Pasting machine

A plastering machine and machine base technology, which is applied in construction and building construction, etc., can solve the problems of heavy processing tasks, mortar falling off, and lower efficiency, and achieve the effects of reducing ground ash, reasonable structure, and improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in conjunction with the accompanying drawings of the above-mentioned embodiments.

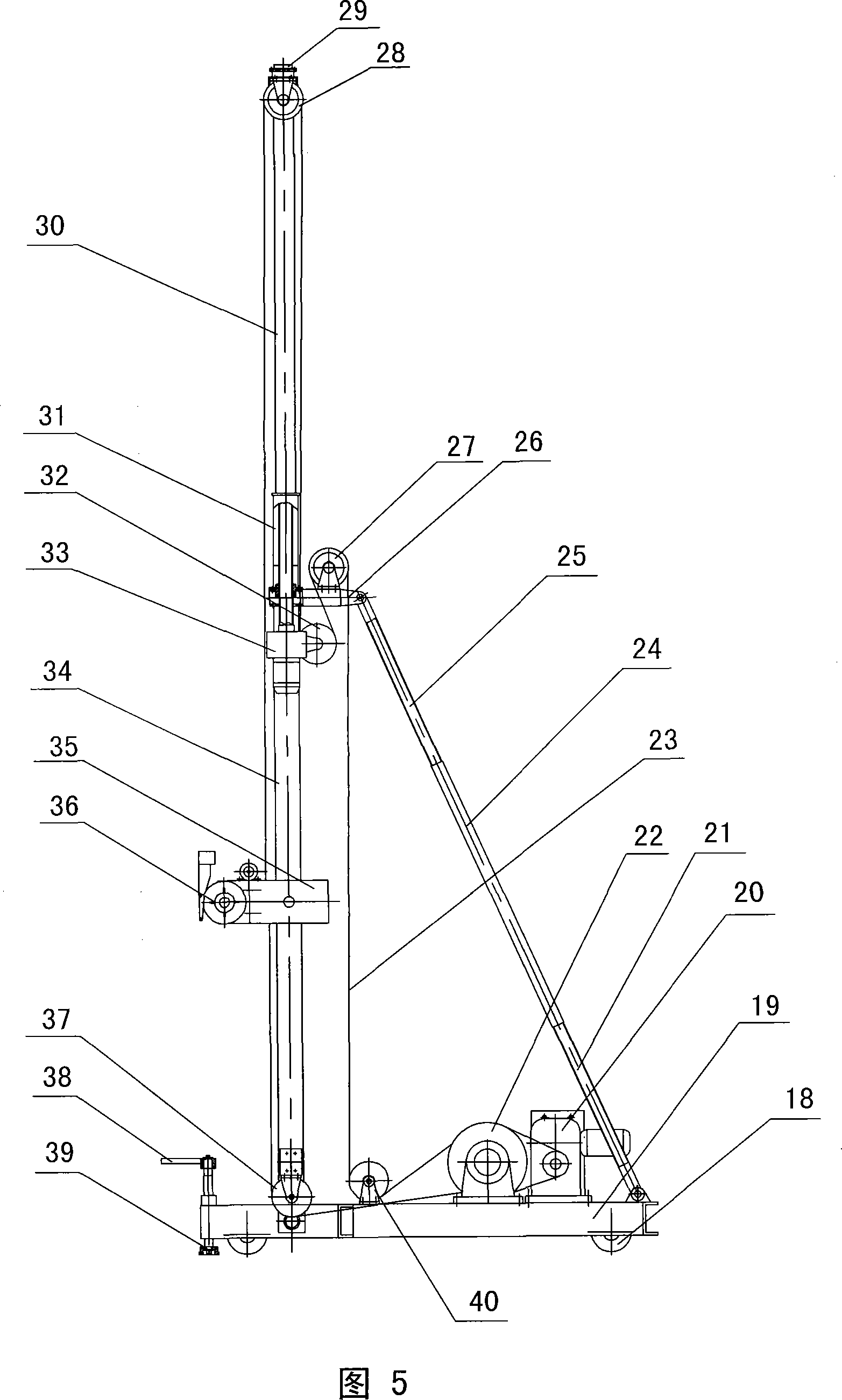

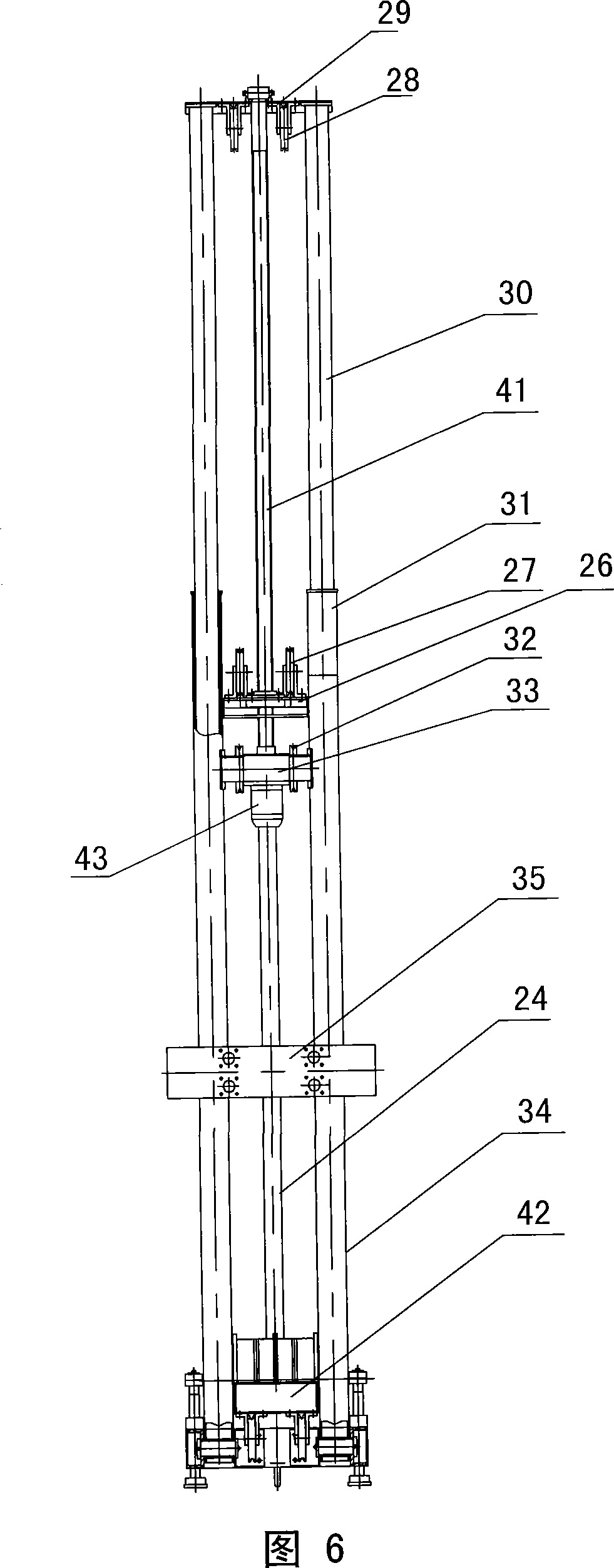

[0025] As shown in Fig. 5 and Fig. 6, the plastering machine according to the present invention includes a base 19, a frame guide rail, a plaster supply device and a plastering head 36, and the plastering head 36 is fitted on the frame guide rail through a lifting frame 35 superior.

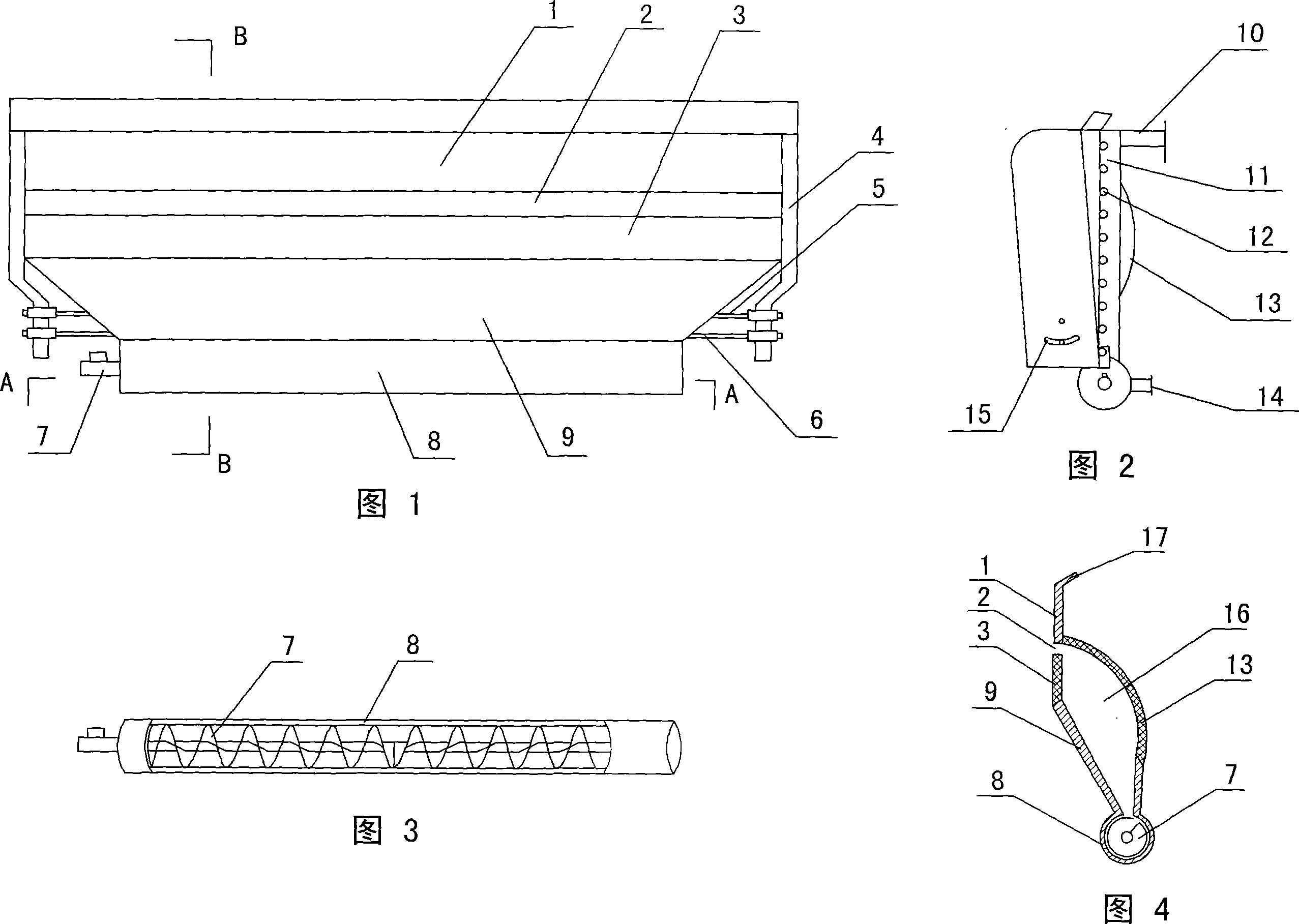

[0026] As shown in Fig. 1, Fig. 2, Fig. 3 and Fig. 4, the plastering head 36 includes a plastering head frame 11, a trowel 1 and an ash storage chamber 16, and the trowel 1 is a rectangular plate installed on the plastering head frame 11 On the top, the front of the ash storage room 16 is made of the soft cover 3 above and the hard cover 9 below. The gap between the upper edge of the surface seal 3 and the lower edge of the spatula 1 forms the ash outlet 2, and the lower edge of the hard surface seal 9 and the lower edge of the bottom pocket 13 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com