Efficient screw cleanser and preparation method thereof

A screw cleaning agent and high-efficiency technology, applied in the directions of detergent compounding agent, detergent composition, chemical instrument and method, etc., to achieve the effect of fast and efficient cleaning, energy saving and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

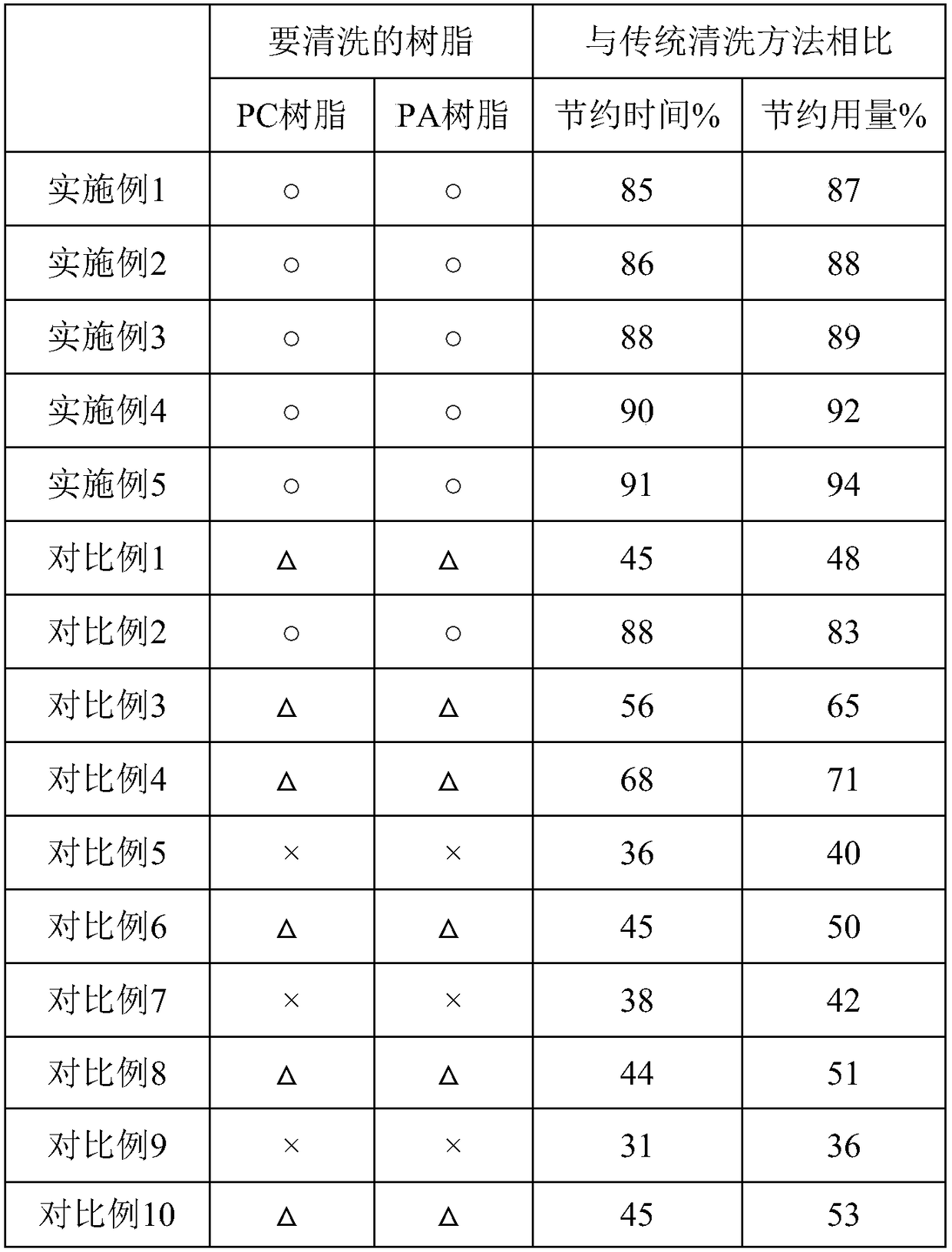

Examples

preparation example Construction

[0053] Second aspect of the present invention provides the preparation method of efficient screw cleaning agent, and step comprises:

[0054] (1) Mix the anionic surfactant and the nonionic surfactant uniformly to obtain a mixture A;

[0055] (2) Add hyperbranched polyamide and fluorine-containing polymer to mixture A, add complex compound and moisturizing agent in turn under stirring, and stir evenly to obtain the high-efficiency screw cleaning agent.

Embodiment 1

[0059] Embodiment 1 provides a kind of high-efficiency screw cleaning agent, by weight, comprises following components: 20 parts of anionic surfactants, 20 parts of nonionic surfactants, 5 parts of complexes, 3 parts of wetting agents, hyperbranched 0.5 parts of polyamide, 5 parts of fluoropolymer.

[0060] Described anionic surfactant comprises sodium lauryl sulfate, sodium dodecylbenzenesulfonate; The weight ratio of described sodium lauryl sulfate, sodium dodecylbenzenesulfonate is 5:6; Wherein, The sodium dodecylsulfate was purchased from Aonic Synthetic Chemical Co., Ltd.; the sodium dodecylbenzenesulfonate was purchased from Nanjing Jiaji Chemical Co., Ltd.

[0061] The nonionic surfactant includes fatty alcohol polyoxyethylene ether, polyethylene glycol, and fluorosurfactant; wherein, the fluorosurfactant is a water-based ethoxylated nonionic fluorocarbon surfactant; The weight ratio of the fatty alcohol polyoxyethylene ether, polyethylene glycol, and water-based ethox...

Embodiment 2

[0070] Embodiment 2 provides a kind of high-efficiency screw cleaning agent, by weight, comprises following components: 100 parts of anionic surfactants, 50 parts of nonionic surfactants, 15 parts of complexes, 8 parts of wetting agents, hyperbranched 3 parts of polyamide, 6 parts of fluoropolymer.

[0071] Described anionic surfactant comprises sodium lauryl sulfate, sodium dodecylbenzenesulfonate; The weight ratio of described sodium lauryl sulfate, sodium dodecylbenzenesulfonate is 5:6; Wherein, The sodium dodecylsulfate was purchased from Aonic Synthetic Chemical Co., Ltd.; the sodium dodecylbenzenesulfonate was purchased from Nanjing Jiaji Chemical Co., Ltd.

[0072] The nonionic surfactant includes fatty alcohol polyoxyethylene ether, polyethylene glycol, and fluorosurfactant; wherein, the fluorosurfactant is a water-based ethoxylated nonionic fluorocarbon surfactant; The weight ratio of the fatty alcohol polyoxyethylene ether, polyethylene glycol, and water-based ethox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com