Steel shot composition for middle-high carbon steel, and preparation method thereof

A medium and high carbon, composition technology, applied in the direction of manufacturing tools, metal processing equipment, abrasives, etc., can solve the problems of short service life, low friction resistance of abrasives, fast wear and tear, and achieve long service life, strong impact resistance, The effect of high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

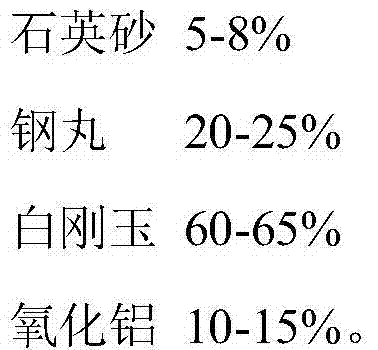

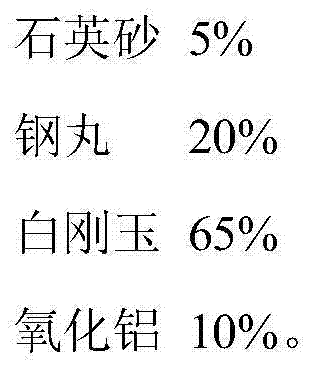

[0024] A steel shot composition for medium-high carbon steel, comprising the following components by weight percentage:

[0025]

[0026] The preparation method of the steel shot composition for medium-high carbon steel comprises the steps of: weighing the following components in sequence: 5kg of quartz sand, 20kg of steel shot, 60kg of white corundum and 10kg of alumina in a mixer , High-speed stirring to mix evenly to get the product.

Embodiment 2

[0028] A steel shot composition for medium-high carbon steel, comprising the following components by weight percentage:

[0029]

[0030] The preparation method of the steel shot composition for medium-high carbon steel comprises the following steps: successively weigh the following components, 5kg of quartz sand, 25kg of steel shot, 60kg of white corundum and 10kg of alumina in a mixer , High-speed stirring to mix evenly to get the product.

Embodiment 3

[0032] A steel shot composition for medium-high carbon steel, comprising the following components by weight percentage:

[0033]

[0034] The preparation method of the steel shot composition for medium and high carbon steel comprises the following steps: successively weigh the following components, 5kg of quartz sand, 20kg of steel shot, 60kg of white corundum and 15kg of alumina in a mixer , High-speed stirring to mix evenly to get the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com