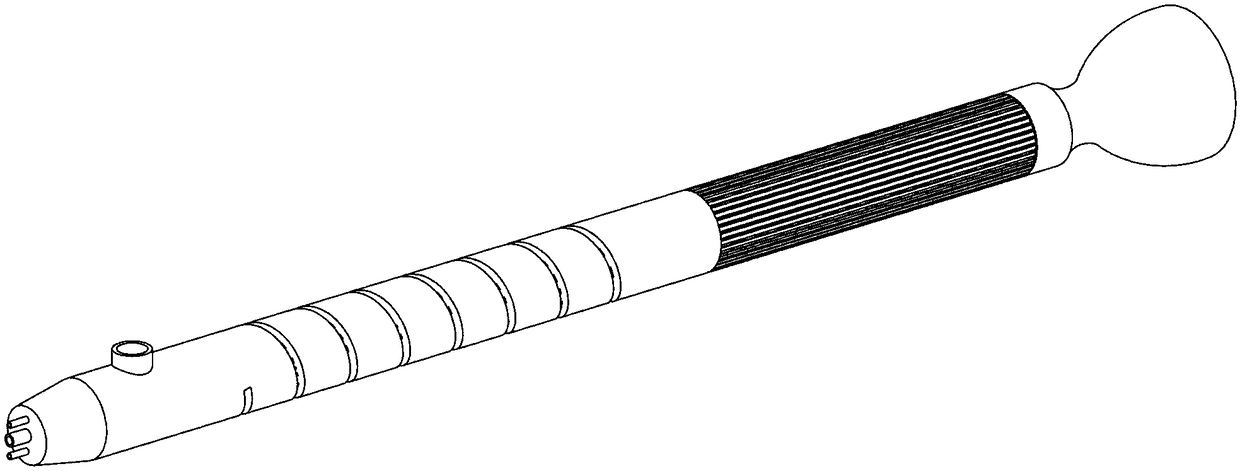

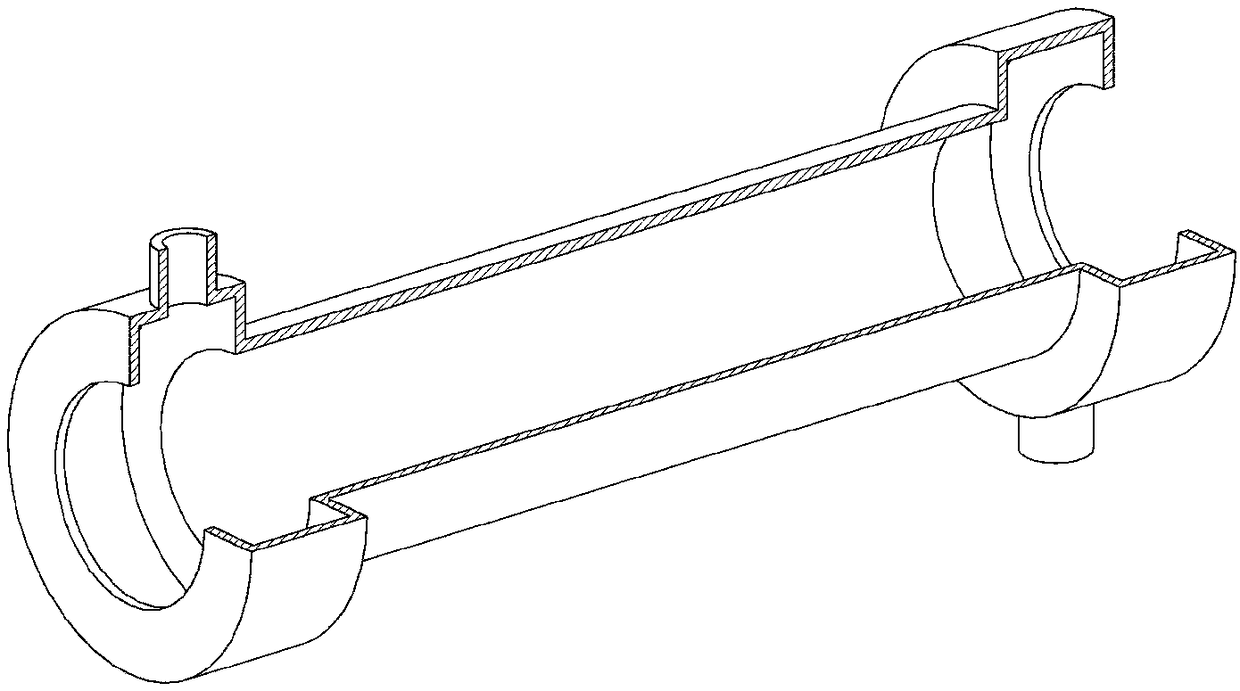

[0037] The present invention is a propulsion structure for a regeneratively cooled pulse detonation engine, such as Figure 5 with Image 6 shown. It includes: detonation tube 1, head 1-1, DDT section 1-2, detonation propagation section 1-3, igniter interface 1-4, Shchelkin spiral obstacle 1-5, heat exchange microchannel 1-6 , fuel inlet 1-7, oxidant inlet 1-8, second stage heater 2, second stage heater fuel inlet 2-1, second stage heater fuel outlet 2-2, partition 3 with impact holes , impact hole 3-1, first stage preheater 4, liquid collection chamber 4-1, first stage preheater fuel inlet 4-2, first stage preheater fuel outlet 4-3, fuel pipeline 5 , oxidant pipeline 6 and igniter 7.

[0038] The propulsion structure of a regenerative cooling pulse detonation engine is characterized in that: the detonation tube 1 is made of nickel-based superalloy, and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydraulic diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com