Swirl mixing device

A swirl mixing and mixer technology, applied in fluid mixers, mixers, mixing methods, etc., can solve the problems of inability to achieve strengthening and rapid mixing, difficult to meet user requirements, and the range of calorific value fluctuations exceeds the standard. Strengthen collision and fusion, improve stability and product quality, effect of short mixing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

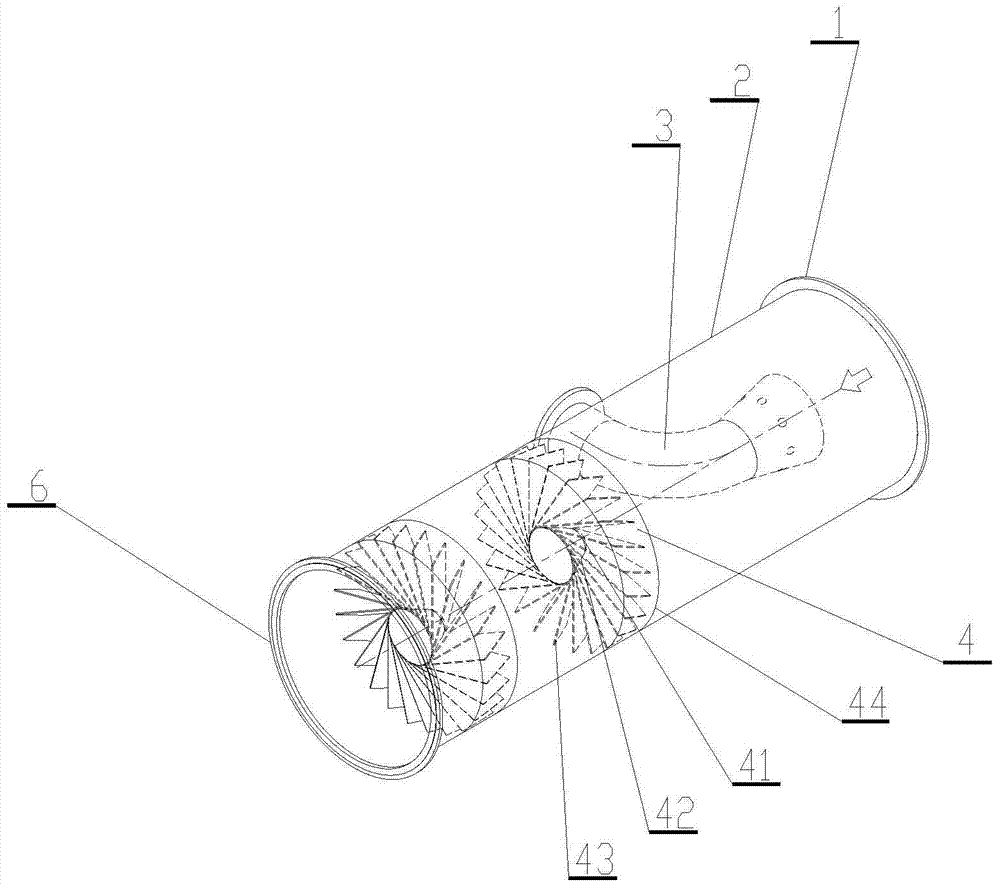

[0032] Such as figure 1 As shown, the embodiment of the swirl mixing device of the present invention consists of an inlet flange 1, a mixer body 2, a mixing medium mixing pipe 3, a swirler 4, and an outlet flange 6, and the components are sequentially connected by welding.

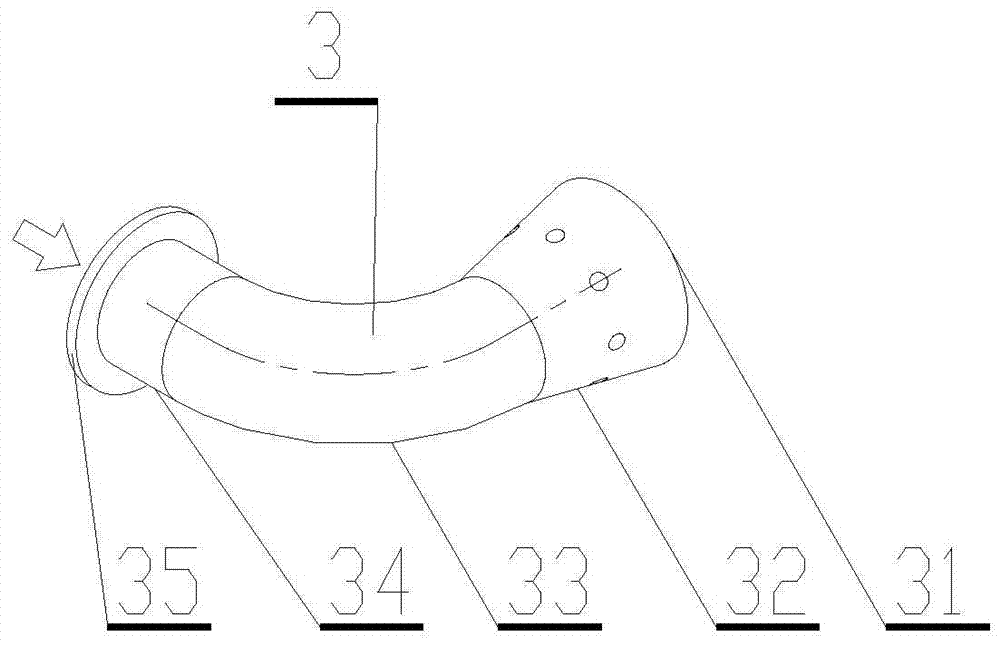

[0033] Such as figure 2 As shown, the mixing medium mixing pipe 3 is composed of a mixing cone block plate 31, a mixing pipe mixing cone 32, a 90° elbow 33 of the mixing pipe, a straight pipe section 34 of the mixing pipe, and a mixing pipe interface flange 35. In turn a solder connection is used. The mixing medium mixing pipe 3 and the mixer body 2 are connected by welding.

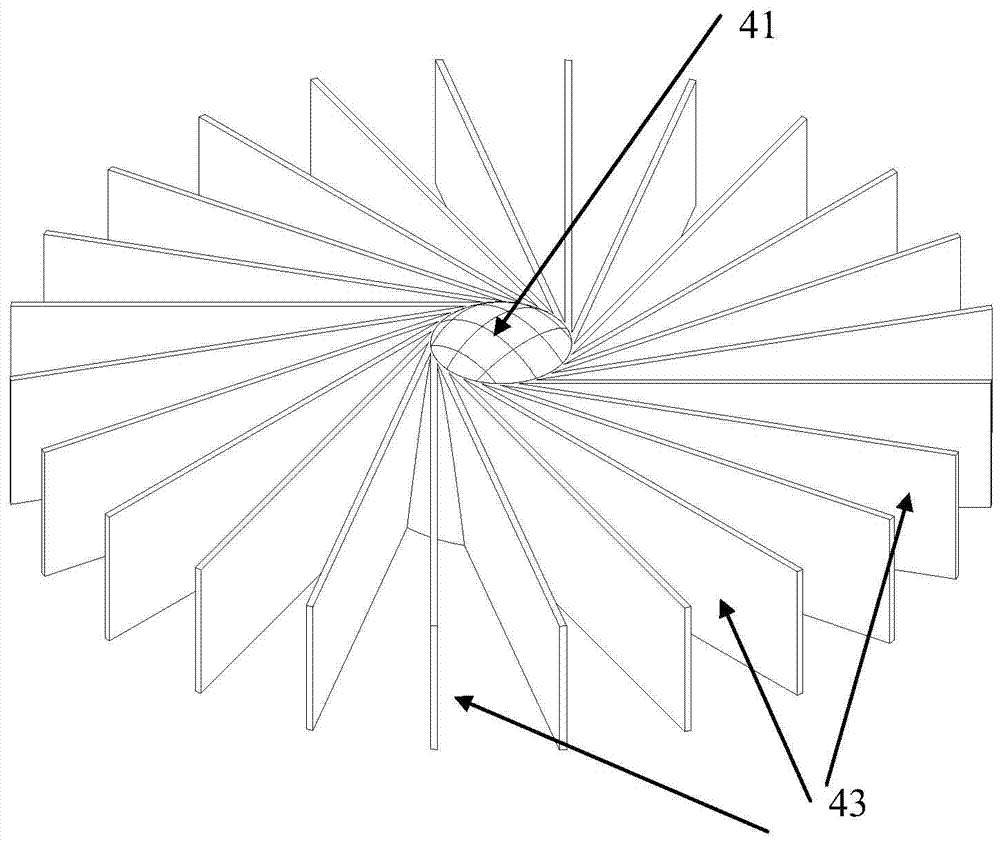

[0034] The swirler 4 is composed of a swirler head 41 , a swirler cone 42 , a swirler blade 43 and a swirler outer cylinder 44 . The parts are joined by welding in turn. The cyclone 4 and the mixer body 2 are connected by welding or flanges.

[0035] In use, the inlet flange 1 and the outlet flange 6 are respectively connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com