Composition, preparation method, application and automobile engine fuel tank

A technology of automobile engine and composition, which is applied in the direction of detergent composition, organic detergent composition, surface active detergent composition, etc., and can solve the problems of high service cost, difficulty in adding additives, secondary fouling of combustion chamber, etc. , to achieve the effect of simple cleaning method, wide application range and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

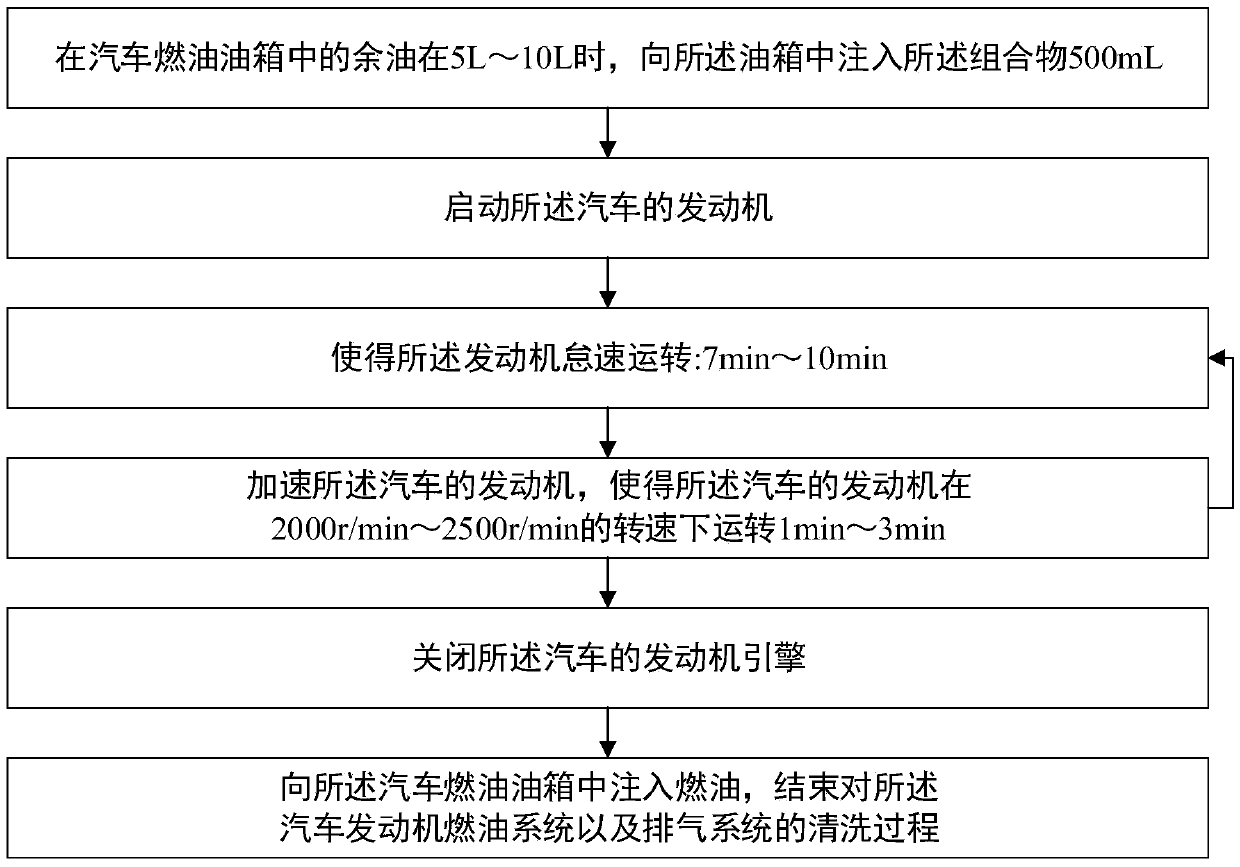

Method used

Image

Examples

Embodiment 1

[0046] Preparation of Embodiment 1 Gasoline Vehicle Engine Fuel System Cleaning Agent

[0047] The formula composition (mass percentage) of gasoline vehicle engine fuel system cleaning agent is as follows:

[0048] 1. Organic solvent: toluene 10%, butyl acetate 7%, acetone 25%, ethanol 30%, ethylene glycol butyl ether 15%, total 87%

[0049] 2. Surfactant: high-efficiency polyetheramine 10%, polyisobutylamine 3%.

[0050] The preparation process is as follows:

[0051] First add 10% high-efficiency polyetheramine and 3% polyisobutylamine into the container, then add 30% ethanol, and mix well by pumping for 5 minutes; then add other organic solvents such as 10% toluene, 7% butyl acetate, and 25% acetone %, 15% ethylene glycol butyl ether, and the pump circulates for 10 minutes to mix evenly, and after filtering, put it into a container to obtain the finished product. The deployment process is carried out in a closed container at normal temperature and pressure.

[0052] The...

Embodiment 2

[0053] The preparation of embodiment two gasoline engine exhaust system cleaning agent

[0054] The formula composition (mass percentage) of gasoline vehicle engine exhaust system cleaning agent is as follows:

[0055] 1. Organic solvent: toluene 10%, acetone 30%, isoethyl alcohol 25%, ethylene glycol ether 10%, dichloromethane 5%, total 80%

[0056] 2. Surfactant: 5% polyisobutenyl amine, 5% polyisobutenyl succinimide, 10% triethanolamine, 20% in total.

[0057] The preparation process is as follows:

[0058] First add 5% of surfactant polyisobutenyl amine, polyisobutenyl succinimide 5%, and triethanolamine 10% into the container, then add 25% isoethyl alcohol, and mix well by pumping for 5 minutes; then add other organic solvents in sequence Acetone 30%, toluene 10%, ethylene glycol ethyl ether 10%, methylene chloride 5%, pump circulation for 10 minutes to mix evenly, filter and put into a container to get the finished product. The deployment process is carried out in a c...

Embodiment 3

[0060] The preparation of embodiment three gasoline vehicle engine fuel system & exhaust system composite cleaning agent gasoline vehicle engine fuel system & exhaust system composite cleaning agent formula composition (mass percentage) is as follows:

[0061] 1. Organic solvent: 6% toluene, 7% butyl acetate, 15% acetone, 15% ethanol, 15% isoethyl alcohol, 5% ethylene glycol ethyl ether, 5% ethylene glycol butyl ether, 5% dichloromethane, total 73%.

[0062] 2. Surfactant: 10% high-efficiency polyetheramine, 5% polyisobutenyl amine, 2% polyisobutenyl succinimide, 10% triethanolamine, 27% in total.

[0063] The preparation process is as follows:

[0064] First add 10% high-efficiency polyetheramine, 5% polyisobutenyl amine, 2% polyisobutenyl succinimide, and 10% triethanolamine into the container, then add 15% ethanol, 15% isoethyl alcohol, and pump for 5 Mix well within 1 minute; then add other organic solvents such as acetone 15%, toluene 6%, butyl acetate 7%, ethylene glyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com