Non-contact solar cell panel cleaning device

A solar panel, non-contact technology, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using gas flow, etc., can solve uneven force, small coverage area, and low efficiency of cleaning equipment and other issues to achieve the effect of improving work efficiency and ensuring work quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

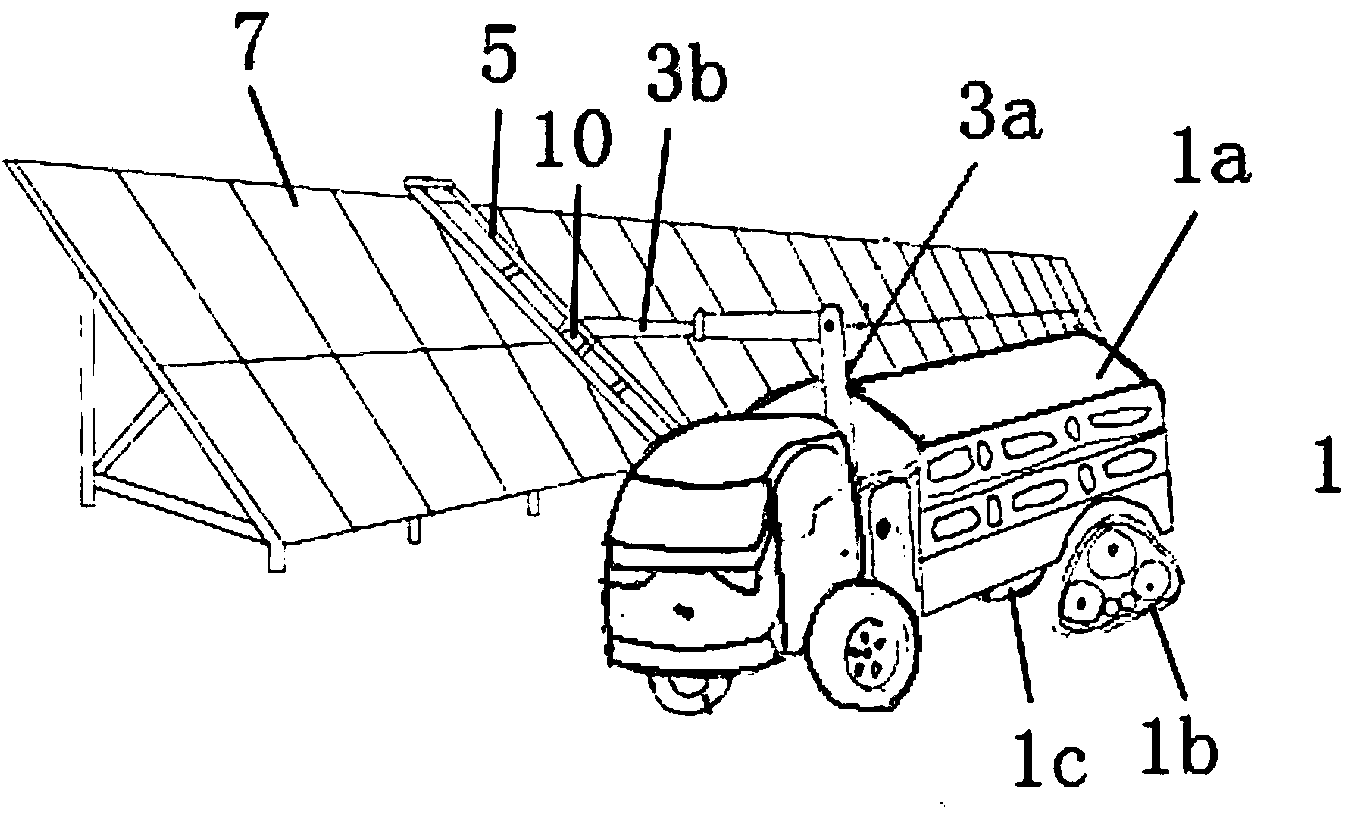

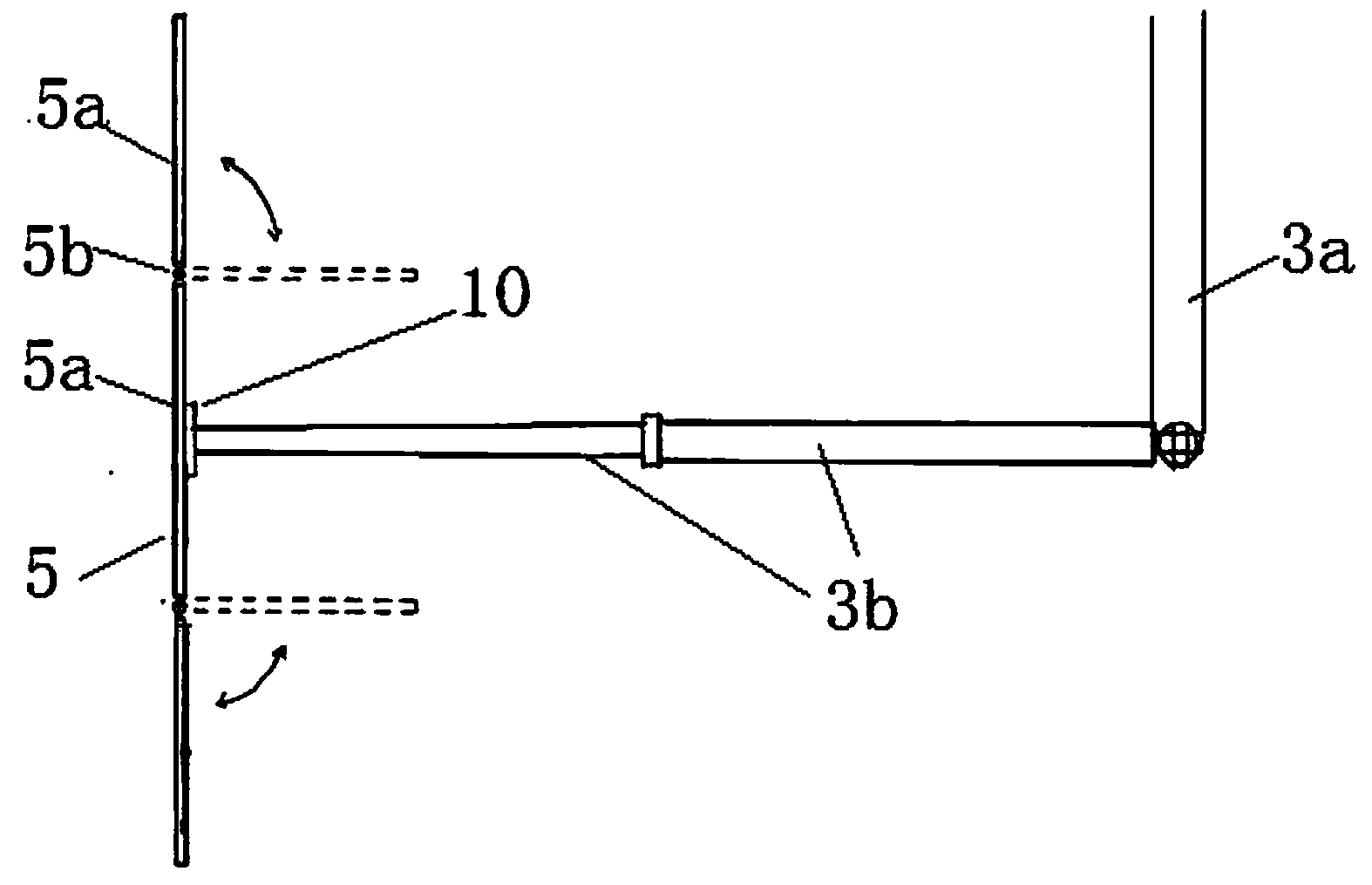

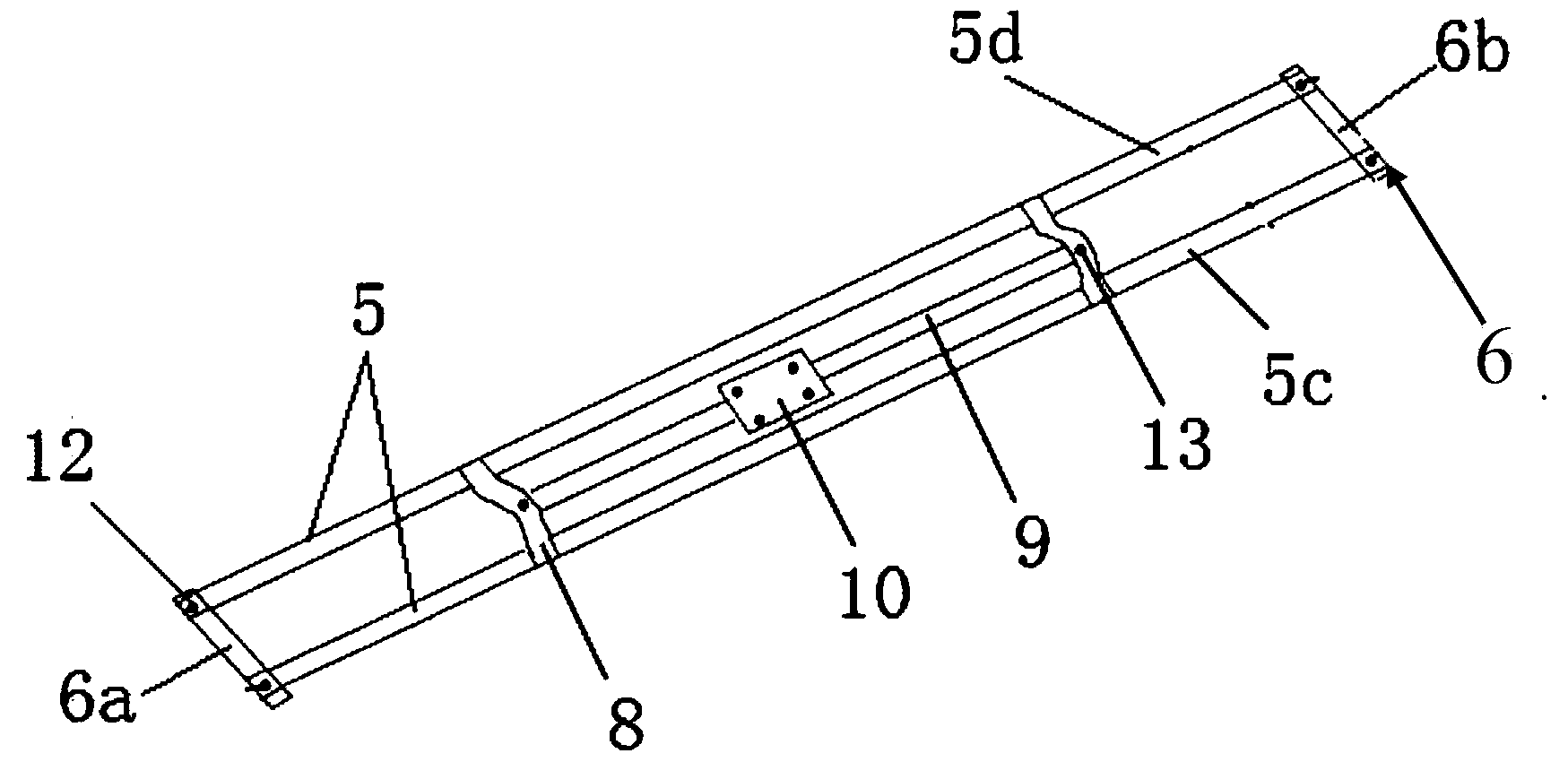

[0034] Referring to the accompanying drawings, it can be seen that the non-contact solar panel cleaning equipment includes a movable device 1 and a cleaning device 2 arranged on the movable device 1, and the cleaning device 2 includes a support mechanism 3 and a cleaning mechanism connected to the support mechanism 3 4.

[0035] The movable device 1 is a car body 1a, and the rear wheels of the car body 1a are triangular track wheels 1b. The car body 1a is equipped with a rotating shaft ( figure 1 Not shown in ), the main cantilever 3a is fixed on the rotating shaft, and the rotating shaft contains the rotating shaft hydraulic motor ( fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com