Patents

Literature

77results about How to "Efficient and quick cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

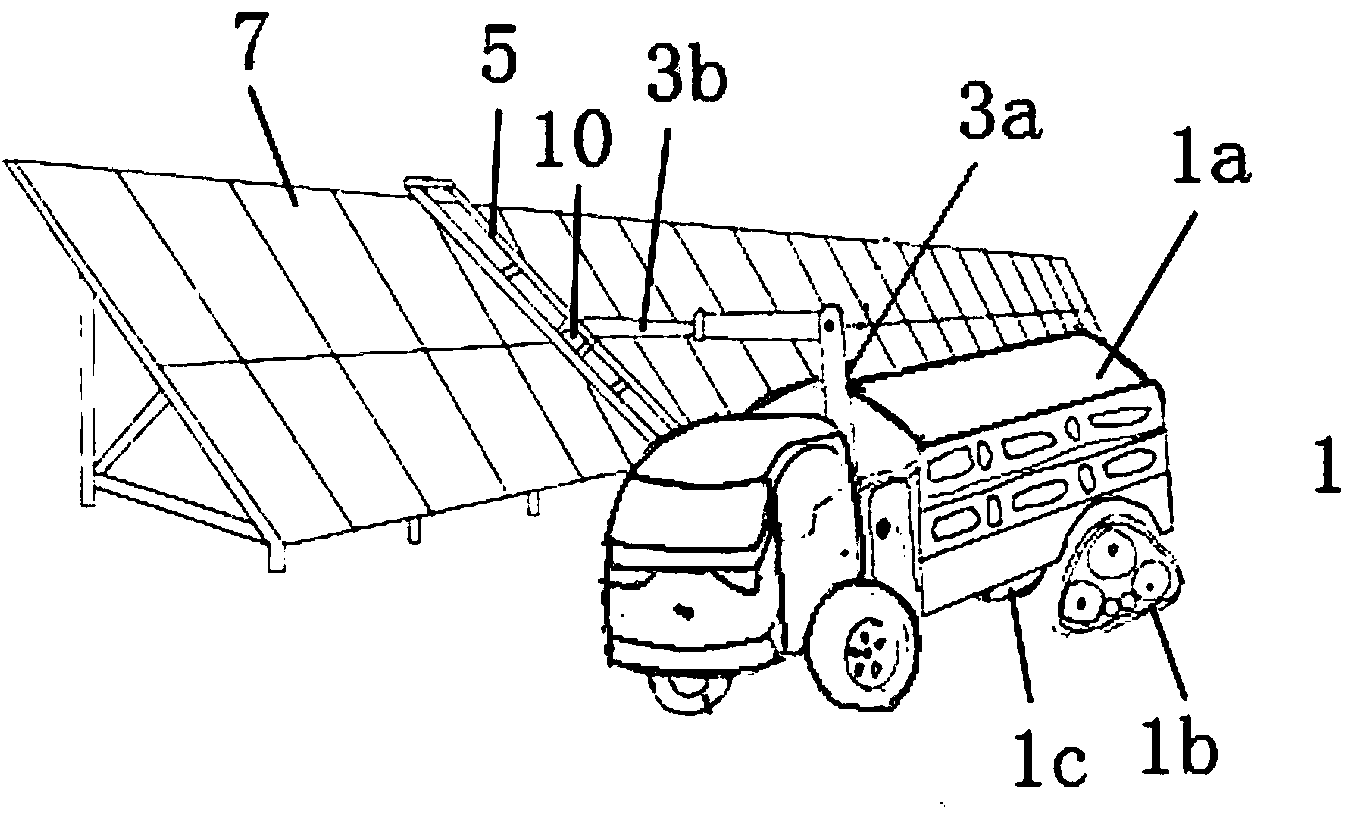

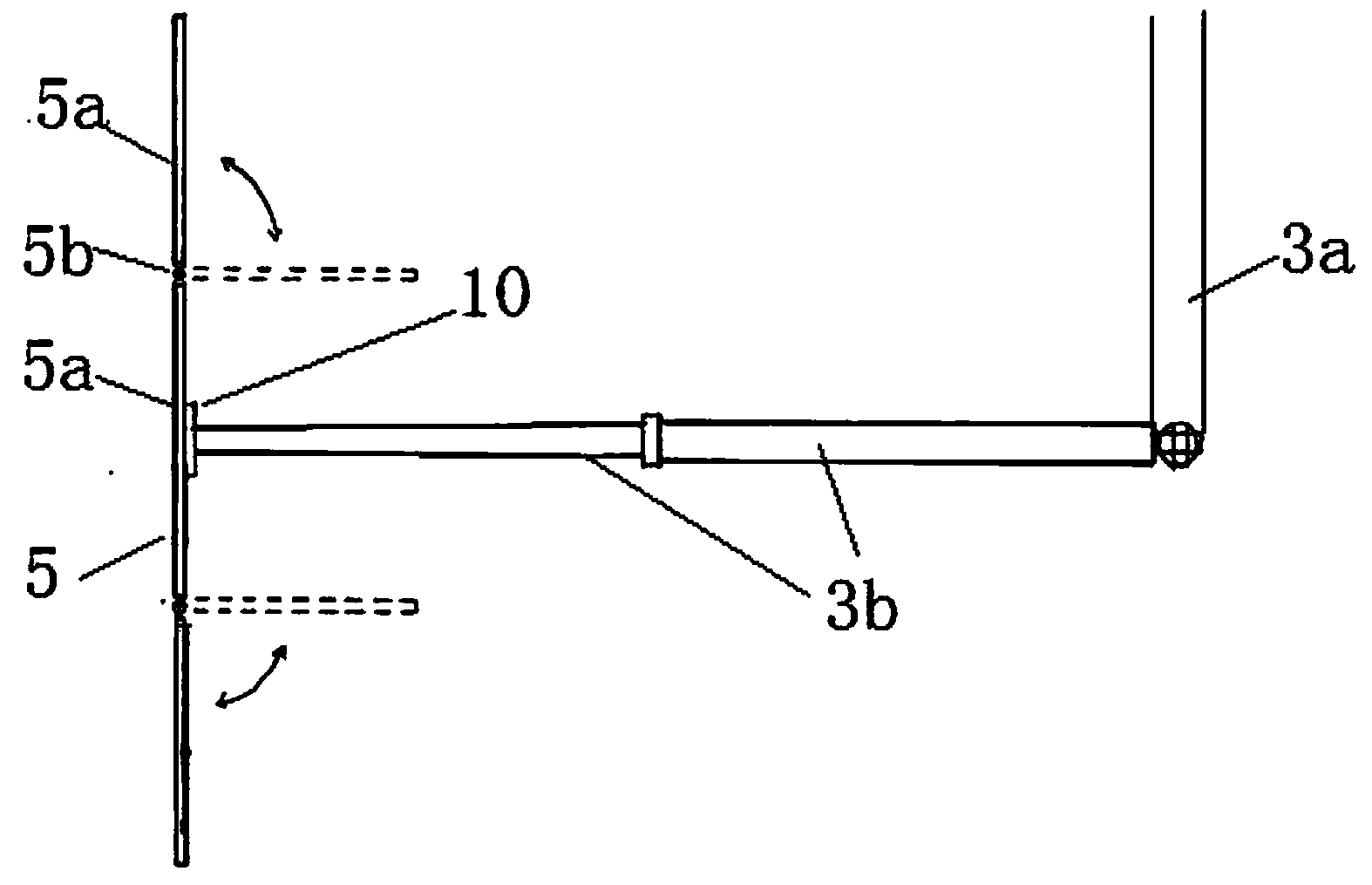

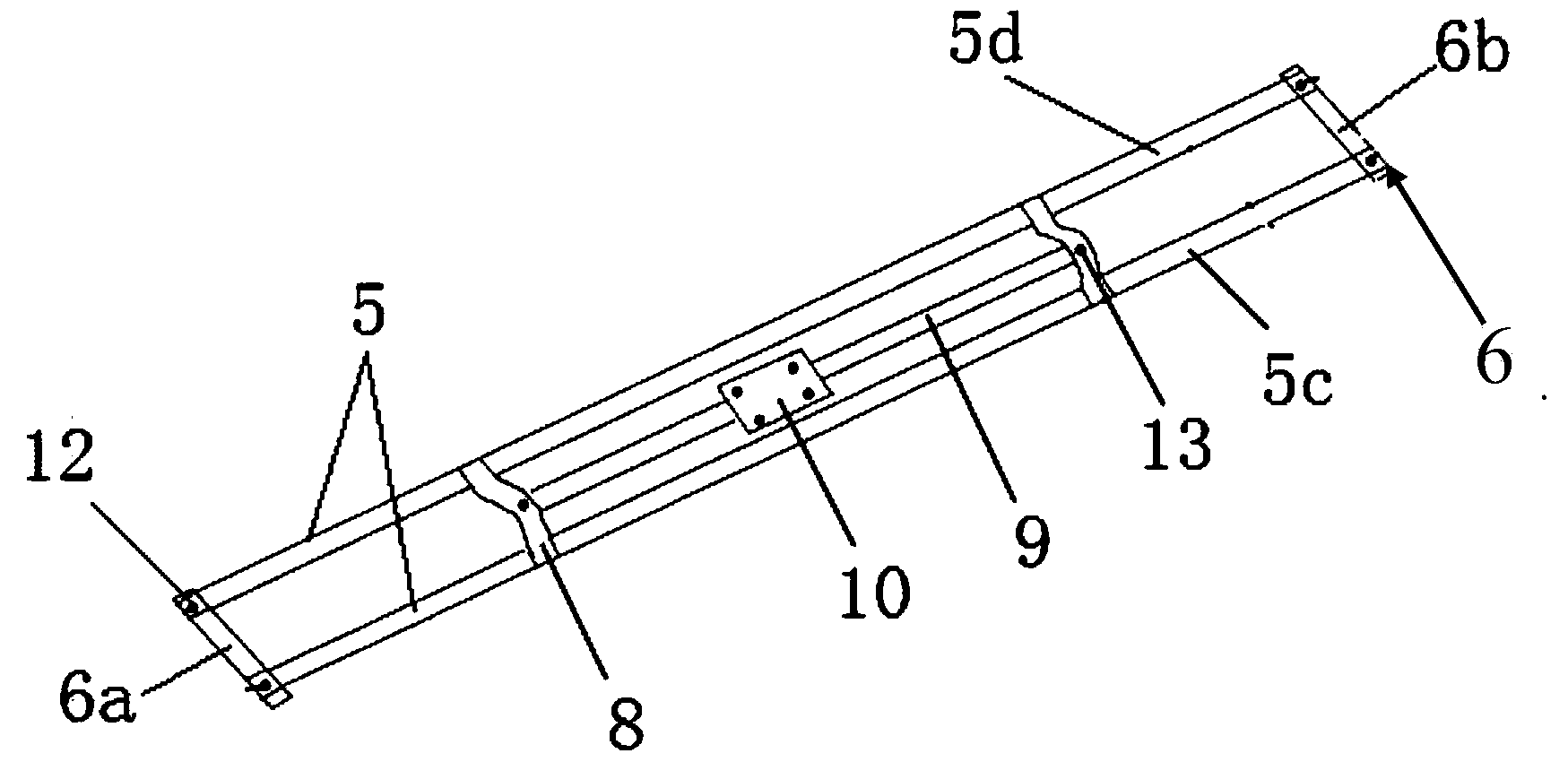

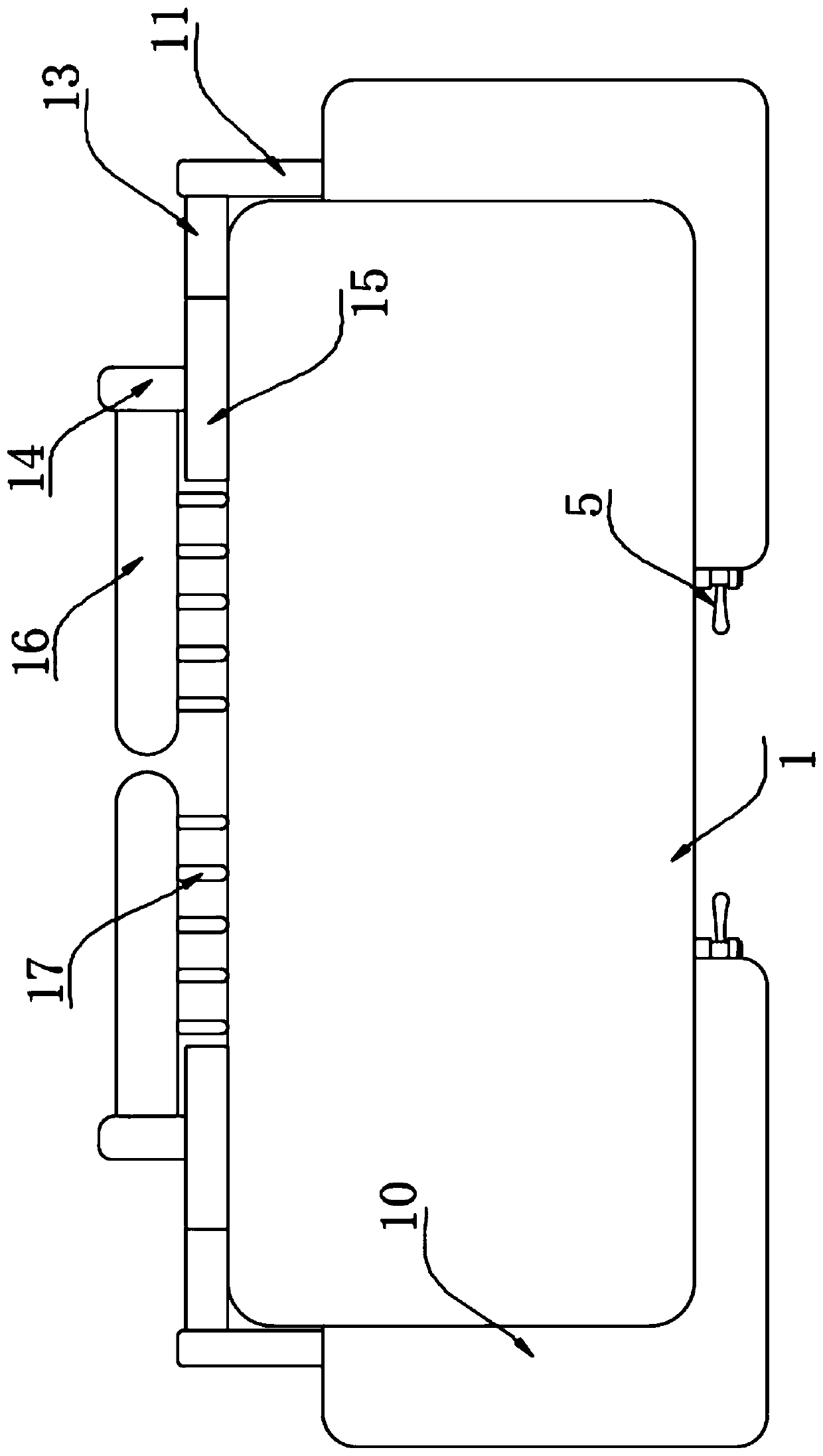

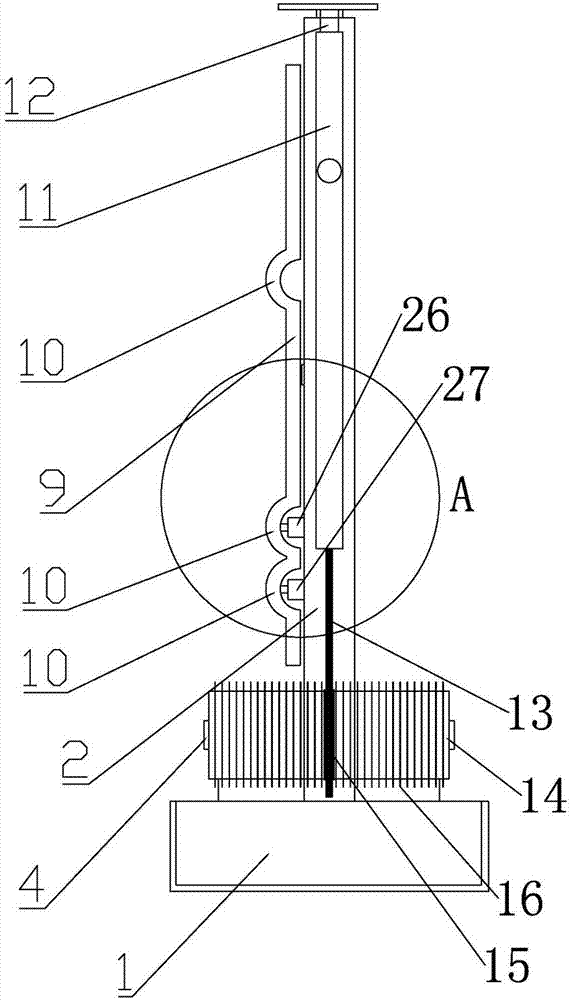

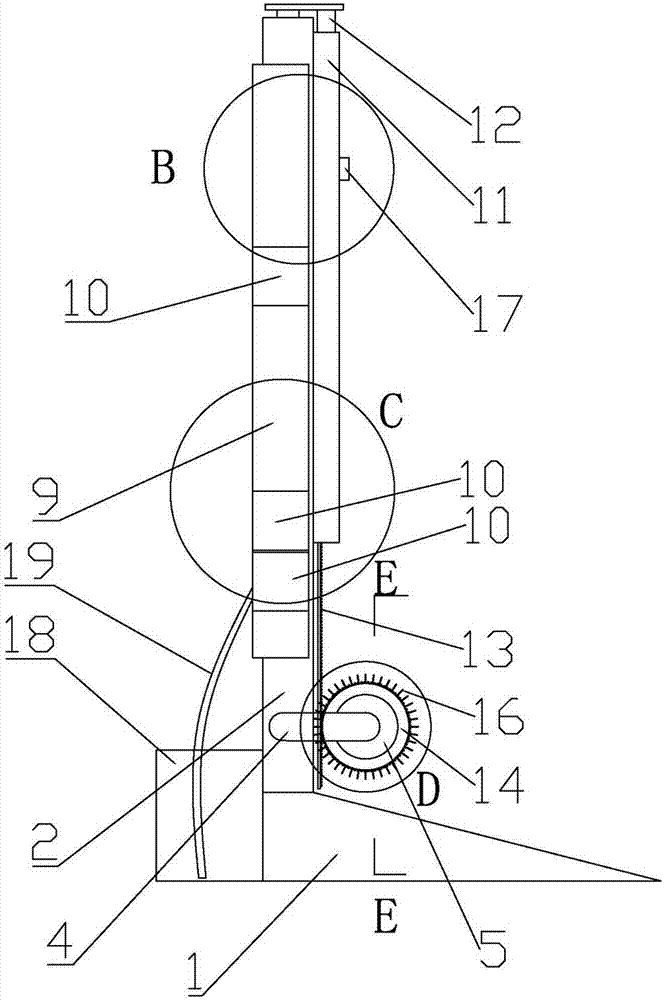

Non-contact solar cell panel cleaning device

InactiveCN103658116ASmooth rideGuarantee the quality of workCleaning using gasesCleaning using liquidsSpray nozzleSolar cell

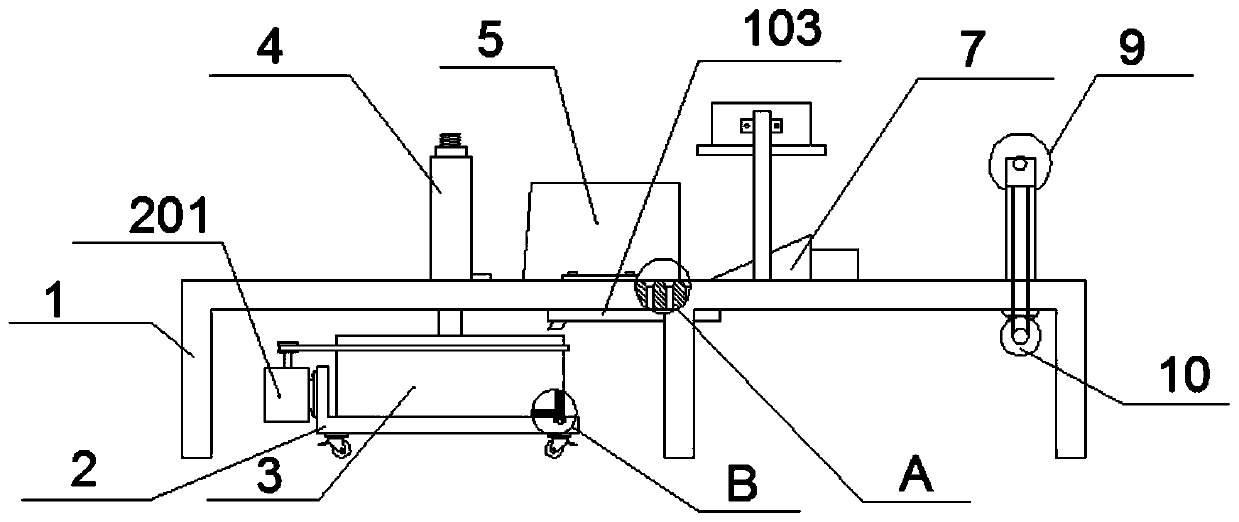

The invention discloses a non-contact solar cell panel cleaning device, and relates to solar cell panel cleaning devices. The non-contact solar cell panel cleaning device comprises a movable device (1) and a cleaning device (2) arranged on the movable device (1). The cleaning device (2) comprises a supporting mechanism (3) and a cleaning mechanism (4) connected with the supporting mechanism (3). The cleaning mechanism (4) comprises a plurality of spray pipe supports (5) arranged at intervals and a fixing mechanism (6) which connects the spray pipe supports (5) into a whole, high pressure spray pipes (14) are arranged on the spray pipe supports (5), cleaning agents used for cleaning a solar cell panel (7) are contained in the high pressure spray pipes (14), spray holes (15) which are formed at intervals are formed in each high pressure spray pipe (14), each spray hole (15) is connected with a spray nozzle (16), and the cleaning agents are sprayed onto the solar cell panel (7) through the spray nozzles (16). When the solar cell panel is cleaned through the non-contact solar cell panel cleaning device, the cleaning mechanism does not need to make contact with the solar cell panel, and therefore the solar cell panel can be effectively protected.

Owner:WUHAN ZHUOCHENG PHOTOVOLTAIC NEW ENERGY CO LTD

Traffic road fence cleaning equipment

InactiveUS20200188964A1Invention be simpleConvenient operationCleaning using toolsRoad cleaningWater supply networkEnvironmental geology

Owner:LIANG LIJUN

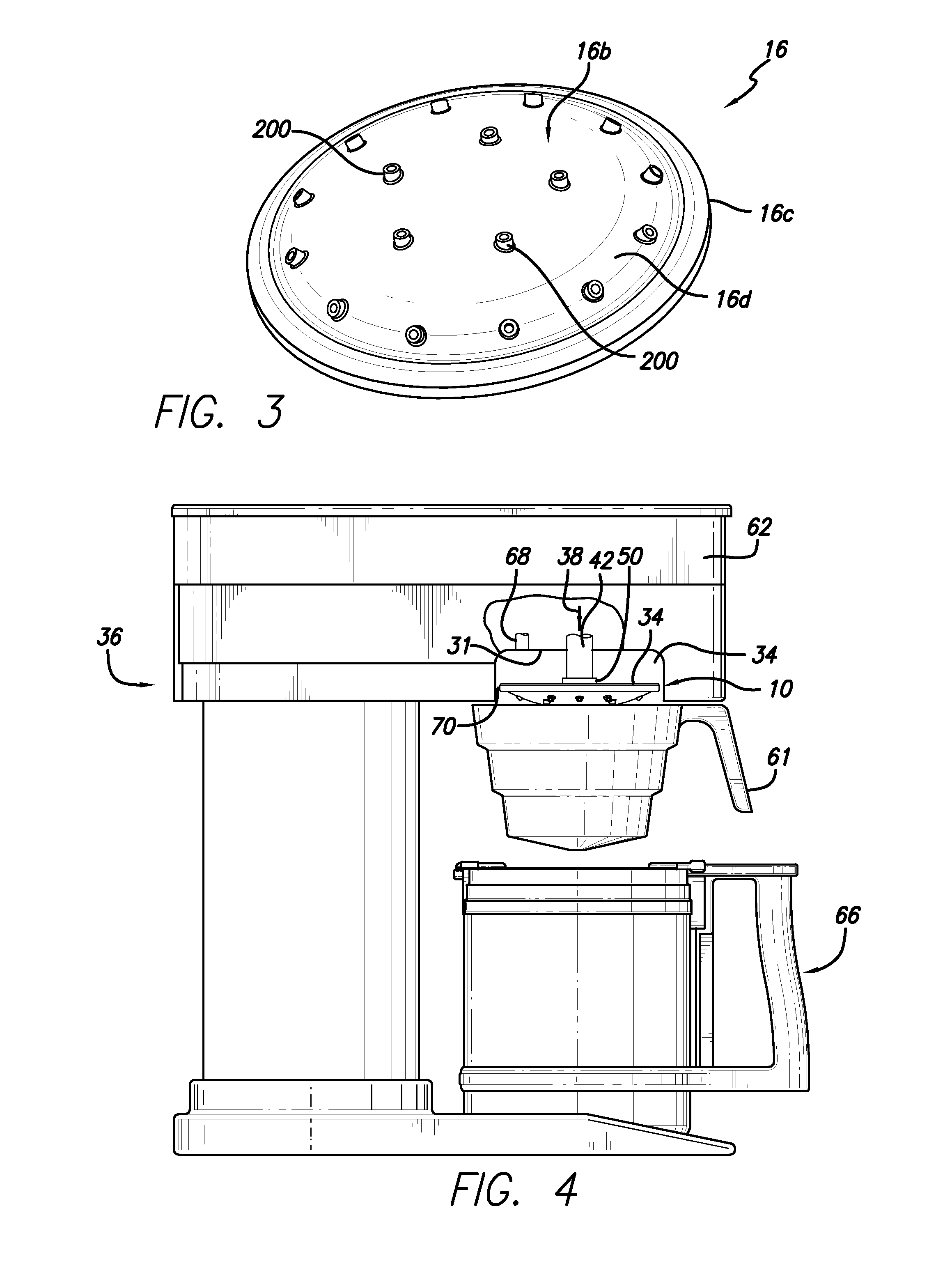

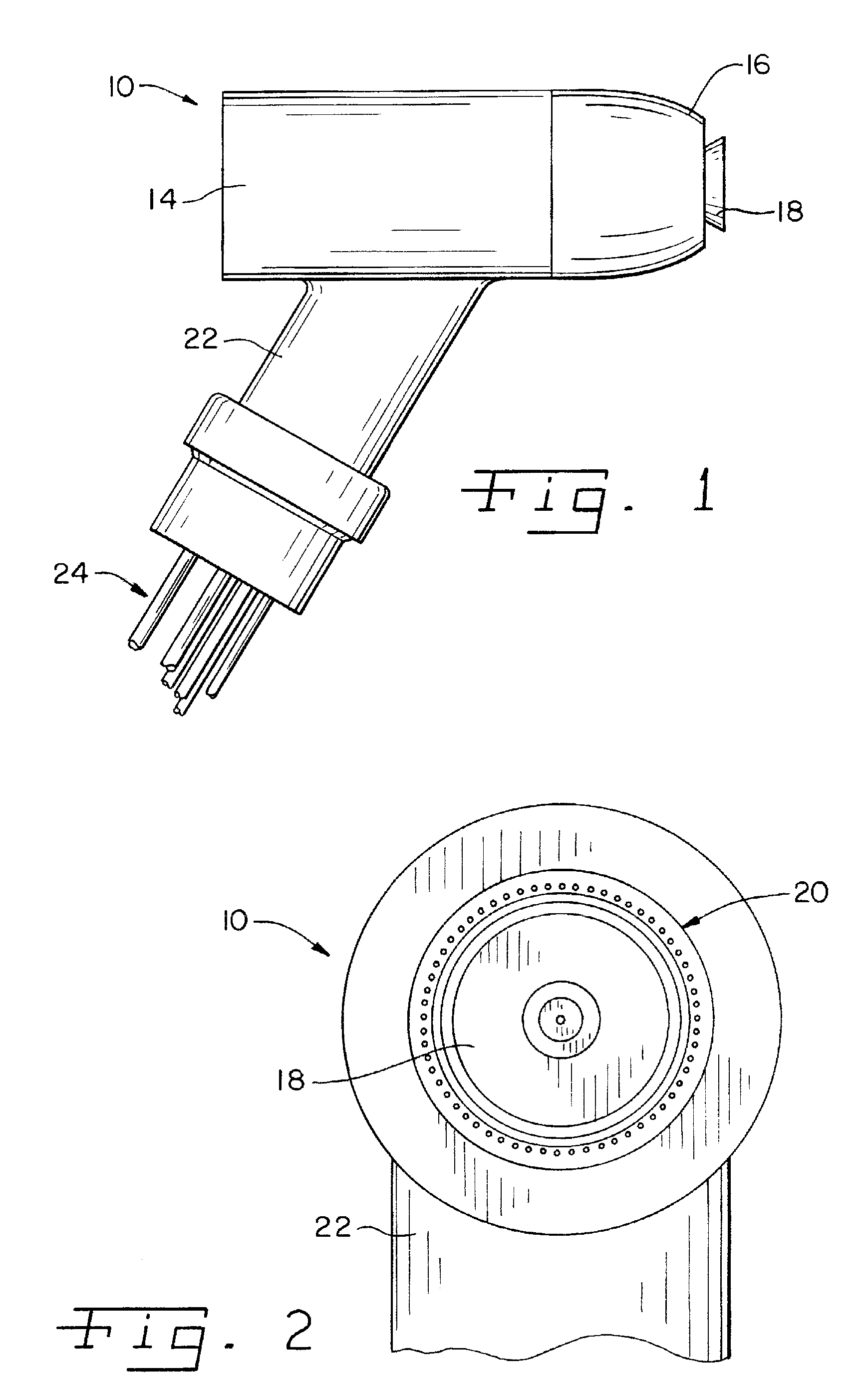

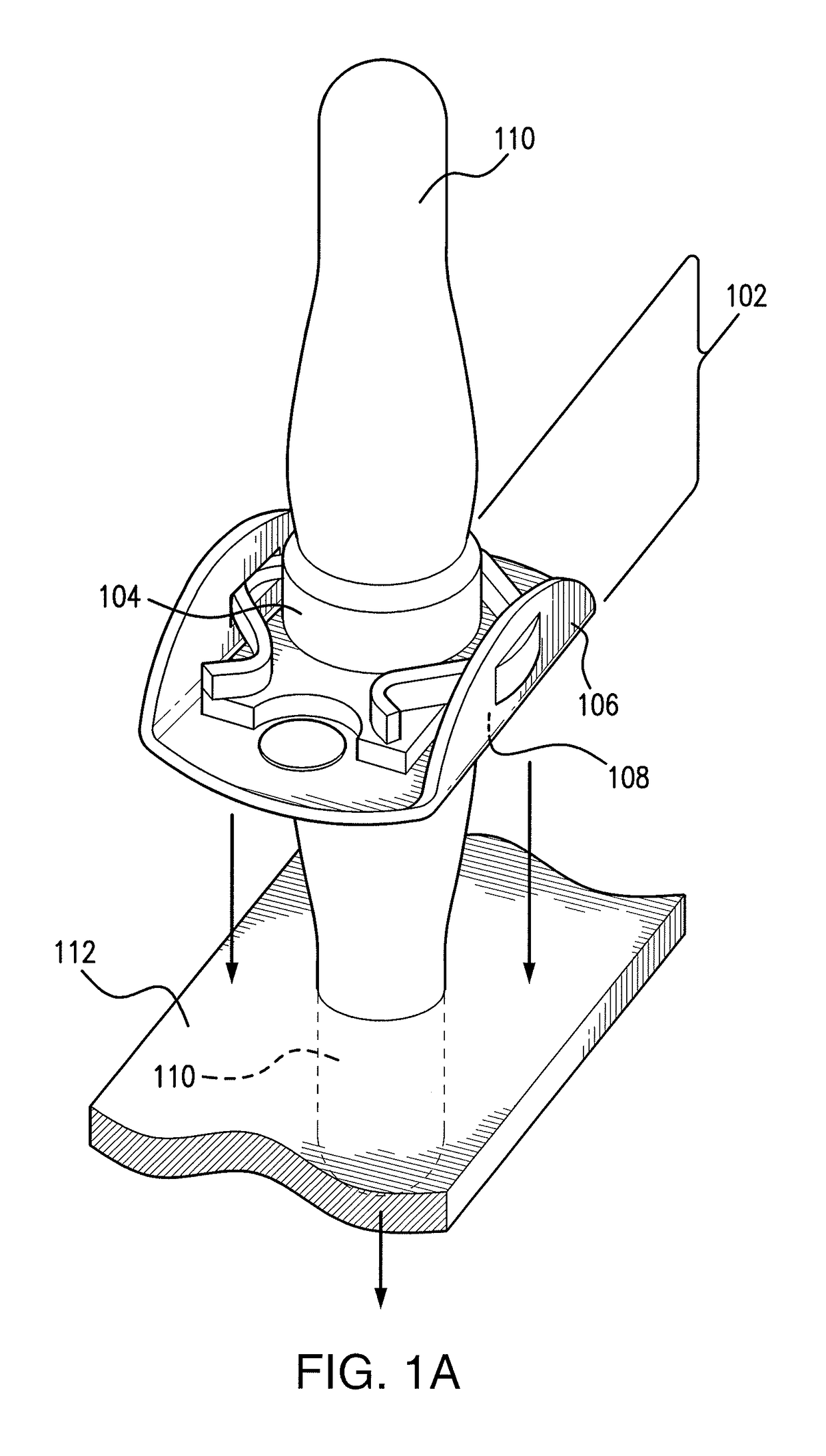

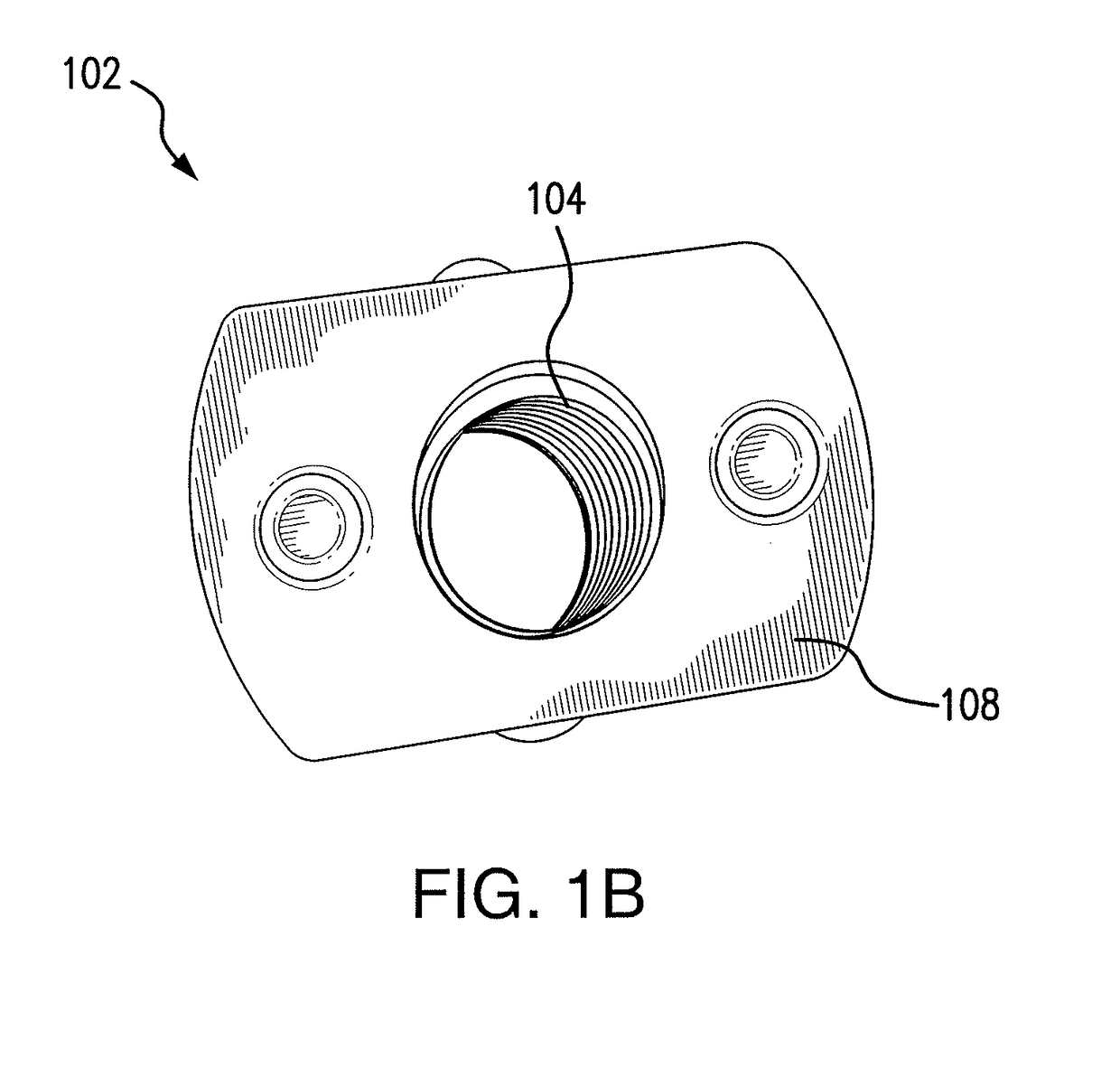

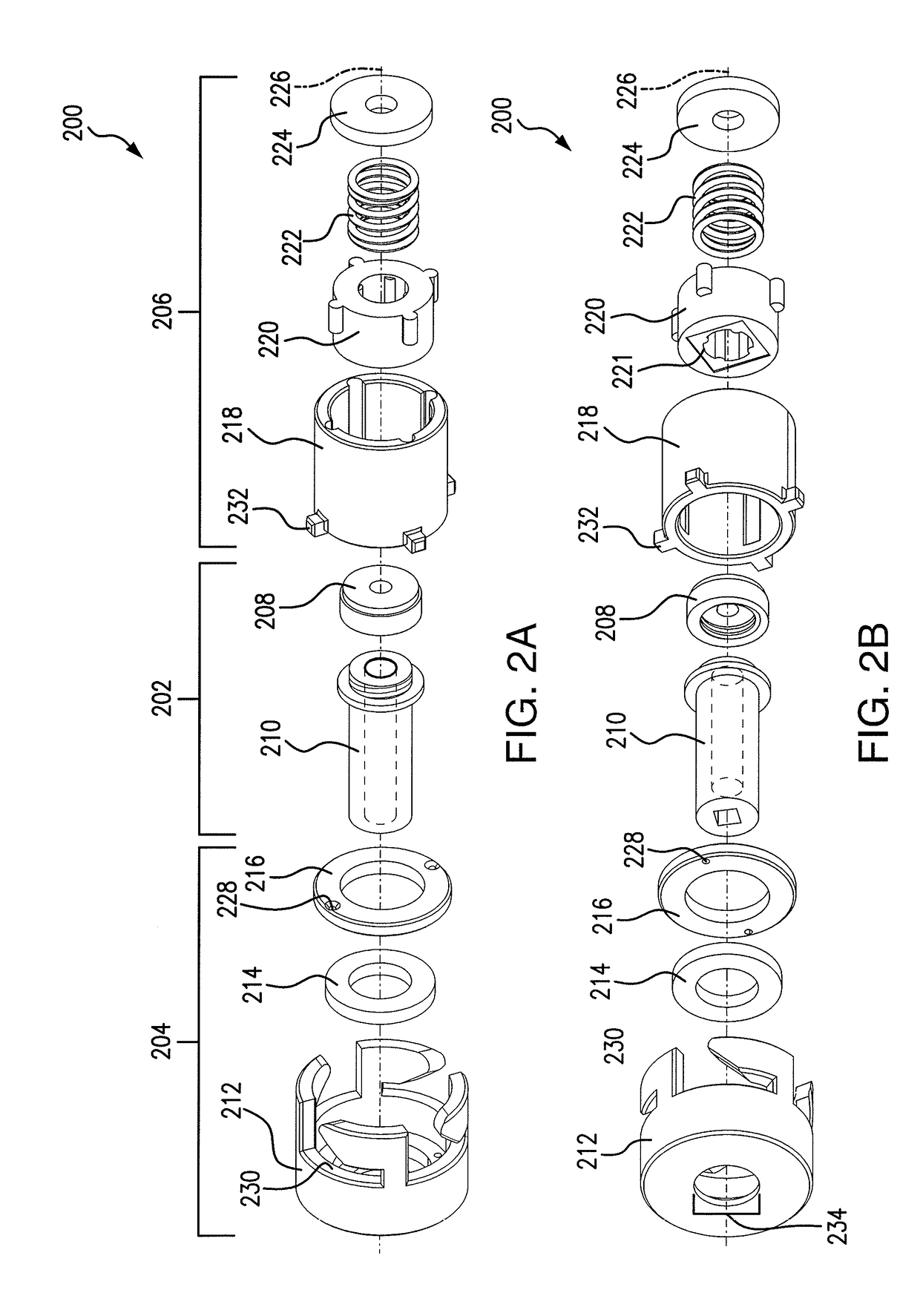

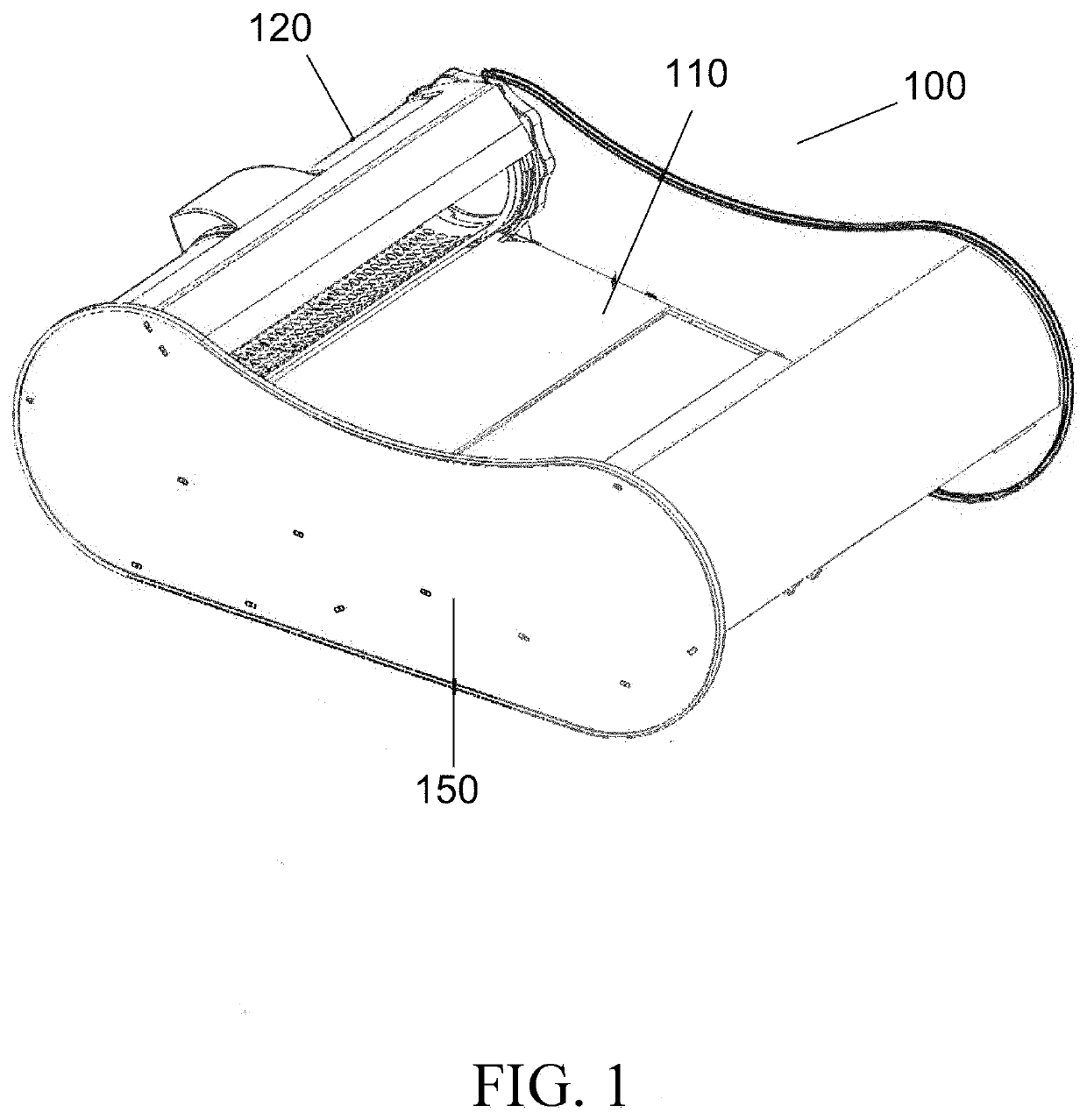

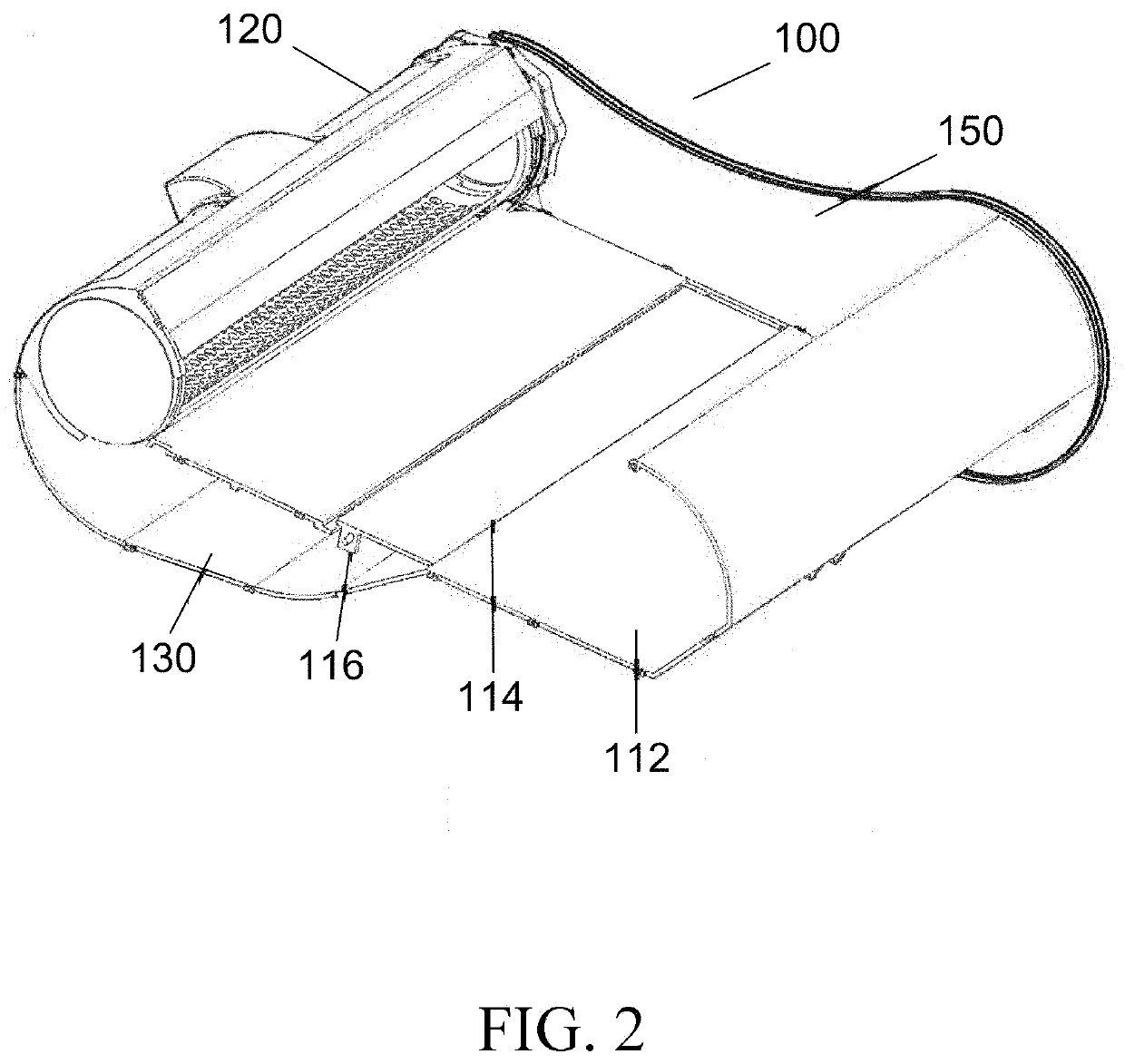

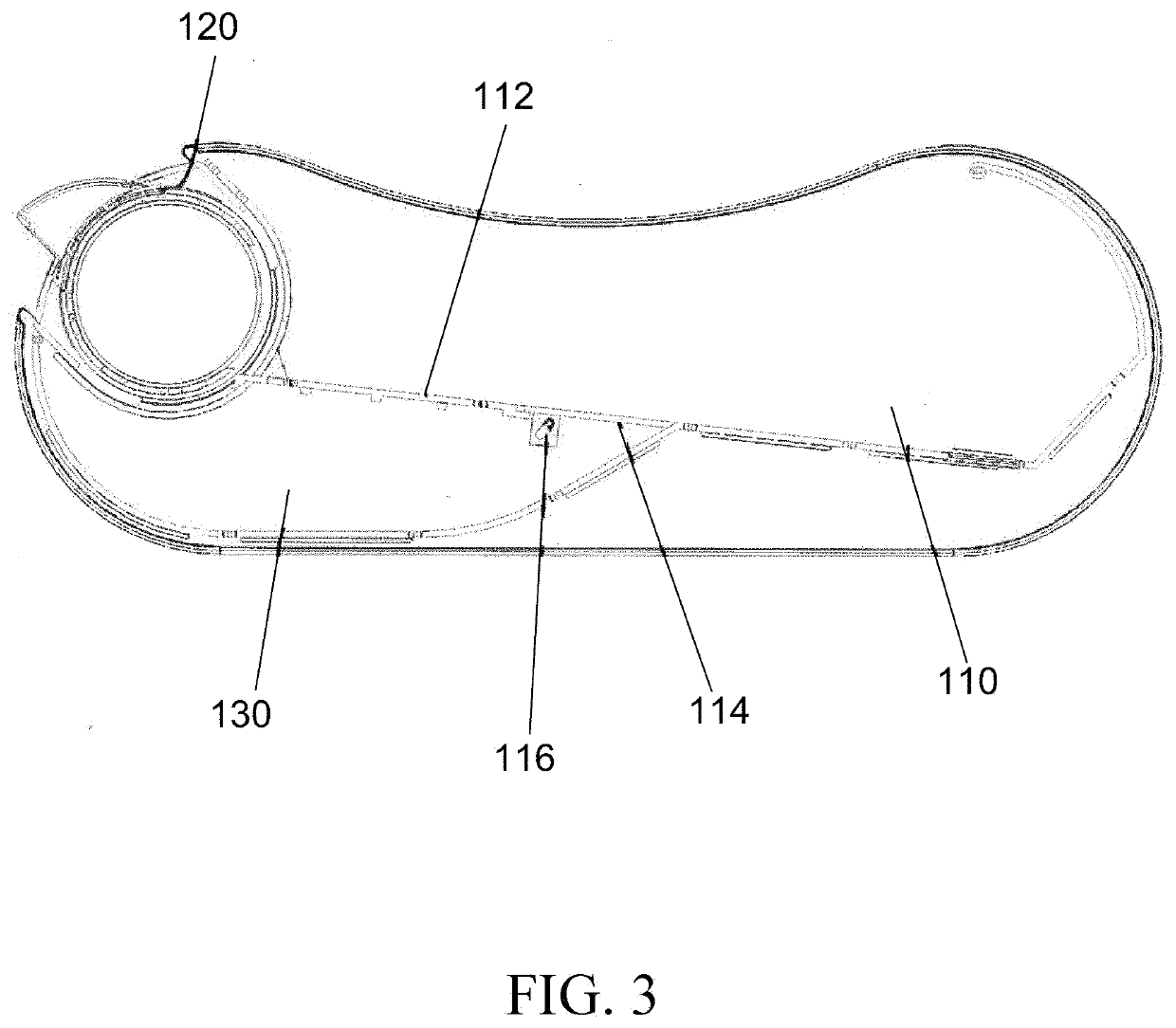

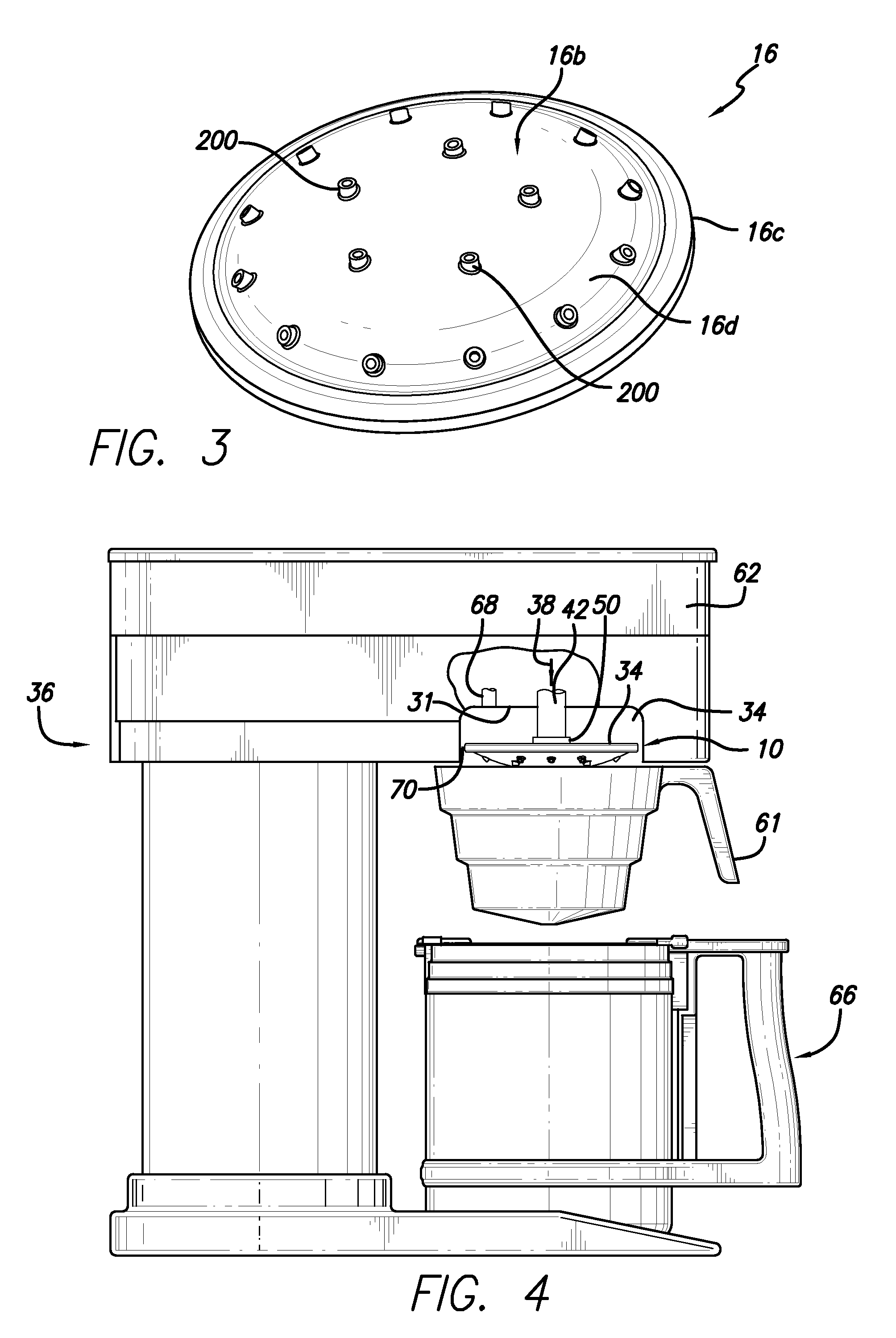

Flexible spray head

ActiveUS20110094393A1Efficient and quick cleaningPrevents accidental and unintended lossSpray nozzlesBeverage vesselsCombined useEngineering

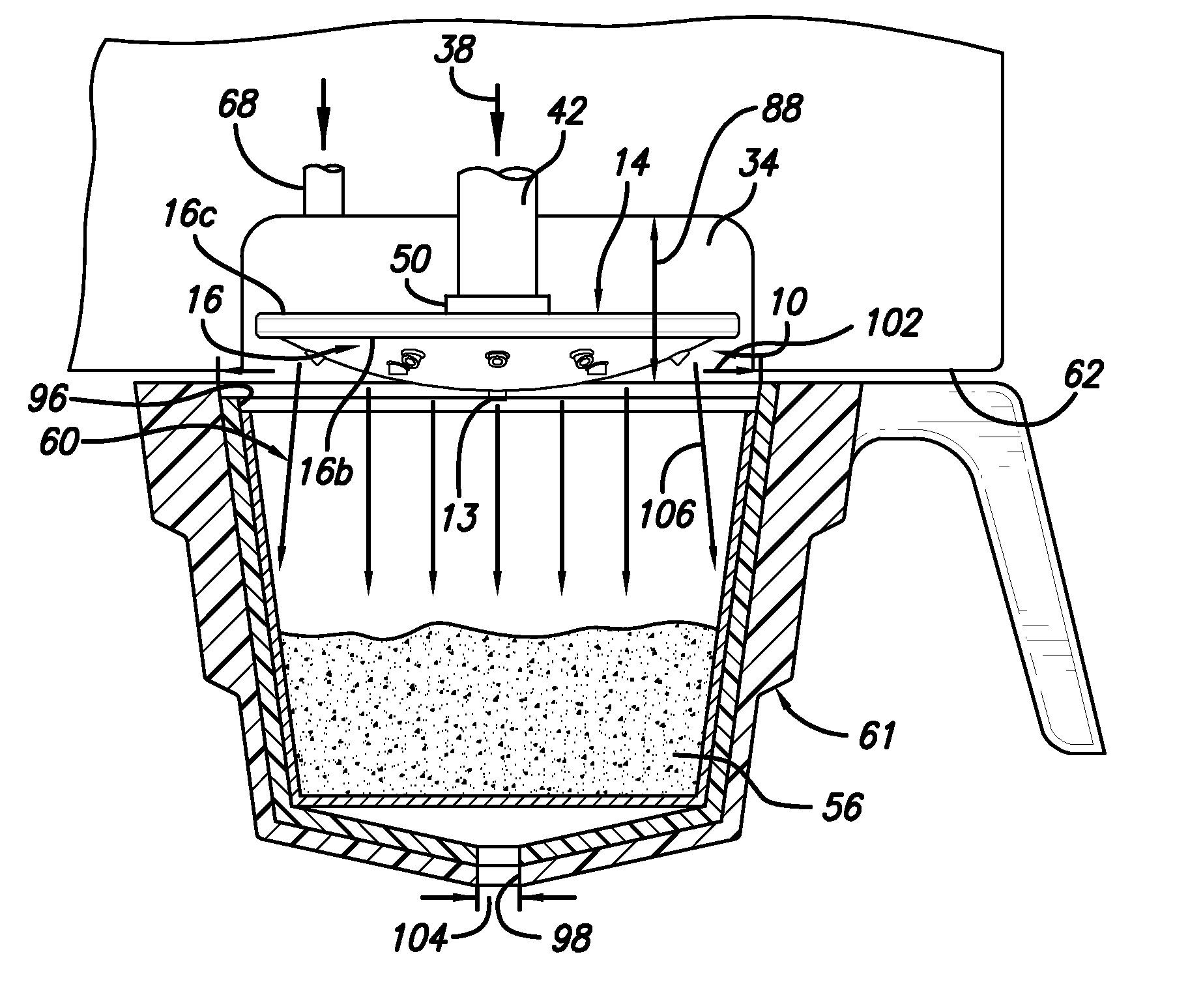

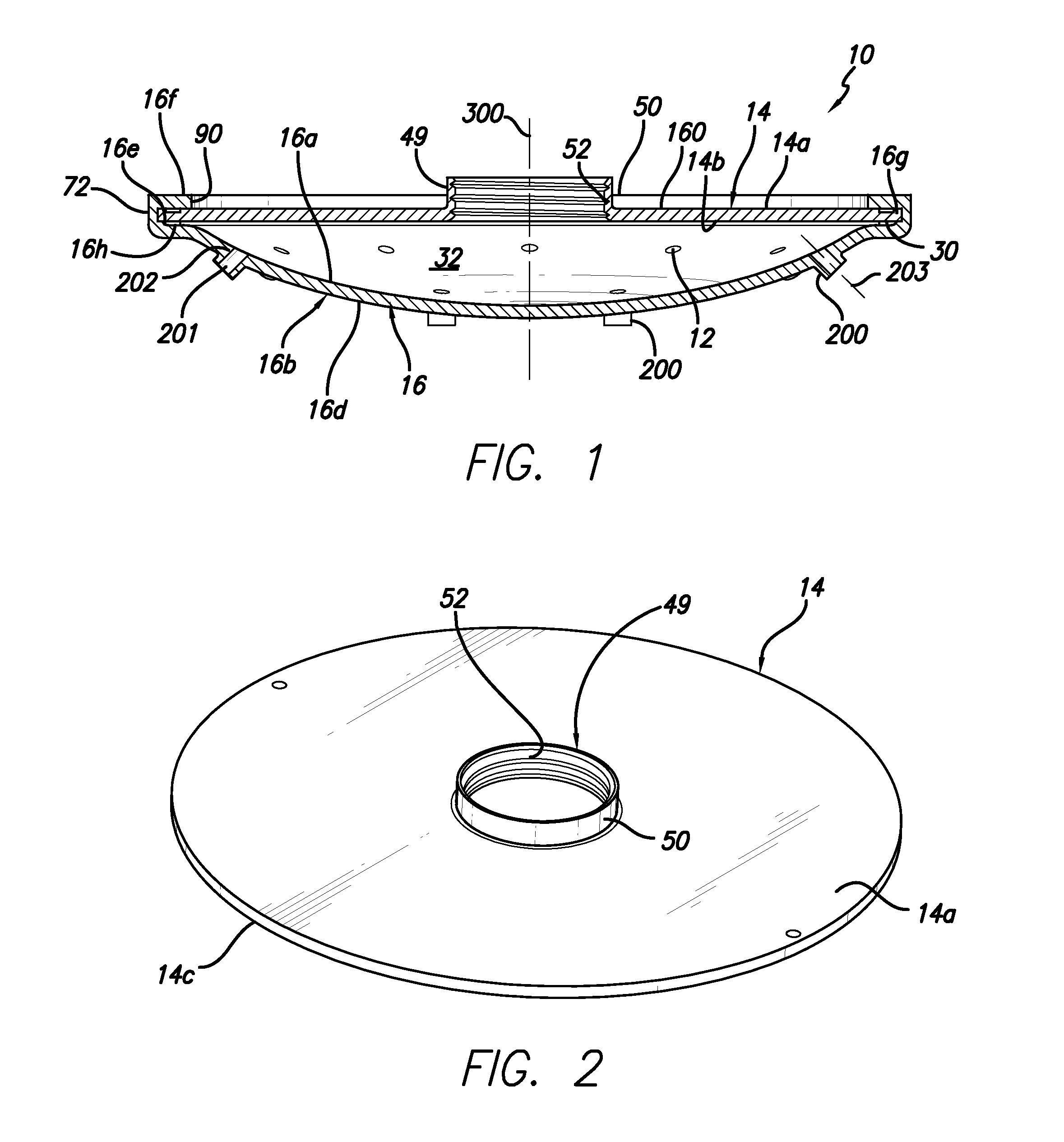

Briefly, and in accordance with the foregoing, disclosed is a spray head for use with, in combination with a beverage making apparatus, as a replacement for other spray heads and a method of using a spray head. The spray head receives liquid from a liquid dispensing path of the beverage making apparatus and distributes liquid over a beverage making substance retained proximate the spray head. The spray head includes two pieces, a first piece for connection to the liquid dispensing path and the second piece which is flexible and removable attachable to the first piece. A cavity is defined between the first and second pieces. Water received form the liquid dispensing path collects in the cavity. The second piece or body portion includes a plurality of holes for dispensing and distributing water from the cavity over the beverage substance. The spray head is removable from the beverage making apparatus for facilitating direct contact and flexion cleaning of the surfaces of at least the body portion of the spray head to remove particles and mineral deposits therefrom.

Owner:BUNN O MATIC

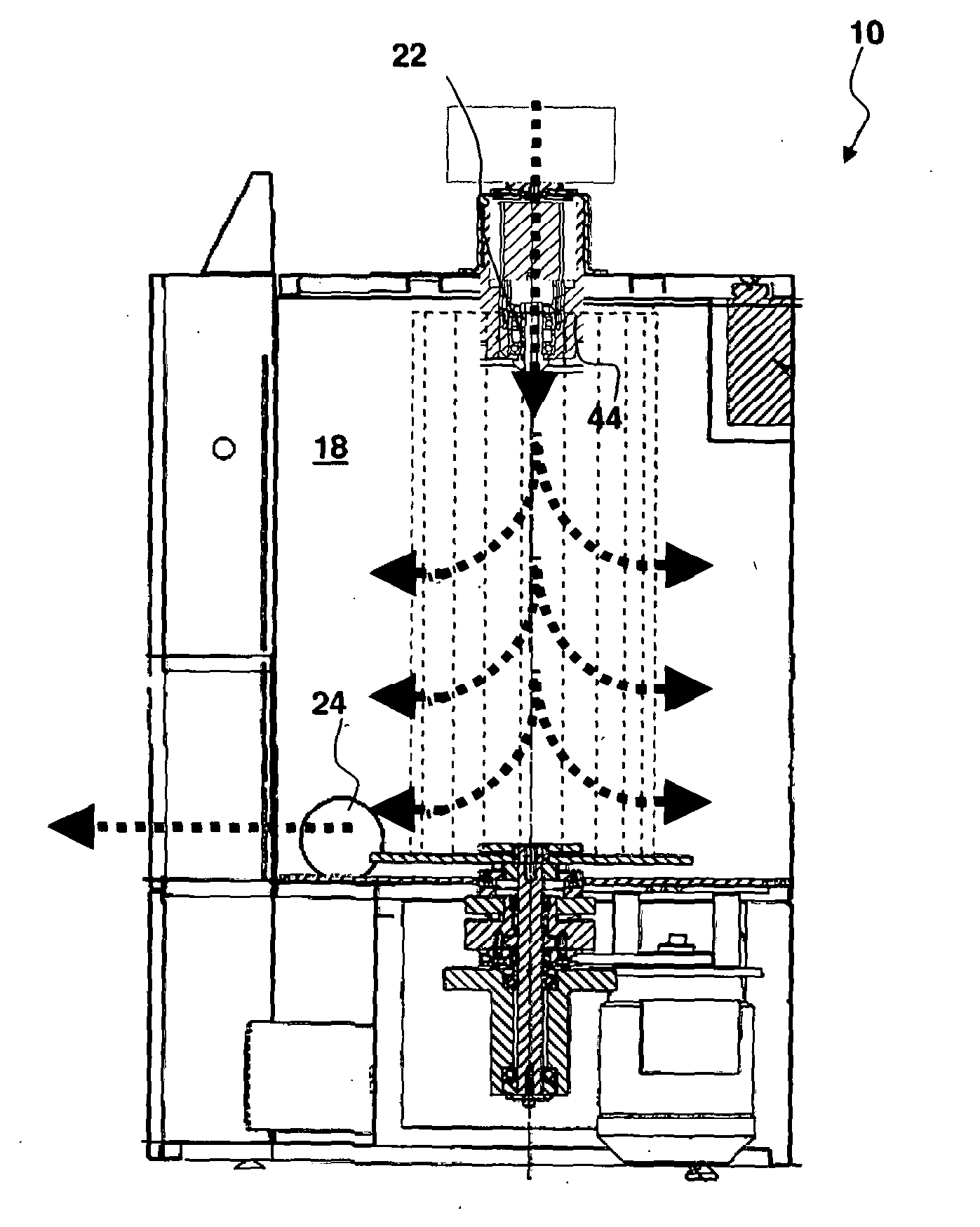

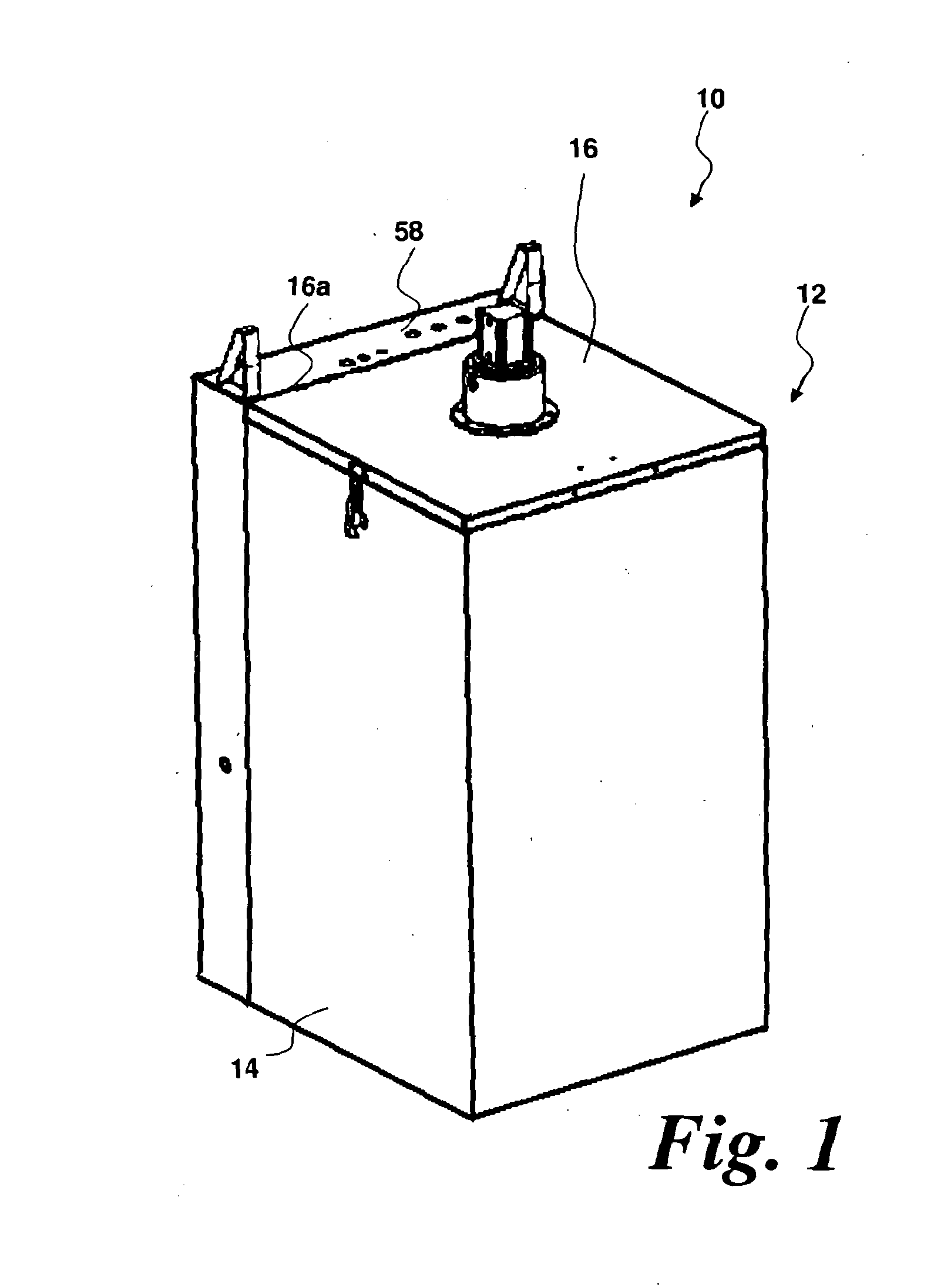

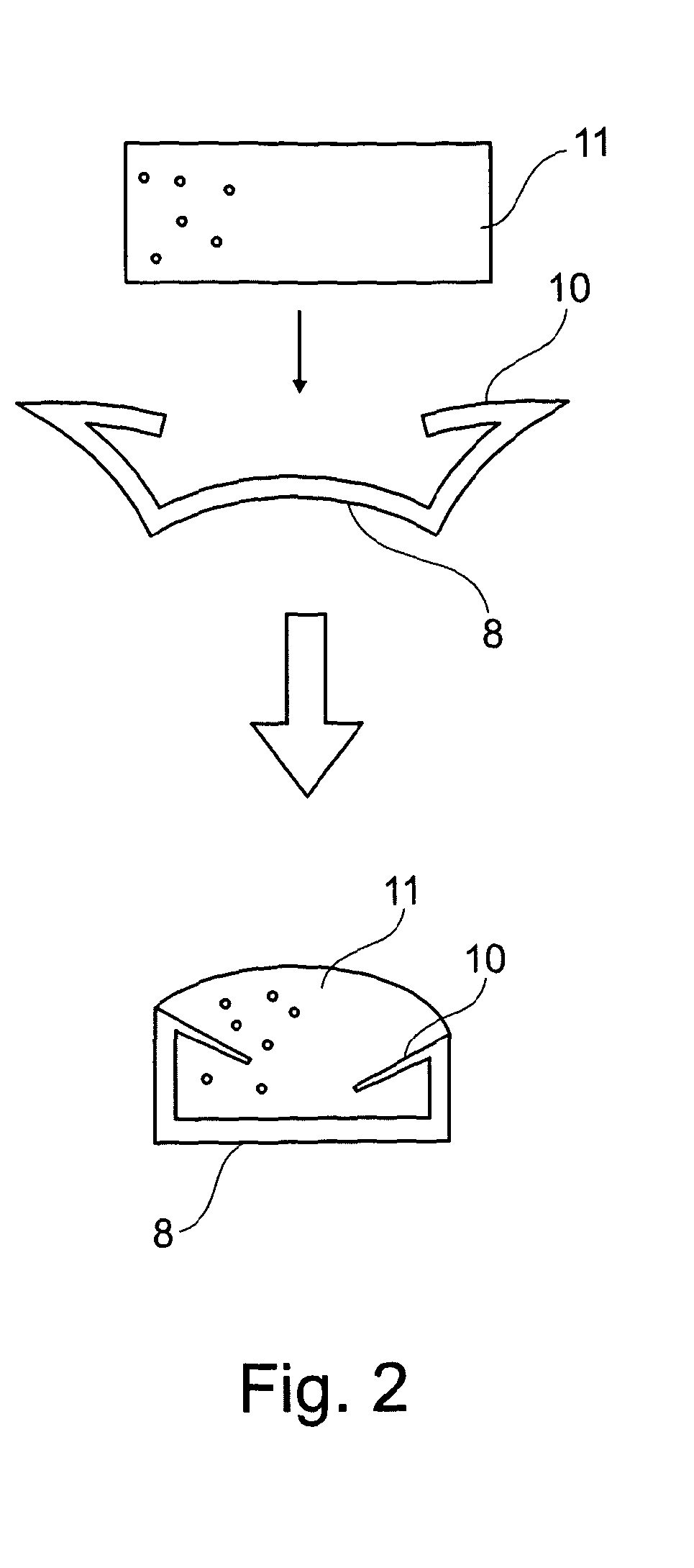

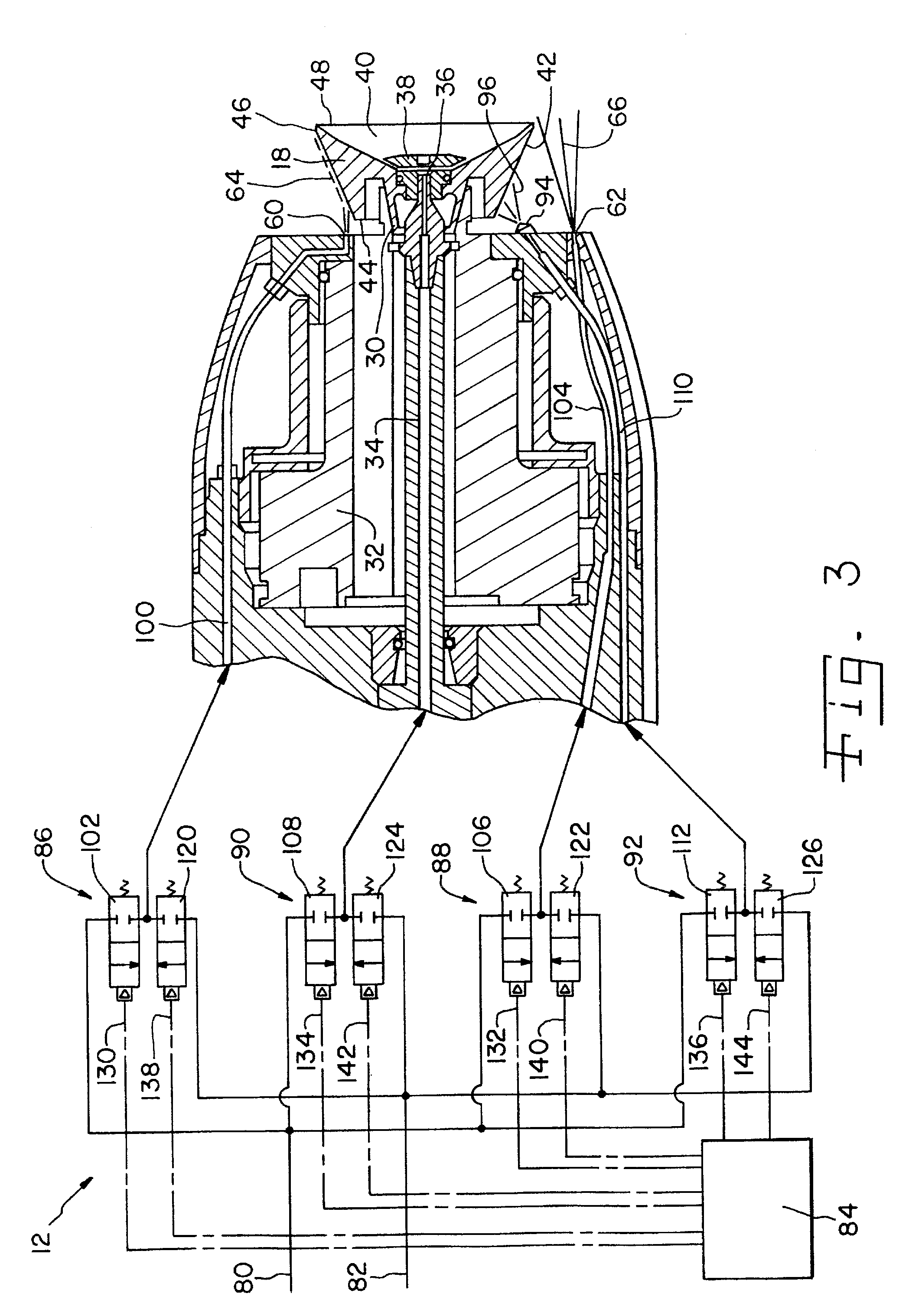

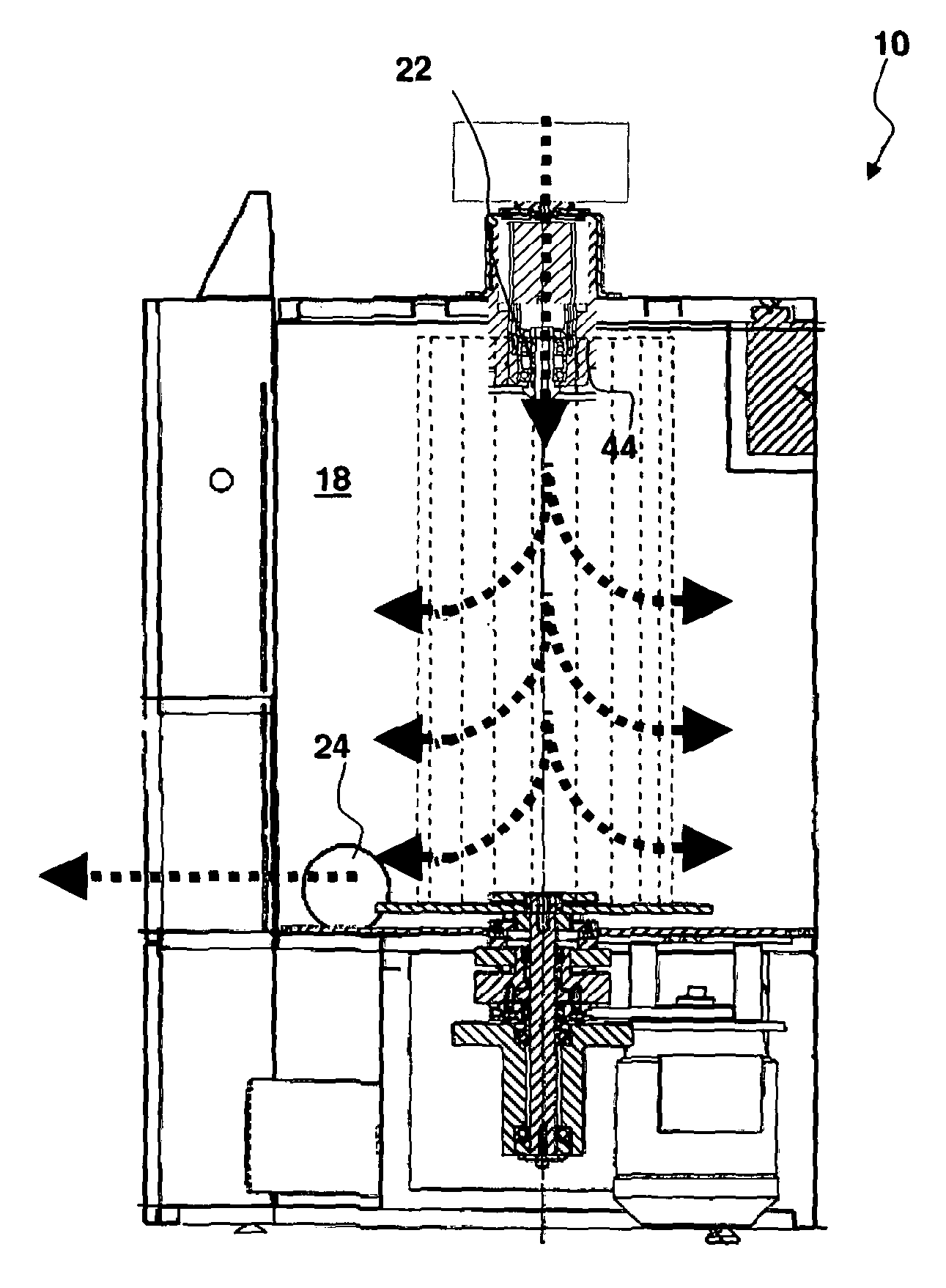

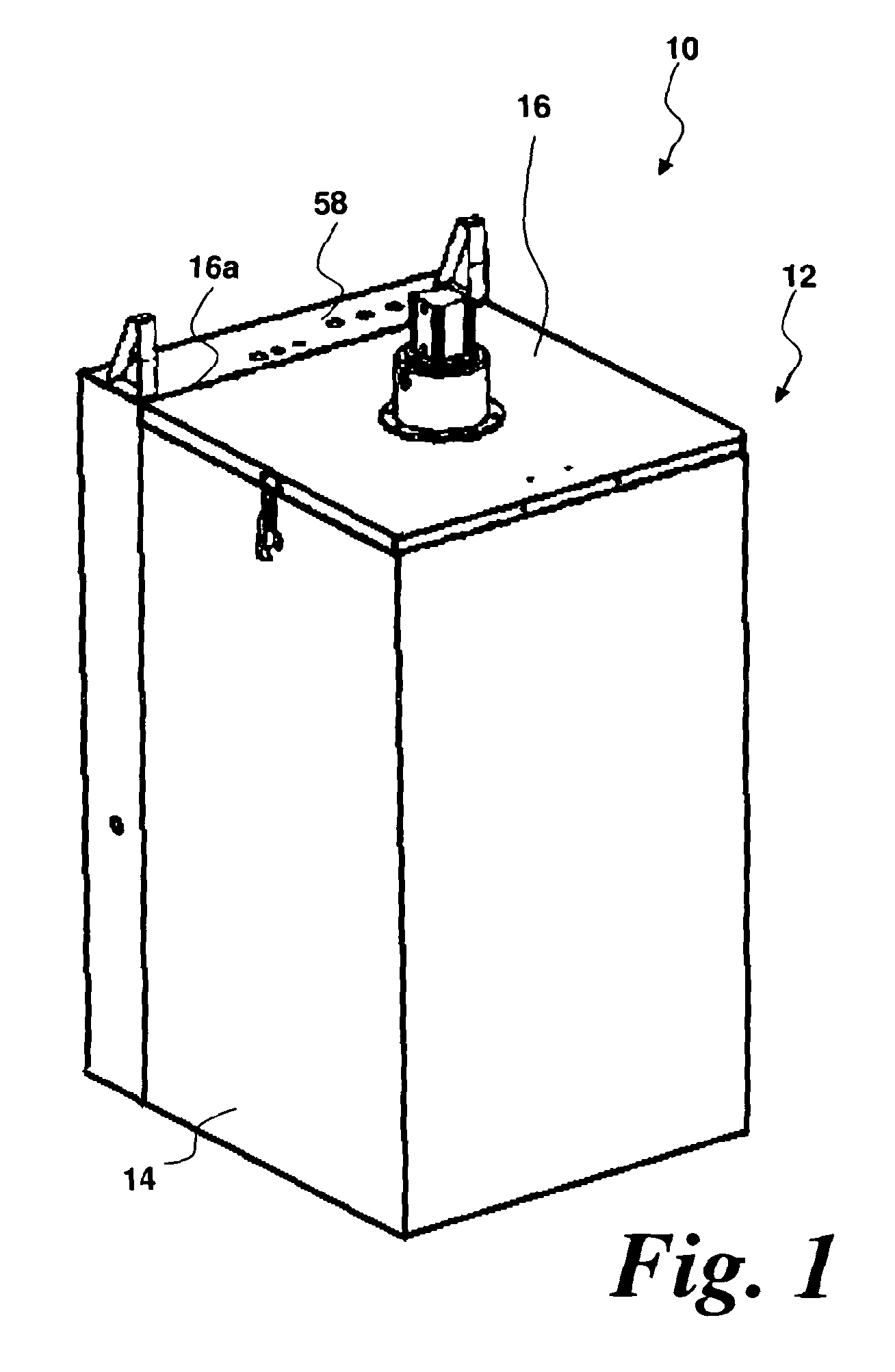

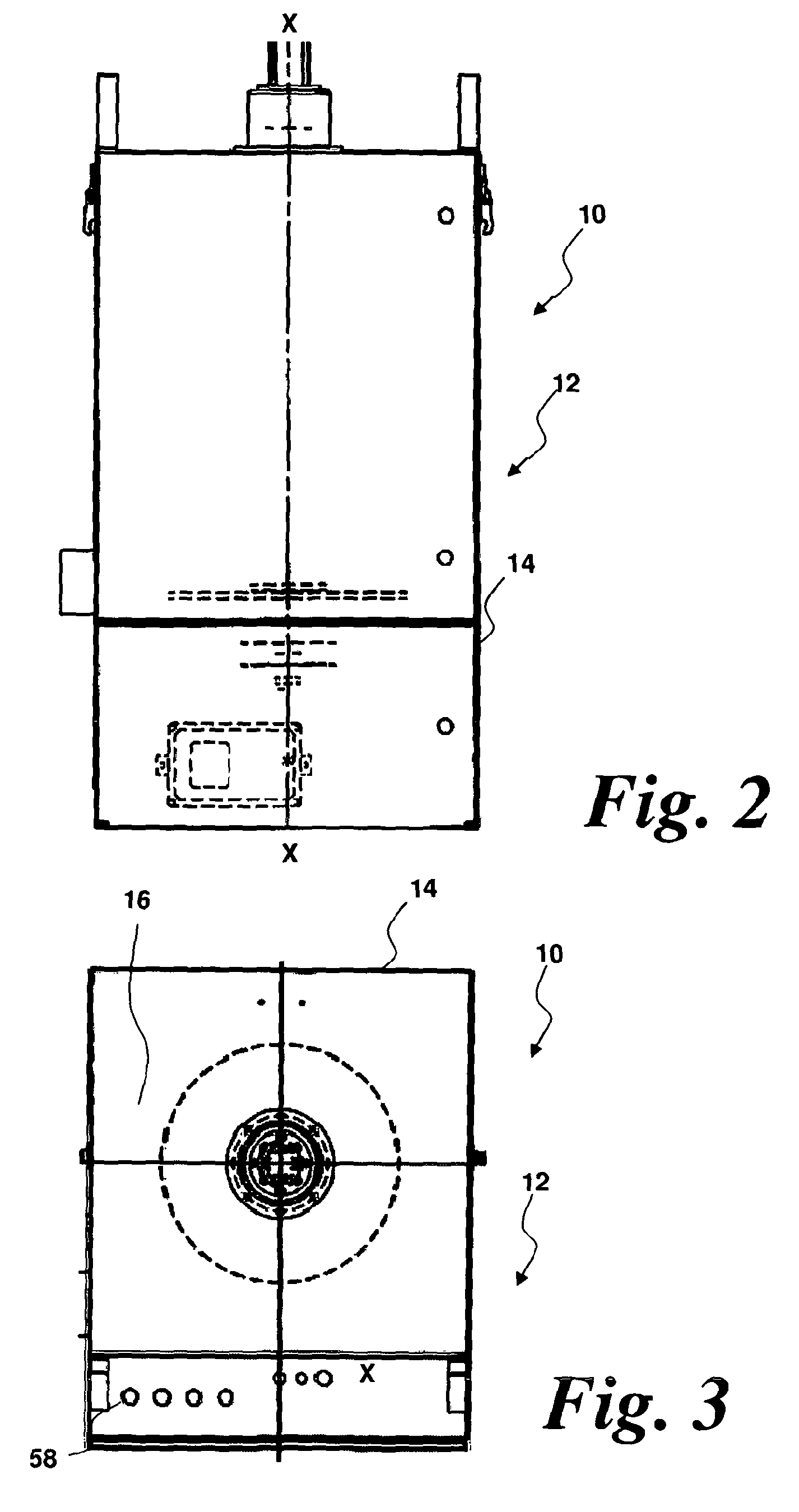

Method and apparatus for cleaning a filter

InactiveUS20140251387A1Efficient and quick cleaningMinimal damageGas treatmentDispersed particle filtrationEngineeringMechanical engineering

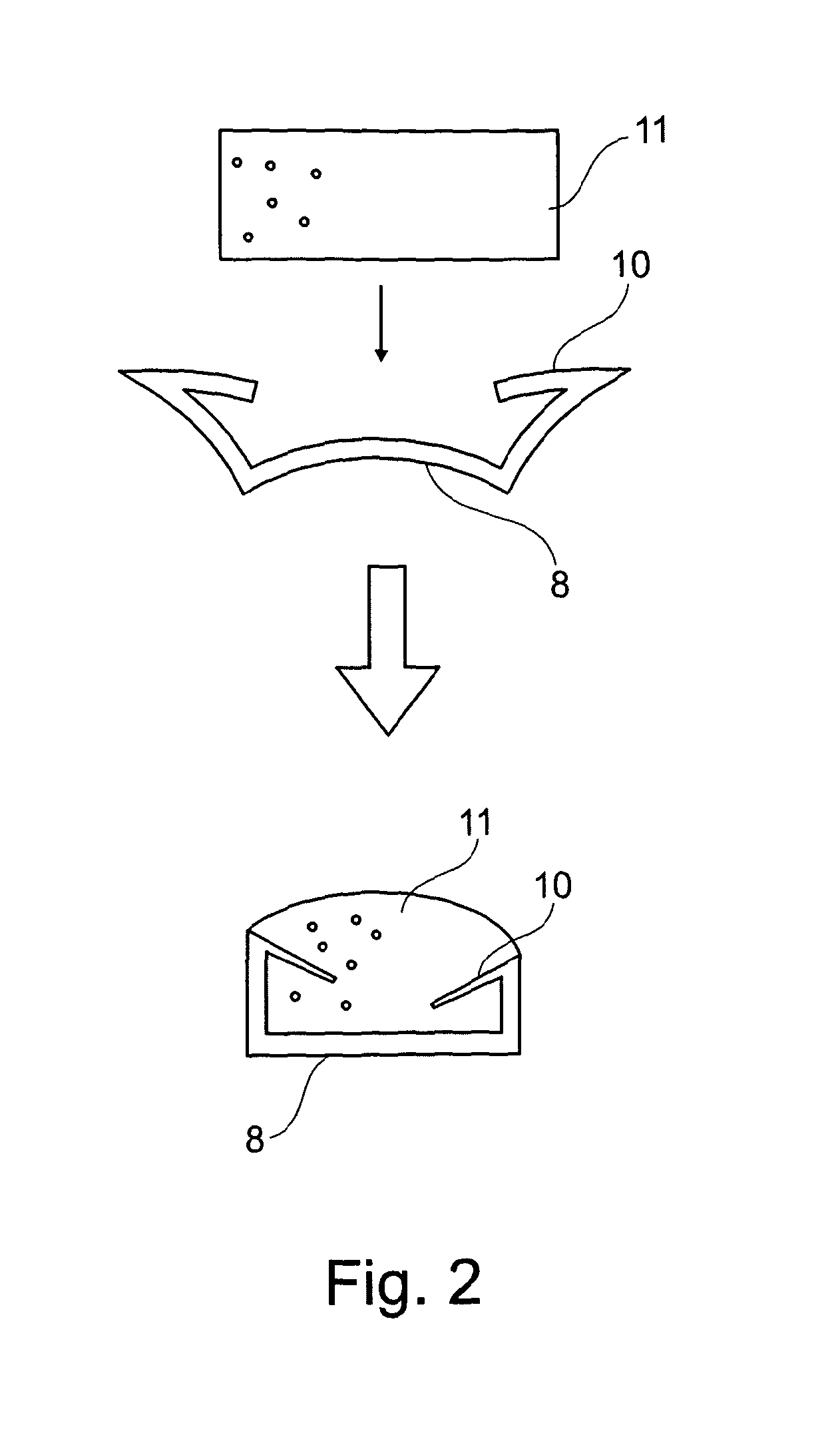

A filter cleaning device includes a cleaning chamber operable to receive a gas filter to be cleaned, the cleaning chamber having an inlet through which a gas flow can be admitted and an outlet for gas flow leaving the cleaning chamber, the inlet and outlet being arranged such that the airflow is forced to pass through at least a part of the filter when inserted, the filter cleaning device further comprising a mechanical agitation arrangement operable, in one mode of operation, to generate a linear oscillation along an axis of the filter when inserted and, in another mode of operation, to rotate the filter about an axis of rotation.

Owner:ROYCE JOHN +1

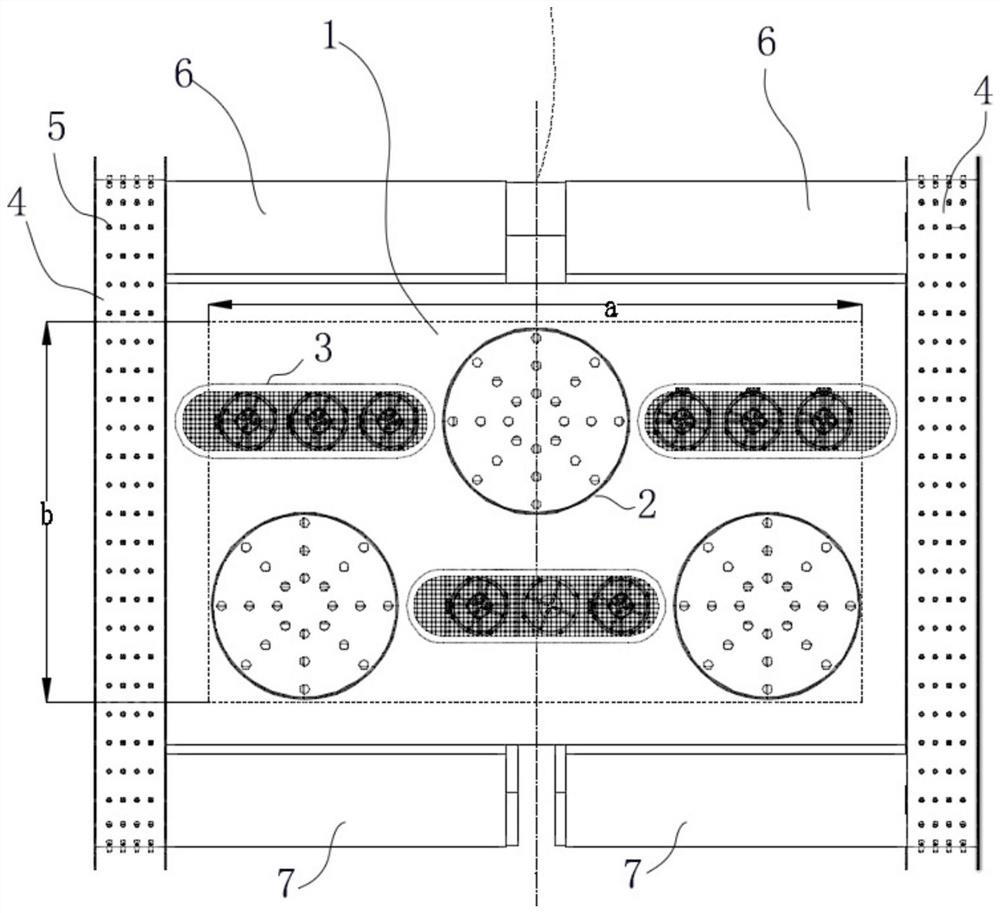

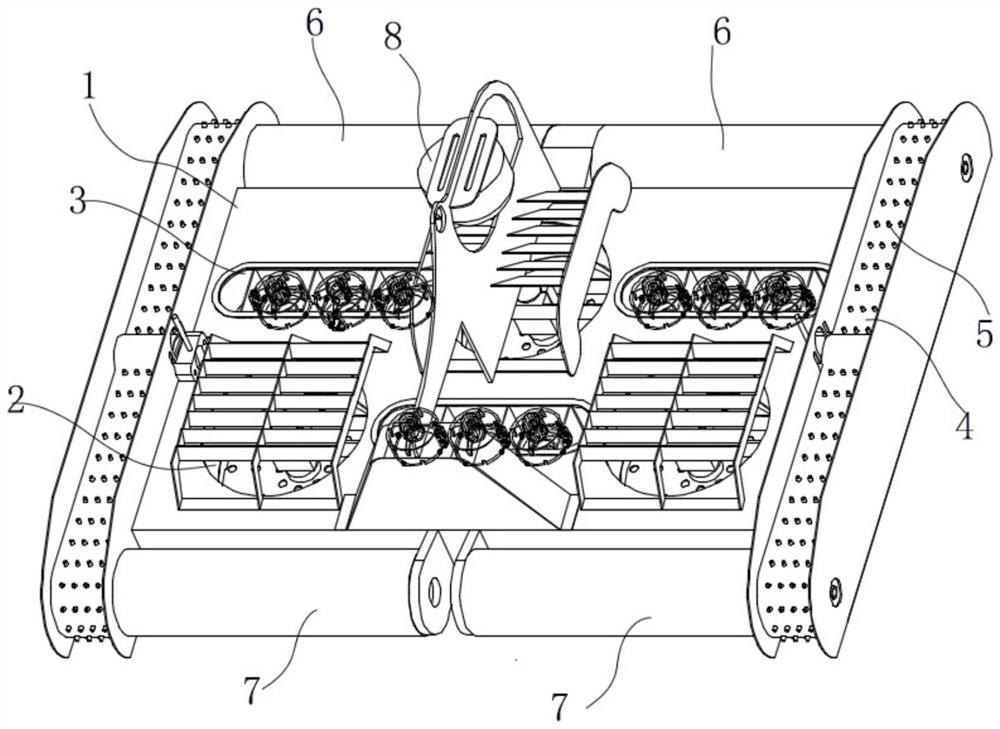

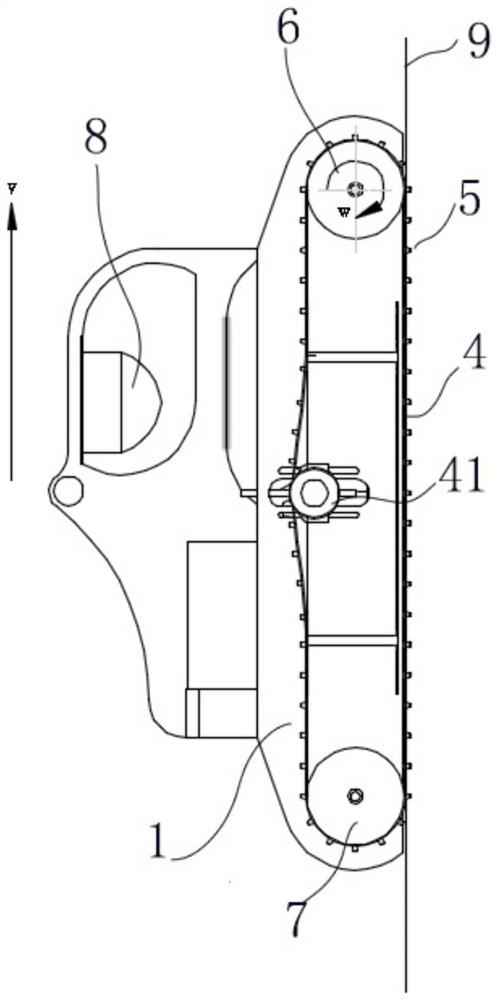

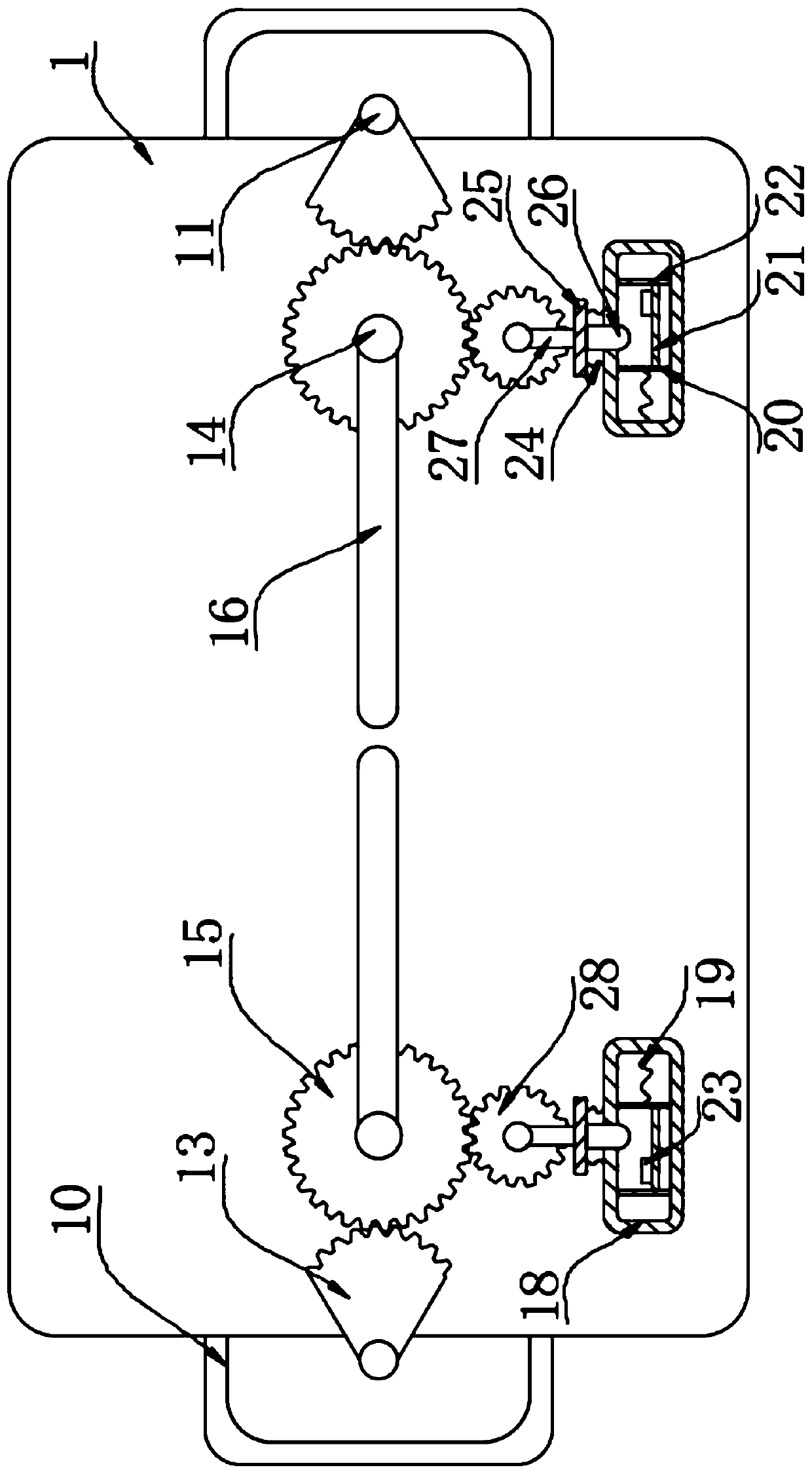

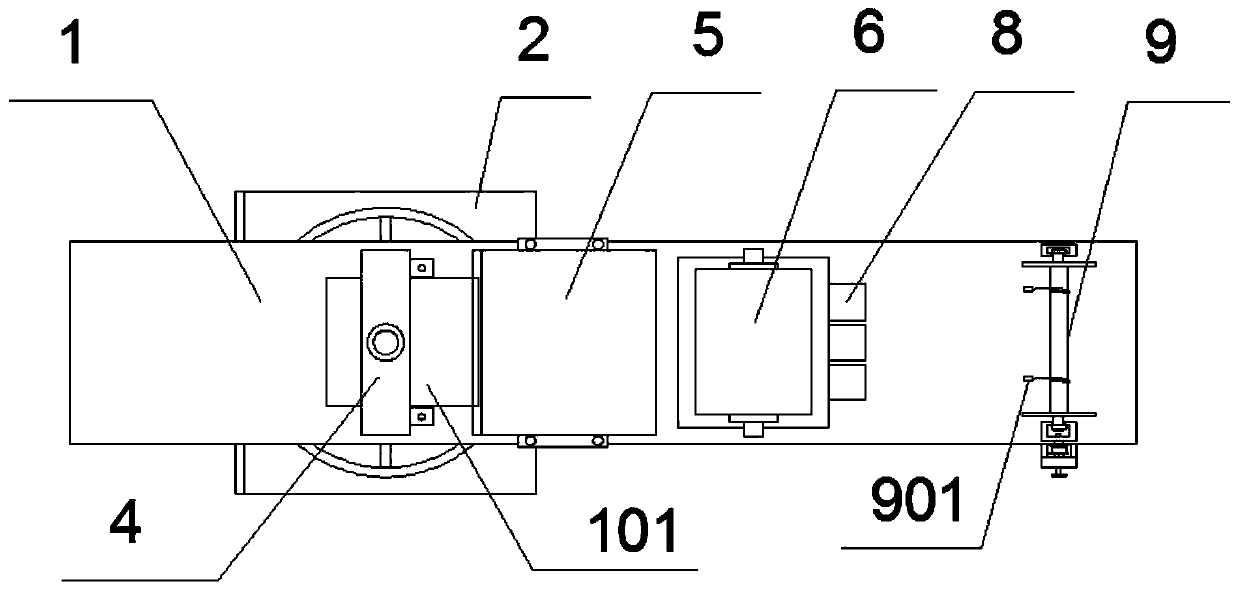

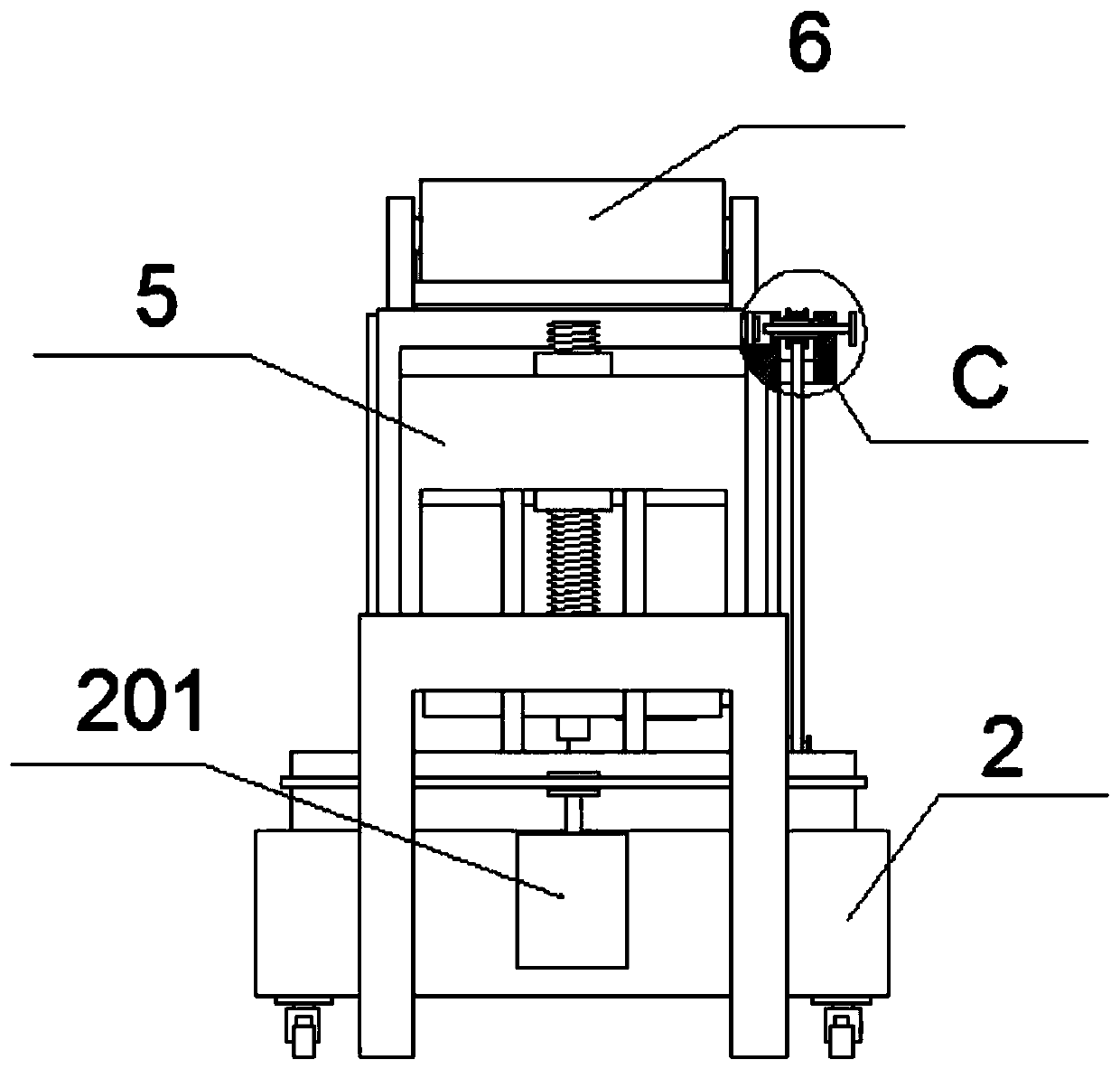

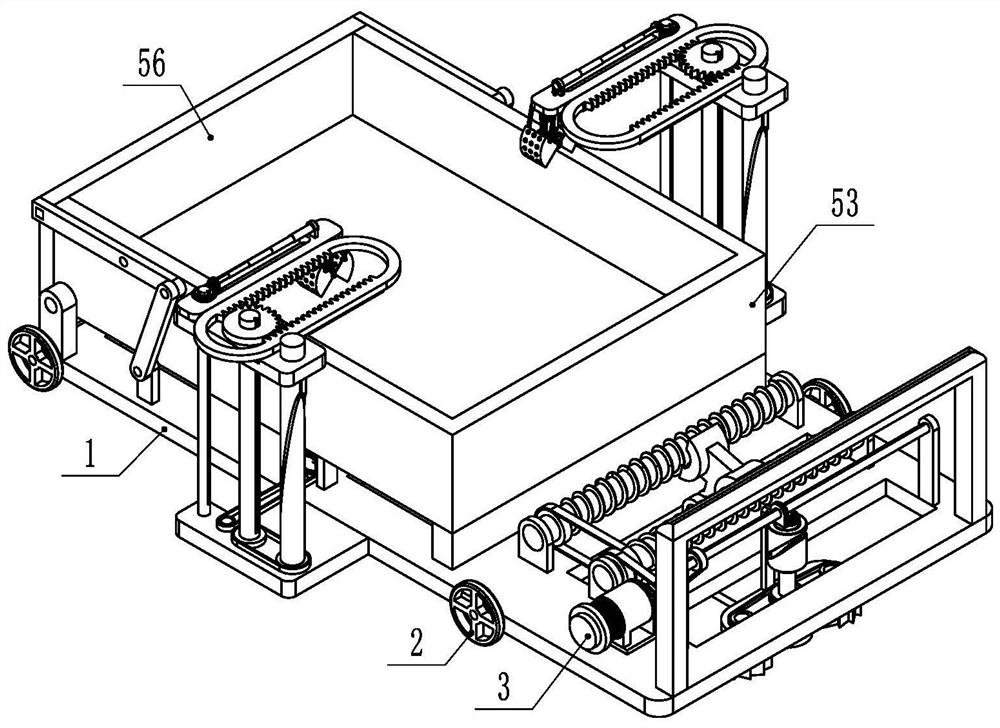

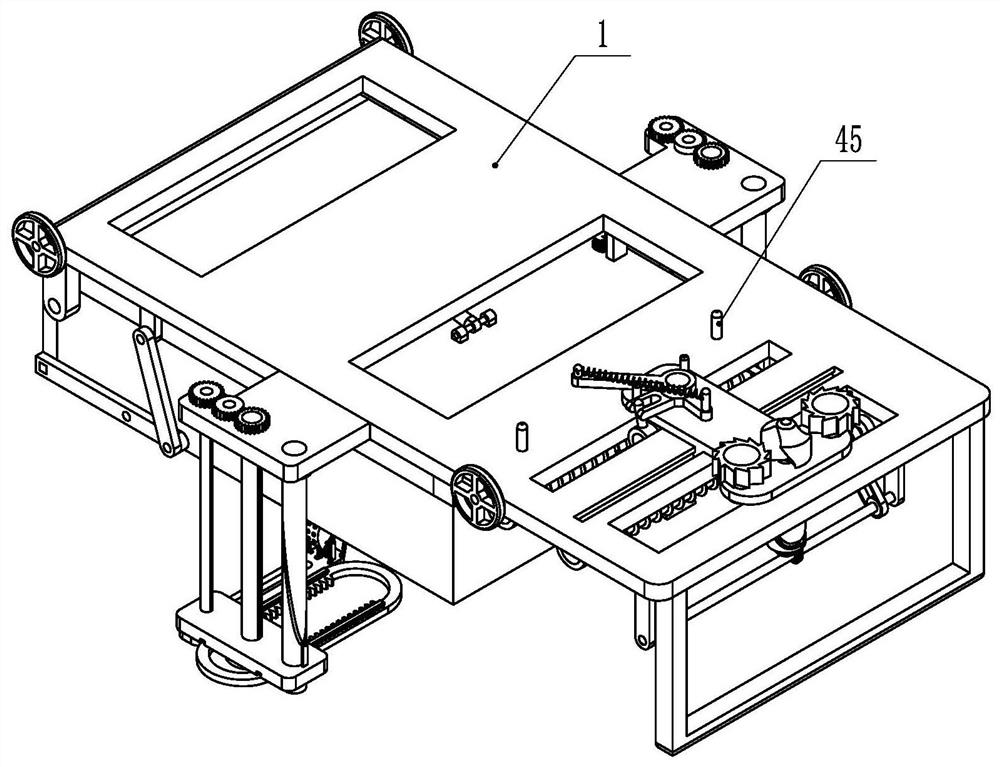

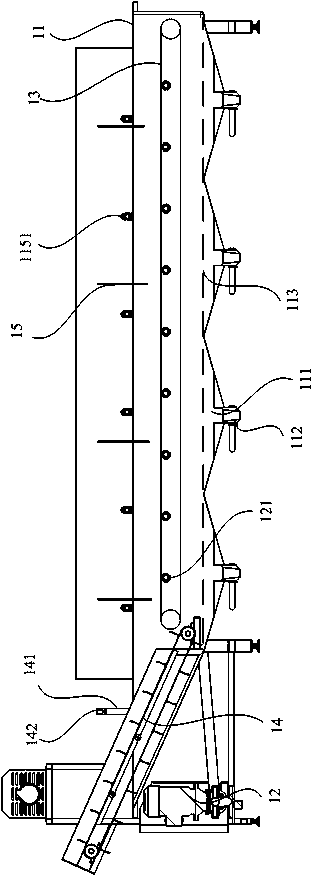

Crawler-type netting cleaning robot for seawater cage culture and netting cleaning method

ActiveCN113275295AFully automatic cleaningEasy to cleanCleaning using liquidsUnderwater vesselsSpray nozzleElectric machinery

The invention discloses a crawler-type netting cleaning robot for seawater cage culture and a netting cleaning method. The netting robot comprises a base frame, a cleaning rotary disc, a rotary disc driving motor and a propeller thruster are installed on the base frame, the rotary disc driving motor is used for driving the cleaning rotary disc to rotate, the propeller thruster is used for adjusting the distance between the cleaning rotary disc and a netting, the cleaning rotary disc is provided with a plurality of flow channels, the tail end of each flow channel is connected with a spraying nozzle for spraying water flow, and the robot is characterized in that the two sides of the base frame are further provided with mutually symmetrical walking crawler belts, the walking crawler belts are respectively connected with a driving motor, and gripping teeth matched with meshes of a to-be-cleaned netting are evenly distributed on the outer surfaces of the walking crawler belts, so that the gripping teeth correspondingly stretch into the meshes of the netting. According to the crawler-type netting cleaning robot for seawater cage culture and the netting cleaning method, the cleaning efficiency of the underwater netting is improved, and the manual labor intensity and the operation cost are reduced.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

Fluid delivery service

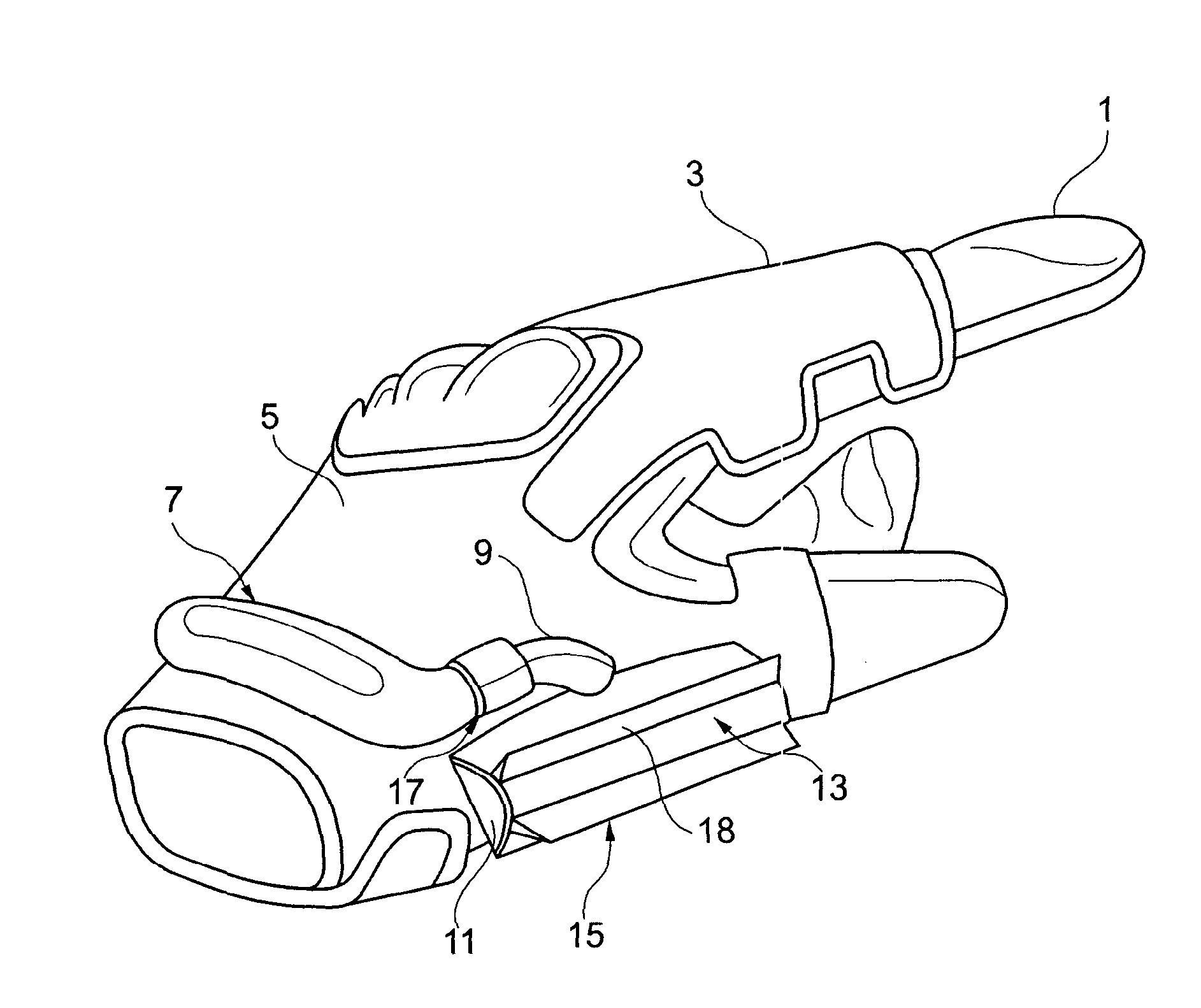

ActiveUS20130269136A1Eliminate and reduce evaporationReduce smearingBoard cleaning devicesCarpet cleanersCapillary actionBiomedical engineering

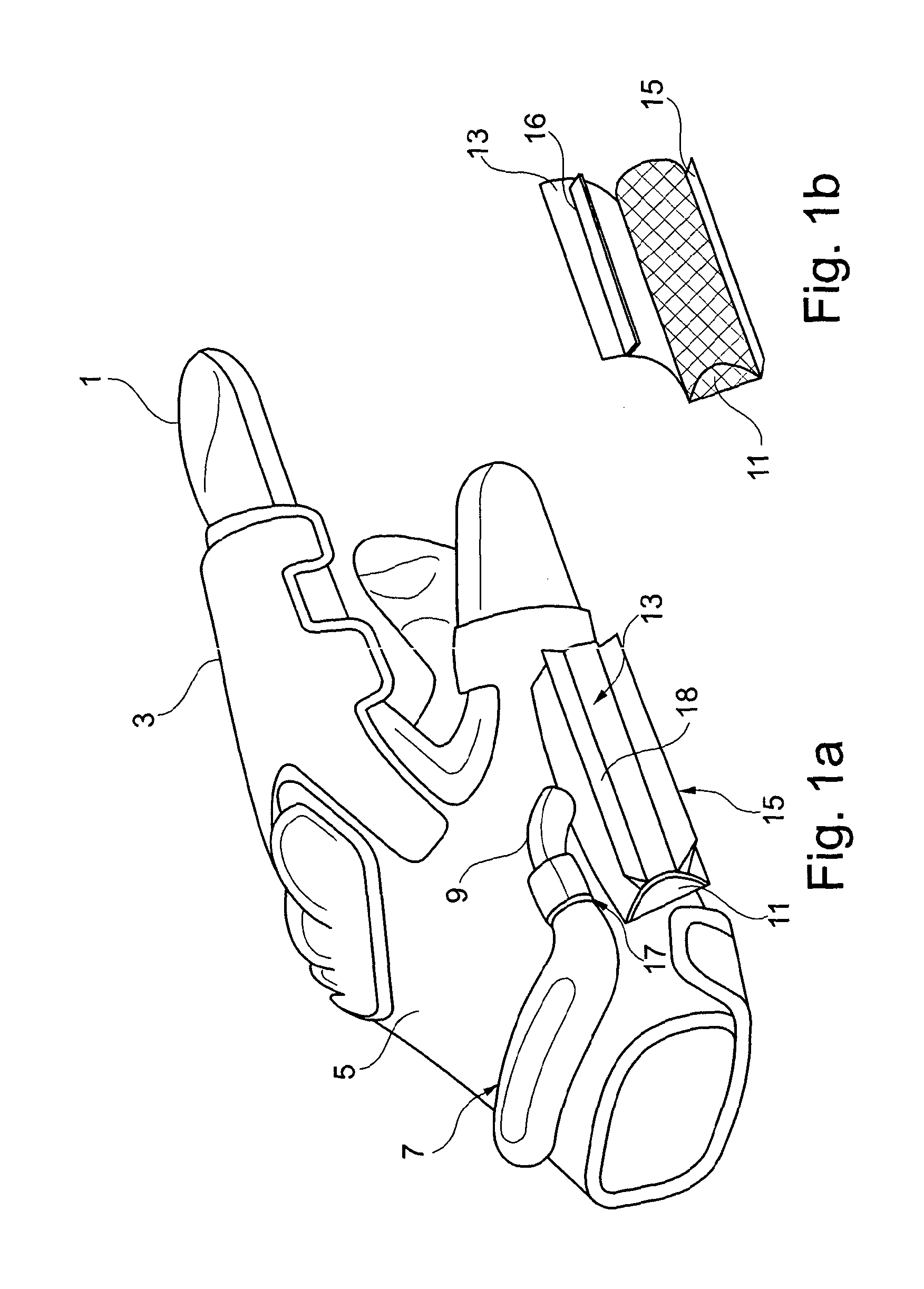

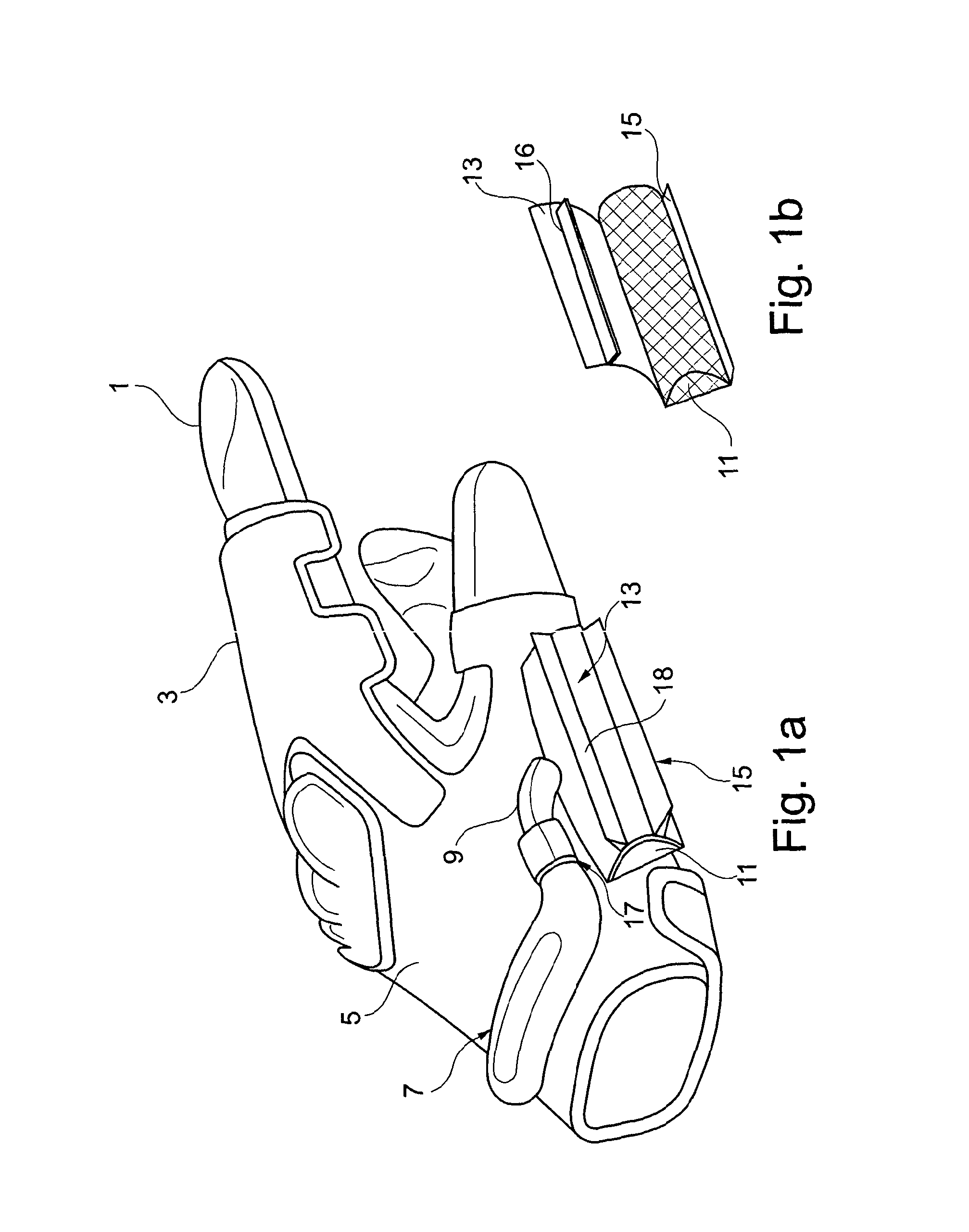

There is herein defined a fluid delivery device (3) for a visor cleaner. The fluid delivery device (3) includes a fluid reservoir (7), which contains cleaning fluid when ready for use. The fluid delivery device (3) also includes an absorbent cleaning element (13) that is arranged to take in fluid from the reservoir (7) by capillary action. In use, the fluid in the reservoir (7) and the absorbent cleaning element (13) are arranged to be in permanent fluid communication.

Owner:VISUAL PRODS

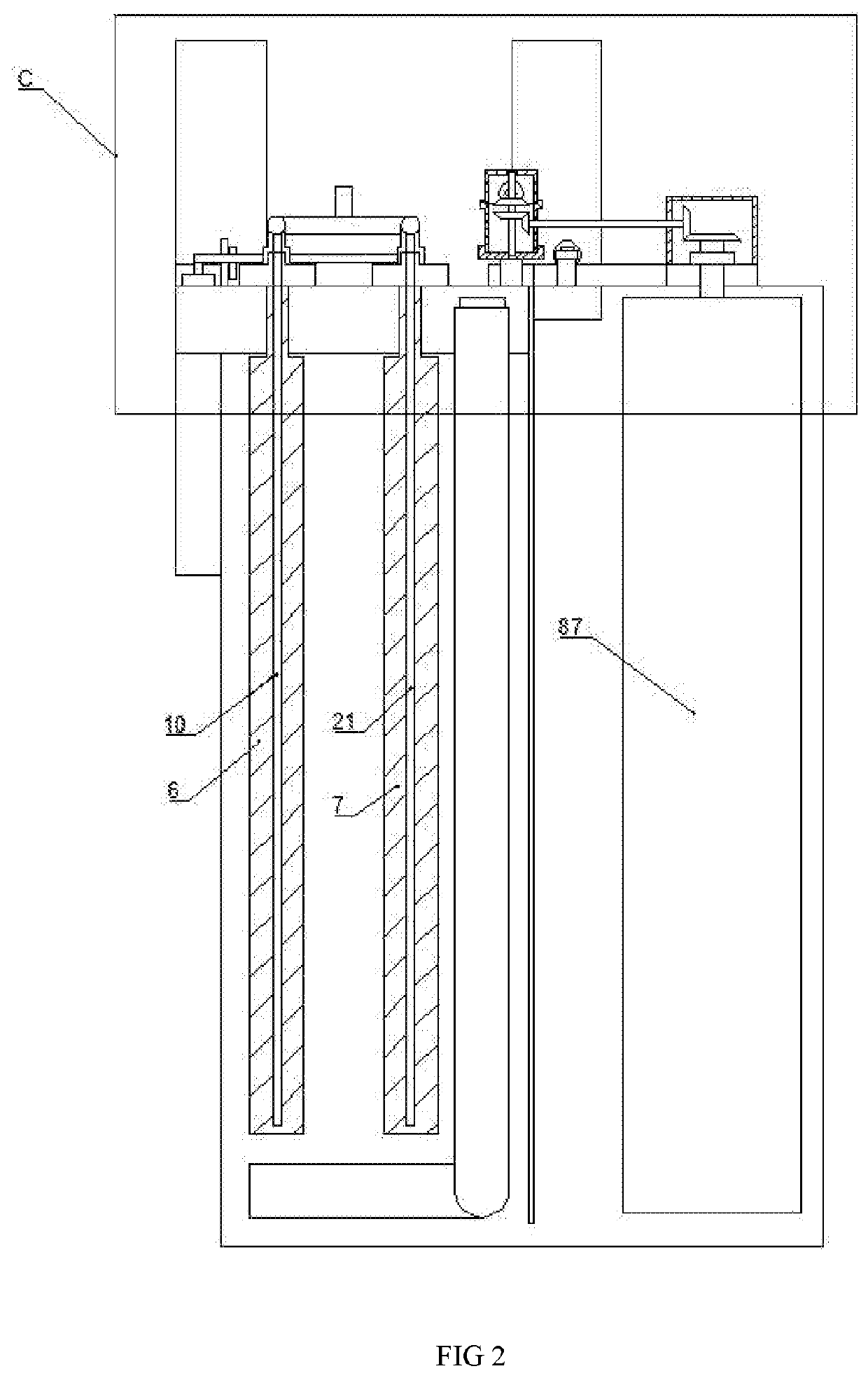

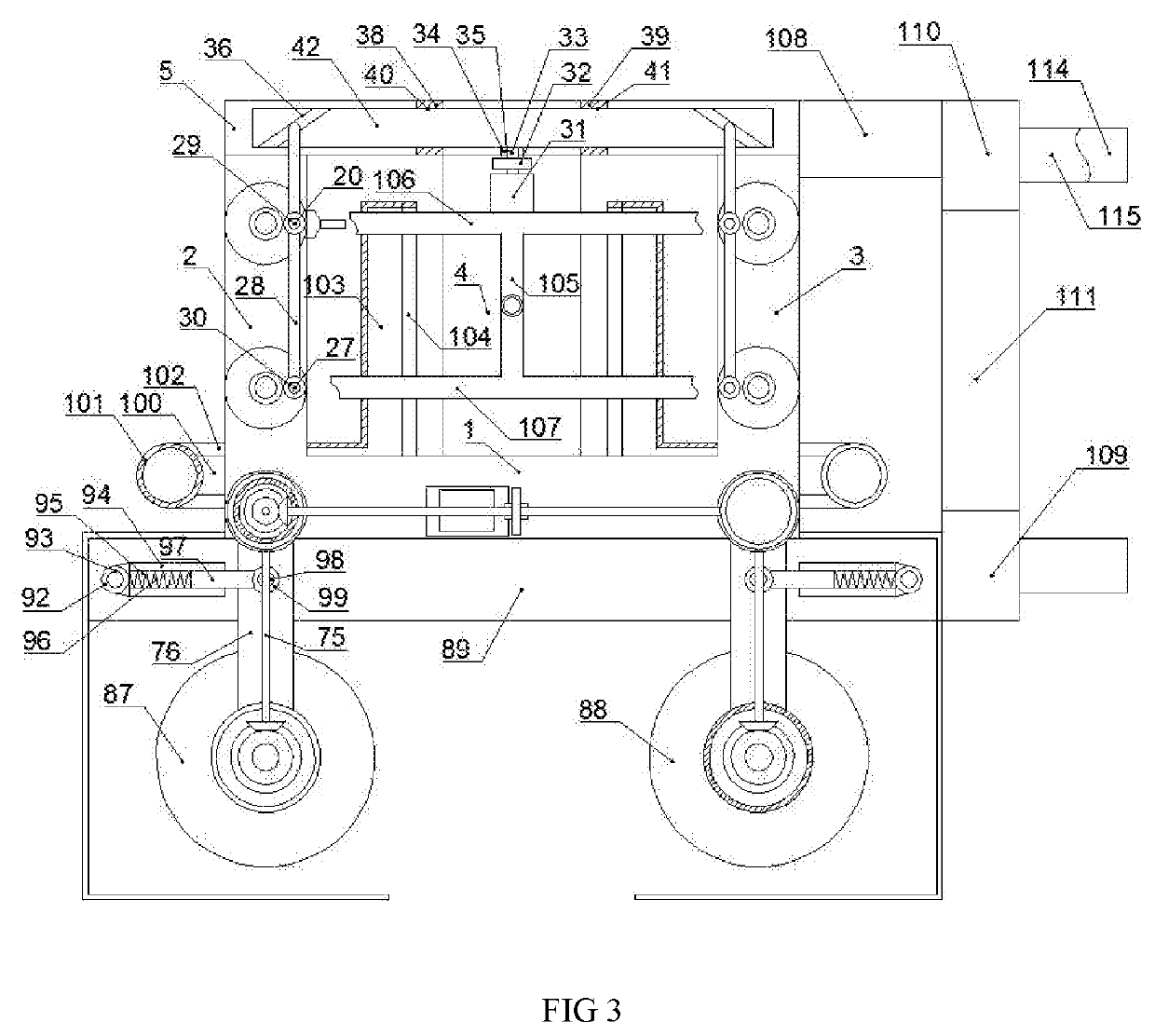

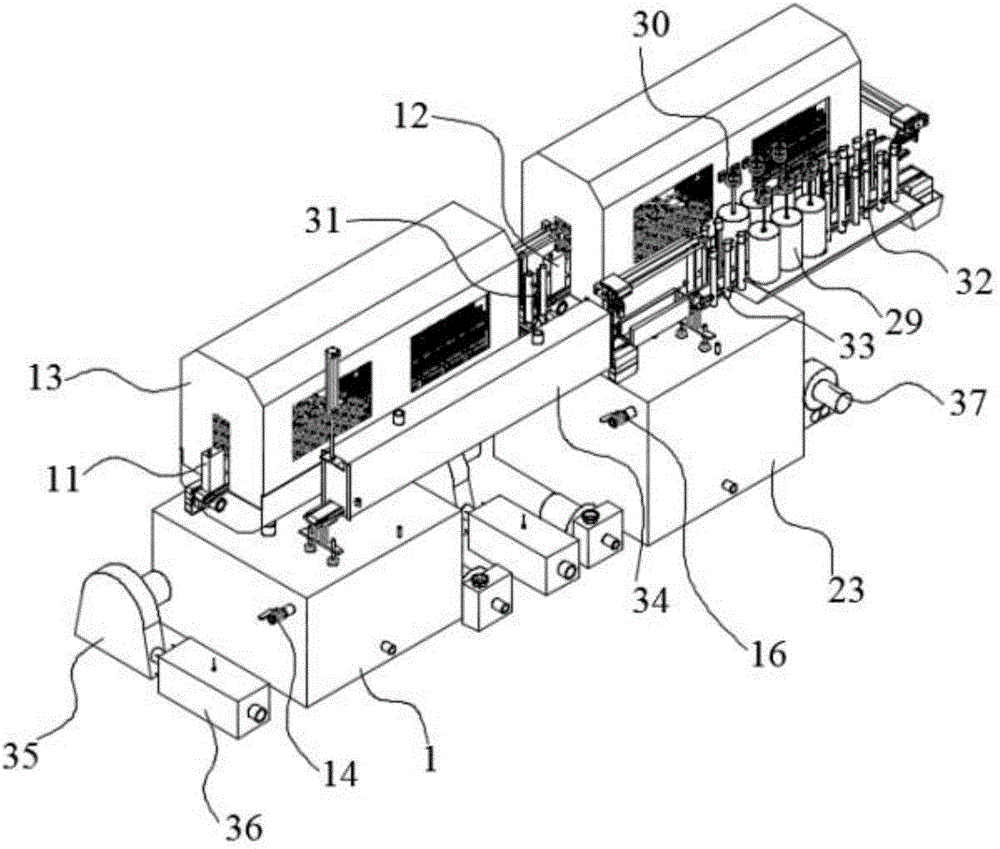

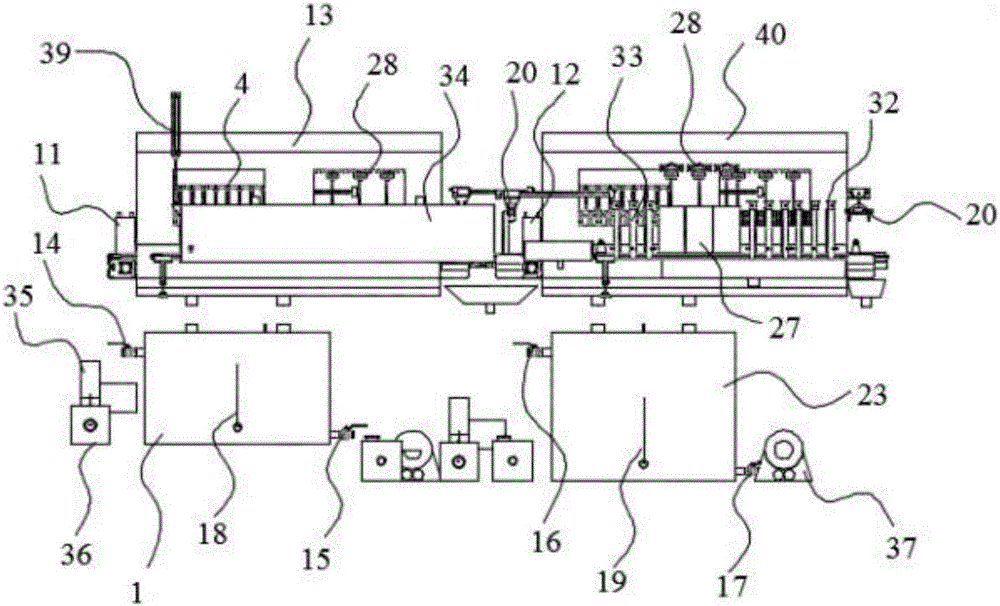

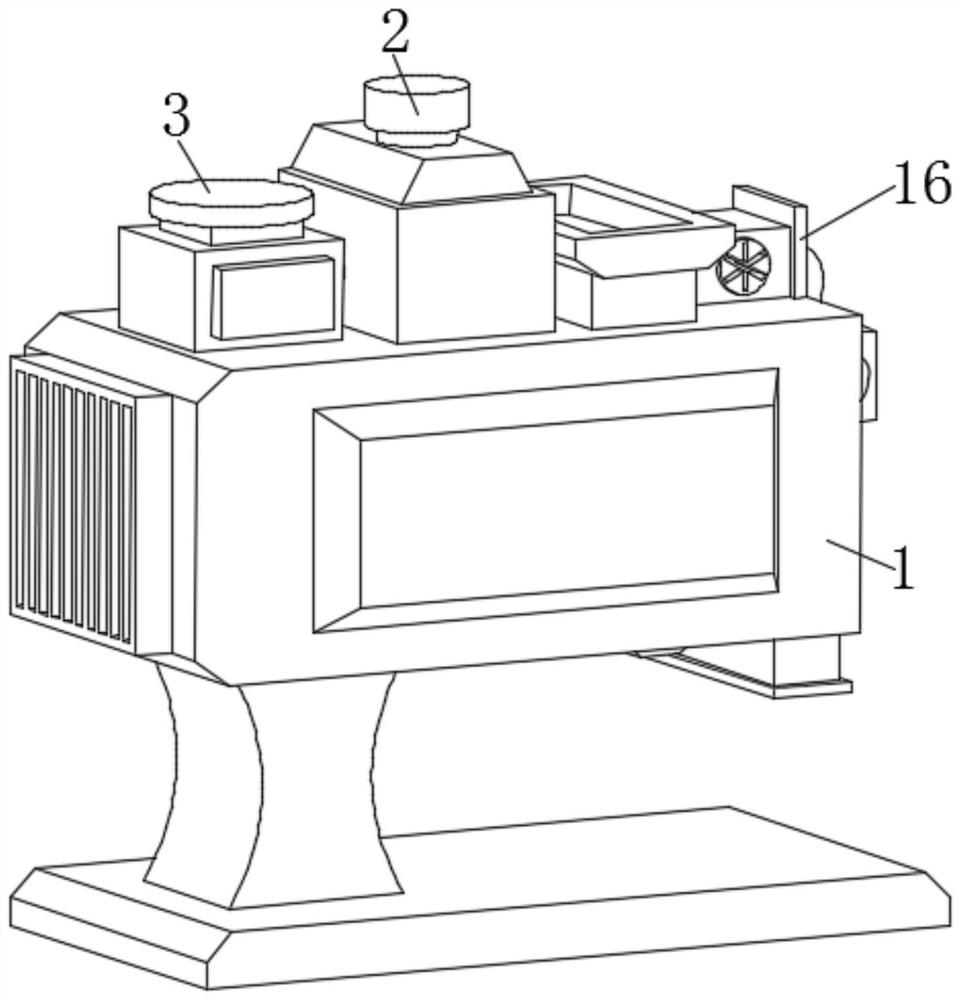

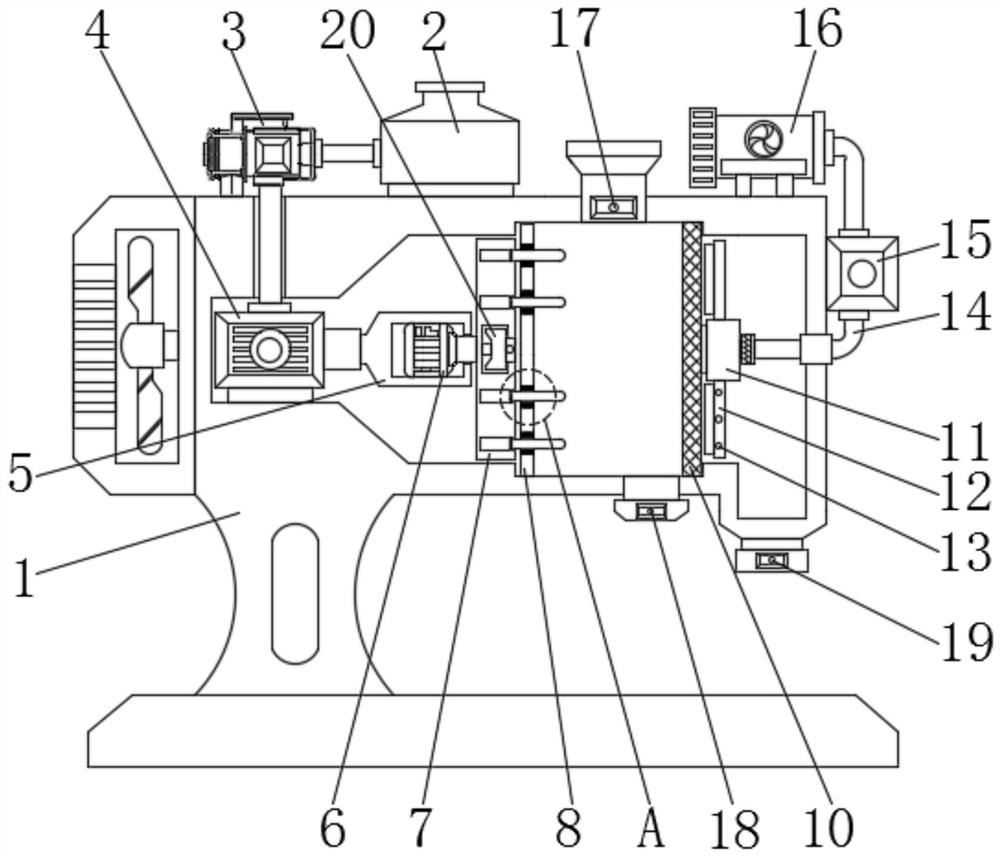

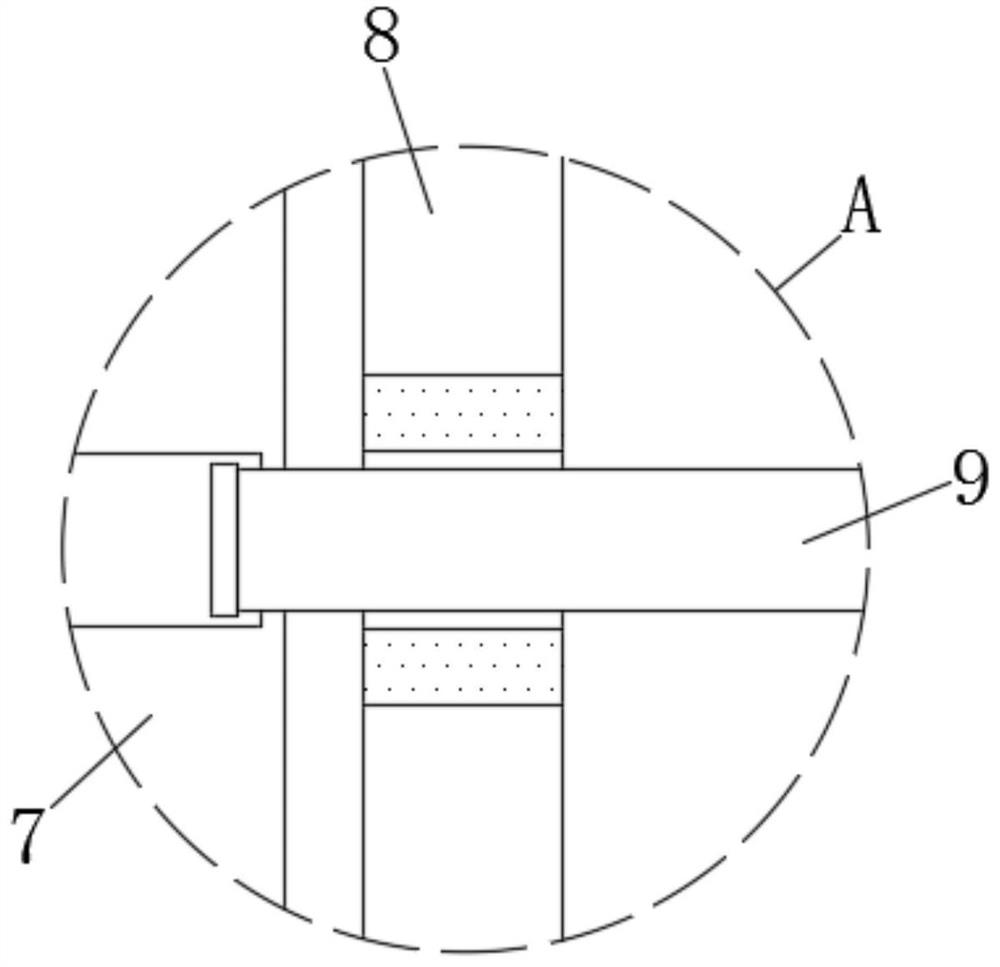

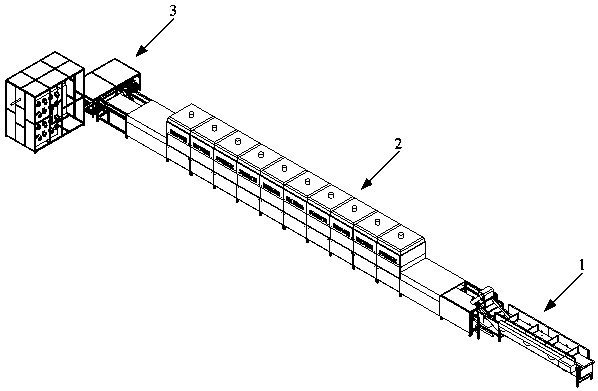

Novel automatic cleaning equipment for zinc-silver batteries

ActiveCN106623195AEffective cleaningRealize automatic cleaningDrying solid materials without heatDrying gas arrangementsElectrical batteryWater rinsing

The invention relates to novel automatic cleaning equipment for zinc-silver batteries. The novel automatic cleaning equipment for the zinc-silver batteries comprises boric acid water flushing module used for flushing away dirt on the surfaces of the batteries, a grabbing and transferring module used for transferring the batteries from one station to the next station, a clear water rinsing module used for flushing away residual dirt and boric acid, a brush washing module used for assisting in washing, a water-blowing air-drying module used for blowing away residual water on the surfaces of the batteries, a sponge wiping module used for wiping the surfaces of the batteries, a drying module used for drying the batteries, and an electrical module used for providing working control commands and power for all the other modules. According to the novel automatic cleaning equipment for the zinc-silver batteries, circuits and electrical connection are modular, sectional design according to functions is achieved on the aspect of structural design, and automation and intellectualization of a system are achieved; an alarm function is achieved through a human-computer interaction interface and an indicator light; and full-automatic cleaning of the zinc-silver batteries can be achieved efficiently and rapidly, the cleaning effect is good, and the safety performance is high.

Owner:NAVAL UNIV OF ENG PLA

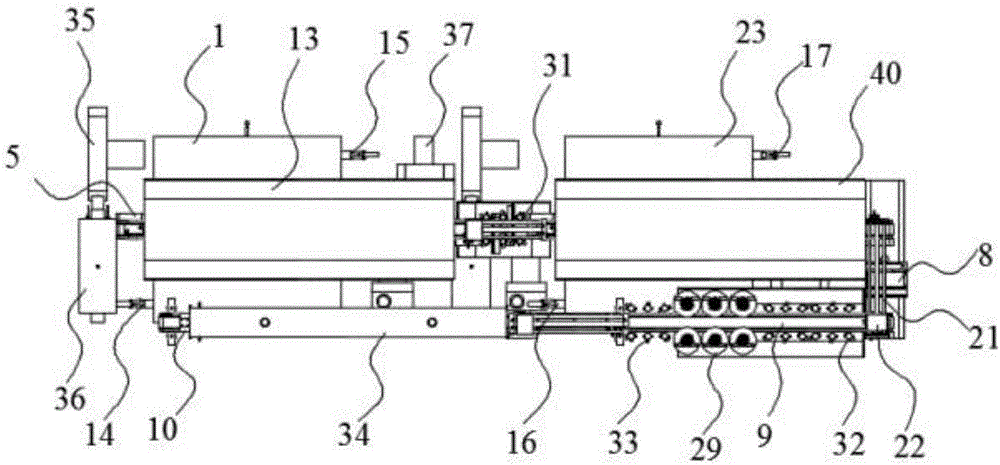

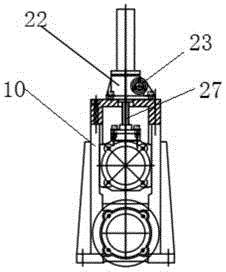

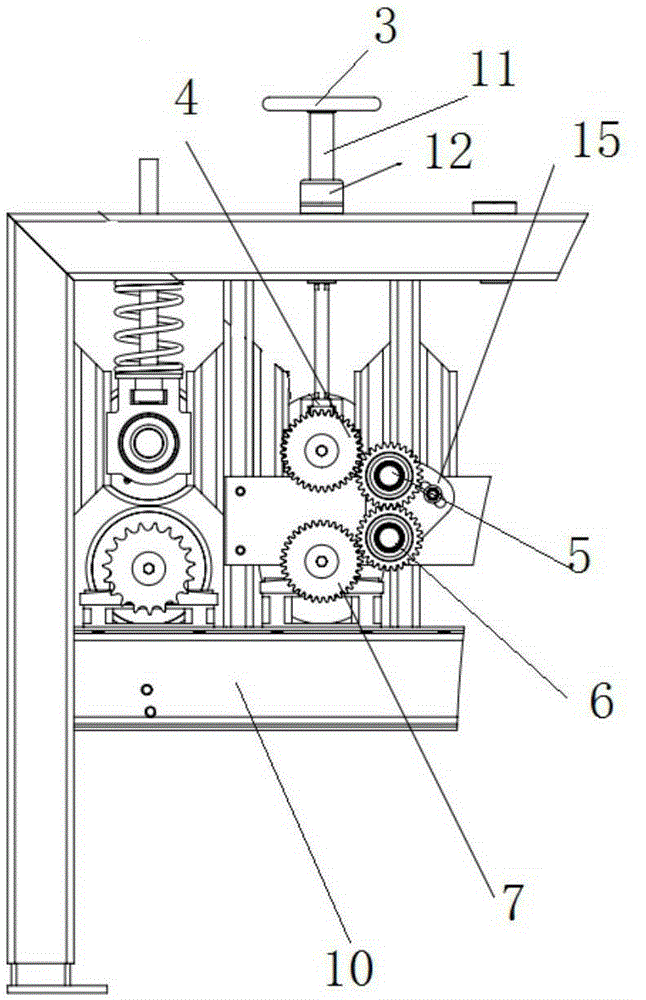

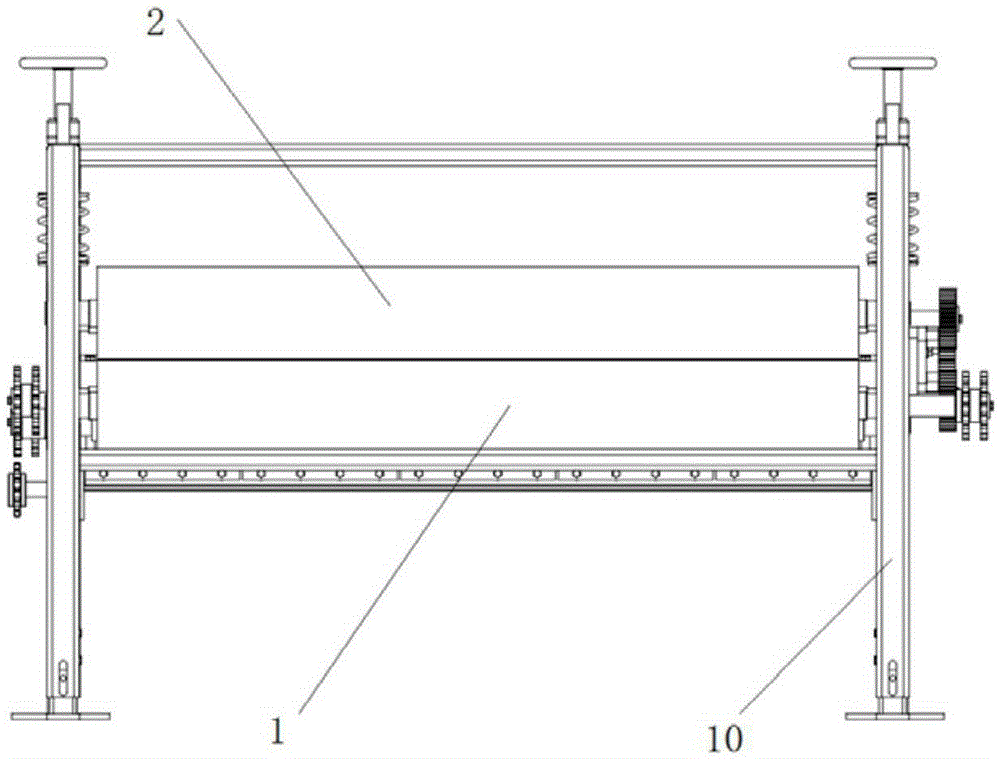

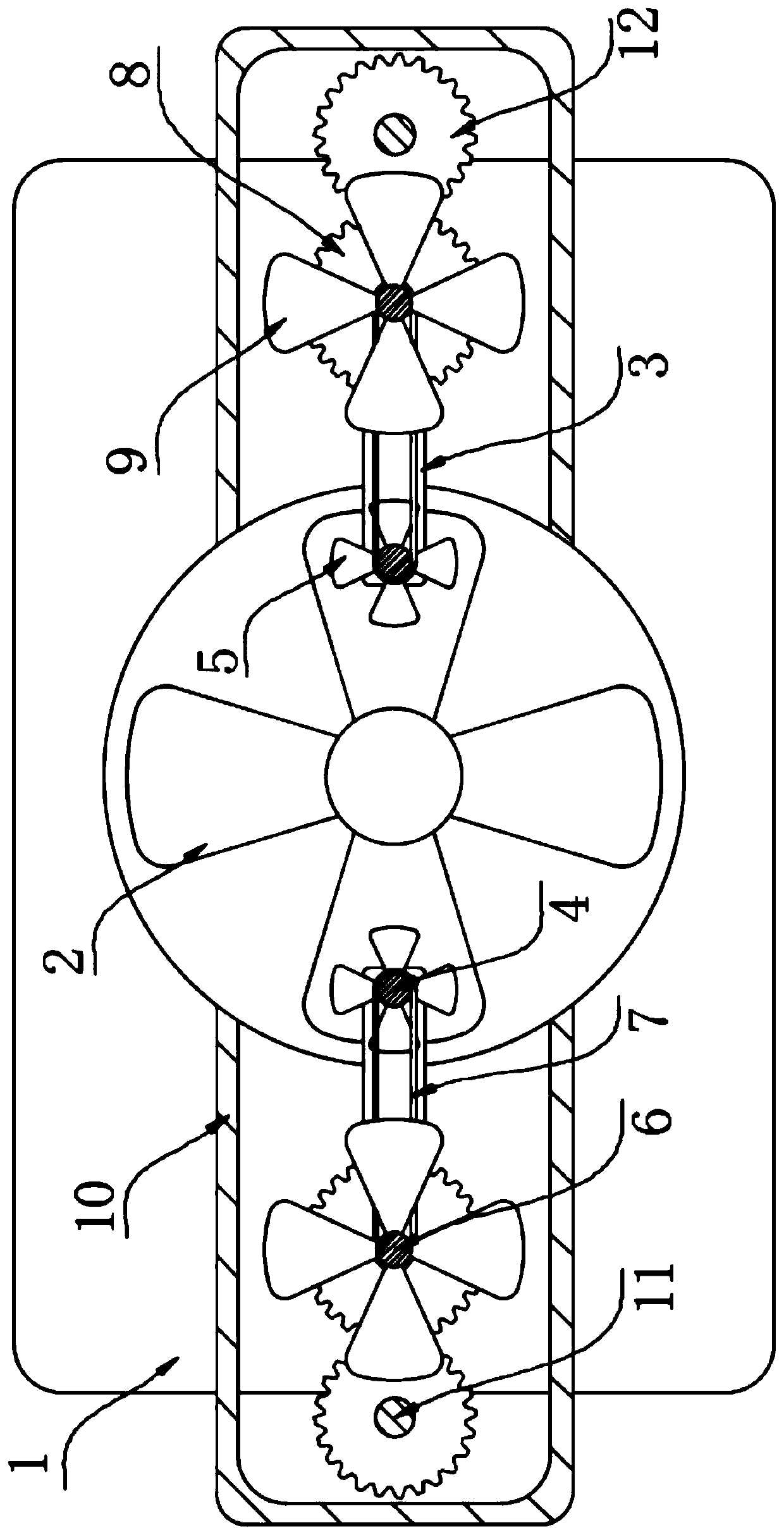

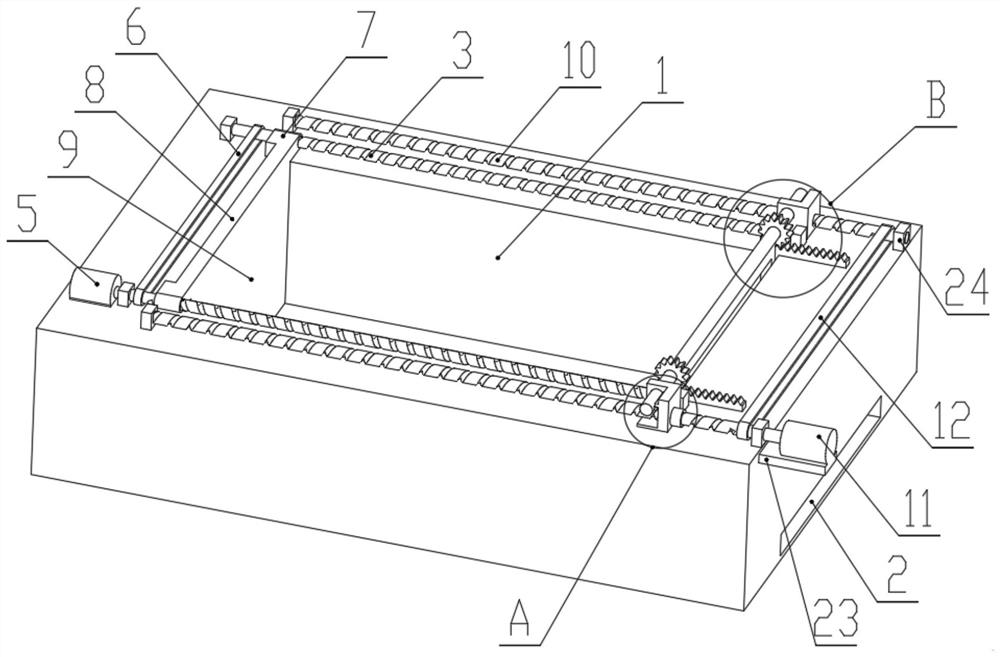

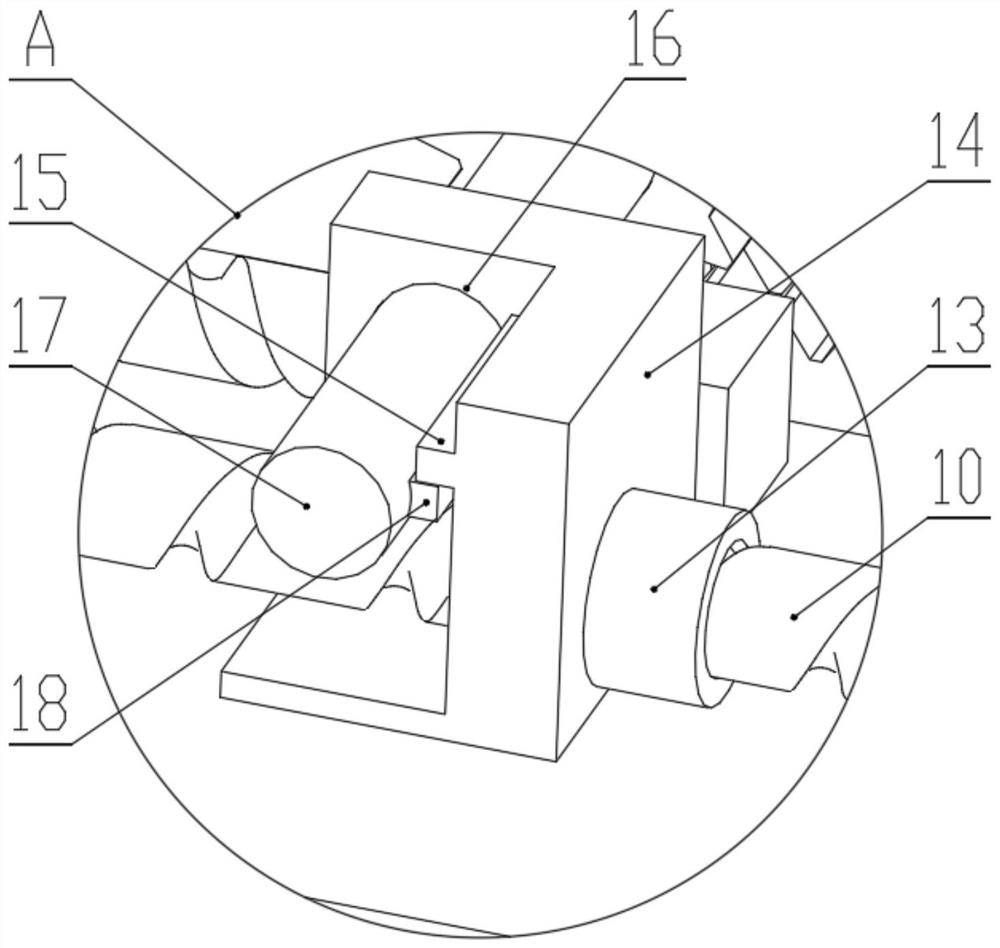

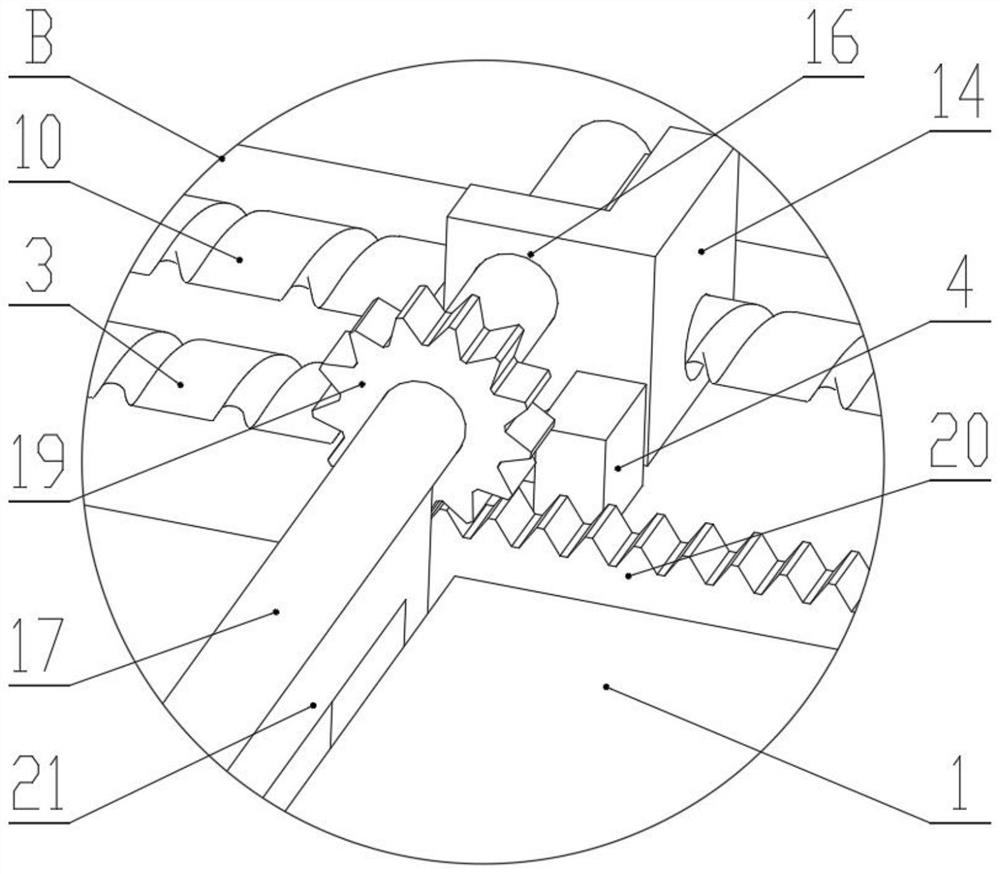

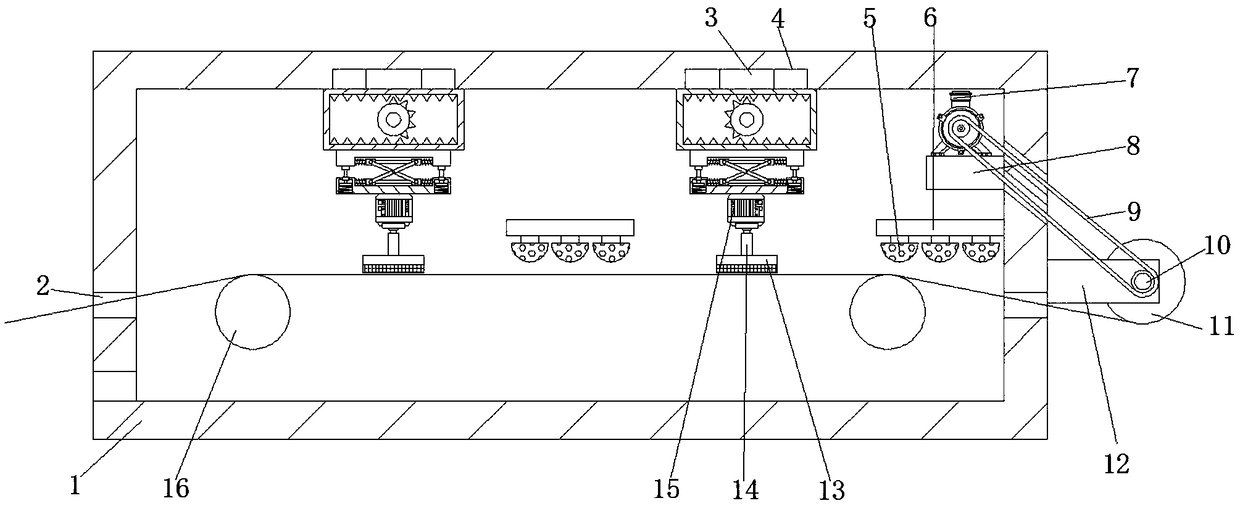

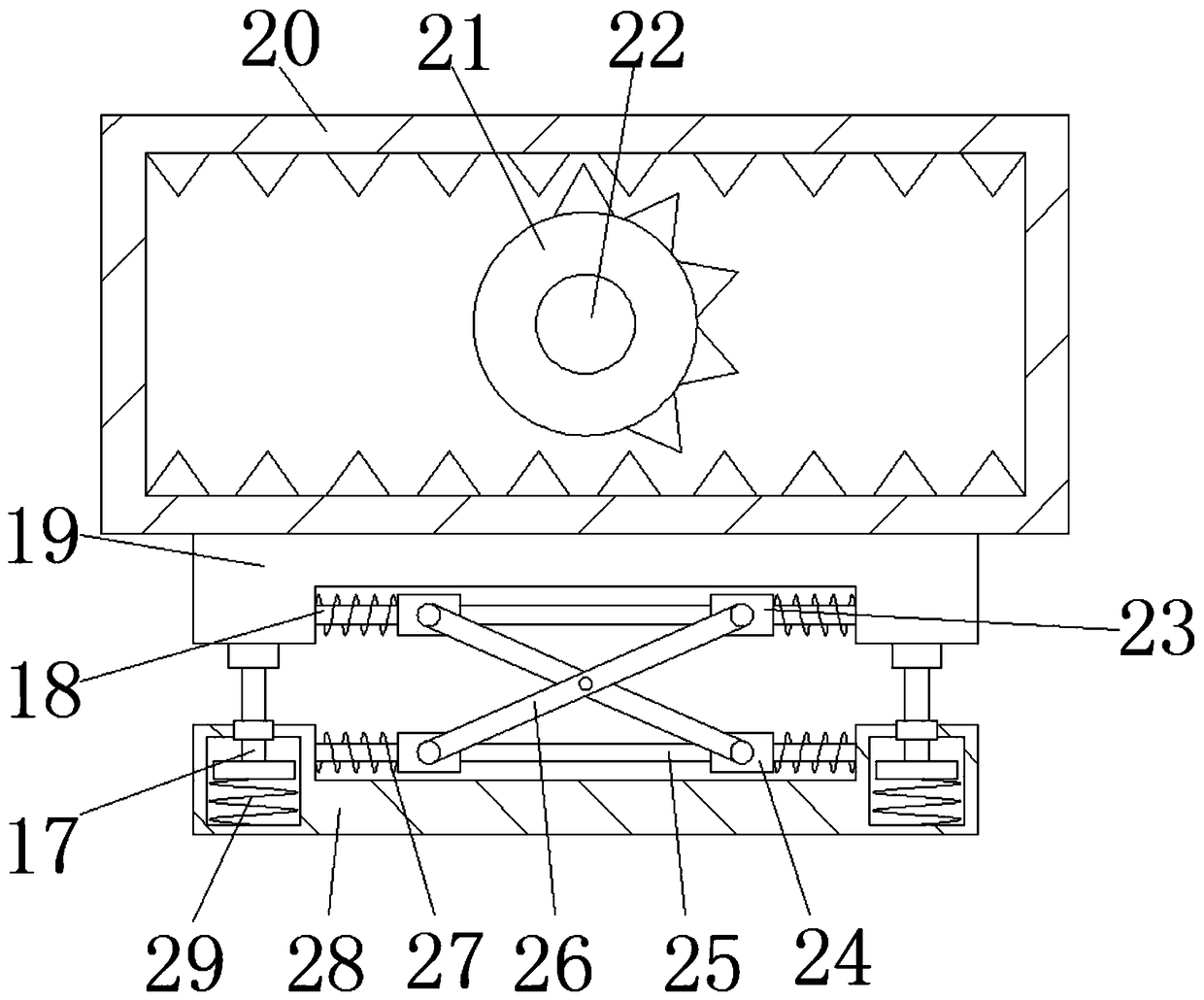

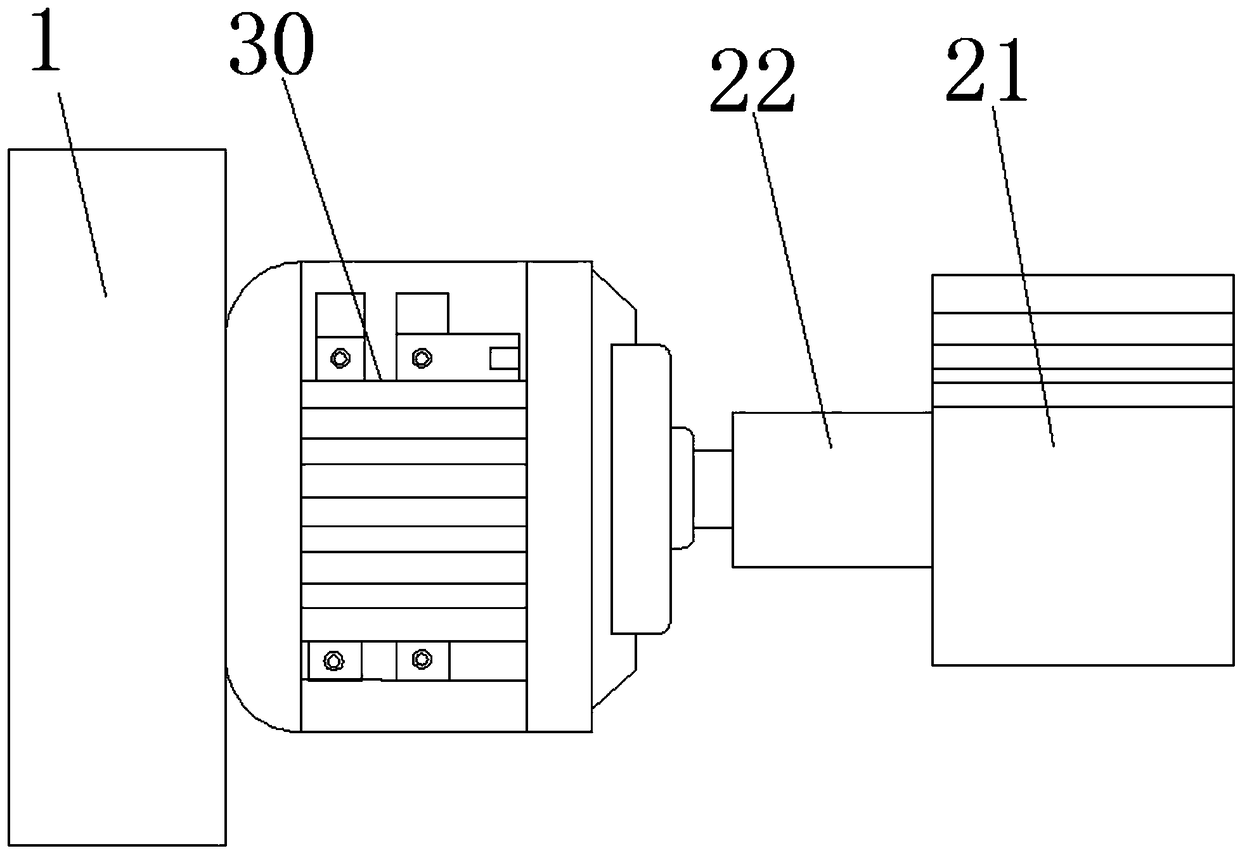

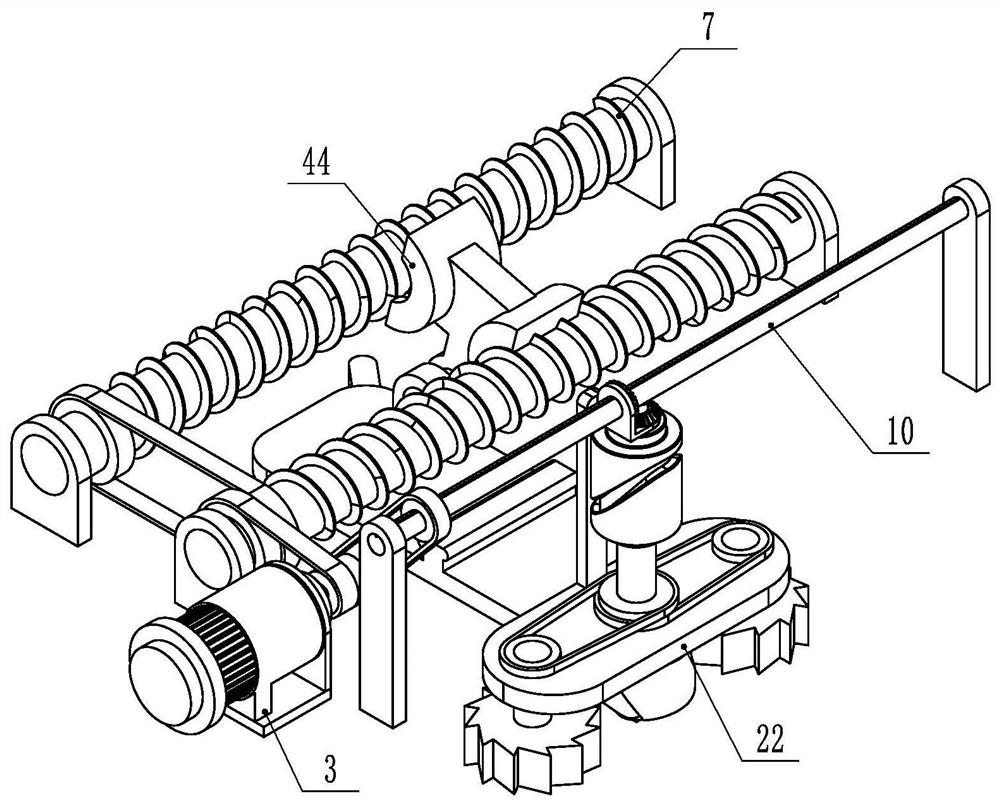

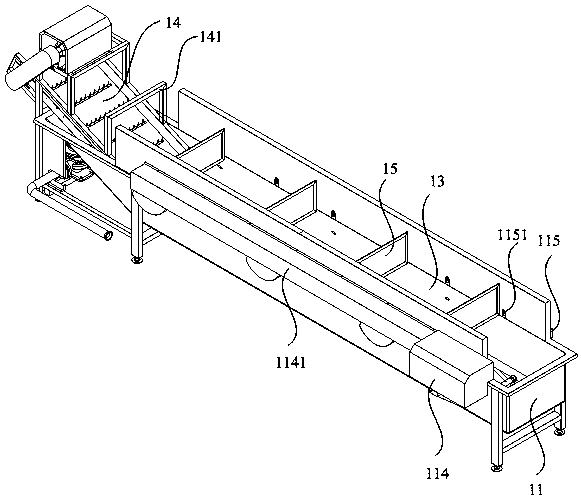

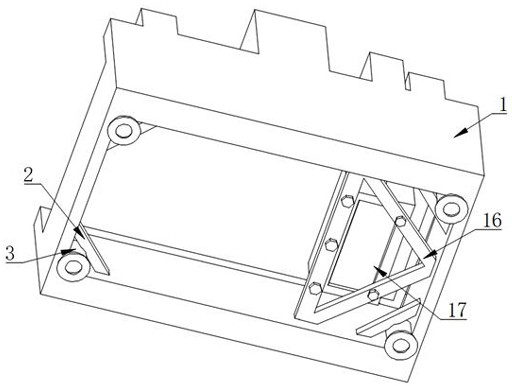

Roller cleaning mechanism of template cleaning machine

InactiveCN105252680AEfficient and quick cleaningImprove transmission efficiencyCleaning using toolsCleaning using liquidsAssembly lineDriving mode

The invention discloses a roller cleaning mechanism of a template cleaning machine. An upper cleaning roller and a lower cleaning roller are installed on a bracket and each comprise a brush roller and a scraper roller. The upper cleaning roller and an upper roll shaft gear are arranged coaxially, and the upper roll shaft gear is installed at the end of the upper cleaning roller. The lower cleaning roller and a lower roll shaft gear are arranged coaxially, and the lower roll shaft gear is installed at the end of the lower cleaning roller. A driving device drives the upper cleaning roller or the lower cleaning roller to rotate, and the upper roll shaft gear and the lower roll shaft gear are in an engaged driving mode through an idle pulley mechanism. The roller cleaning mechanism of the template cleaning machine is provided with the gear driving system, thereby being high in driving efficiency and realizing the purpose of cleaning templates efficiently; the interval between the upper cleaning roller and the lower cleaning roller can be adjusted in time as needed, so that demands of assembly line production are met, and the productivity can be improved. Meanwhile, the roller cleaning mechanism is easy to install and maintain, saves power output and has quite good practicability.

Owner:ZHUO DA NEW MATERIAL TECH GRP

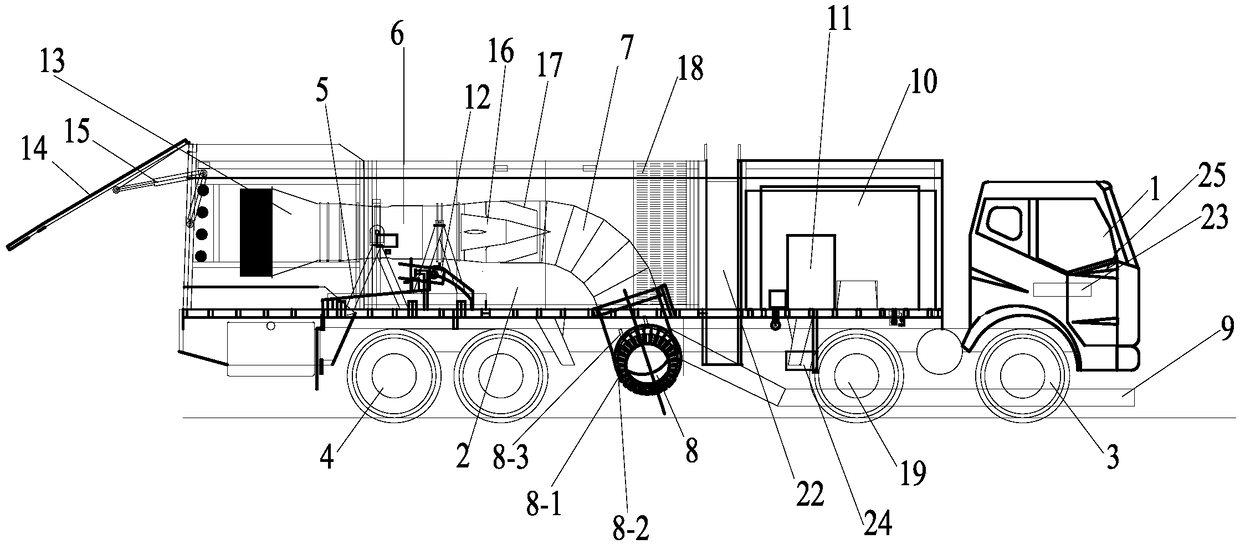

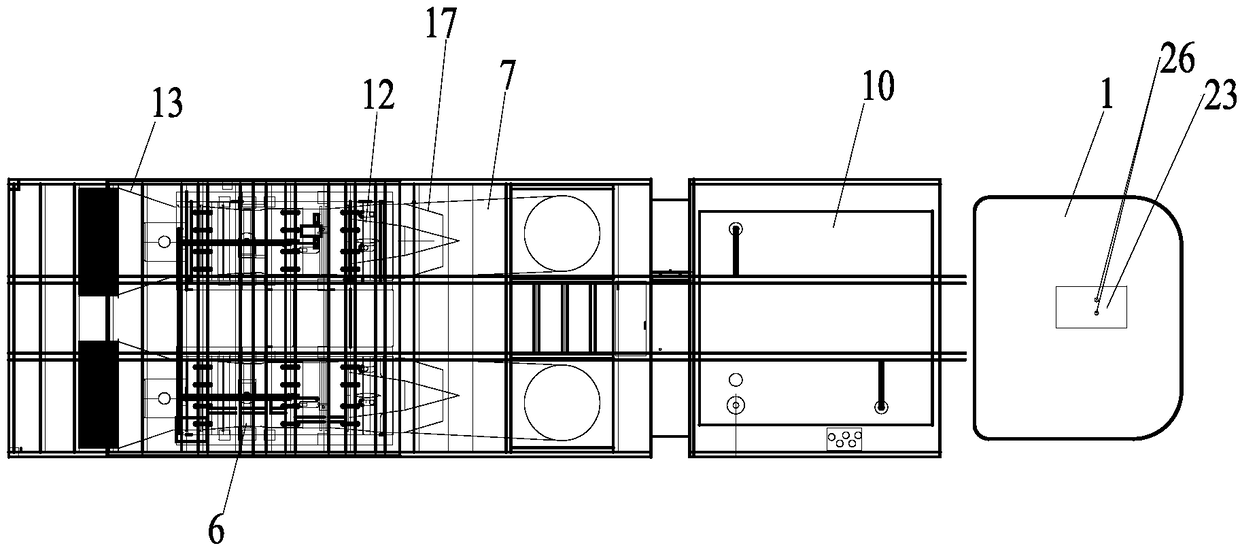

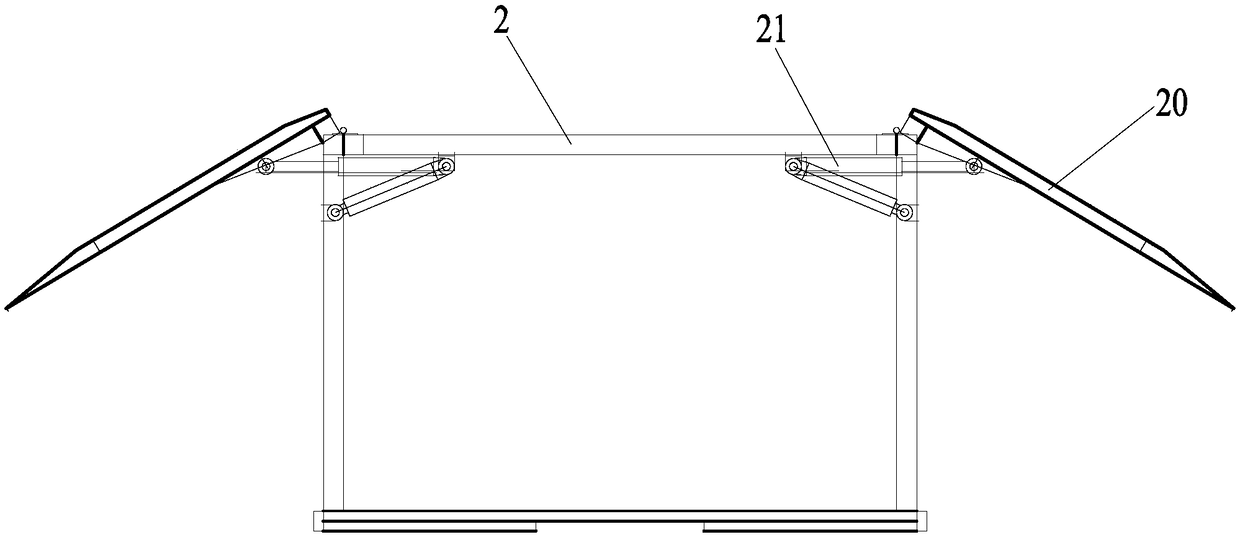

Supersonic axial-flow turbojet snow-blowing vehicle

InactiveCN109322272AEasy and effective cleaningEfficient cleanupSnow cleaningHydraulic motorDrive wheel

The invention belongs to the technical field of airport and highway guaranteeing equipment and relates to a supersonic axial-flow turbojet snow-blowing vehicle. The supersonic axial-flow turbojet snow-blowing vehicle comprises a vehicle head and a compartment driven by the vehicle head, wherein the vehicle head is provided with vehicle head supporting steering wheels, and front steering wheels anda supporting driving wheel set are arranged on the bottom face of the compartment. The supersonic axial-flow turbojet snow-blowing vehicle is characterized in that two rows of supporting seats are parallelly arranged on a bottom plate of the compartment, an axial-flow turbojet engine for snow blowing is arranged on each row of supporting seat, air inlet net covers are arranged at the air inlet ends of the axial-flow turbojet engines for snow blowing, the air outlet ends of the axial-flow turbojet engines for snow blowing are in sealing connected with main jet pipes, jet opening structures atthe lower ends of the main jet pipes face towards the side face of the compartment, and way-clearing pipes are further connected to the main jet pipes and extend forwards to the lower part of the vehicle head along the bottom of the compartment; and an oil supply oil tank is arranged in the position, close to the vehicle head, of the compartment and communicates with oil inlets of the axial-flow turbojet engines for snow blowing, and each axial-flow turbojet engine for snow blowing is provided with a hydraulic motor in a matched mode. The supersonic axial-flow turbojet snow-blowing vehicle ishigh in operation efficiency and significant in sweeping effect.

Owner:WUXI YOUPENG AUTOMOBILE SERVICE

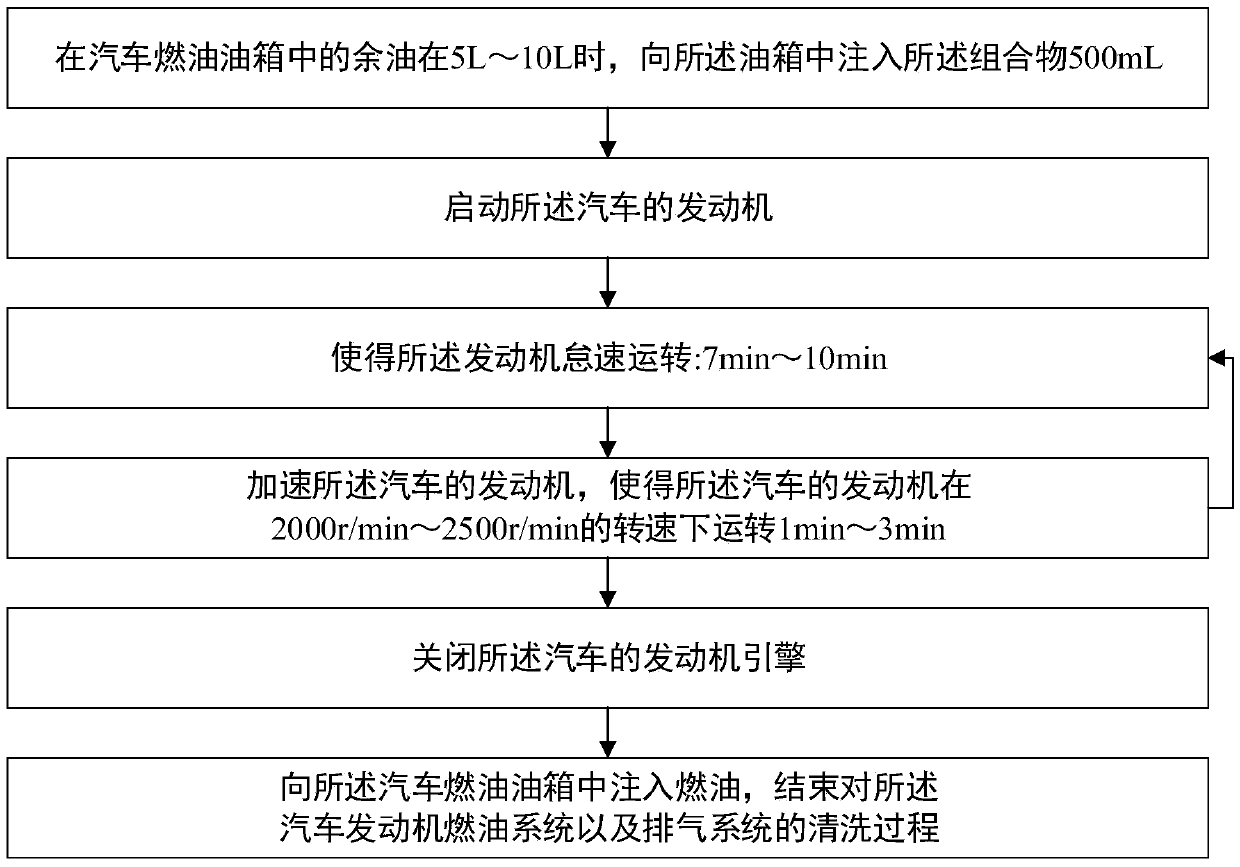

Composition, preparation method, application and automobile engine fuel tank

InactiveCN109652223AReduce contentLow costOrganic detergent compounding agentsNon-ionic surface-active compoundsFuel tankFuel oil

The invention discloses a composition, its preparation method and application and an automobile engine fuel tank. The composition comprises the following ingredients (by mass): an organic solvent composed of at least three of the following ingredients: 0% to 30% of aromatic hydrocarbon, 0% to 15% of ester, 0% to 30% of acetone, 20% to 50% of alcohol, 5 % to 30% of ether and 0% to 10% of dichloromethane; a surfactant composed of at least three of the following ingredients: 0-10% of polyether amine; 0-5% of polyisobutylamine, 0-5% of polyisobutene succinimide, 0-10% of monoethanolamine and 0-10%of triethanolamine. The mass percent of the organic solvent is 70-95%, and the mass percent of the surfactant is 5-30%. The composition has clear and transparent appearance. The heat of combustion ofthe composition is less than or equal to the heat of combustion of fuel oil and greater than or equal to 2500 kJ / kg. The composition has the same copper sheet corrosivity with the fuel oil. By the method, the composition can be prepared. The composition can be applied to automotive engine full and exhaust system cleaning. The fuel tank can prompt the cleaning time.

Owner:蔡洪涛

High-efficiency air conditioner external unit

ActiveCN111457483ARealize reciprocating swingEasy to useMechanical apparatusNoise suppressionFan bladePhysics

The invention discloses a high-efficiency air conditioner external unit. The high-efficiency air conditioner external unit comprises an external unit body and an external unit fan mounted on the external unit body, two symmetric cleaning mechanisms are mounted on the external unit body, each cleaning mechanism comprises a mounting plate fixed to the front end of the external unit body, the front end of each mounting plate is rotatably connected with a mounting shaft, the peripheral side walls of the mounting shafts are fixedly provided with fan blades, the front end of the external unit body is rotatably connected with a rotating shaft, and the rotating shaft and the mounting shafts are jointly sleeved with a belt. The external unit has the advantages that a swing plate continuously swings, a scraping rod can clean frost accumulated on the rear end of the external unit body in winter, and can clean dust accumulated on the rear end of the external unit body in summer, the ventilation position of the rear end of the external unit body is cleaner and free of shielding, the external unit fan can better work, the use effect of an air conditioner is better, and the property of the air conditioner cannot be affected by frosting and dust accumulation.

Owner:西臣仕(江苏)空调冷冻设备有限公司

Novel home cleaning tool

The invention discloses a novel home cleaning tool, capable of effectively solving the problem that a broom can be stained by hair, fluff, dust and mud. The cleaning tool comprises a dustpan, a dustpan rod, telescopic rods and hollow rolling wheels, wherein the dustpan rod is fixedly arranged at the upper side of the dustpan and a piston is inserted in the dustpan rod; hollow shafts are fixed to the lower ends of the left and right sides of the dustpan rod; a baffle plate is arranged at the left side of the dustpan rod in a mode of sliding up and down; the telescopic rods include a thick telescopic rod and a thin telescopic rod; the thick telescopic rod is arranged at the front side of the dustpan rod in a sliding mode in a vertical direction, and the thin telescopic rod is inserted into the thick telescopic rod; each hollow rolling wheel is rotatably arranged on the corresponding hollow shaft; and a plurality of hollow brush rods, which communicate with the interior of each hollow rolling wheel, are uniformly distributed on the hollow rolling wheel. The cleaning tool provided by the invention is mainly used for cleaning some hair tangled on the broom; the dustpan rod enables the brush rods on the rolling wheels spray gas and water by virtue of the piston device, so that dirt on the broom can be cleaned more efficiently and more strongly; and by arranging a linkage control structure on the dustpan rod, gears can be selected optionally, so that relatively high autonomy and flexibility are guaranteed.

Owner:王博为

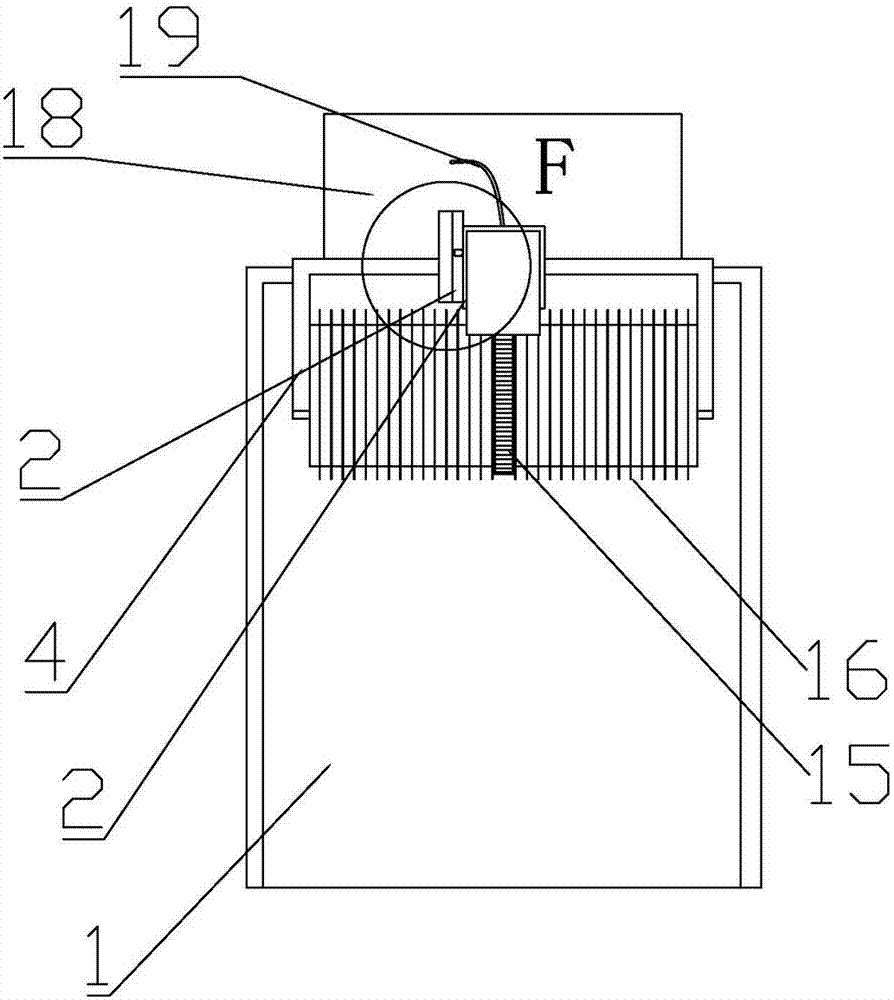

Internal cleaning device of coating environment-friendly mechanical equipment

ActiveCN112547729AIncrease productivityReduce labor intensityHollow article cleaningElectrophoretic coatingsElectric machineryEngineering

The invention discloses an internal cleaning device of coating environment-friendly mechanical equipment. The internal cleaning device comprises an electrophoresis tank, a discharging opening is formed in the lower side of the right end of the electrophoresis tank, first lead screws are arranged at the front side and the rear side of the upper end of the electrophoresis tank correspondingly, and the left ends and the right ends of the first lead screws and first bearing pedestals form bearing connecting structures correspondingly; the first bearing pedestals are fixedly installed on the upperend surface of the electrophoresis tank, the left end of the first lead screw at the front side of the electrophoresis tank is connected with the shaft end of a first motor, the first motor is fixedlyinstalled on the upper end surface of the electrophoresis tank, and the left ends of the first lead screws at the front side and the rear side of the electrophoresis tank are connected with each other through a first belt transmission mechanism; and the first lead screws are in threaded connection with first lead screw nuts. According to the internal cleaning device of the coating environment-friendly mechanical equipment, residual solutions in the electrophoresis tank can be conveniently, rapidly and efficiently cleaned, the solutions needing to be replaced can be efficiently discharged, theproduction efficiency is greatly improved, and the labor intensity of workers is reduced.

Owner:中山协立科技工业有限公司

Efficient processing device for textile fabric

ActiveCN109183300AAvoid damageQuick washTextile treatment machine partsTextile treatment by spraying/projectingEngineeringTextile processing

The invention provides an efficient processing device for textile fabric, which comprises a cleaning box. Mounting plates are fixedly welded on the right outer wall of the cleaning box; two sliding grooves are symmetrically embedded at the left side and the right side of the upper end of the cleaning box, and sliding blocks are slidably connected inside; the middle parts of rotating rods are connected through a bolt and are rotarily mounted together, and the lower ends are connected through bolts and rotarily mounted onto second sliding blocks; the second sliding blocks slidably sleeve a second fixing rod, and the outer side of each second sliding block is fixedly welded with a damping spring; the left side and the right side of a damping plate are provided with mounting grooves, and damping rods are arranged inside; the damping plate is in passing connection with the upper ends of the damping rods, a shaft sleeve is arranged at the connection place, and the upper end is fixedly weldedonto a connection block. The structure is simple, the operation is convenient, the fabric for textile processing can be cleaned efficiently and quickly, and promotion and use are worthy.

Owner:TONGXIANG YOUKESI TEXTILE TECH CO LTD

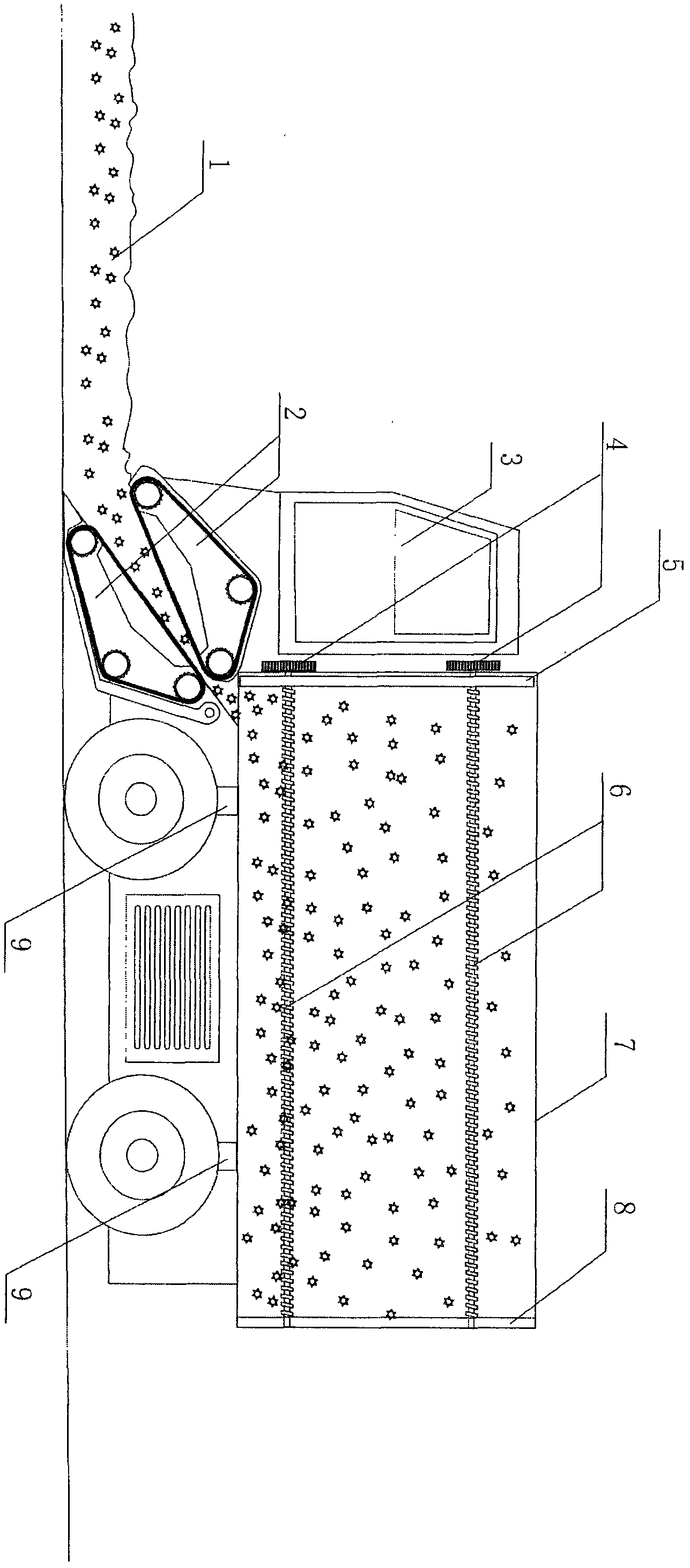

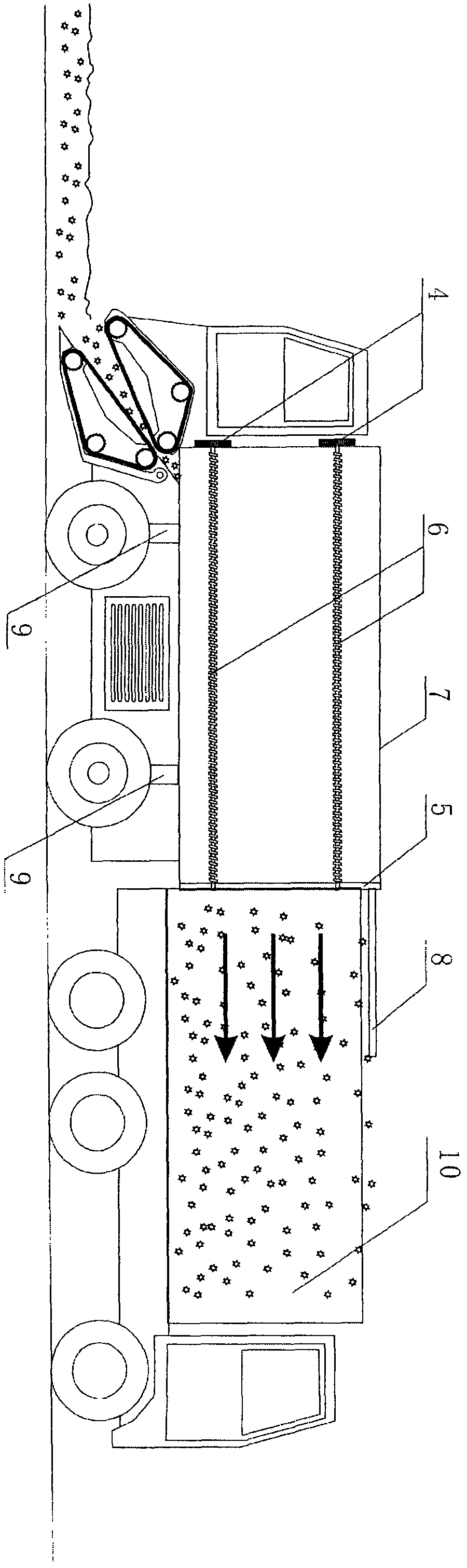

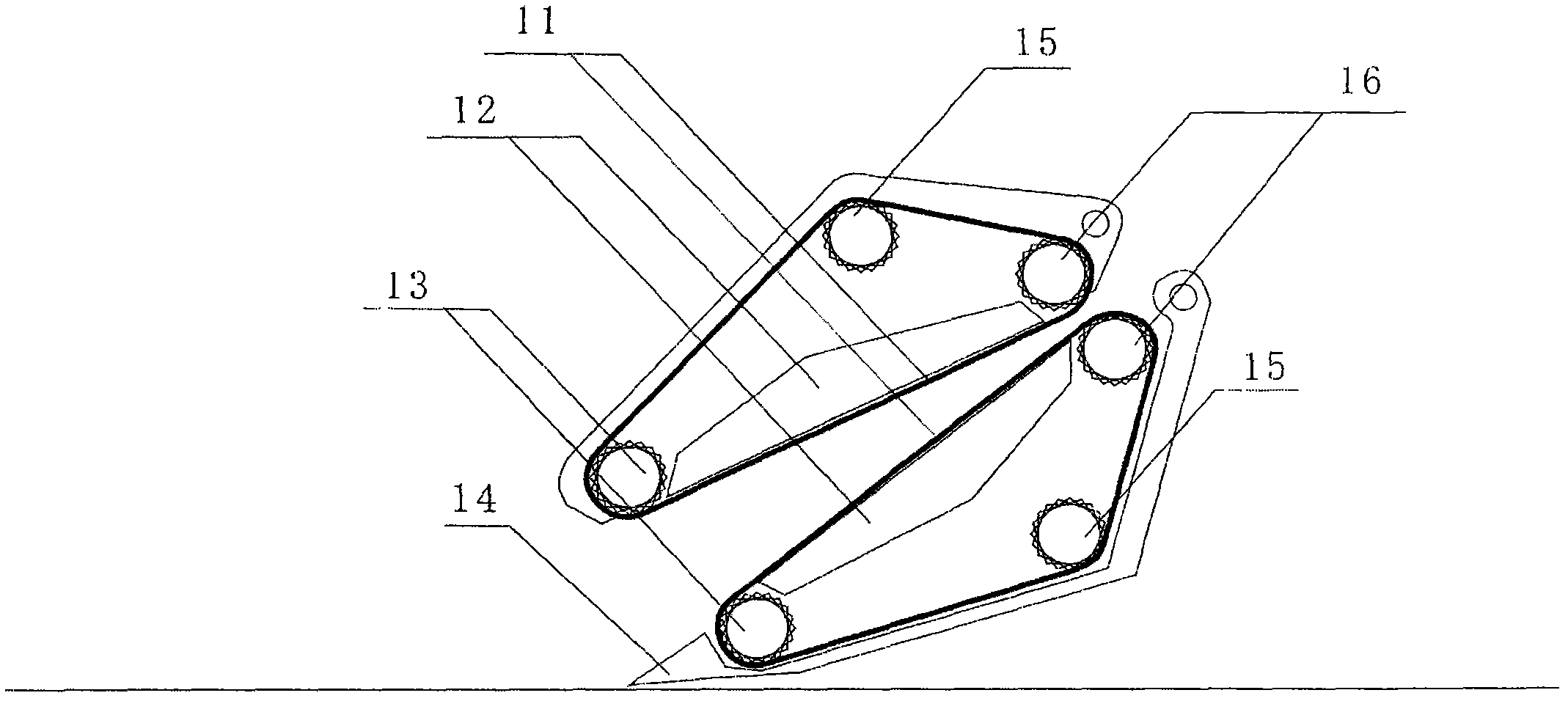

Compression container type urban snow-clearing truck

InactiveCN102121238AEasy to cleanAvoid inconvenienceLarge containersSnow cleaningSnowpackSocial benefits

The invention relates to a compression container type urban snow-clearing truck which can be used for achieving integral high-density and quick clearing by shoveling, compressing, packaging and transporting and thoroughly solving the shortcoming of the existing snow-clearing machine such as low efficiency. According to the invention, a compression package process is adopted, thus the clearing and transporting times are greatly reduced and the clearing and transporting costs are also greatly reduced; the accumulated snow on urban roads can be cleared high-efficiently and quickly right away after snow falls; and the accumulated snow is prevented from being laminated to be ice to cause higher difficulty in clearing, so that the urban traffic is more smooth and the traffic accident is avoided, therefore, the compression container type urban snow-clearing truck has the advantages of great social benefit and economical effect.

Owner:闫传东

Tank body used for storing printing ink

InactiveCN110817159AEfficient and quick cleaningPrevent adhesionLarge containersTank wagonsBristleElectric machinery

The invention discloses a tank body used for storing printing ink. A sealing cover plate is arranged at the upper end of a main tank body. A stirring motor is fixedly connected to the center area of the sealing cover plate. A stirring shaft is arranged at the inner axis position of the main tank body. The upper end of the stirring shaft rotationally penetrates the sealing cover plate and is connected with the output end of the stirring motor. A pair of connecting beams are fixedly connected to the same side of the stirring shaft in a spaced manner in the up-down direction. The left ends of thepair of connecting beams are fixedly connected with the inner side of a scraping plate which is vertically arranged, the scraping plate is arranged close to the side wall of the main tank body, and the outer side face of the scraping plate is connected with multiple hard bristles A in the length direction of the scraping plate. The hard bristles A are matched with the side wall of the main tank body in a contact manner. An arc stirring rod is fixedly connected to the bottom end of the stirring shaft, the stirring rod is arranged close to a bottom plate, multiple hard bristles B are connectedto the lower portion of the stirring rod in the length direction of the stirring rod, and the hard bristles are matched with a bottom plate in a contact manner. By means of the tank body, the phenomenon of precipitation or agglomeration which is likely to happen due to long-term storage can be effectively dealt with, and in addition, the labor load of workers can be reduced.

Owner:XUZHOU SUNUP INK CHEM

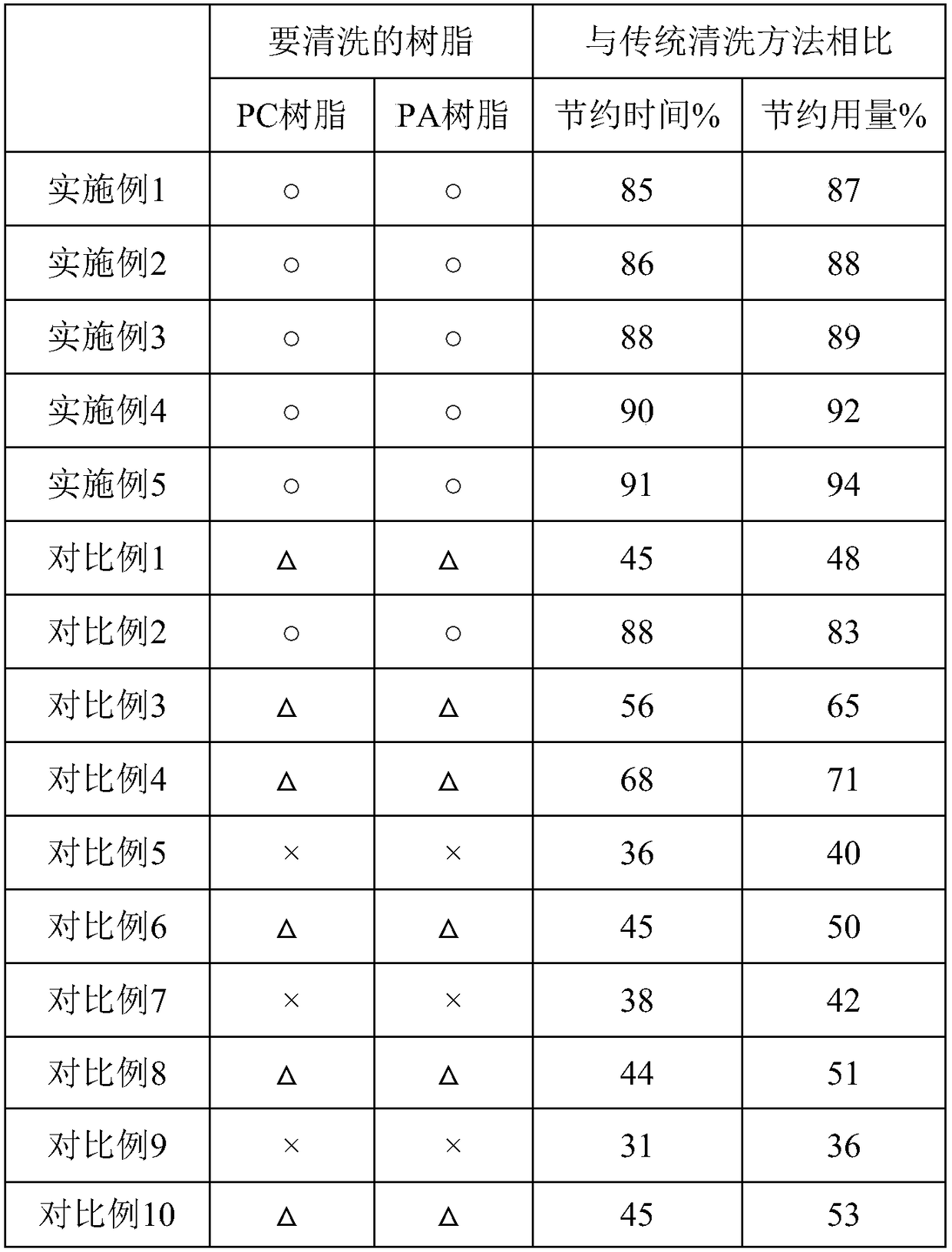

Efficient screw cleanser and preparation method thereof

ActiveCN109486566AEfficient and quick cleaningShorten the timeInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsCleaning methodsSURFACTANT BLEND

The invention relates to the field of screw cleansers, particularly to an efficient screw cleanser and a preparation method thereof. The efficient screw cleanser is composed of anionic surfactant, nonionic surfactant, complex and wetting agent. The efficient screw cleanser is rapid and efficient in cleaning, energy-saving and environmentally friendly. Compared with traditional cleaning methods, the efficient screw cleanser can save cleaning time by more than 80%, complete the cleaning process within on step and minimize the time consumed by a machine for coloring, transferring and cleaning shutdown, thereby greatly improving the production efficiency. Besides, the efficient screw cleanser can achieve certain maintaining effects on equipment and reduce energy consumption of the equipment tosave energy resources and achieve environmental protection and high efficiency.

Owner:赤途实业(上海)有限公司

Method and apparatus for cleaning a filter

InactiveUS9561459B2Minimal damageEfficient and quick cleaningGas treatmentDispersed particle filtrationOperation modeEngineering

A filter cleaning device includes a cleaning chamber operable to receive a gas filter to be cleaned, the cleaning chamber having an inlet through which a gas flow can be admitted and an outlet for gas flow leaving the cleaning chamber, the inlet and outlet being arranged such that the airflow is forced to pass through at least a part of the filter when inserted, the filter cleaning device further comprising a mechanical agitation arrangement operable, in one mode of operation, to generate a linear oscillation along an axis of the filter when inserted and, in another mode of operation, to rotate the filter about an axis of rotation.

Owner:ROYCE JOHN +1

Rewashing machine for cotton cloth production

ActiveCN109695111AEfficient and quick cleaningSustainable cleaning abilityTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsEngineeringWater leak

The invention provides a rewashing device for cotton cloth production. The rewashing device comprises a console, a cloth sinking mouth, water leaking holes, a collecting tray, a cleaning cart, a lifting stud, a drum, a wind deflector, a blower, a reel, a cloth angle clip, an interlocking rod, a belt pulley cylinder and a retarding motor, wherein the cloth sinking mouth is formed in the middle of the top of the console; a cloth sinking frame is fixed on the top of the cloth sinking mouth through bolts; multiple sets of water leaking holes are formed in the top of the console on one side of thecloth sinking mouth; blowout prevention plates are fixedly arranged at the tops of the water leaking holes through bolts; a bracket is welded and fixed on the two sides of the console; and a dryer isfixed in the middle of the bracket through bolts. Through setting the drum and a cleaning device, sustainable cleaning ability is provided for the rewashing device, so that cotton cloth can be rapidlyand efficiently cleaned; and when the water level of the cleaning device is lowered as the water absorption of the cotton cloth is too large, the position of the cotton cloth can be adjusted throughthe lifting stud, thereby effectively increasing the working distance of the cleaning device.

Owner:惠州市新联大科技有限公司

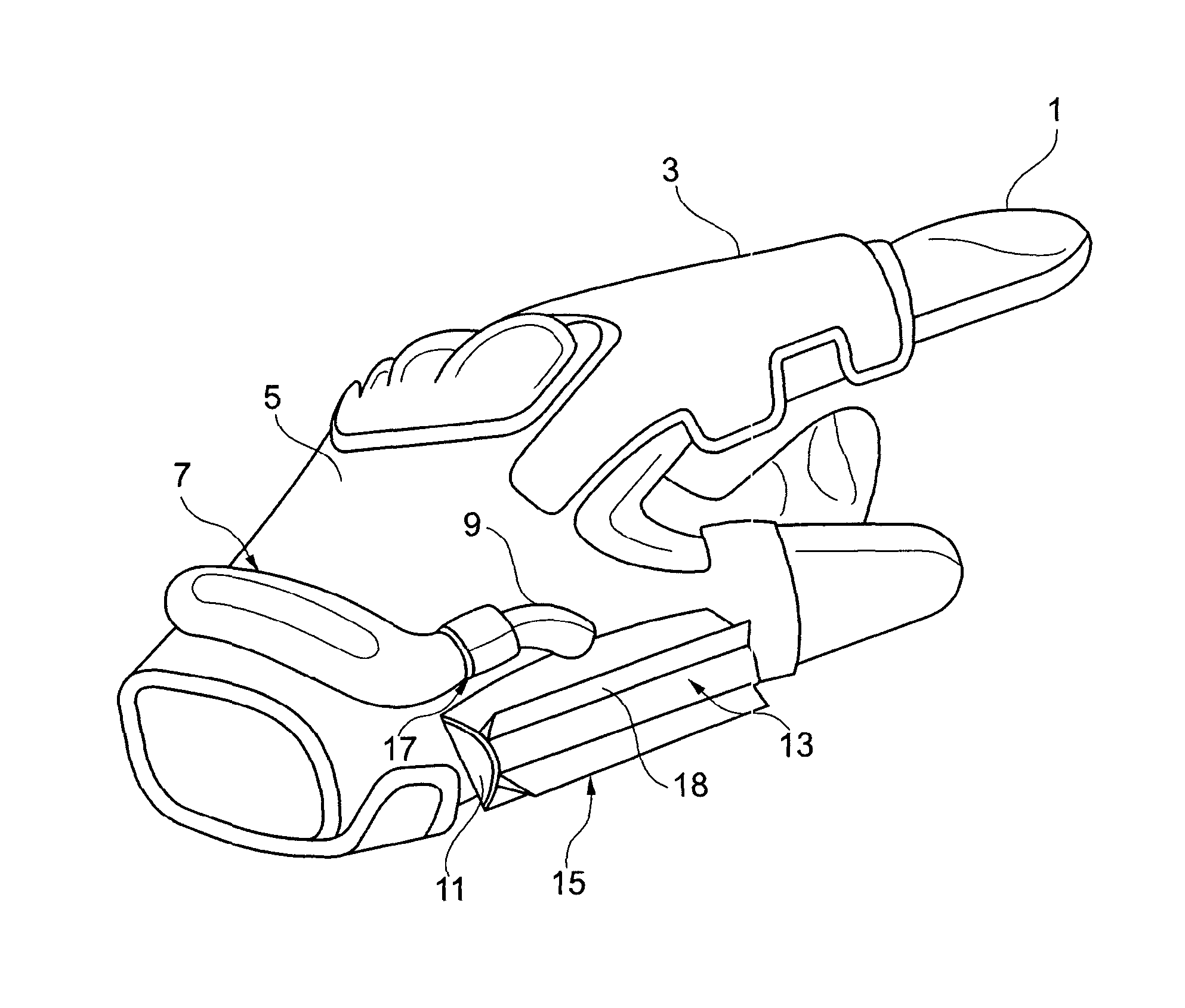

Nutplate Rotary Abrasion Tool

ActiveUS20180369873A1More secure attachmentIncrease efficiency and effectivenessPortable grinding machinesCleaning using toolsMechanical engineeringFaying surface

A system includes an abrasion component containing an abrasion pad configured to clean a faying surface of a nutplate and a shaft attached to the abrasion pad and configured to rotate the shaft and the abrasion pad during cleaning of the nutplate, which includes abrading the faying surface with the abrasion pad. The system further includes a base configured to attach to a pressure applicator, and the pressure applicator, which is configured to attach to the base, hold the nutplate such that the faying surface is capable of contacting the abrasion pad during the cleaning of the nutplate, and apply pressure to the nutplate such that the nutplate contacts the abrasion pad during the cleaning of the nutplate. Furthermore, the abrasion component is configured to rotate the abrasion pad within at least one of the base and the pressure applicator during the cleaning of the nutplate.

Owner:LOCKHEED MARTIN CORP

Steel shot composition for middle-high carbon steel, and preparation method thereof

The present invention discloses a steel shot composition for middle-high carbon steel, and a preparation method thereof, and belongs to the field of abrasive materials. The steel shot composition comprises, by weight, 5-8% of quartz sand, 20-25% of steel shot, 60-65% of white corundum, and 10-15% of alumina. The invention further discloses the preparation method of the steel shot composition. According to the present invention, the steel shot composition has characteristics of high impact resistance, high abrasion resistance, long service life, effective work-piece surface roughness increasing and meeting of production requirements, wherein the surface roughness Ra achieves 1.6-2.4 [mu]m after the middle-high carbon steel work-piece is subjected to a shot blasting texturing treatment; and the environmental pollution can be effectively reduced, and the steel shot is not easily broken so as to substantially reduce dust pollution during the impeller blasting and shot blasting process, ensure the surface quality of the blasted work-piece, and reduce the environmental pollution.

Owner:马鞍山市申马机械制造股份有限公司

Hygienic filter and disposal device

ActiveUS20200037572A1Easily filter outWastefully discardedSievingScreeningEnvironmental engineeringMechanical engineering

A hygienic filter and disposal apparatus comprising a main compartment a base platform, a front end, and a back end, and adapted to contain granular material and waste; a secondary compartment adapted to contain granular material; a door connecting the main compartment to the secondary compartment; and a filter element, comprising porous walls around a cavity and a first opening into said cavity, the walls adapted to filter waste out of the granular material; wherein the back end is proximate to the first opening at a first position where the front end and the back end of the base platform are level; wherein in a second position the front end is lifted higher than the back end and the granular material and waste are directed through the first opening into the cavity; wherein in the second position the filter element retains waste in the cavity and permits the granular material to fall through the porous walls into the secondary compartment; wherein in a third position the back end is higher than the front end and the door opens and directs the granular material into the main compartment; and wherein the device is adapted to sequence from the first position to the second position to the third position.

Owner:HERNANDEZ BARRERA JOHN FERNANDO

Efficient desilting device for water conservancy project

ActiveCN113202160ALoose realizationEfficient and quick cleaningSoil-shifting machines/dredgersArchitectural engineeringSlide plate

An efficient desilting device for a water conservancy project comprises a bottom plate, wherein the front side of the surface of the lower end of the bottom plate is slidably connected with a first sliding plate capable of reciprocating left and right, the surface of the front end of the first sliding plate is fixedly connected with a key-shaped plate, and a drill bit capable of reciprocating up and down while rotating is installed in the middle of the lower end of the key-shaped plate; a containing box capable of being overturned backwards is hinged to the upper end of the bottom plate, a tail door making contact with the surface of the rear end of the containing box is arranged on the rear side of the upper end of the bottom plate, and when the containing box is overturned backwards, a structure that the tail door is overturned upwards to be disengaged from the containing box can be formed; and extension plates are fixedly connected to the middles of the surfaces of the left end and the right end of the bottom plate respectively, long sleeve plates capable of moving up and down are mounted at the upper ends of the extension plates respectively, long mounting plates capable of moving left and right are mounted at the upper ends of the long sleeve plates respectively, and buckets capable of being folded inwards or unfolded outwards intermittently are mounted at the lower ends of the long mounting plates respectively. Blocky sundries at the river bottom can be fished through the bucket which can be intermittently folded inwards or opened outwards.

Owner:鄂州市水利建筑设计研究院有限公司

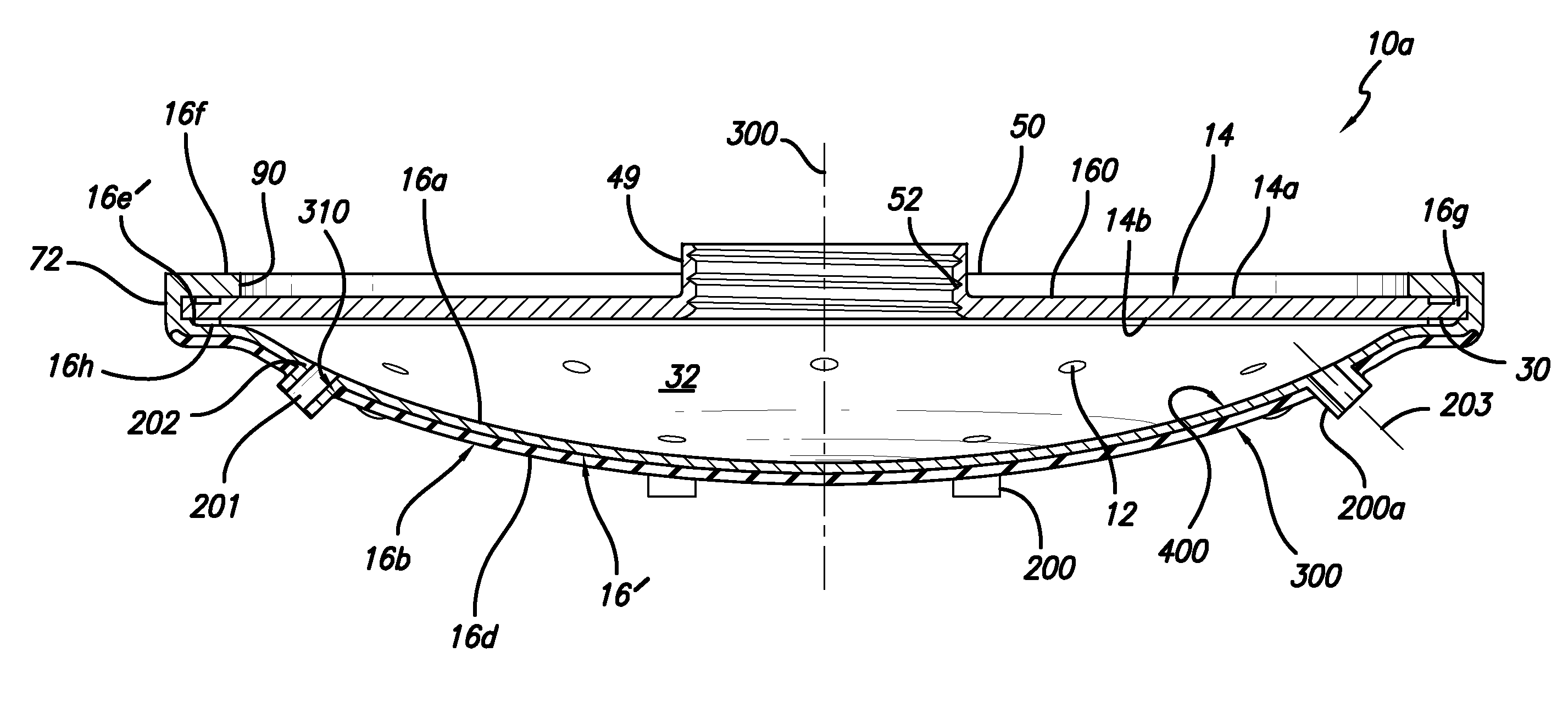

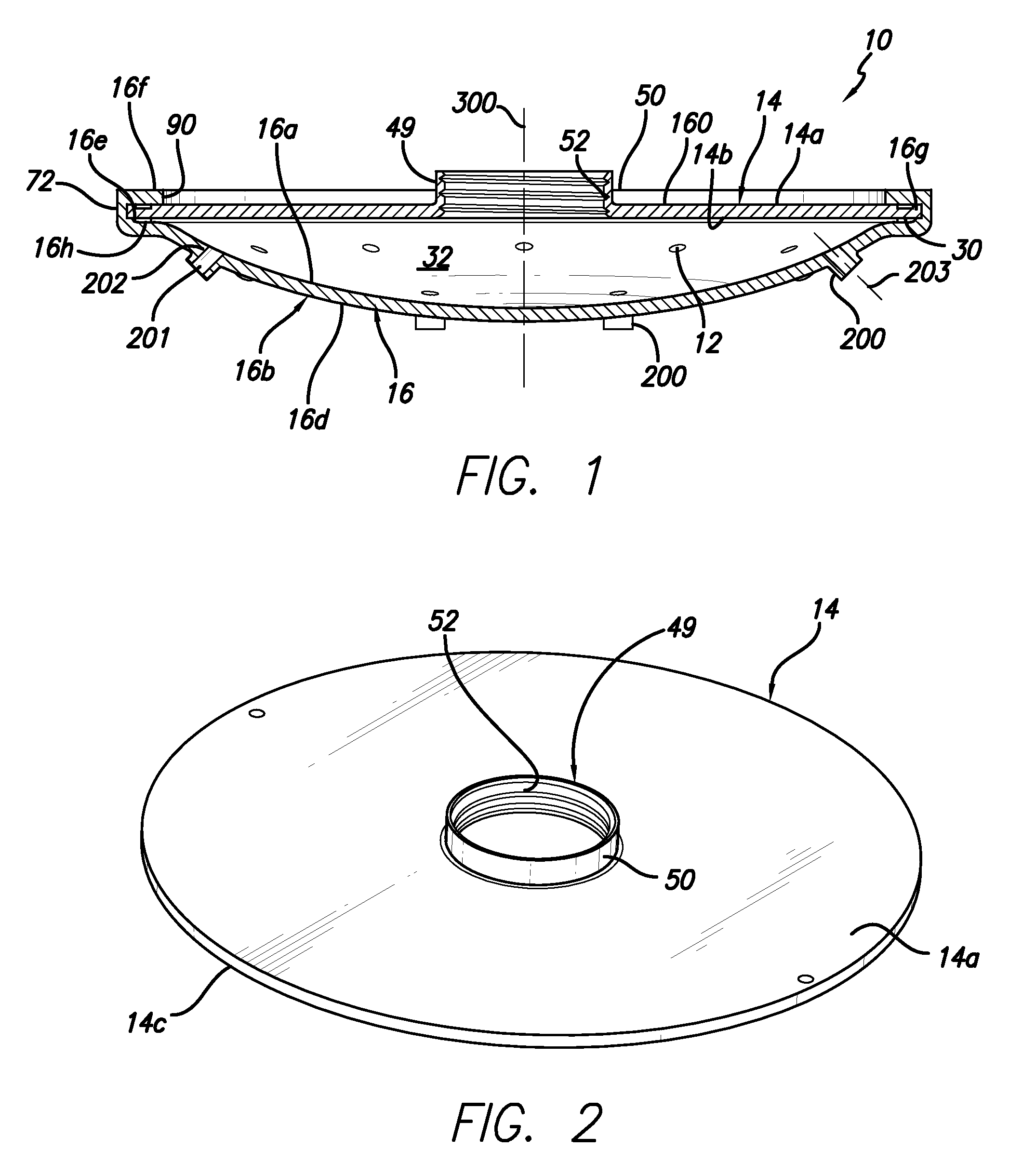

Flexible spray head

InactiveUS9084511B2Efficient and quick cleaningPrevents accidental and unintended lossSpray nozzlesBeverage vesselsCombined useMechanical engineering

Briefly, and in accordance with the foregoing, disclosed is a spray head for use with, in combination with a beverage making apparatus, as a replacement for other spray heads and a method of using a spray head. The spray head receives liquid from a liquid dispensing path of the beverage making apparatus and distributes liquid over a beverage making substance retained proximate the spray head. The spray head includes two pieces, a first piece for connection to the liquid dispensing path and the second piece which is flexible and removable attachable to the first piece. A cavity is defined between the first and second pieces. Water received form the liquid dispensing path collects in the cavity. The second piece or body portion includes a plurality of holes for dispensing and distributing water from the cavity over the beverage substance. The spray head is removable from the beverage making apparatus for facilitating direct contact and flexion cleaning of the surfaces of at least the body portion of the spray head to remove particles and mineral deposits therefrom.

Owner:BUNN O MATIC

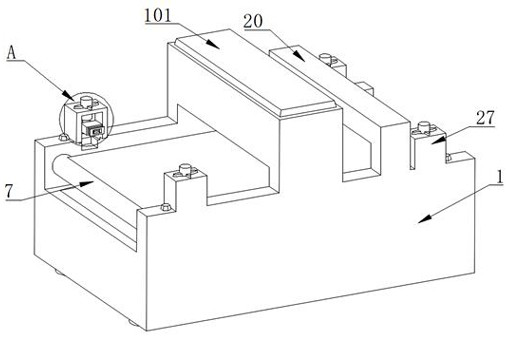

Hydraulic drive type filter press and filter pressing method

InactiveCN113617088ASolve the problem that is difficult to take outEfficient and quick cleaningStationary filtering element filtersHydraulic cylinderElectric machinery

The invention discloses a hydraulic drive type filter press and filter pressing method. The hydraulic drive type filter press comprises a frame, an oil tank, an oil pump, a hydraulic cylinder, a feeding port valve, a discharging port valve and a liquid outlet valve, the oil tank and the oil pump are installed outside the top end of the frame, and the oil tank, the oil pump and the hydraulic cylinder are communicated through oil pipes. By arranging a motor, a push plate, a pressing plate and a stirring rod, the push plate drives the pressing plate to synchronously rotate through the stirring rod, the stirring rod stirs and crushes a filter cake subjected to filter pressing, and the crushed filter cake flows out of a discharge port; and when the output shaft of the hydraulic cylinder retracts, certain friction force between the stirring rod and the pressing plate makes the pressing plate move synchronously, the pressing plate moves to a certain position and stops, and the stirring rod is drawn out from a through groove in the surface of the pressing plate, so that residues adhered to the surface of the stirring rod are scraped, the problem that filter cakes subjected to filter pressing of an existing filter press are difficult to take out can be effectively solved, and the filter press is faster and more efficient than manual cleaning.

Owner:芜湖市海川矿业有限公司

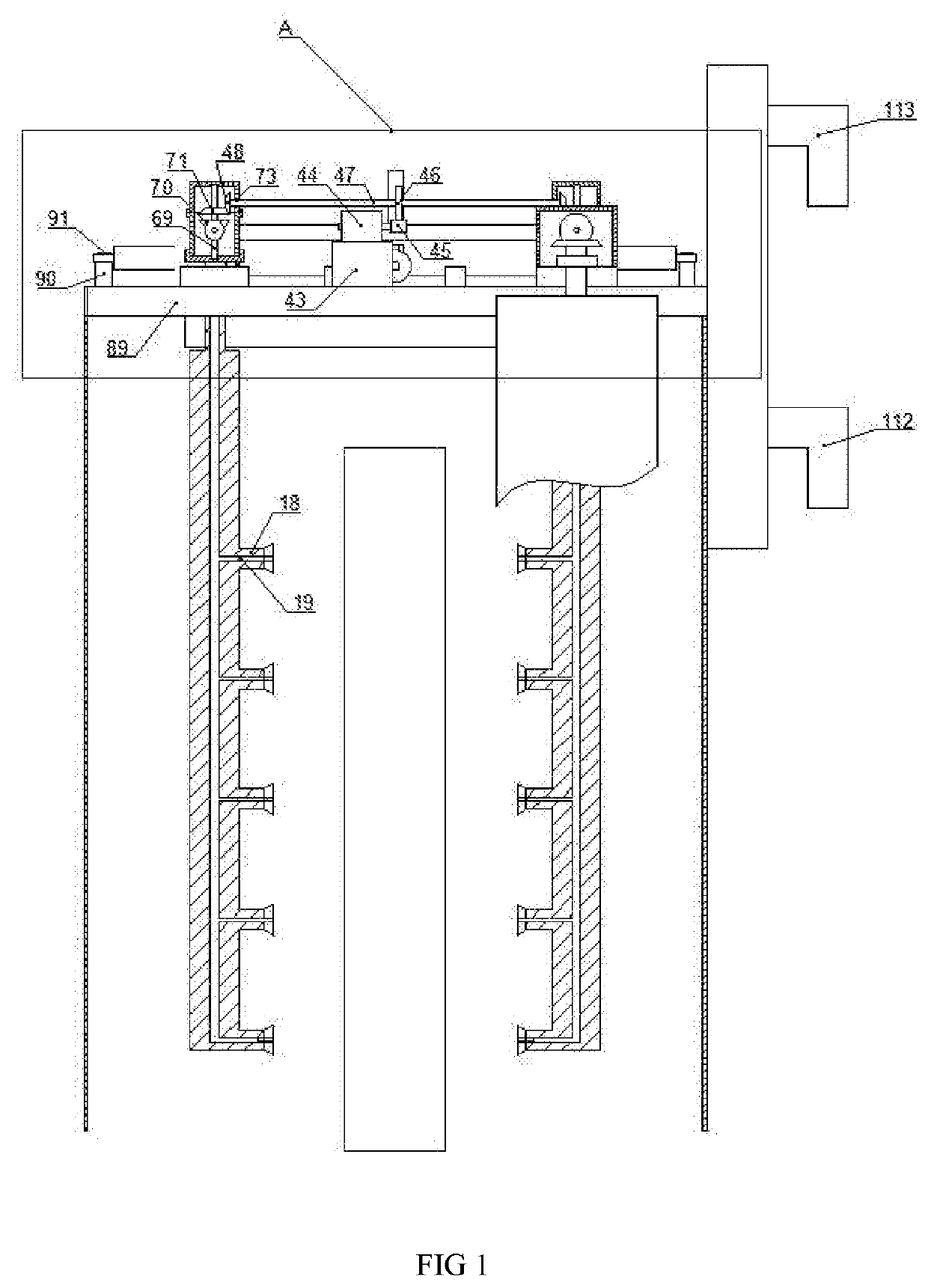

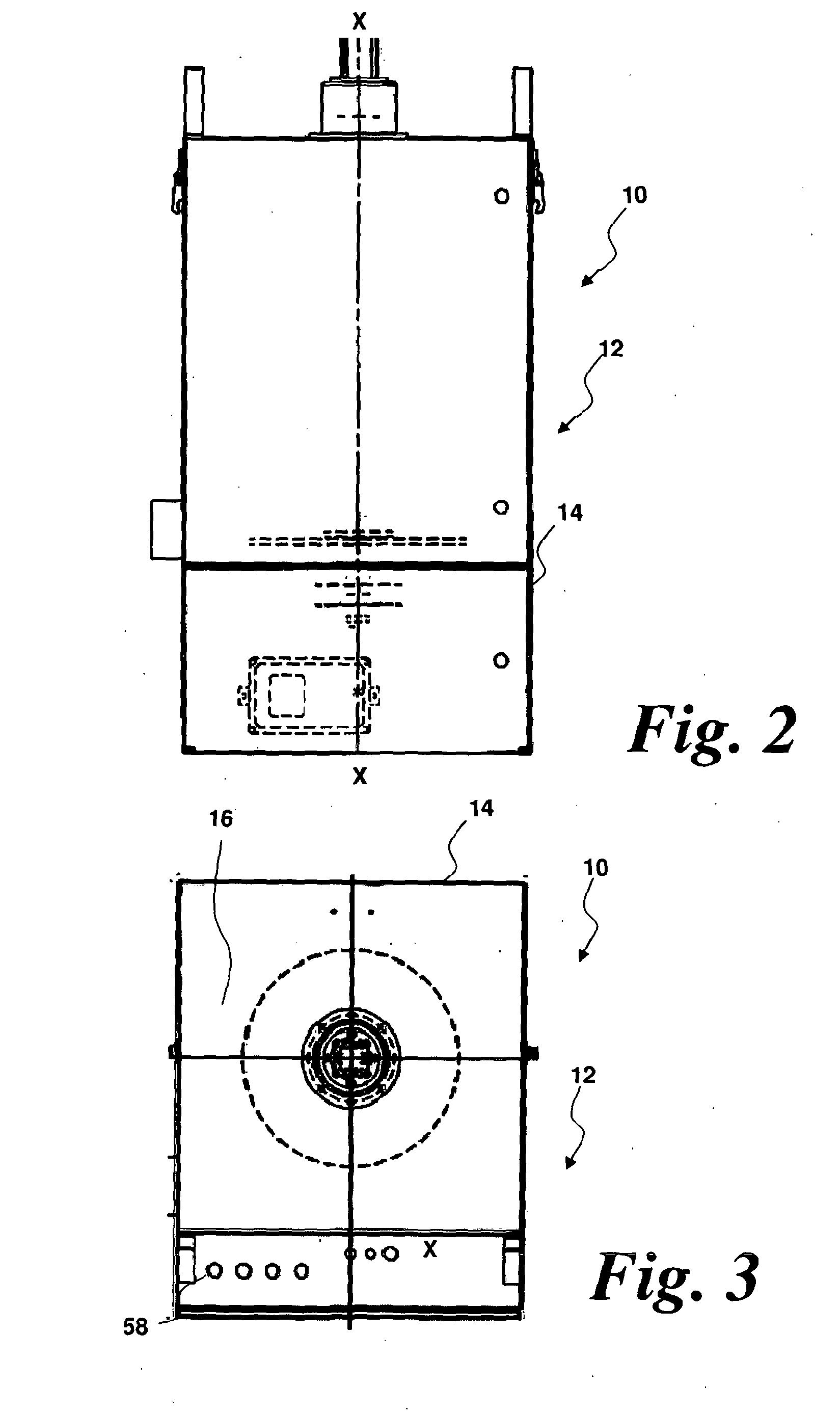

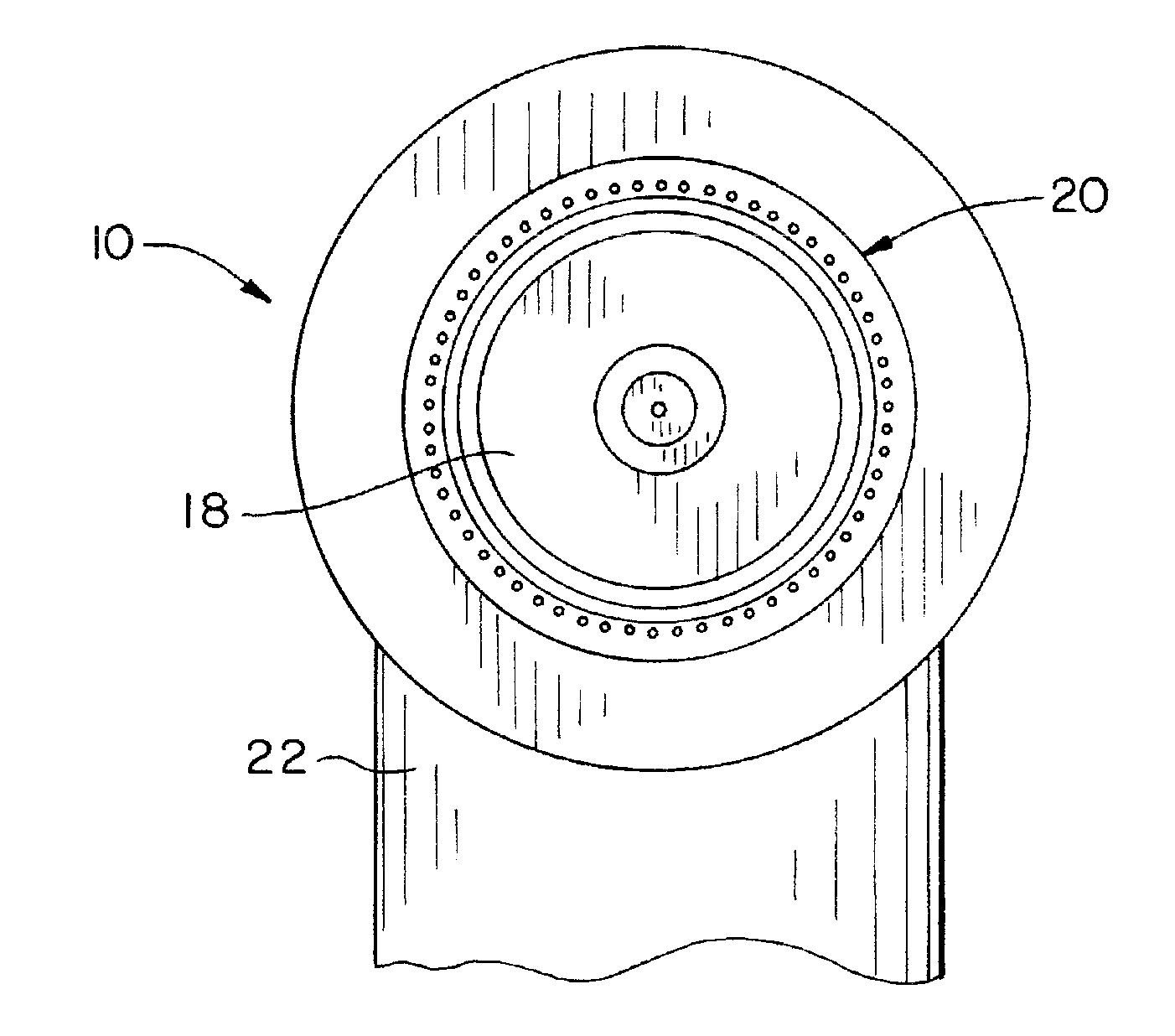

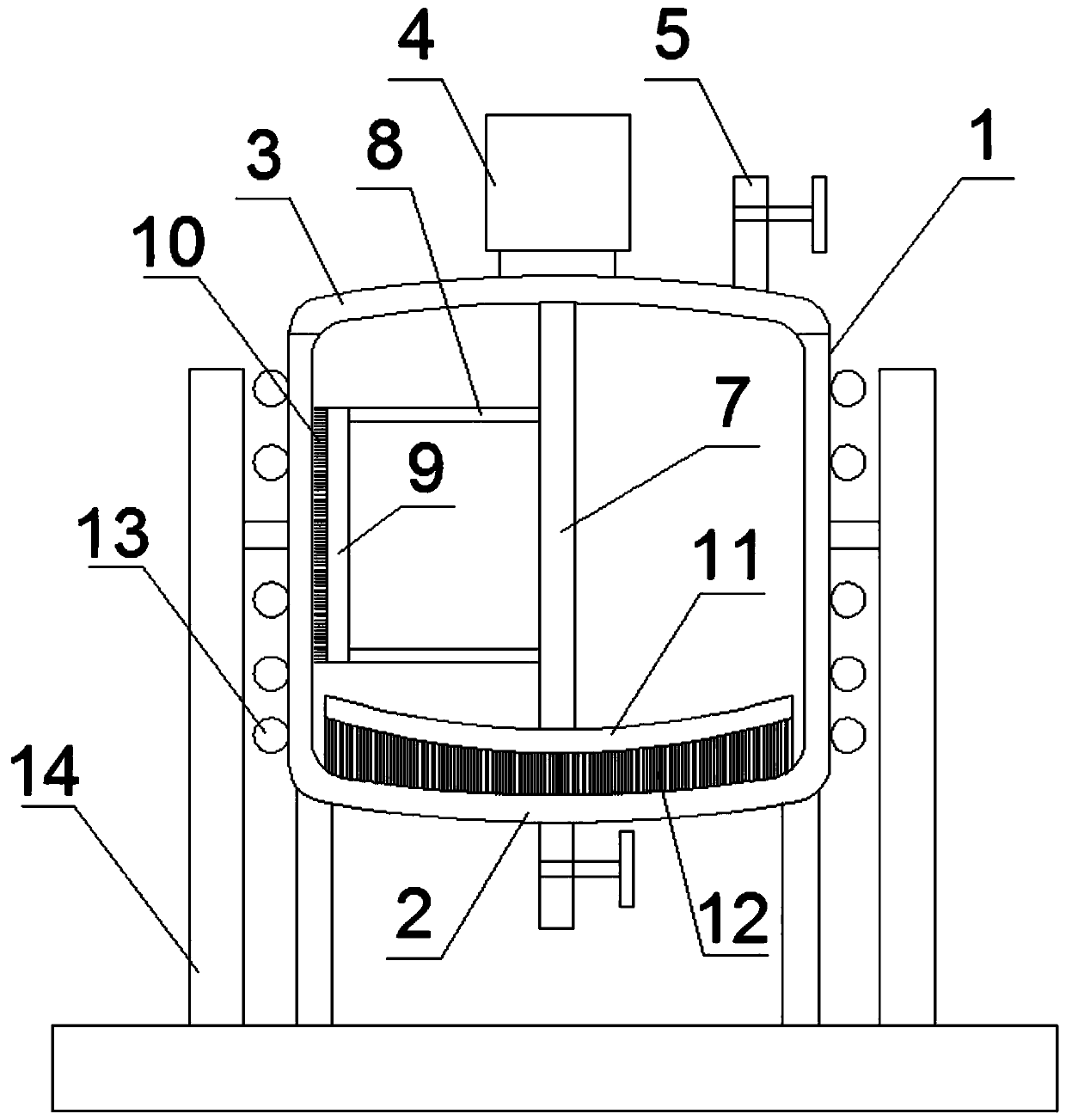

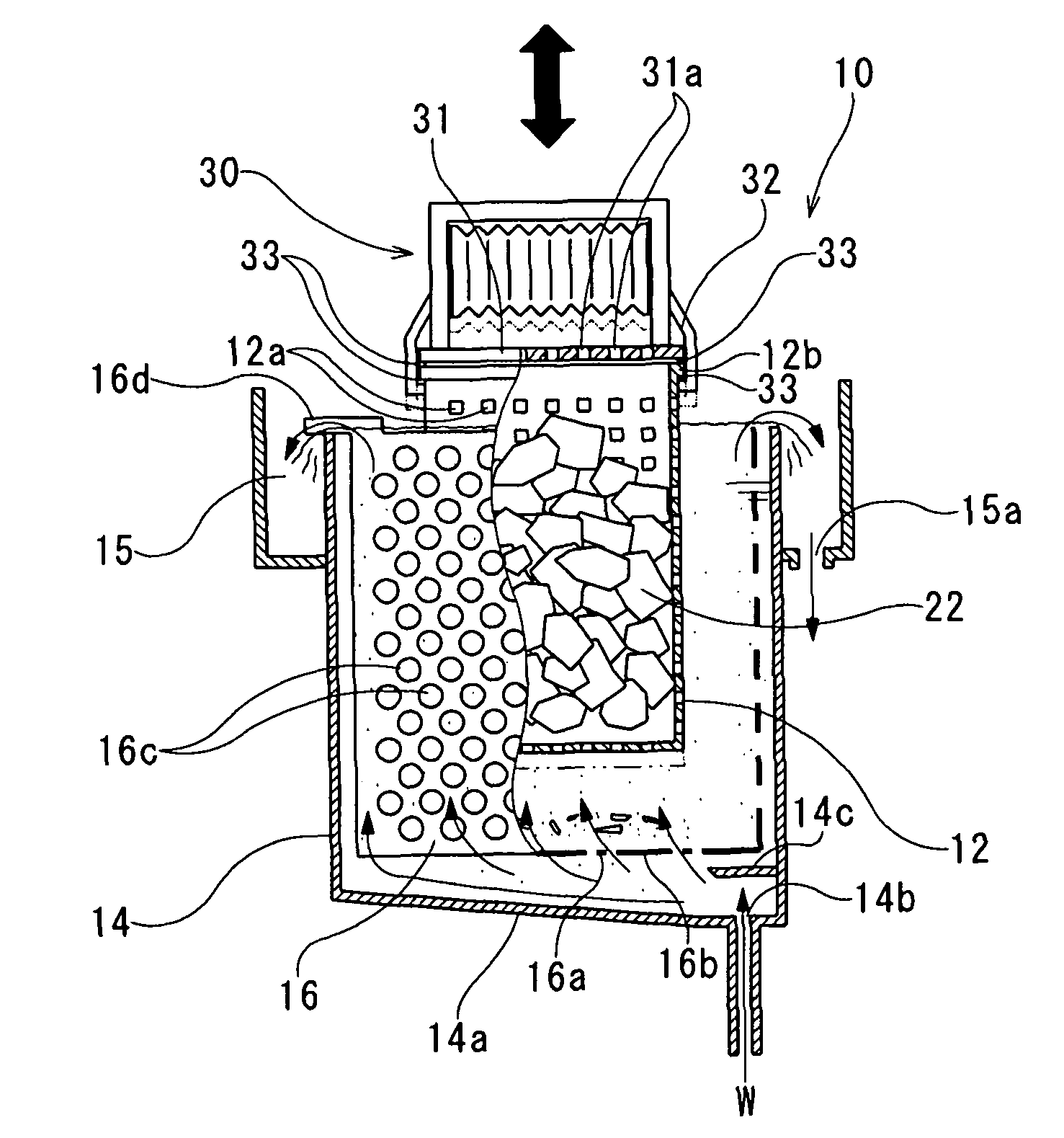

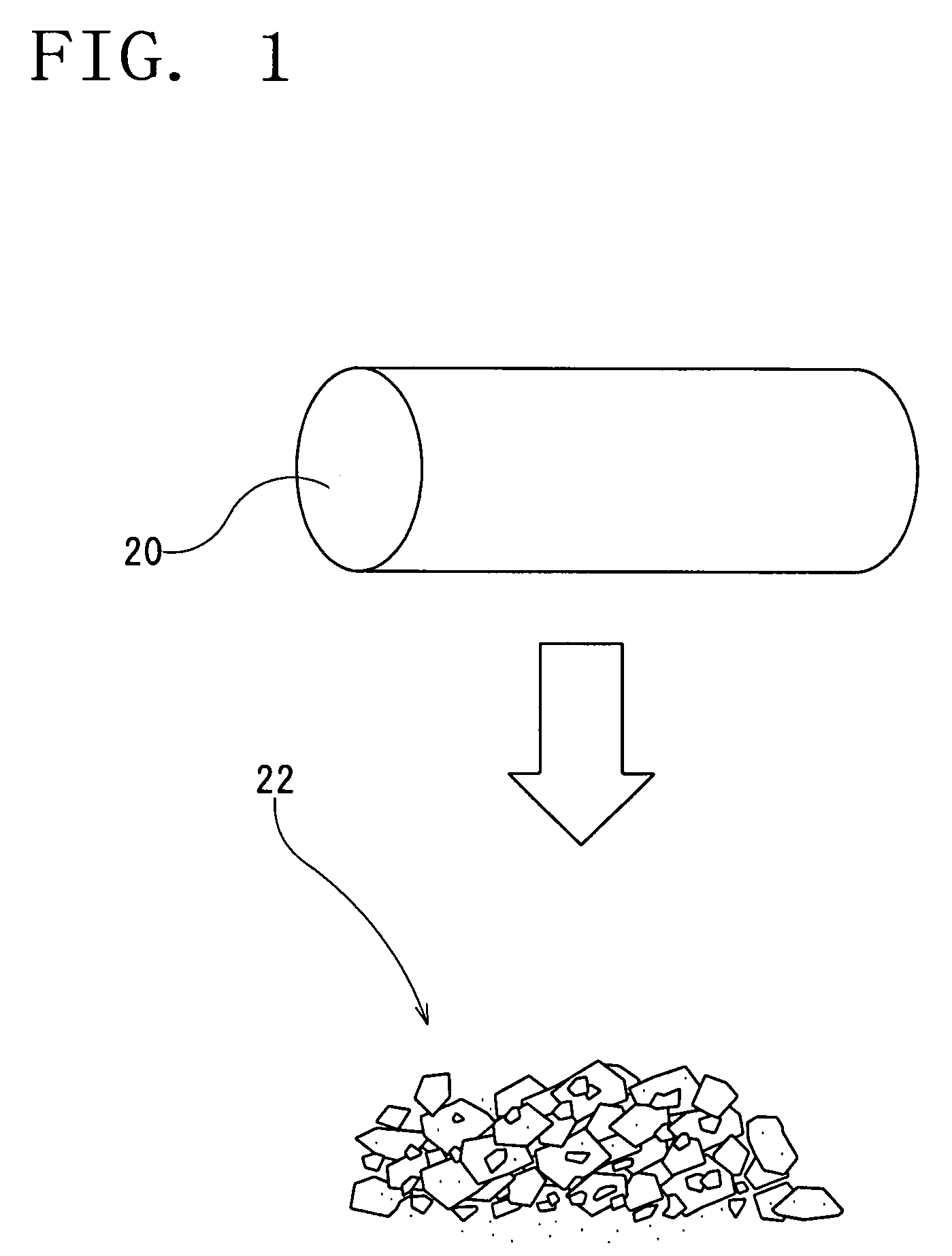

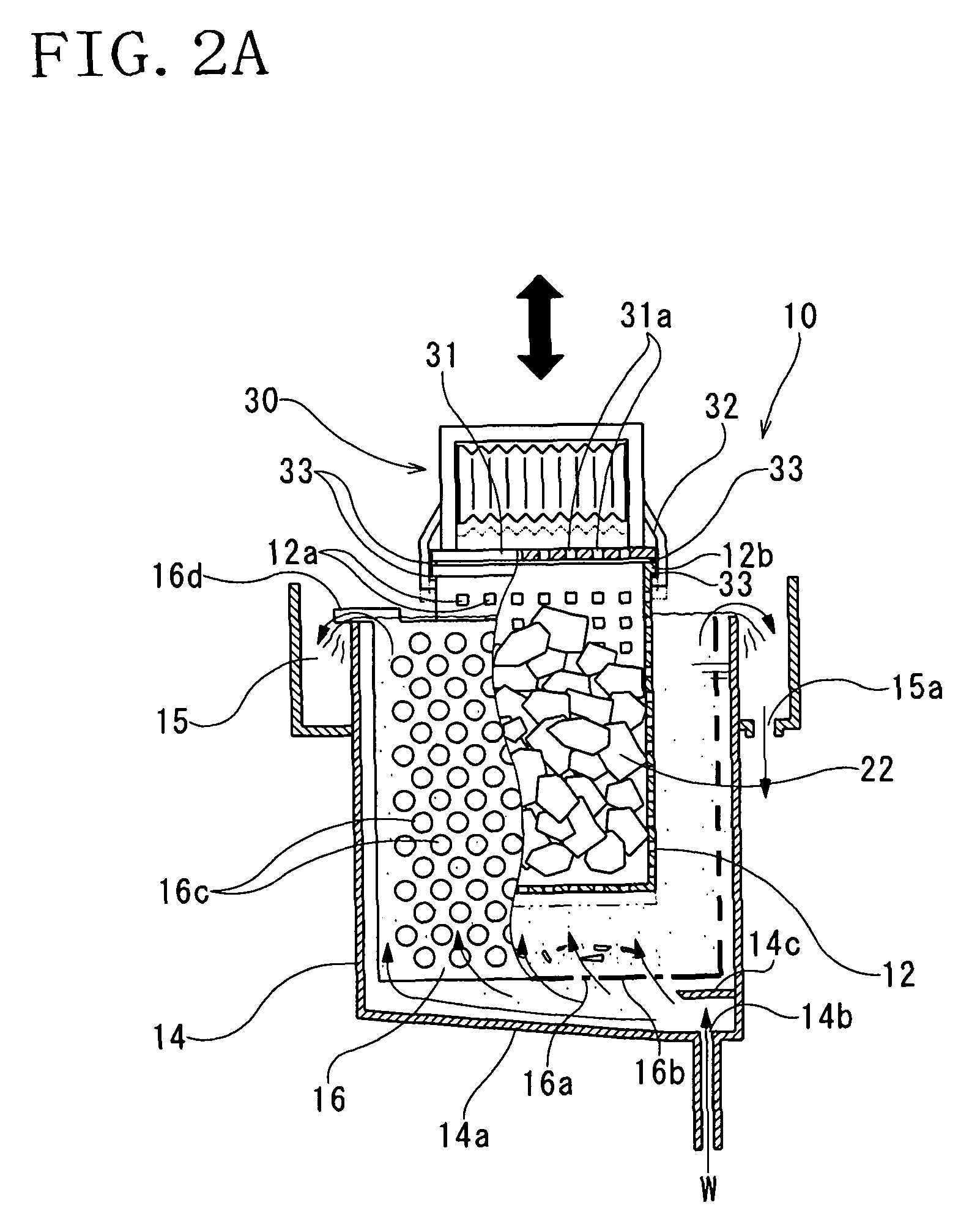

Rinsing apparatus and rinsing method for polycrystalline silicon lump

ActiveUS8887744B2Efficient and quick cleaningEfficient removalAfter-treatment apparatusCleaning using liquidsRinse waterPolycrystalline silicon

A rinsing apparatus for polycrystalline silicon lump which is obtained by cutting or breaking a rod of polycrystalline silicon, including: a wash basket having a plurality of through holes, which carries the polycrystalline silicon lump; a wash tank in which the wash basket is provided therein, in which rinse water is continuously supplied from a water supply port which is arranged at a bottom part of the wash tank; an inner cage having a plurality of openings which is smaller than the through holes of the wash basket at a bottom part thereof, provided in the wash tank, in which the wash basket is stored therein; and a swing device holding and swinging the wash basket in the inner cage, and: an overflow part which recovers the rinse water overflowed from an upper portion of the wash tank is provided at the wash tank.

Owner:HIGH-PURITY SILICON CORP

Fluid delivery service

ActiveUS9198554B2Easy to cleanEfficient and quick cleaningBoard cleaning devicesCarpet cleanersVisorBiomedical engineering

A fluid delivery device (3) for a visor cleaner. The fluid delivery device (3) includes a fluid reservoir (7), which contains cleaning fluid when ready for use. The fluid delivery device (3) also includes an absorbent cleaning element (13) that is arranged to take in fluid from the reservoir (7). In use, the fluid in the reservoir (7) and the absorbent cleaning element (13) are arranged to be in permanent fluid communication.

Owner:VISUAL PRODS

Crab microwave processing equipment and method

InactiveCN109221308AComprehensive cleaningEfficient and quick cleaningClimate change adaptationBaking ovenMicrowaveWater pipe

The invention provides a crab microwave processing equipment and method. The crab microwave processing equipment comprises a cleaning assembly, a microwave heating assembly and a spray assembly; the cleaning assembly comprises a cleaning water tank, a bubble generator, a first conveying device and an elevator, and the microwave heating assembly comprises a microwave heating tunnel, a second conveying device and multiple first microwave generators; the spray assembly comprises a water heating assembly and a spray channel, the water heating assembly comprises a microwave heating box, a water pipe, a heat preservation water tank and multiple second microwave generators, and the spray channel is internally provided with a third conveying device and multiple spray heads. By means of the crab microwave processing equipment, useful resource recycling and reusing are achieved, energy consumption is effectively lowered, and the harmless processing efficiency is improved. Cooked processing is conducted on crabs through the crab microwave processing equipment, and dirt and impurities on the surfaces of live crabs and cooked crabs are effectively cleaned away.

Owner:山东科朗特微波设备有限公司 +1

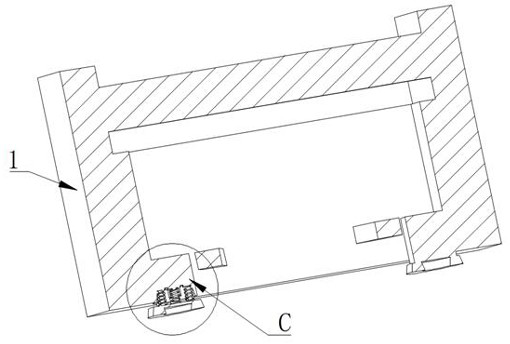

Cold storage plate production cutting device

InactiveCN113977305AReduce the amplitudeTo achieve the effect of shock and noise reductionNon-rotating vibration suppressionWork clamping meansEngineeringMechanical engineering

The invention discloses a cold storage plate production cutting device in the technical field of cold storage plate production. The device comprises a production machine body, a supporting bottom plate and a second gas conveying pipe, a first limiting stopper is mounted at the upper end of the production machine body, a first electric push rod is mounted in the first limiting stopper, the transmission end of the first electric push rod is connected with a connecting block, a second electric push rod is installed in the connecting block, a connecting column is connected to the transmission end of the second electric push rod, a movable ring sleeve is installed at the upper end of the connecting column, a limiting block is installed at the front end of the movable ring sleeve, and rolling wheels are installed in the limiting block. According to cold storage plate production cutting device, a limiting part, a damping part and a cleaning part are arranged, so that the device can limit the movement range of a cold storage plate, and it is guaranteed that the cold storage plate is effectively cut; the overall working noise of the device is effectively reduced; and the cut cold storage plate can be cleaned immediately, so that the next production procedure can be carried out quickly.

Owner:江苏盈达机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com