Patents

Literature

30results about How to "Solve the problem that is difficult to take out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

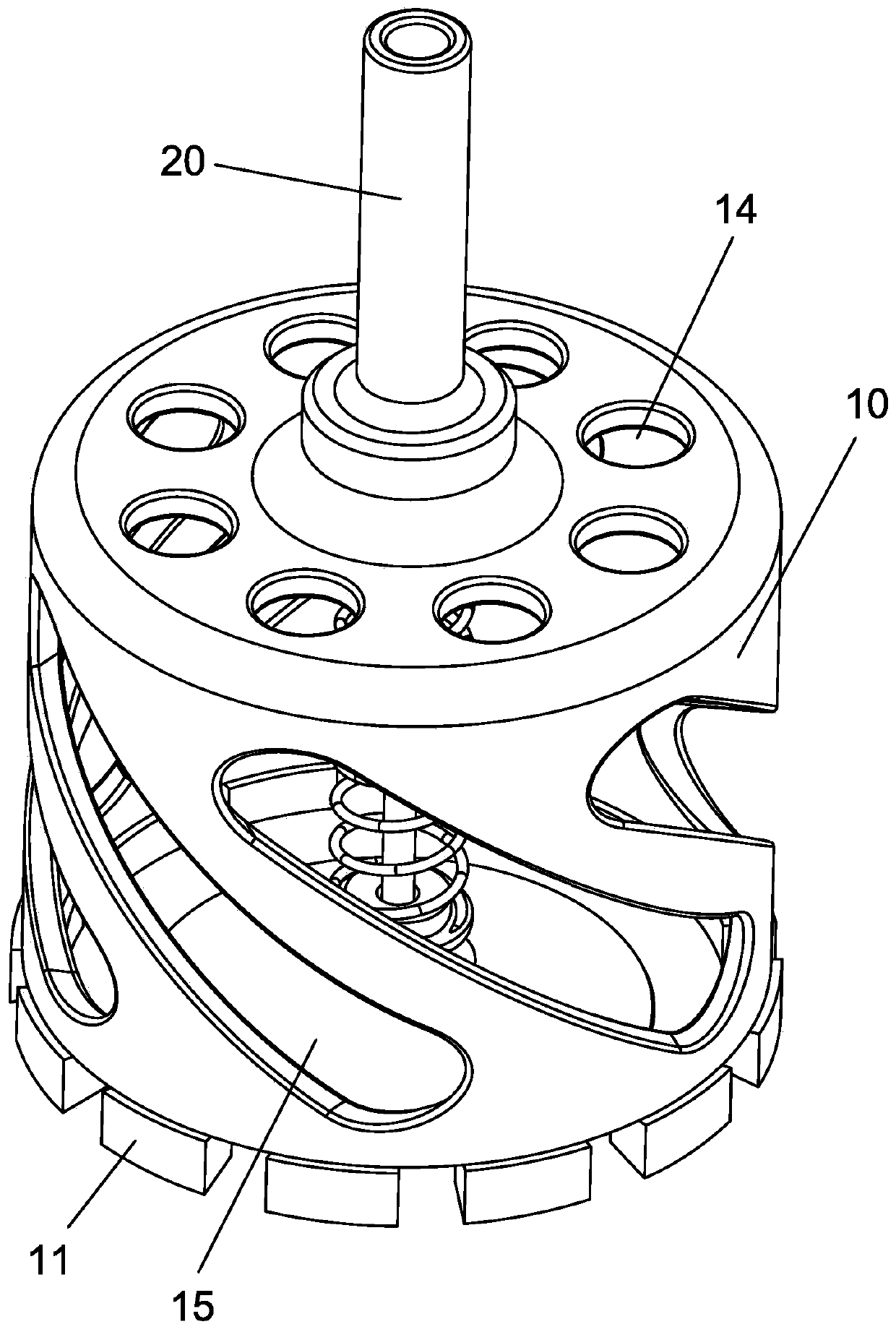

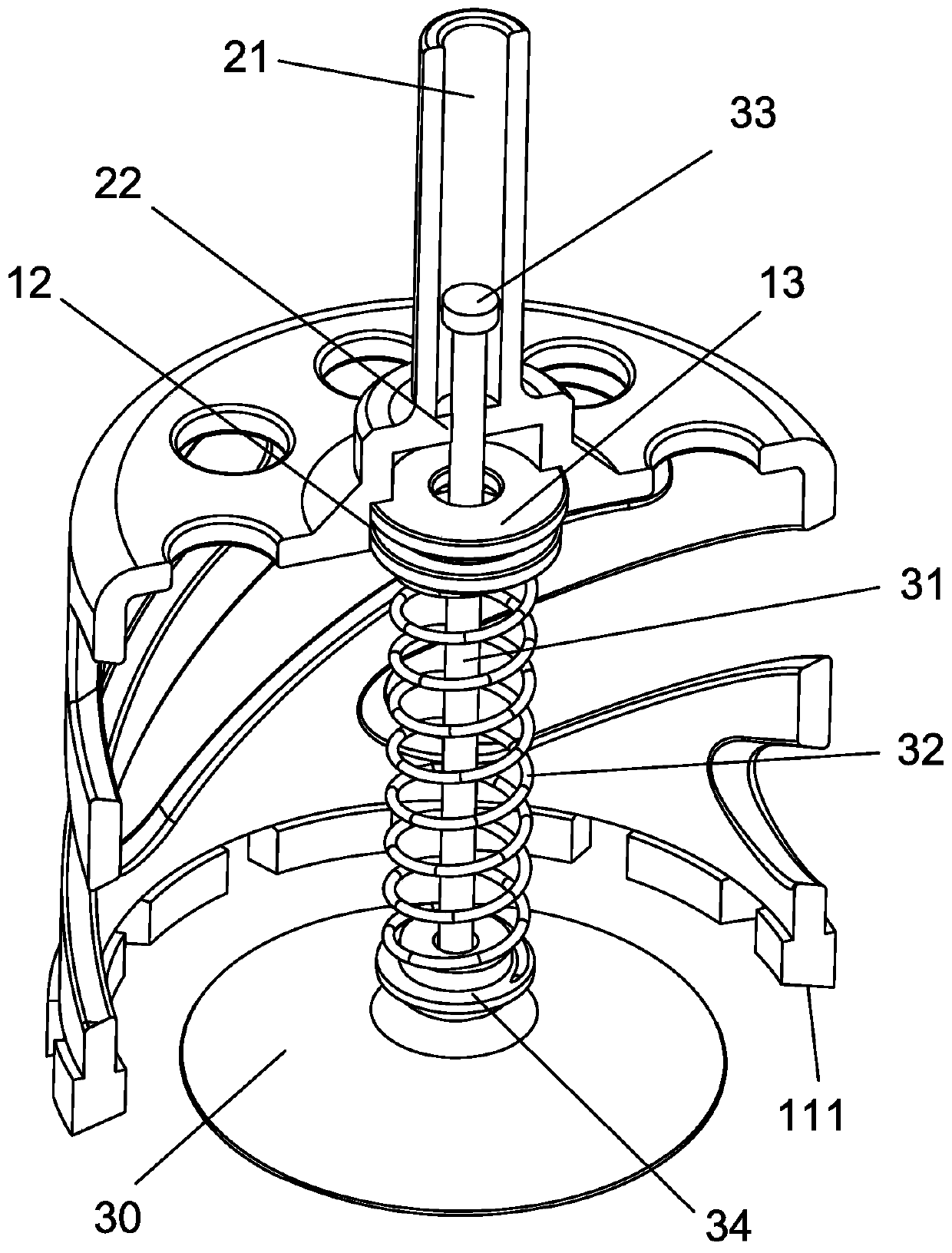

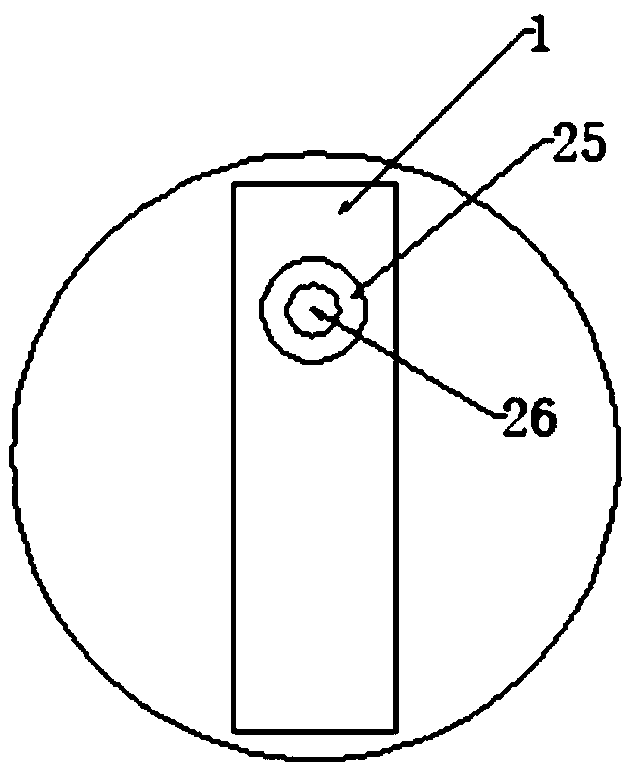

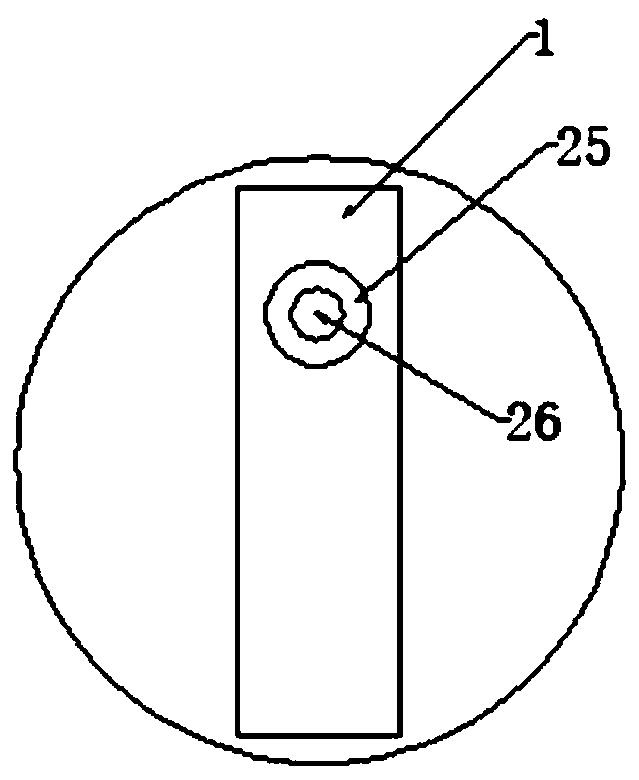

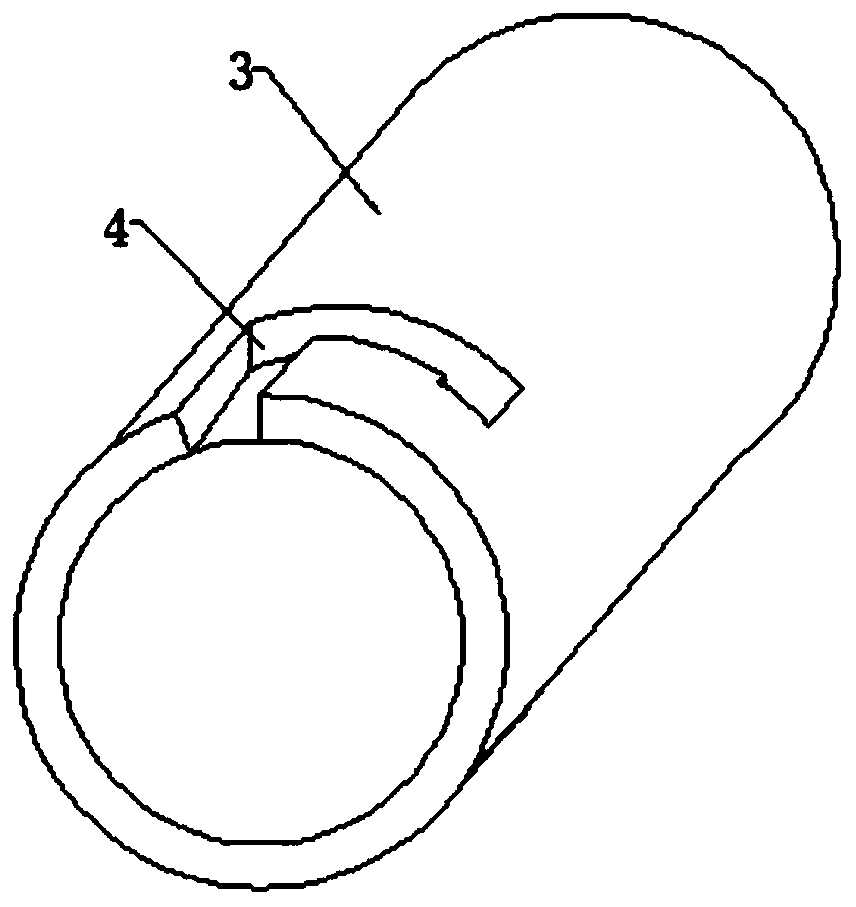

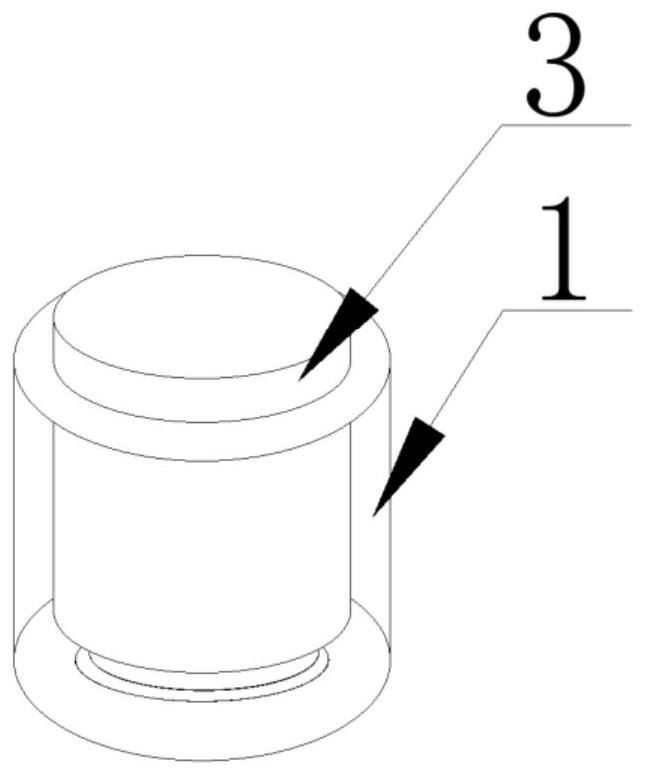

Double-layer glass trepanning device

ActiveCN110142881AServe as a centering supportSolve the problem that is difficult to take outWorking accessoriesGrinding machinesBarrel ShapedEngineering

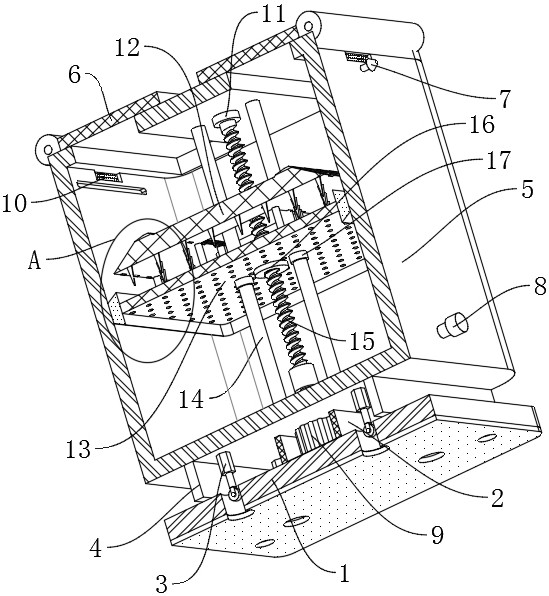

The invention provides a double-layer glass trepanning device. A trepanning device body is included and is in a barrel shape. A drill handle is arranged on the top of the trepanning device body. The bottom of the trepanning device body is provided with diamond grinding blocks evenly distributed at intervals in the circumference direction of the trepanning device body. A suction cup is arranged inthe trepanning device body. The adsorption face of the suction cup deviates away from the drill handle. The center of the face, towards the drill handle, of the suction cup is provided with a centering rod. The drill handle is provided with a sliding hole communicating with an inner cavity of the trepanning device body. The centering rod and the sliding hole circumferentially rotate and are in sliding fit in the axial direction. The double-layer glass trepanning device has the advantages that during double-layer glass trepanning, the situation that after head-layer glass trepanning is finished, middle glass leftovers fall into the part between double-layer glass and is hard to take out is avoided.

Owner:YIZHONG CONSTR GRP CO LTD

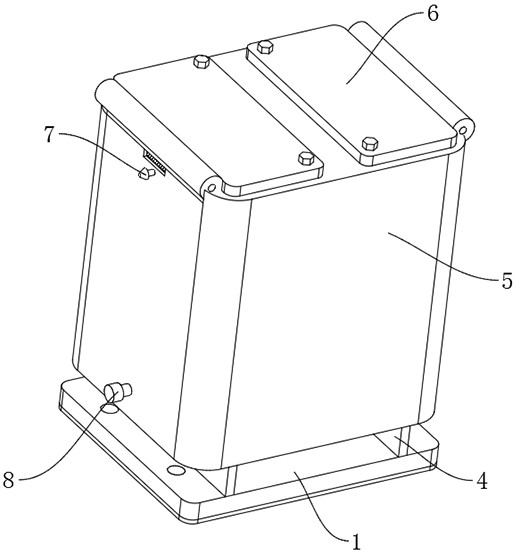

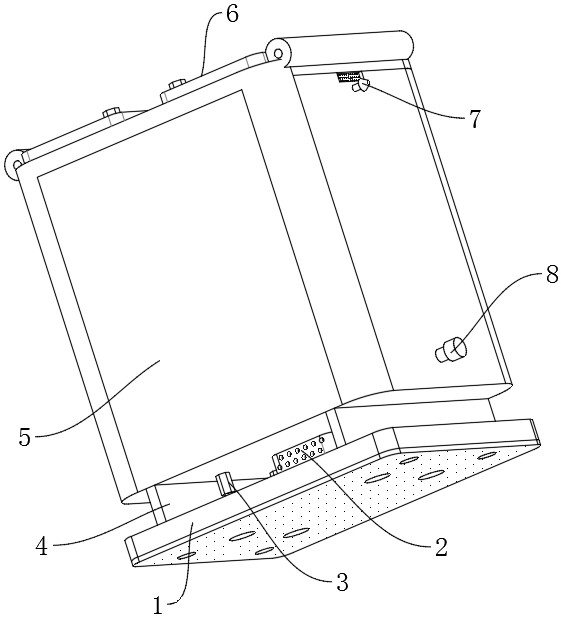

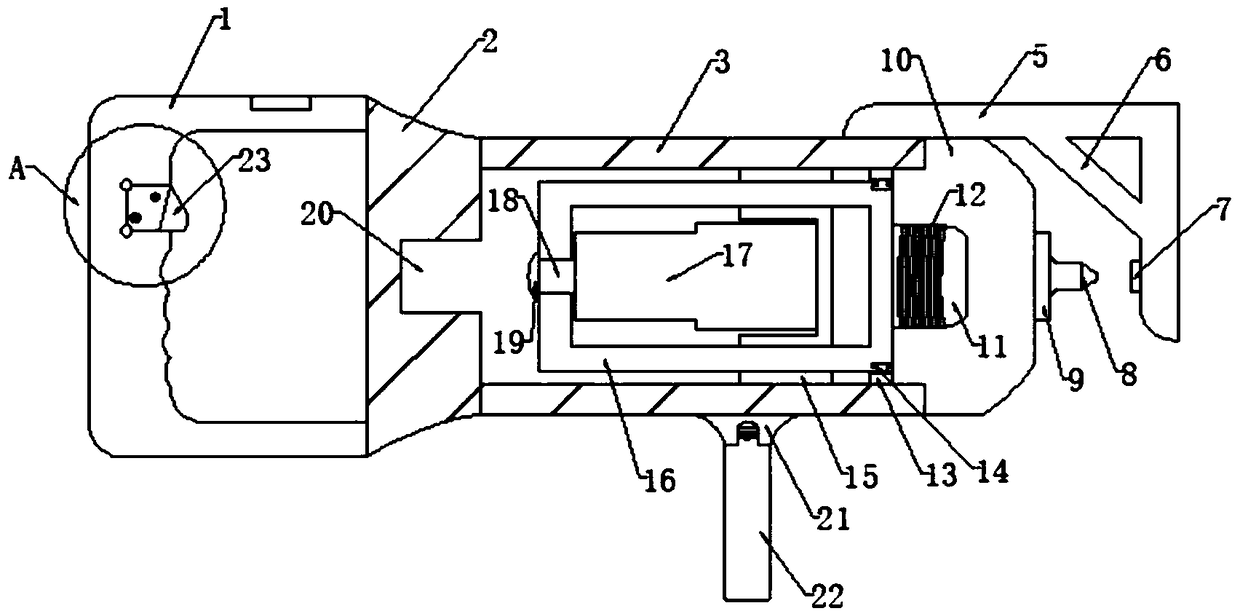

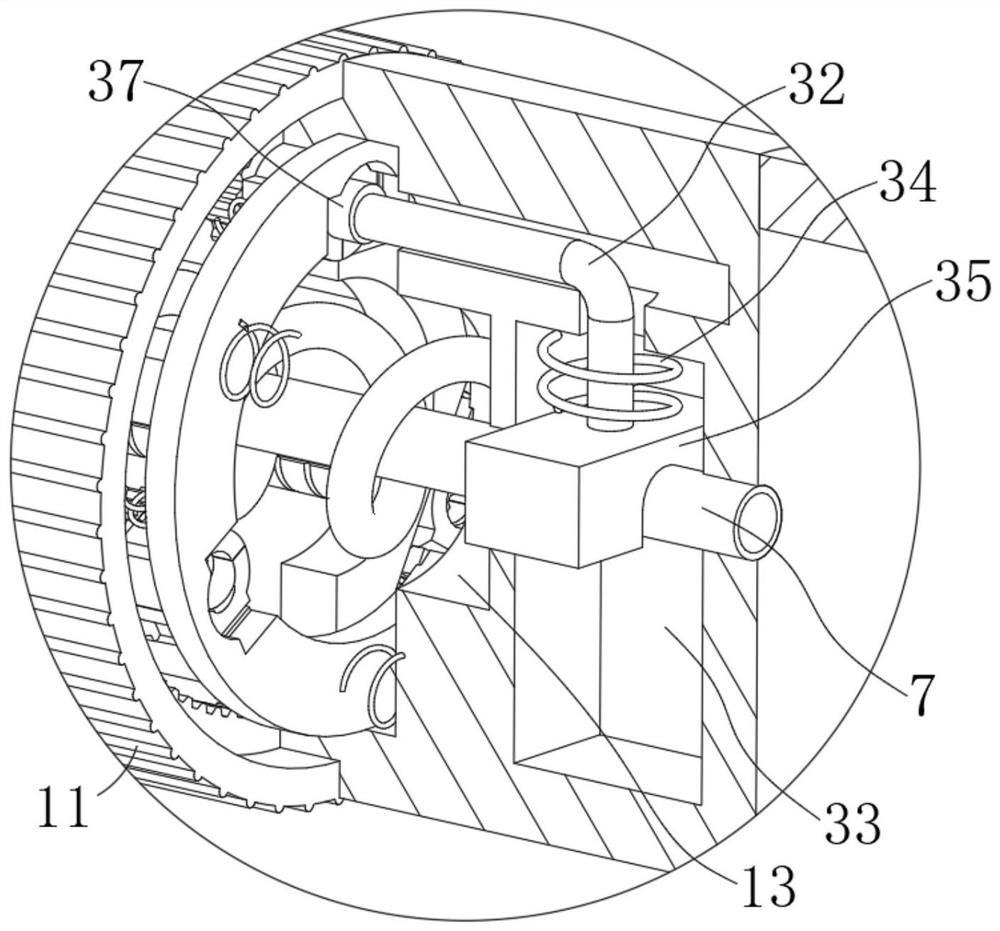

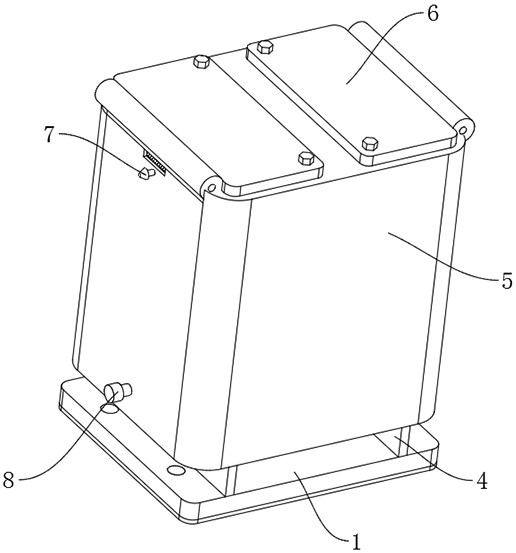

Intelligent storage device for grease storage

ActiveCN114212400AWith filter functionSolve the problem that is difficult to take outLarge containersTank wagonsOil and greaseLiquid state

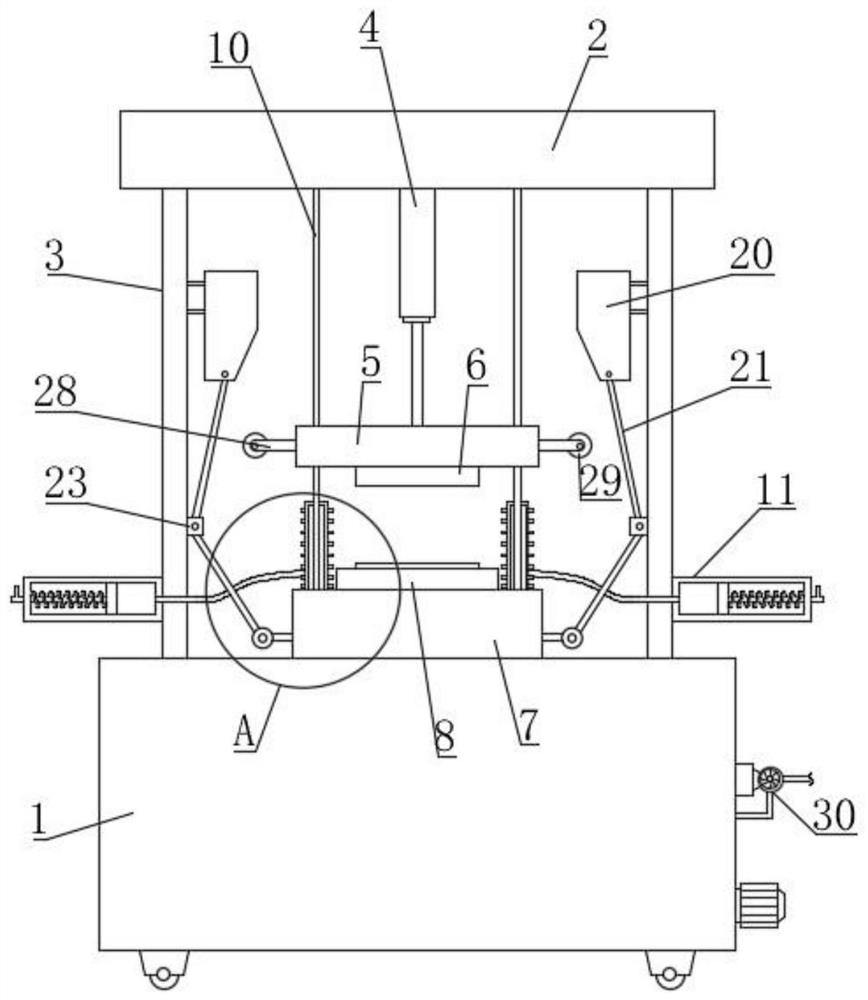

The invention relates to the technical field of grease storage, in particular to an intelligent storage device for grease storage, which comprises a bottom plate, a storage tank is mounted at the top of the bottom plate through a support plate, a moving mechanism is arranged at the bottom of the storage tank, a heating plate is mounted in the storage tank through a jacking mechanism, and a plurality of filter holes are formed in the heating plate. The outer wall of the heating plate is fixedly sleeved with a circle of rubber piston, the outer wall of the rubber piston abuts against the inner wall of the storage tank, and the top of the heating plate is connected with a heating assembly through a fixing column. The lard stored in the storage tank can be heated through the hot plate, the lard solidified into paste can be melted into liquid, the liquid lard is discharged through the discharging port, the problem that the lard is difficult to take out after being solidified in a traditional storage tank is solved, and after the liquid lard flows out of the storage tank, due to the liquid state of the lard, the lard is not prone to falling off. The lard adhered to the inner wall of the storage tank can be reduced, the lard preservation amount is guaranteed to the maximum extent, and excessive waste is avoided.

Owner:南通科达化工机械制造有限公司

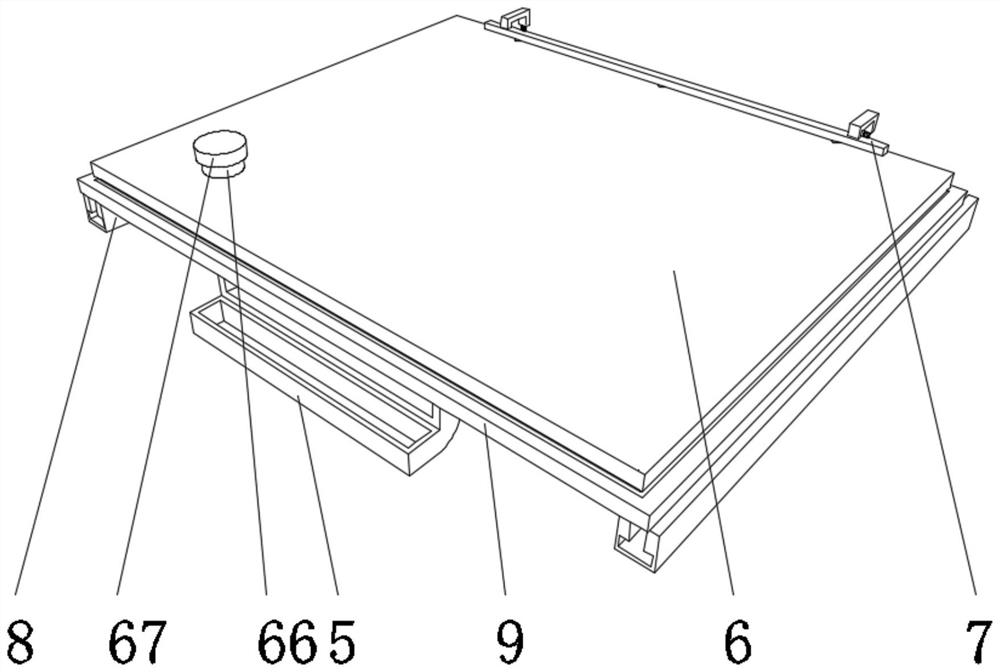

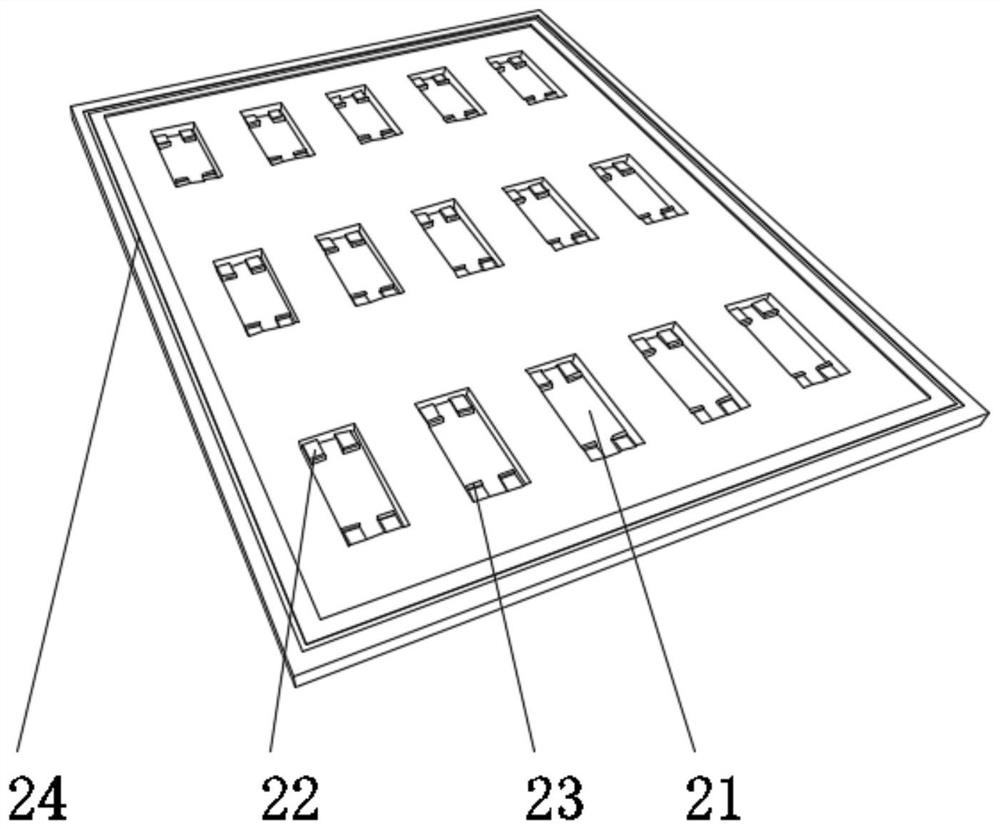

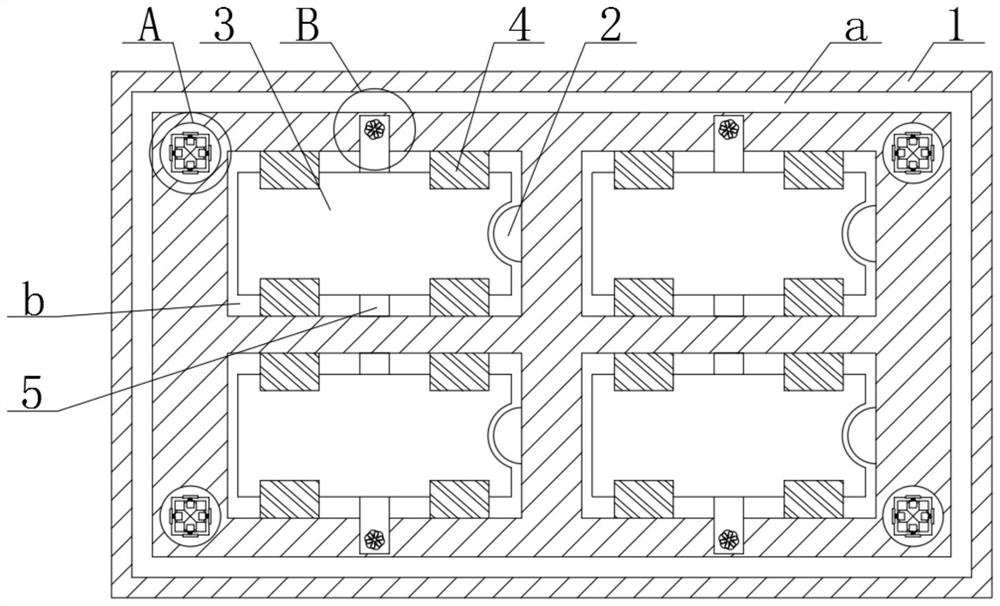

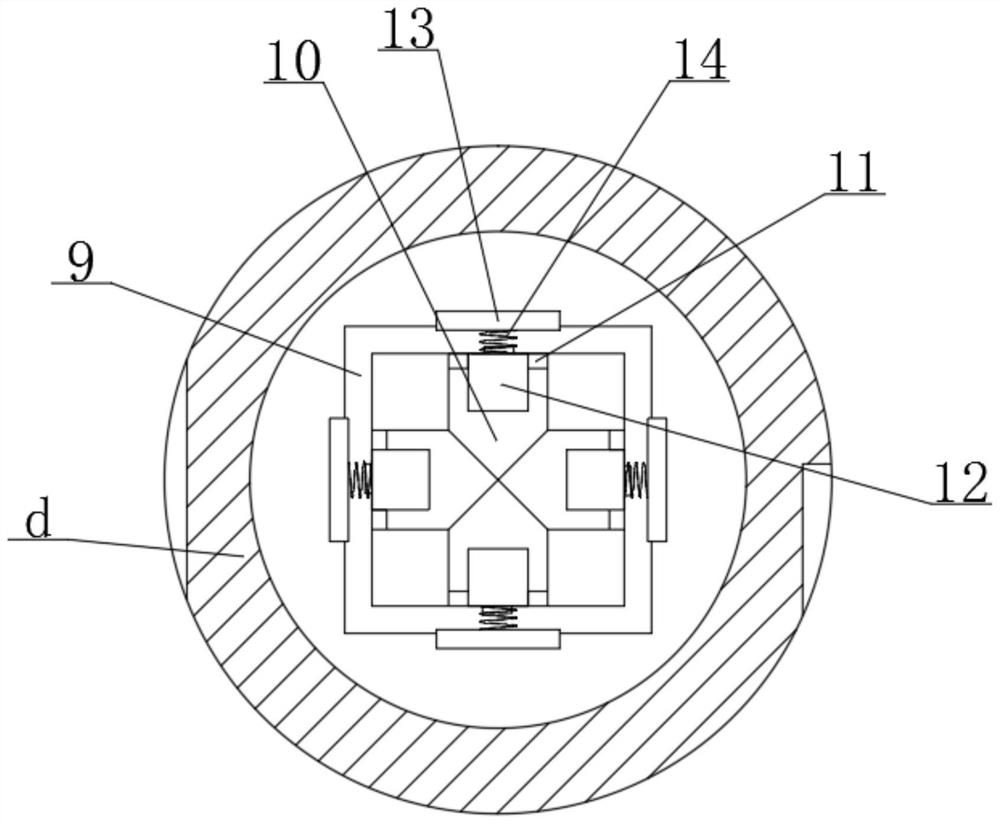

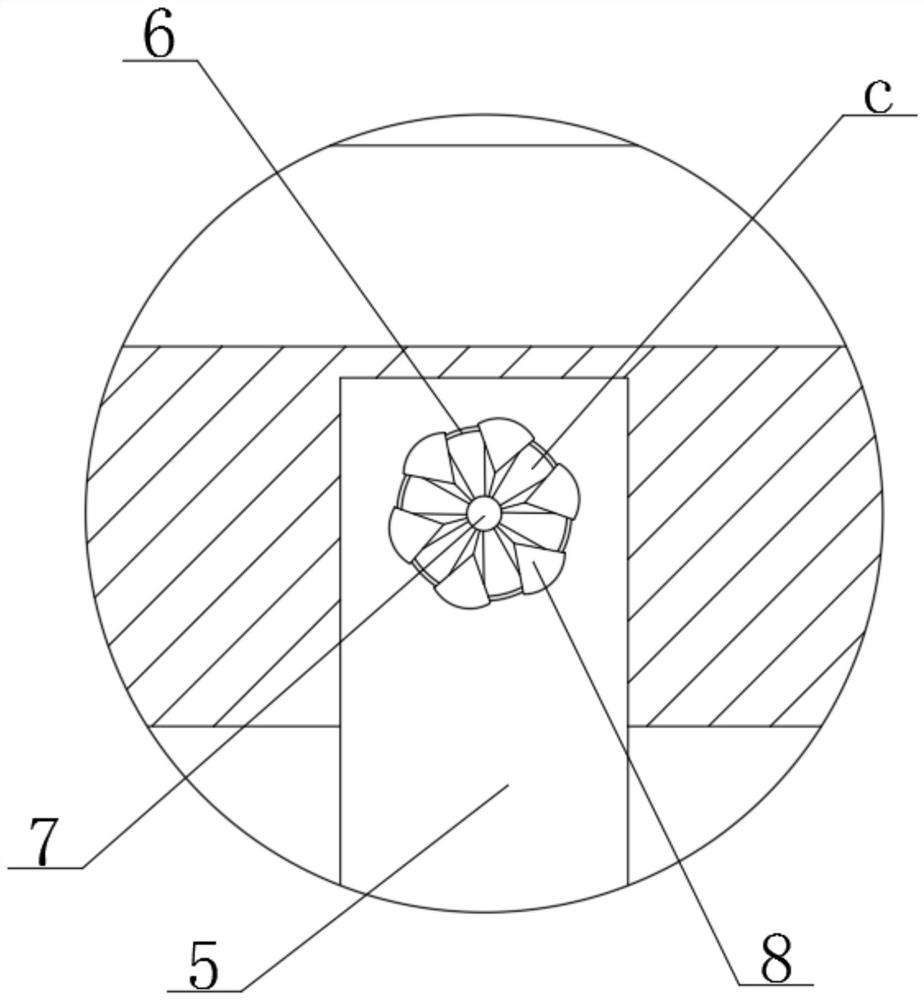

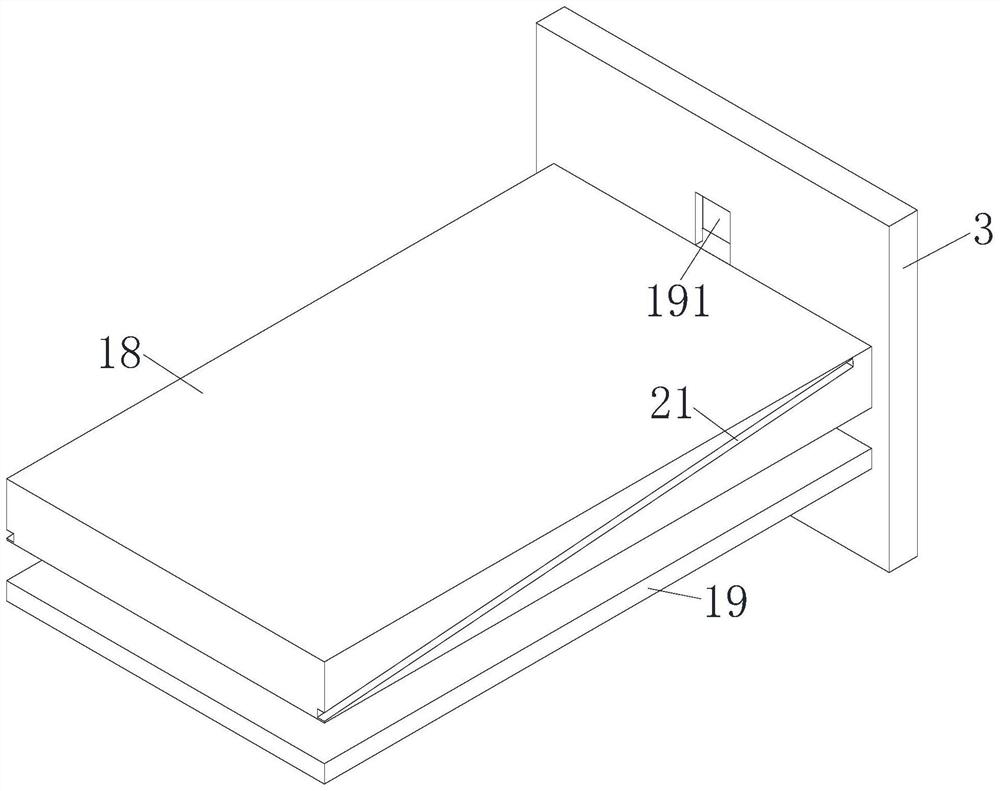

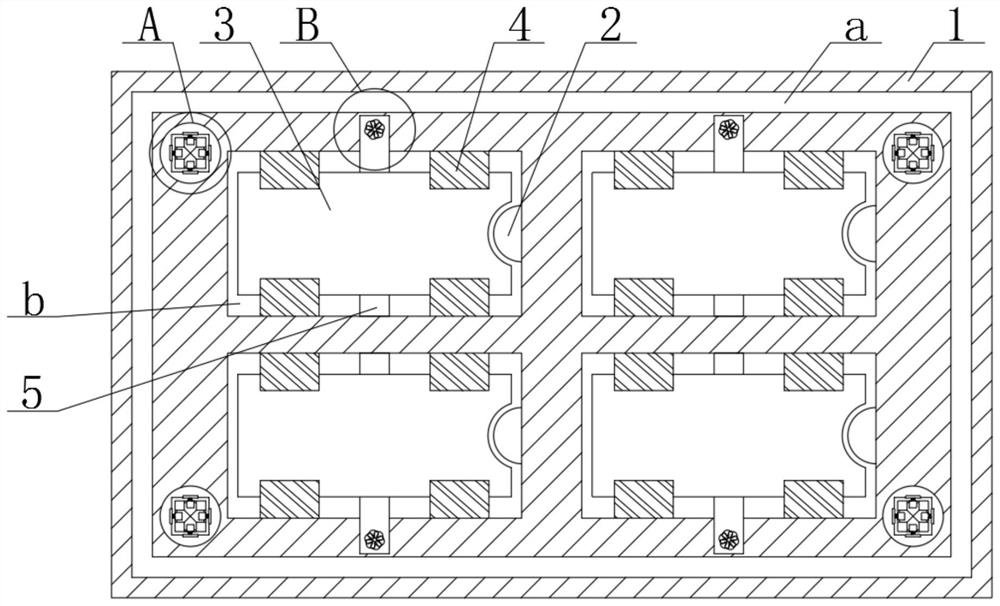

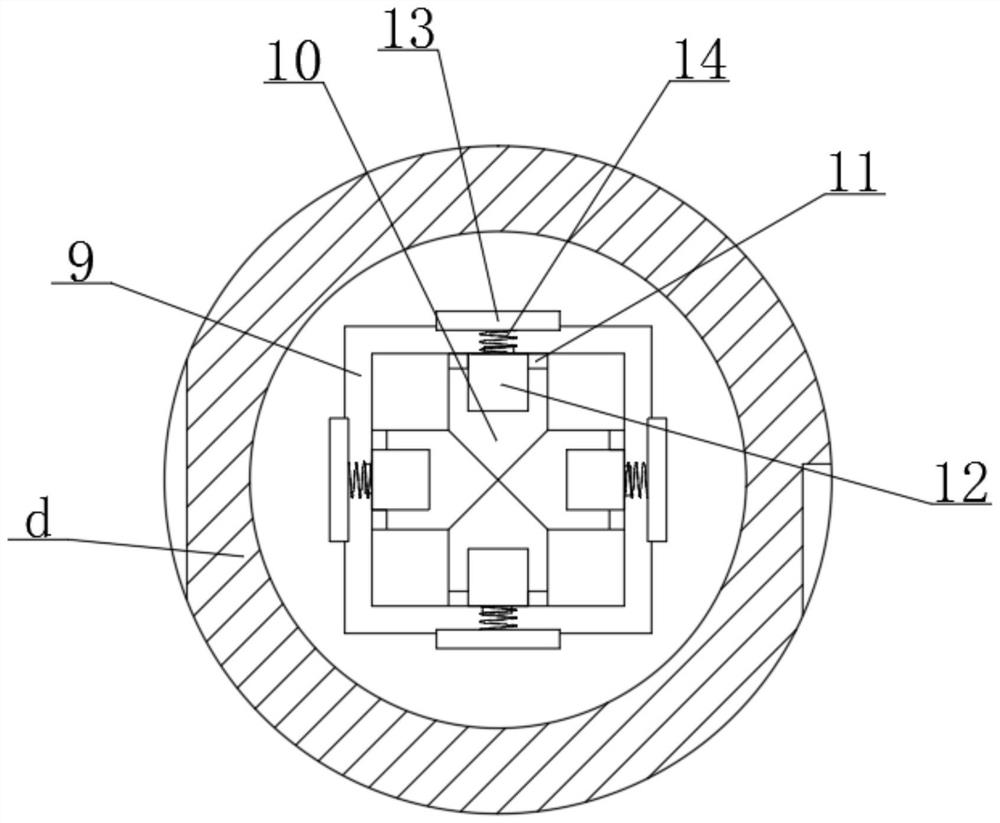

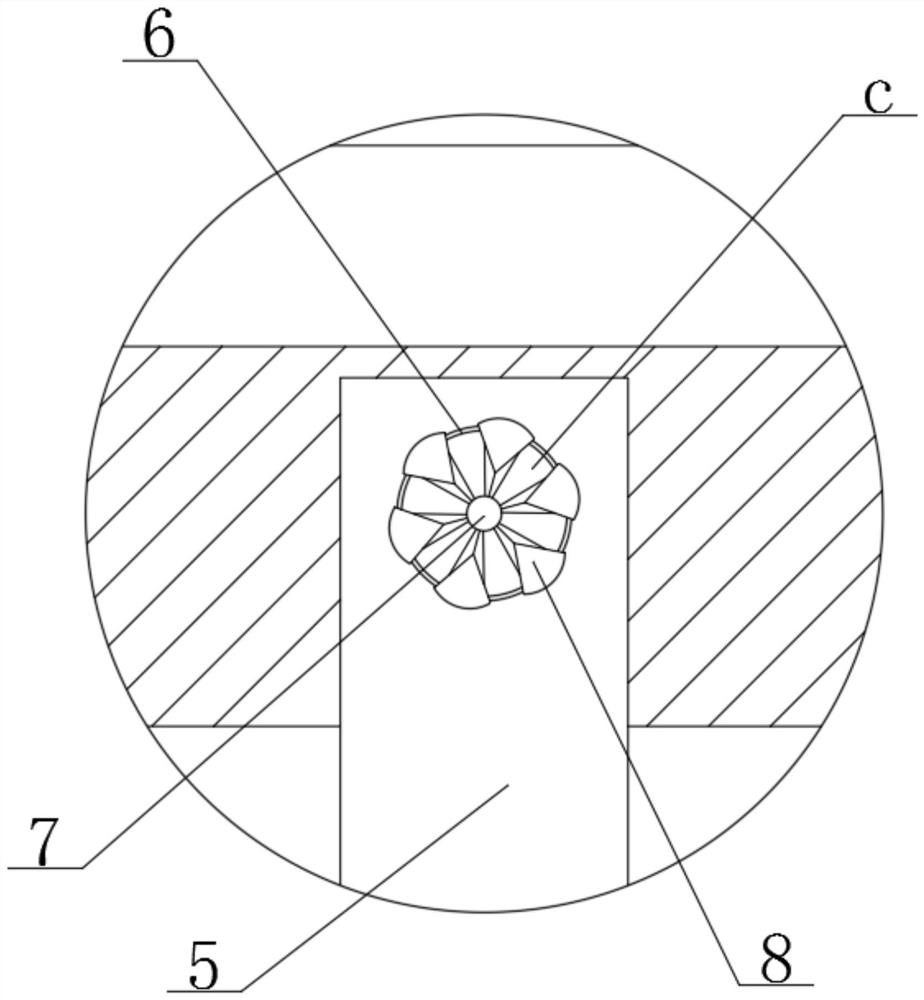

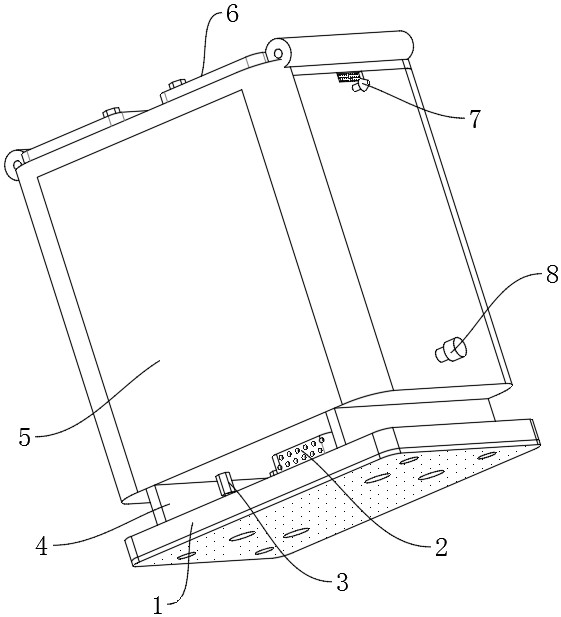

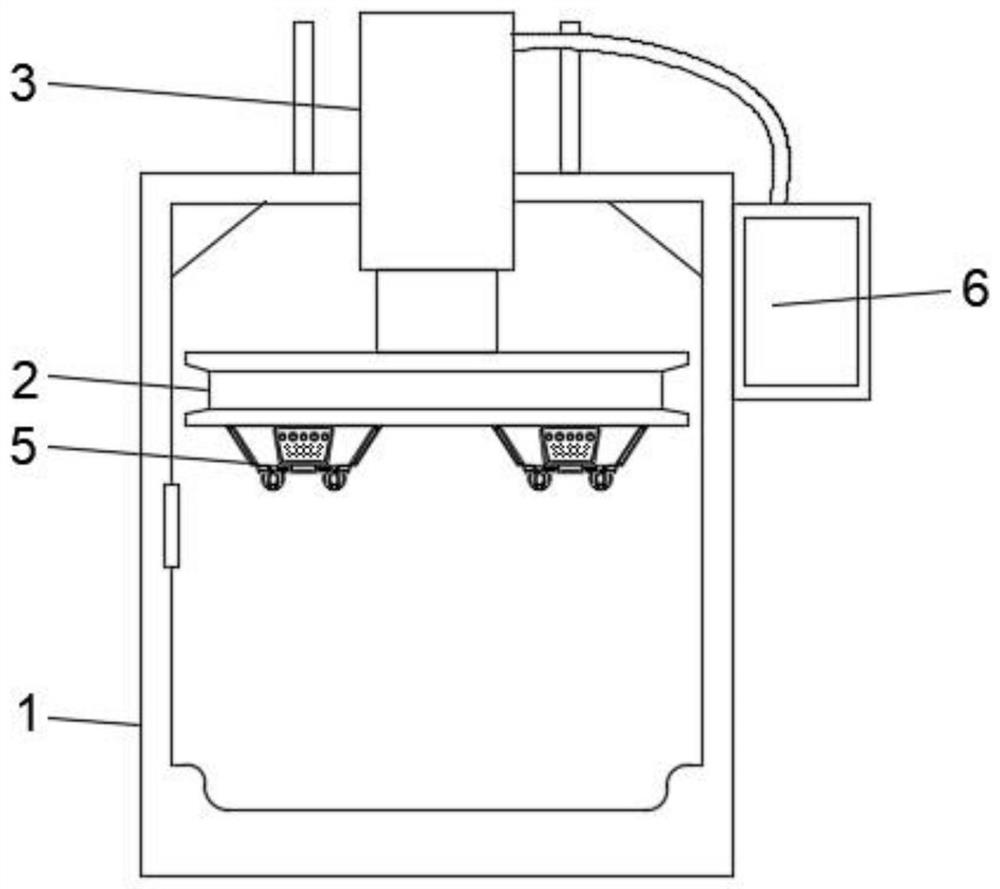

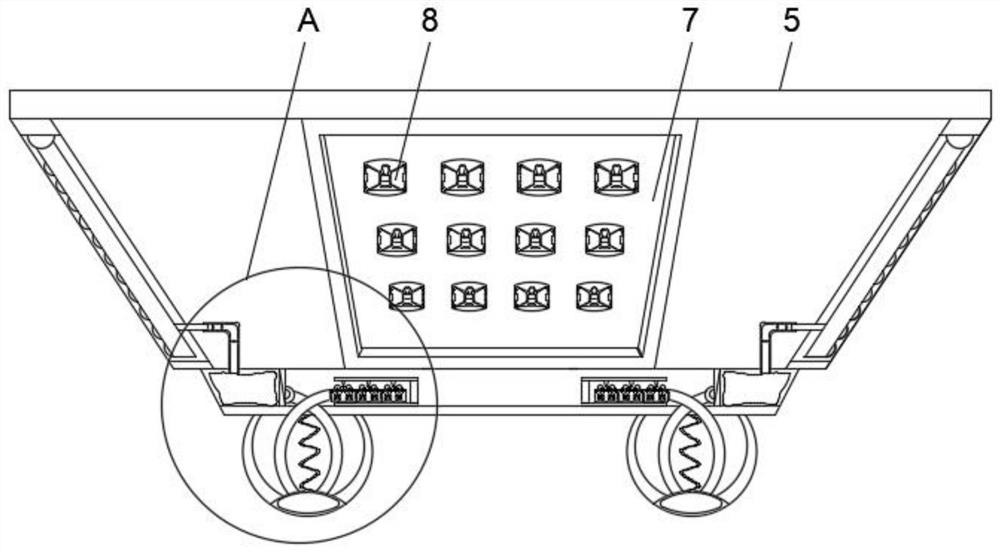

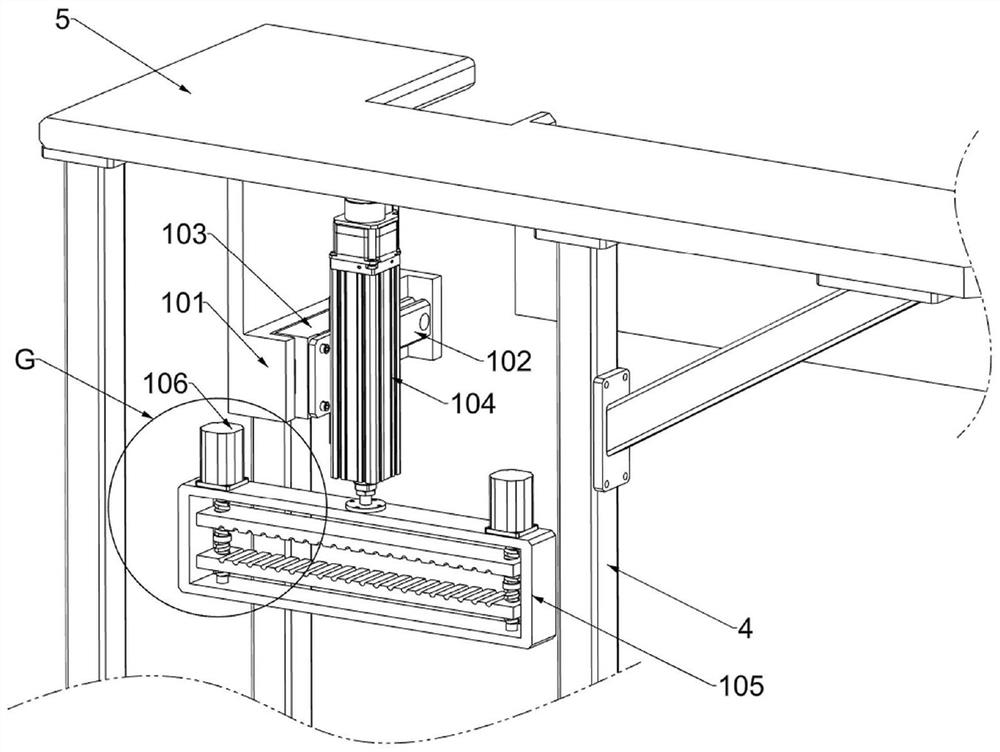

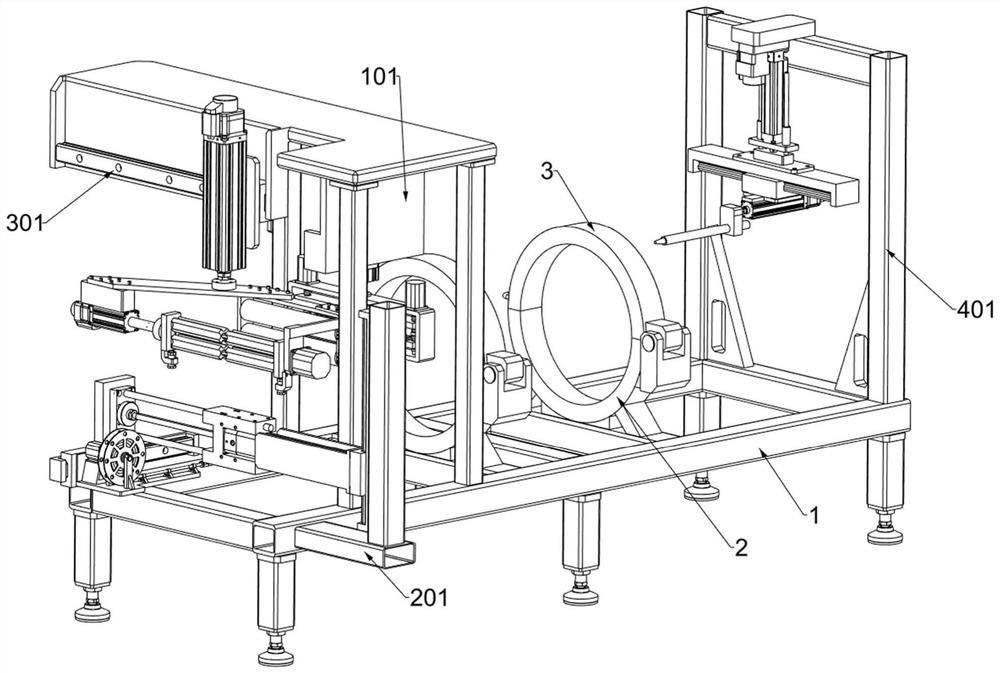

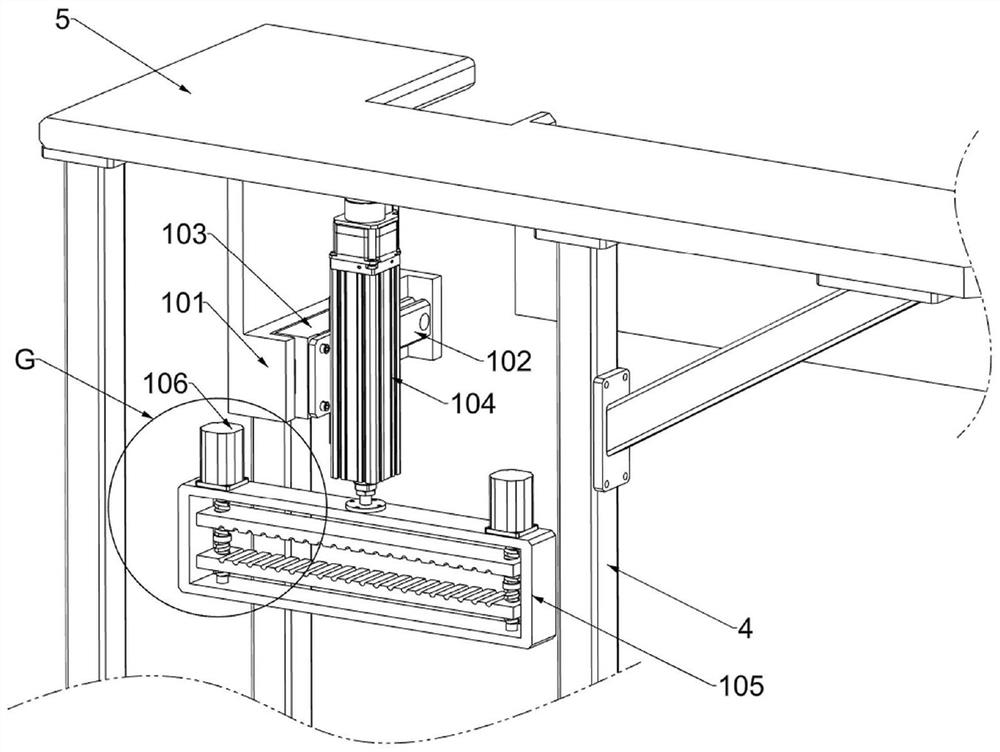

Vamp hot press molding equipment and use method thereof

InactiveCN113331540AReduce impactImprove the effect of thermoformingShoemaking devicesVibration suppression adjustmentsEngineeringMechanical engineering

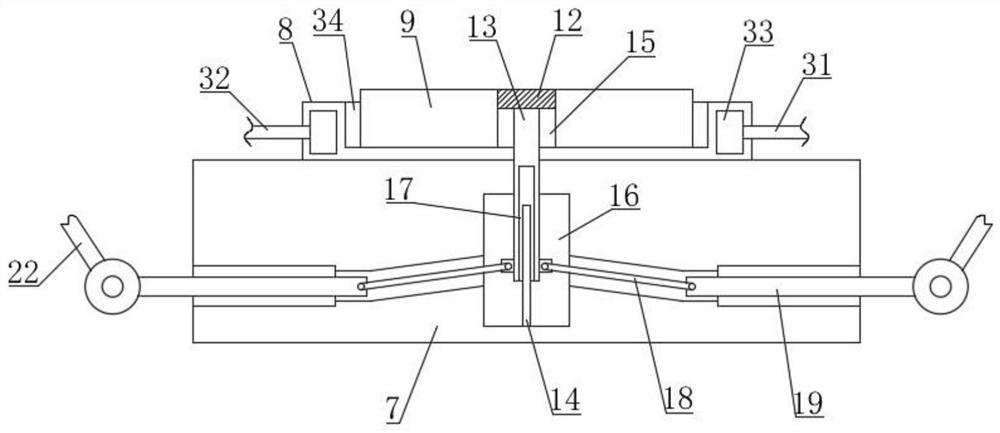

The invention belongs to the technical field of vamp processing, and aims to solve the problems that at present, after hot press molding, the temperatures of the surfaces of a vamp and a bearing plate are high, operators are easily scalded in the taking-out process, the vamp is inconvenient to take down, the vamp is easily adhered to the bearing plate due to hot press molding, and the vamp taking-out difficulty is further increased. The vamp hot press molding equipment comprises a fixing box, a pressing plate assembly and a bearing plate, a lifting air cylinder is installed at the bottom of a top plate, the bottom end of the lifting air cylinder is connected with a connecting base, the pressing plate assembly is installed at the bottom of the connecting base, a cooling table is installed at the top of the fixing box, a containing groove is formed in the cooling table, the bearing plate is located in the containing groove, and a groove is formed in the bearing plate. According to the vamp hot press molding equipment, the vamp can be rapidly cooled, harm to operators in the taking-out process is avoided, the vamp can be jacked up so that the vamp can be separated from the bearing plate, and the operators can take down the vamp conveniently.

Owner:阜阳和益鞋业有限公司

Soil pollution treatment equipment

PendingCN108555009ASolve the problem that is difficult to take outContaminated soil reclamationCasting moldPollution

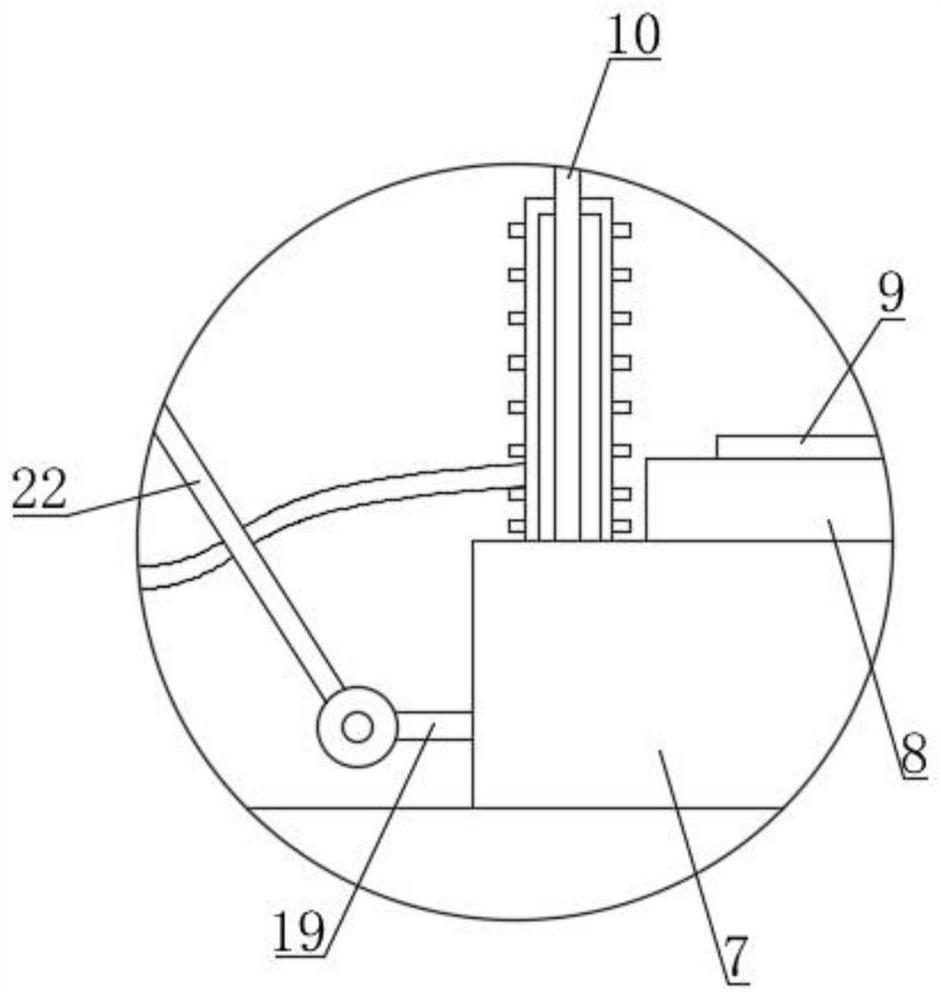

The invention discloses soil pollution treatment equipment in the field of soil pollution treatment equipment. The soil pollution treatment equipment comprises a treatment box and a casting mold mechanism, the casting mold mechanism comprises a supporting rod and a U-shaped casting mold barrel, a cavity is formed in the side wall of the casting mold barrel, feeding ports communicated with the cavity are formed in the side wall of the casting mold barrel, through holes communicated with the cavity are uniformly formed in the outer wall of the casting mold barrel, and the supporting rod is vertically disposed in the treatment box. The casting mold barrel is fixed to the end, away from the treatment box, of the supporting rod, a hinge rod is hinged to the supporting rod and located under thecasting mold barrel, and the length of the hinge rod is greater than the outer radius of the casting mold barrel. The inner wall of the treatment box sleeves an electromagnetic iron ring, the electromagnet ring is composed of multiple arc-shaped electromagnets, the treatment box is internally provided with a stirring shaft, the stirring shaft sleeves the supporting rod and is connected with a motor for driving the stirring shaft to rotate, and an outlet is formed in the bottom of the treatment box.

Owner:贵州杉海沿环保科技有限责任公司

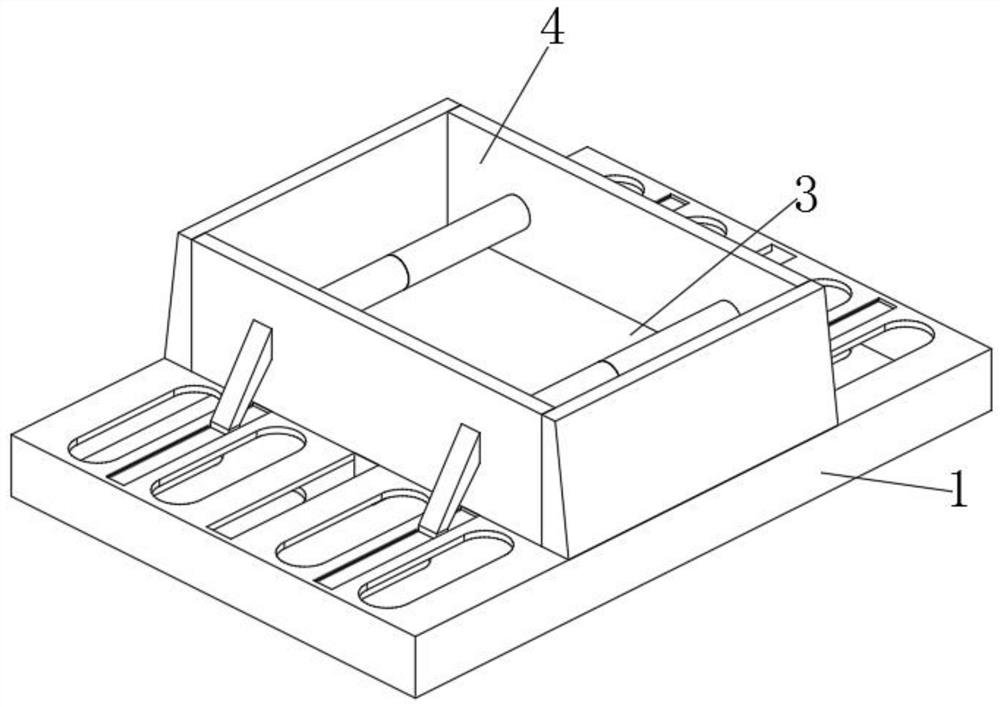

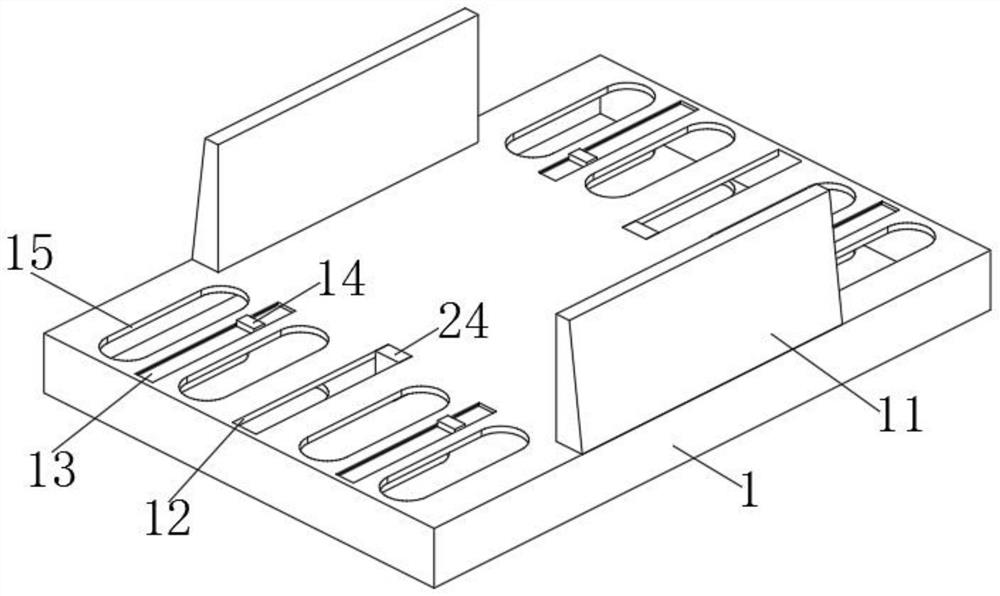

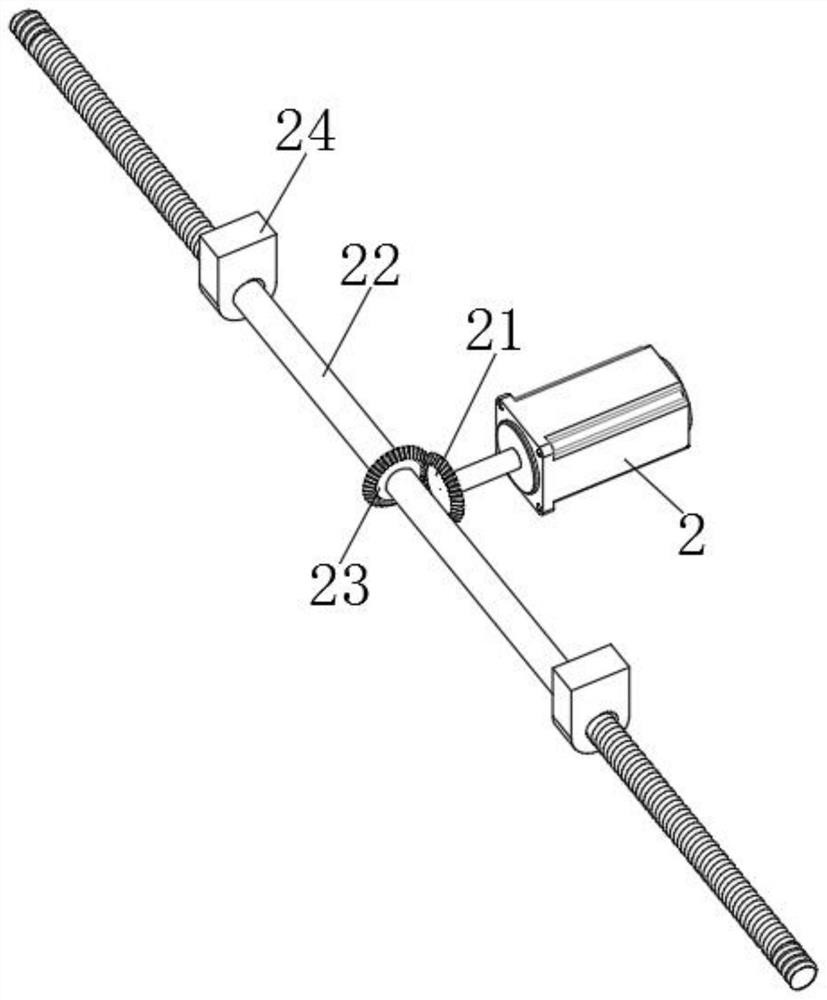

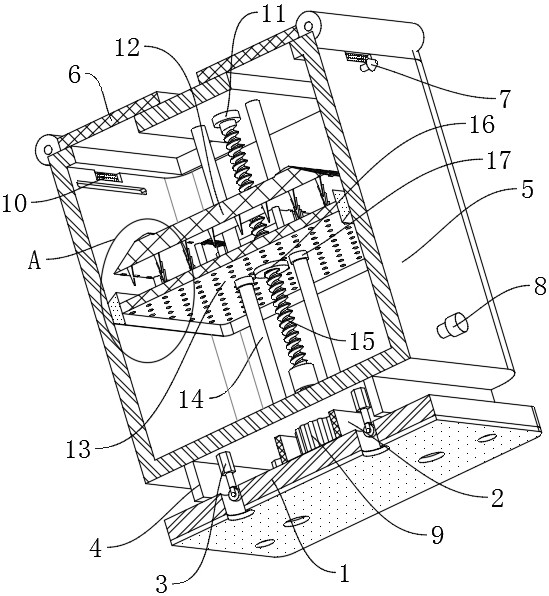

A molding device for the production of concrete block bricks

ActiveCN113119284BSolve the problem that is difficult to take outAvoid drillingMouldsBrickArchitectural engineering

The present invention relates to the technical field of concrete, in particular to a molding device for the production of concrete block bricks, which includes two side plates that can approach or move away from each other and two fixed plates that are perpendicular to the side plates. The side plate, the fixed plate and a supporting plate can form a sealed mold cavity, all of which are arranged above the bottom plate, and the top surface and the bottom surface of the bottom plate are provided with a plurality of strip-shaped through holes corresponding to each other. Used to clean up sundries in the production process. In the present invention, by using the servo motor to drive the two side plates to separate automatically, the problem that the traditional mold side plate is difficult to take out after the concrete block brick is formed is solved, and, through the mutual approach or separation of the two side plates, Two cylinders can be formed in the inner cavity of the mold, so that holes will appear on the brick body after the concrete is cooled, which reduces the operation steps, saves costs and avoids damage to the strength of the brick body itself caused by punching holes after forming.

Owner:安徽省友邦混凝土有限公司

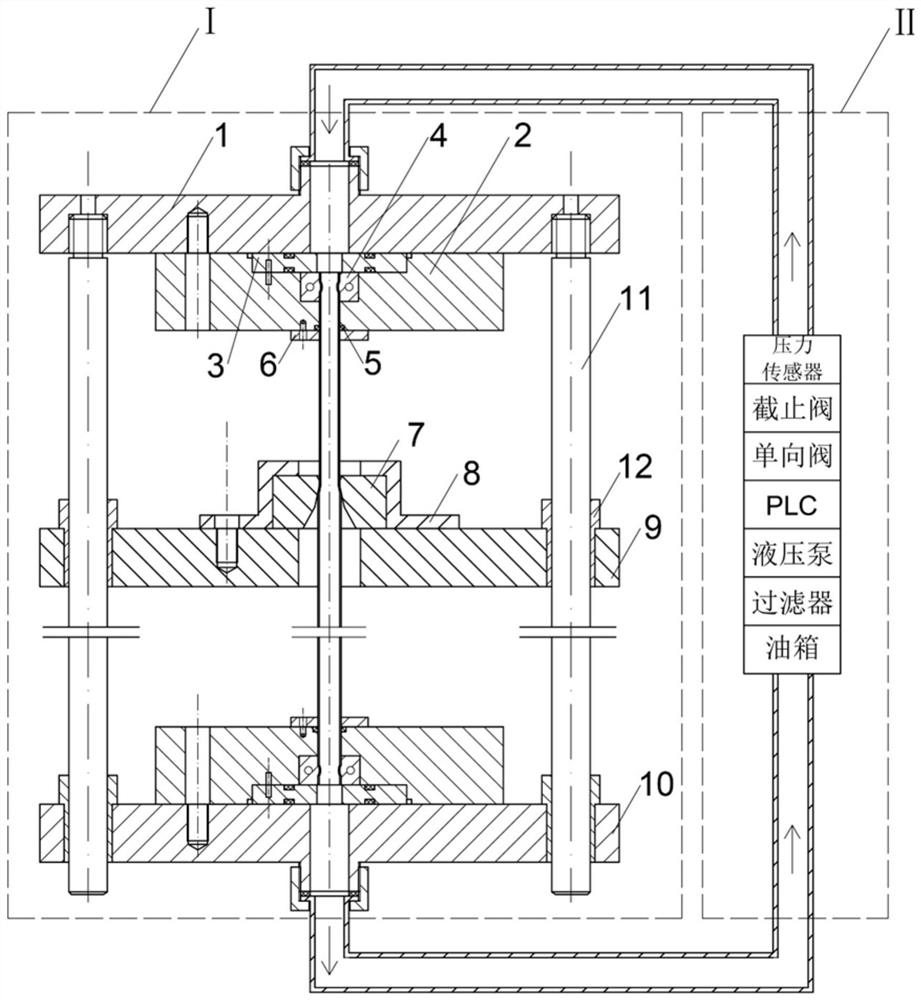

Hydraulic drive type filter press and filter pressing method

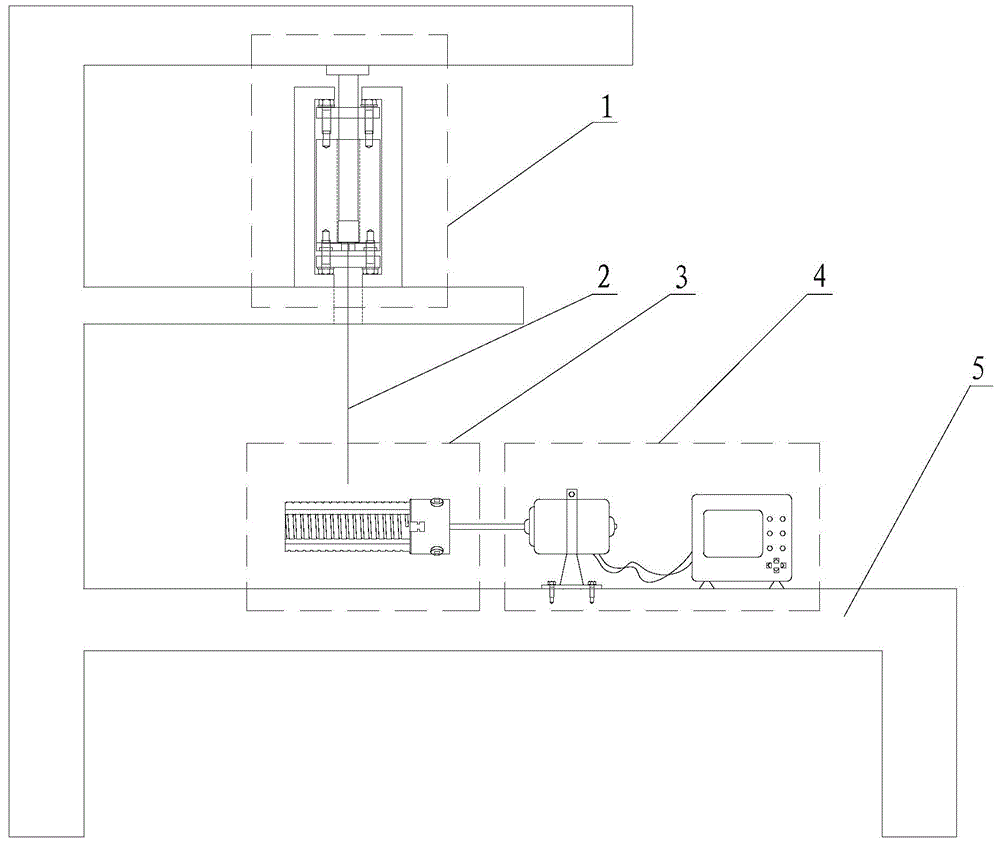

InactiveCN113617088ASolve the problem that is difficult to take outEfficient and quick cleaningStationary filtering element filtersHydraulic cylinderElectric machinery

The invention discloses a hydraulic drive type filter press and filter pressing method. The hydraulic drive type filter press comprises a frame, an oil tank, an oil pump, a hydraulic cylinder, a feeding port valve, a discharging port valve and a liquid outlet valve, the oil tank and the oil pump are installed outside the top end of the frame, and the oil tank, the oil pump and the hydraulic cylinder are communicated through oil pipes. By arranging a motor, a push plate, a pressing plate and a stirring rod, the push plate drives the pressing plate to synchronously rotate through the stirring rod, the stirring rod stirs and crushes a filter cake subjected to filter pressing, and the crushed filter cake flows out of a discharge port; and when the output shaft of the hydraulic cylinder retracts, certain friction force between the stirring rod and the pressing plate makes the pressing plate move synchronously, the pressing plate moves to a certain position and stops, and the stirring rod is drawn out from a through groove in the surface of the pressing plate, so that residues adhered to the surface of the stirring rod are scraped, the problem that filter cakes subjected to filter pressing of an existing filter press are difficult to take out can be effectively solved, and the filter press is faster and more efficient than manual cleaning.

Owner:芜湖市海川矿业有限公司

Automatic press riveting machine specially applied to aircraft combination and installation

The invention discloses an automatic press riveting machine specially applied to aircraft combination and installation. The machine comprises a handle, a connecting block, a press riveting machine shell, a press riveting head and a press riveting pad, wherein the handle is in a left-square-bracket shape, a press riveting switch is arranged on the inner side of the handle, the connecting block is arranged on one side of the handle, the handle is tightly welded and fixed to the connecting block, one end of the connecting block is provided with the press riveting machine shell, the connecting block is tightly welded and fixed to the press riveting machine shell, and the press riveting head is arranged at one end of the press riveting machine shell. The press riveting pad is arranged on one side of the press riveting machine shell, the press riveting pad is a movable pad, and an L-shaped sliding groove is formed in one side of the press riveting machine shell. The press riveting cushion isembedded into the press riveting machine shell through the sliding groove and is tightly attached and fixed to the press riveting machine shell. The automatic press riveting machine specially appliedto aircraft combination and installation can achieve handheld press riveting so that a part of complex or large parts can be subjected to press riveting by moving the press riveting machine, and combination and installation are facilitated for workers.

Owner:晨龙飞机(荆门)有限公司

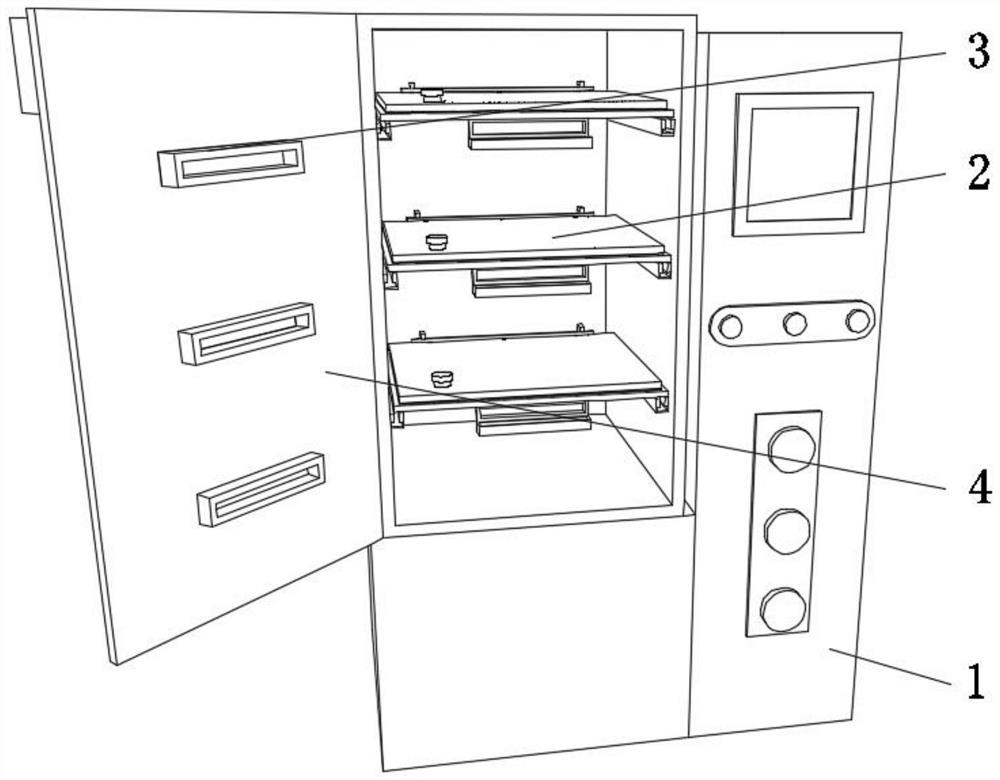

Optical module low-temperature performance testing device

PendingCN113884279AReduce waiting timeImprove test efficiencyOptical apparatus testingPhotovoltaic energy generationPhysicsActivated carbon

An optical module low-temperature performance testing device disclosed by the present invention comprises a high and low-temperature aging machine body, a storage assembly arranged in the high and low-temperature aging machine body and a cover body arranged above the storage assembly, the storage assembly comprises storage grooves and a supporting blocks arranged in the storage grooves, adsorption grooves are formed in the cover body, any two adsorption grooves are connected through a flow channel. The invention specifically relates to the technical field of optical module testing. According to the optical module low-temperature performance testing device, by arranging the cover body, when the high-low temperature aging machine body works, activated carbon is added into the cover body through a feeding port, and then the cover body is elastically shaken through the springs, so that the activated carbon is uniformly distributed in the storage grooves, and the interiors of the storage grooves can be dried; the damage to the optical module caused by frost solidification and frost liquefaction into water is avoided, and meanwhile the problem that the optical module is frozen in the storage grooves and is difficult to take out is solved.

Owner:WUHAN DONGHU UNIV

Packaging box provided with convenient hard disc pick-and-place function as well as used for computer hard disc production and packaging

InactiveCN112849684ASolve the problem that is difficult to take outEasy to fixRigid containersInternal fittingsEngineeringMechanical engineering

The invention relates to the technical field of packaging boxes, in particular to a packaging box provided with a convenient hard disc pick-and-place function as well as used for computer hard disc production and packaging. The packaging box comprises a packaging box body, wherein a clamping groove is formed in the front end surface of the packaging box body; placing grooves are formed in the front end surface of the packaging box body; limiting blocks are fixedly connected with the left ends of the inner side walls of the placing grooves; elastic sheets are fixedly connected with both the top ends and the bottom ends of the inner side walls of the placing grooves; hard discs are arranged in the placing grooves; pulling ropes are fixedly connected with the bottom ends of the inner wall sides of the placing grooves; clamping rings are fixedly connected with the inner sides of the pulling ropes; mounting holes are formed in one side of the packaging box body; connecting blocks are fixedly connected with the front end surface of the packaging box body; and clips are fixedly connected with the front ends of the connecting blocks. Through the arranged elastic sheets, pulling ropes, clamping rings and clips, the packaging operation and the fixing operation are quite convenient, the packaging efficiency of the packaging box is greatly improved, and the problem that the hard discs in the packaging box body are difficult to pick up is solved; and the packaging box is quite convenient to use, simple to operate, simple in process and relatively low in cost.

Owner:陕西优民惠科技有限公司

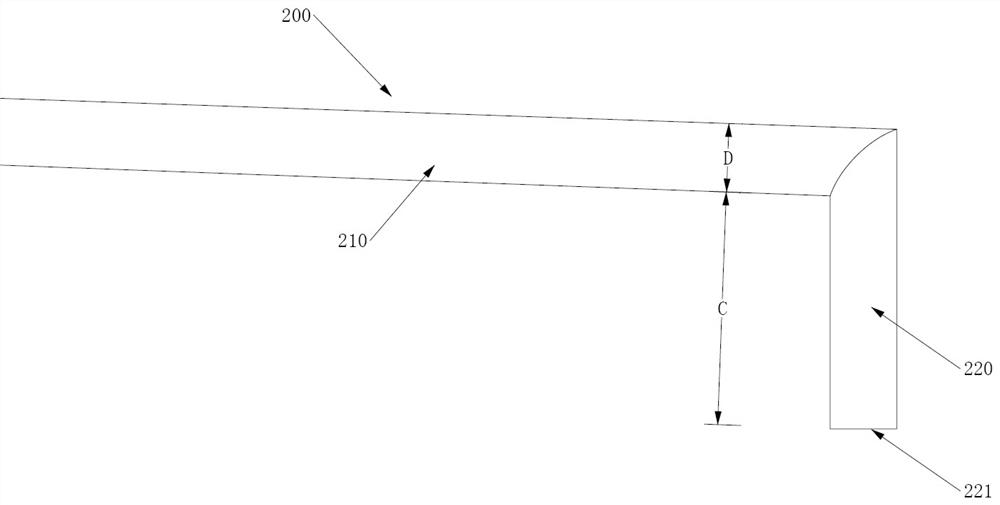

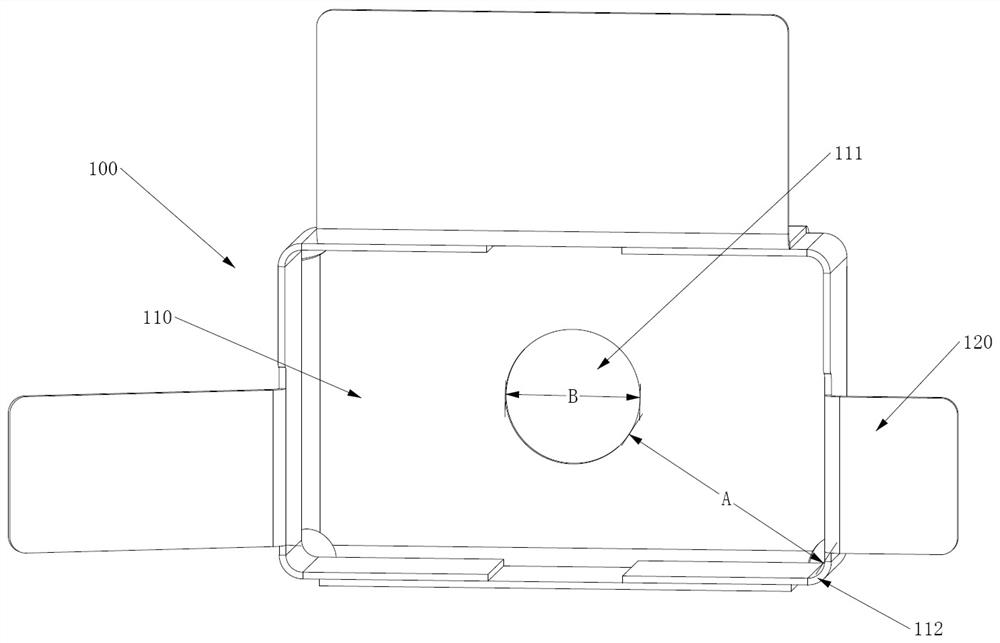

Support brackets, picking workpieces, and vehicle dashboards

ActiveCN106915258BWill not affect the bearing strengthSolve the problem that is difficult to take outDashboardsMetal-working hand toolsDashboardInterior space

Disclosed are a support frame, a pick-up workpiece and a vehicle dashboard. The support frame (100) comprises: a support main body (110) forming an enclosed internal space, and a processing through hole (111) provided on a first surface of the support main body (110), the processing through hole (111) being used for a pick-up workpiece (200) and / or a fastening workpiece to pass through, wherein the maximum size of the processing through hole (111) is B, the processing size of the support frame (100) is b, the maximum size of the pick-up workpiece (200) passing through the processing through hole (111) is L, and the maximum size of the fastening workpiece is l; and B-b ≥ L+l. In the support frame (100), by designing a specific size for each part or each element, various types of fastening workpieces accidentally dropped into the enclosed internal space of the support frame (110) can be extracted therefrom under any extreme scenario, solving the problem of the difficulty in extracting dropped components, while also ensuring that the size of the processing through hole (111) does not affect the bearing strength of the support frame (100), maintaining the original technical effect thereof.

Owner:NIO CO LTD

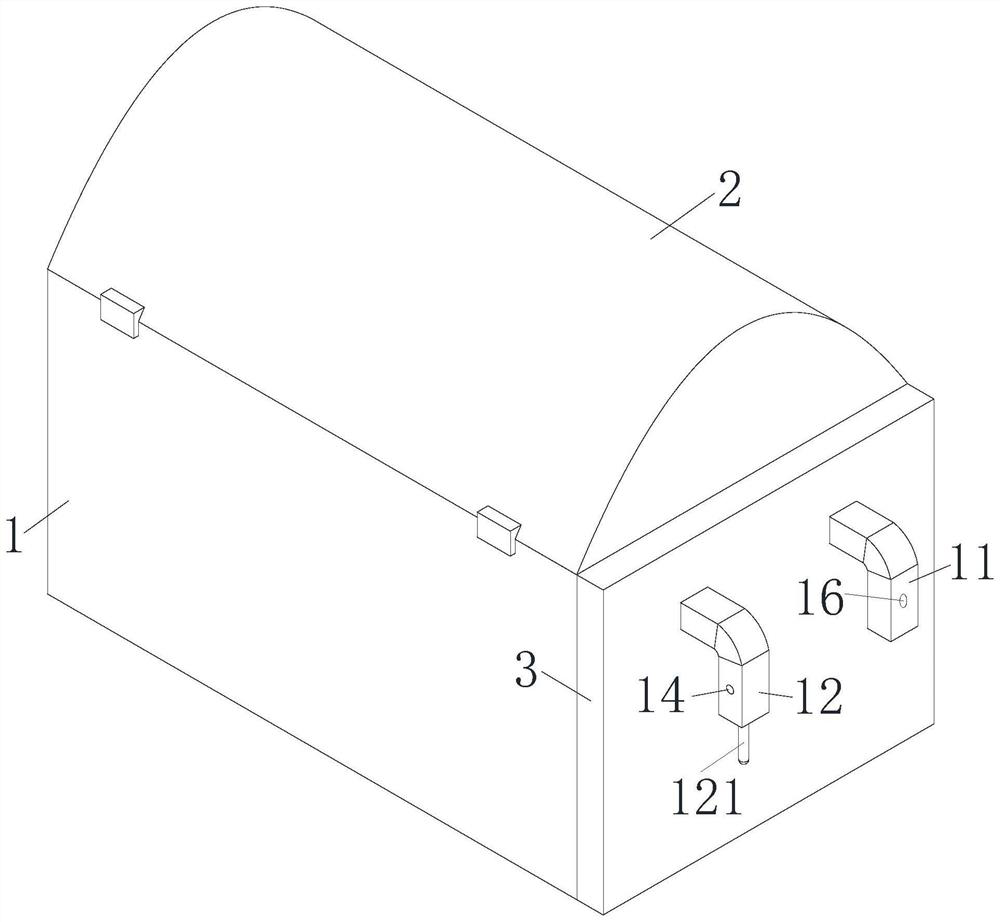

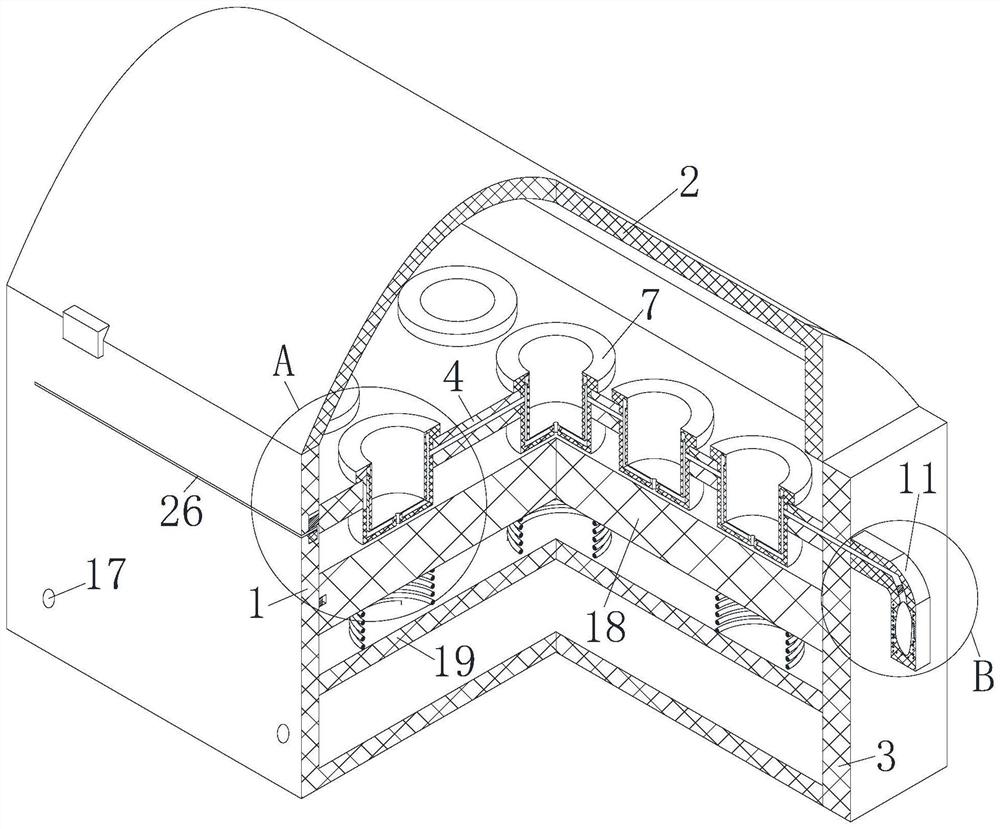

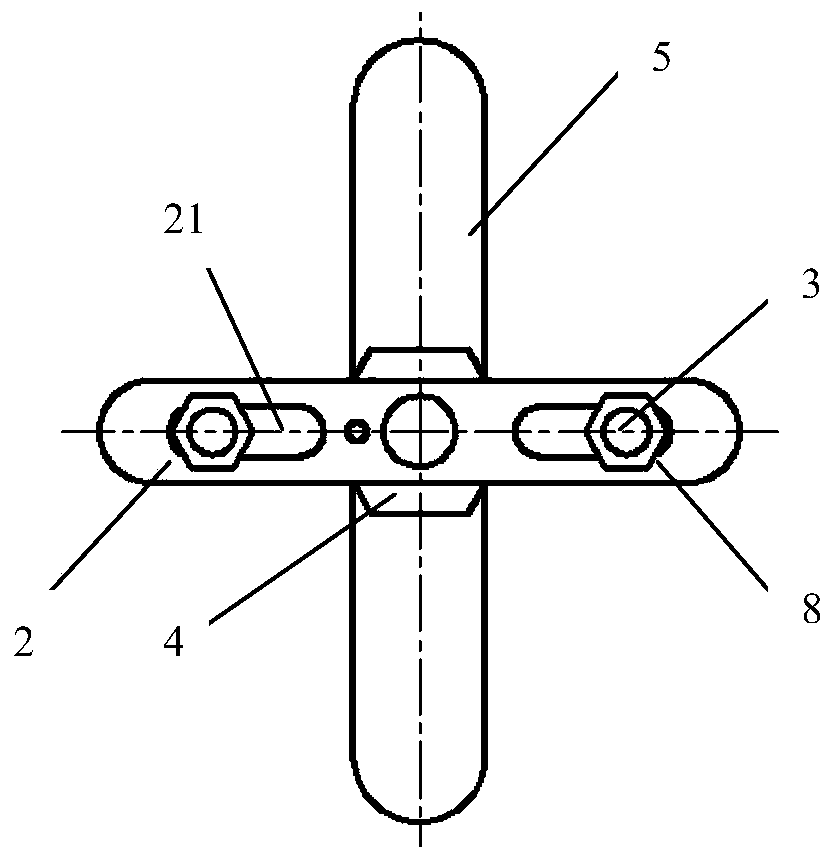

Screw insulating device for six-surface top press

The invention relates to the technical field of insulation, in particular to a screw insulating device for a six-surface top press. The screw insulating device for the six-surface top press comprisesa six-surface top press screw, a protective cover body and a protective top cover; a diassembling hole is formed at the center position of the upper surface of the protective top cover; the protectivecover body comprises a first semi-cylindrical protective cover and a second semi-cylindrical protective cover; and the protective cover body is formed by mutually embedding the first semi-cylindricalprotective cover and the second semi-cylindrical protective cover. The connecting screw can be integrally protected through cooperation of the protective cover body and the protective top cover, particularly comprehensive closed protection on the screw head can avoid shortcircuit of the screw head by metal foreign body lapping; through cooperation of multiple groups of embedded teeth and cavities, the stress generated when the six-surface top press works can be effectively dispersed, so that the service life of an insulating device is prolonged; meanwhile, the insulating device adopts an integrated structure, so that the problem in the traditional insulating structure that a screw rod insulating sleeve is taken out of a big cushion block difficultly after being stressed to deform is solved and accessories are convenient to change.

Owner:SF DIAMOND CO LTD

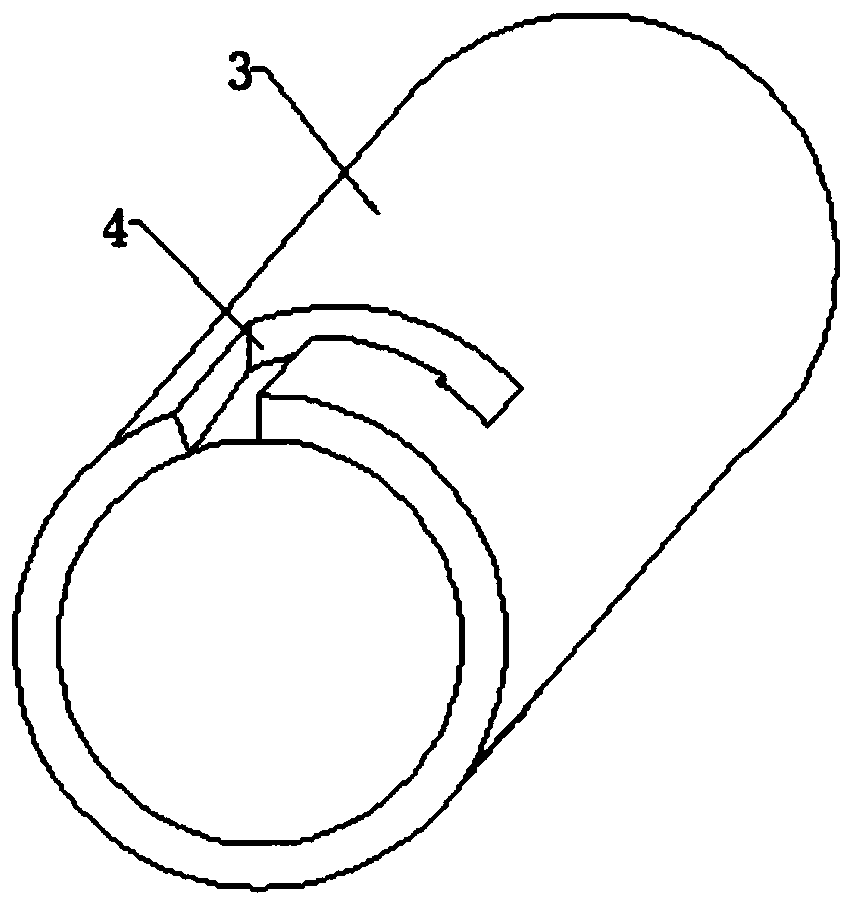

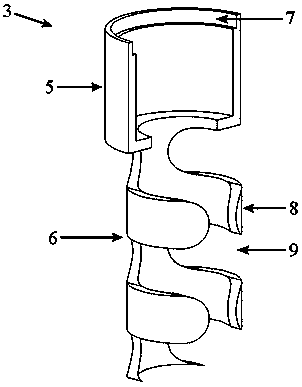

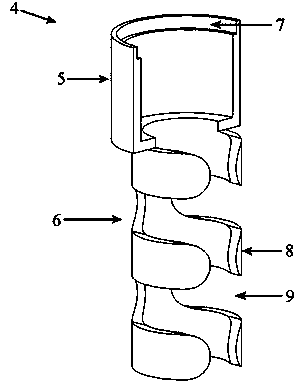

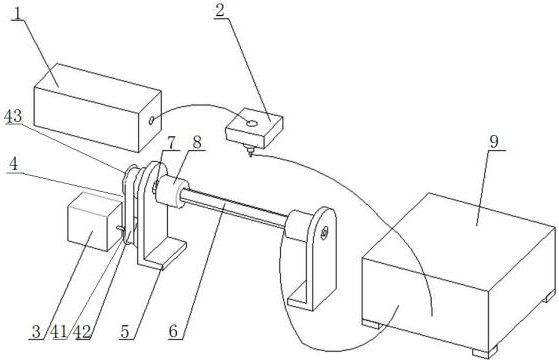

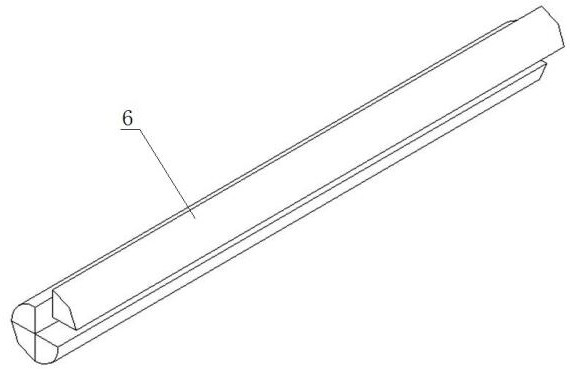

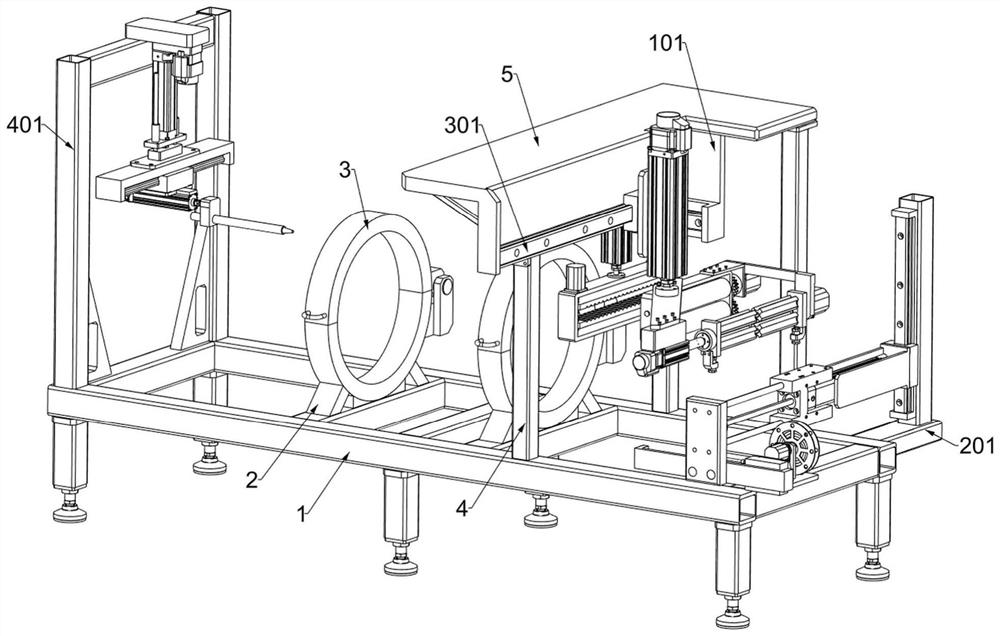

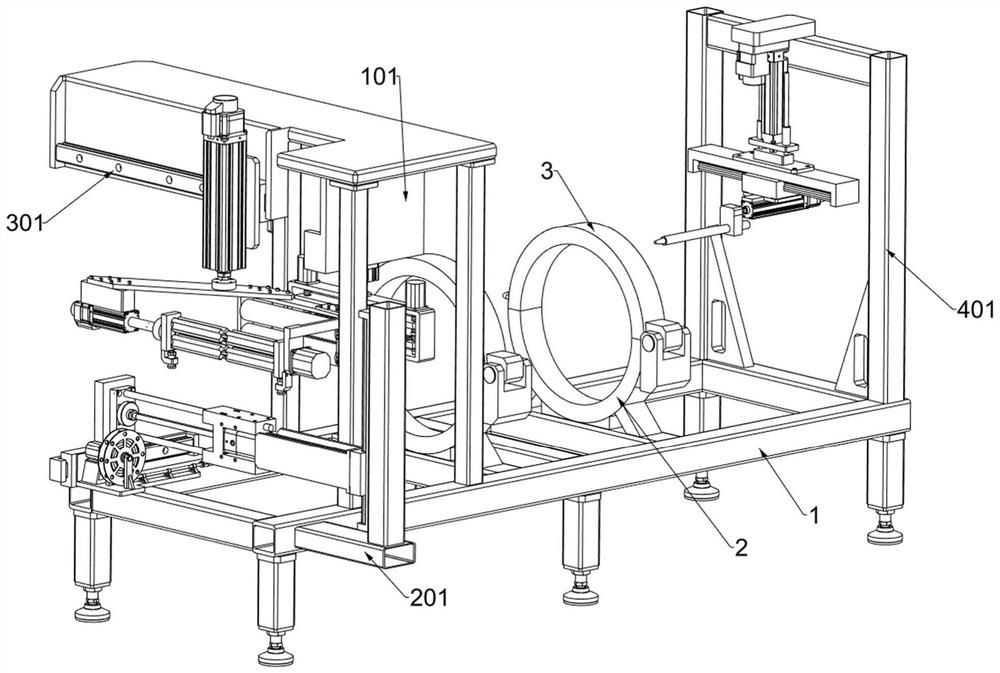

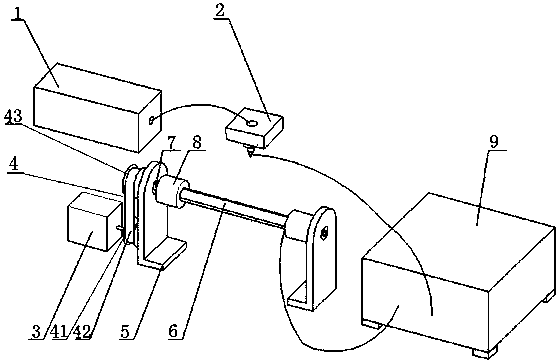

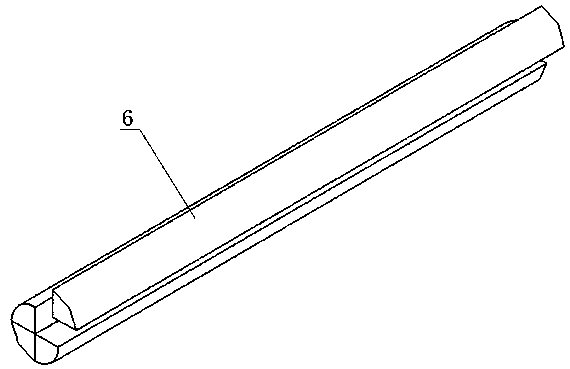

Electrospinning tubular stent collection device and electrospinning equipment

ActiveCN108866645BSolve the problem that is difficult to take outEasy to take outFilament/thread formingSpinningCoupling

The present invention relates to the technical field of electrospinning, more specifically, to an electrospinning tubular support collection device and electrospinning equipment, including a support frame and a collector rotatably connected to the support frame, and the collector includes a split tubular structure and a Coupling used to constrain the split tubular structure, the coupling is detachably connected to both ends of the split tubular structure; one end of the split tubular structure is connected to a transmission mechanism, and the transmission mechanism is connected to a drive motor; the split tubular structure is conductive Structure, the split tubular structure is applied with a negative voltage, and the fibers formed by the splitting of the charged jet released from the positive voltage end are oriented and collected on the outer surface of the split tubular structure due to the action of the electric field force. The split-type tubular structure of the present invention is a cylinder under the fixation of the coupling. After the coupling is released, the split-type tubular structure is separated, and the tubular support can be easily taken out without destroying the original appearance of the tubular support. Solved the problem that the tubular stent was difficult to take out.

Owner:FOSHAN QINGZI PRECISION MEASUREMENT & CONTROL TECH

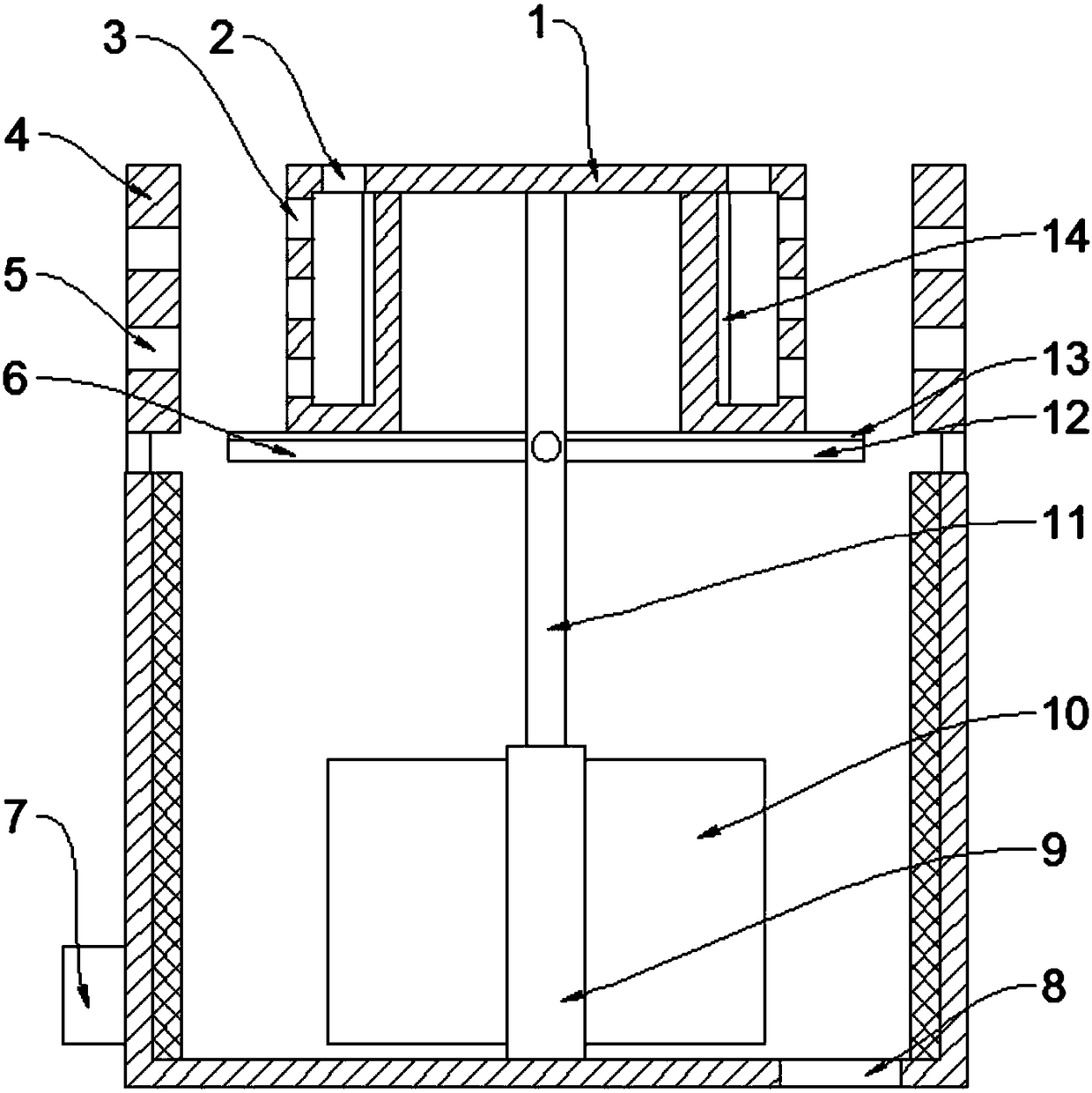

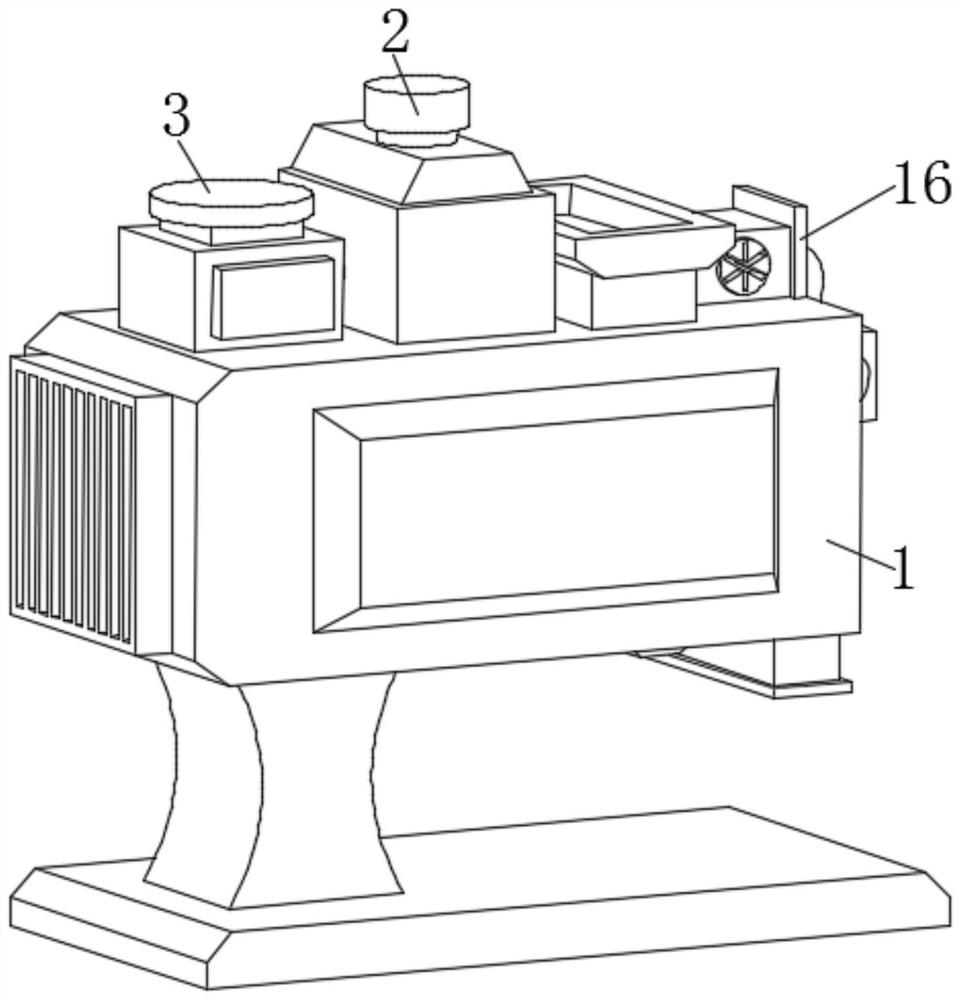

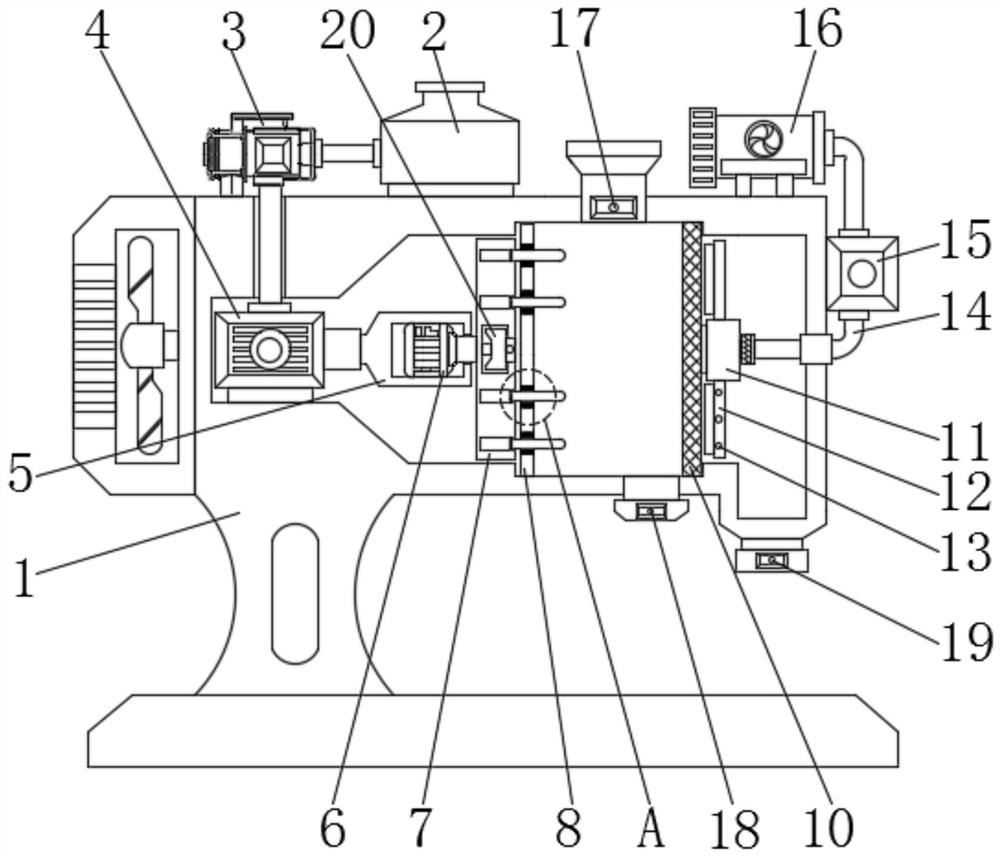

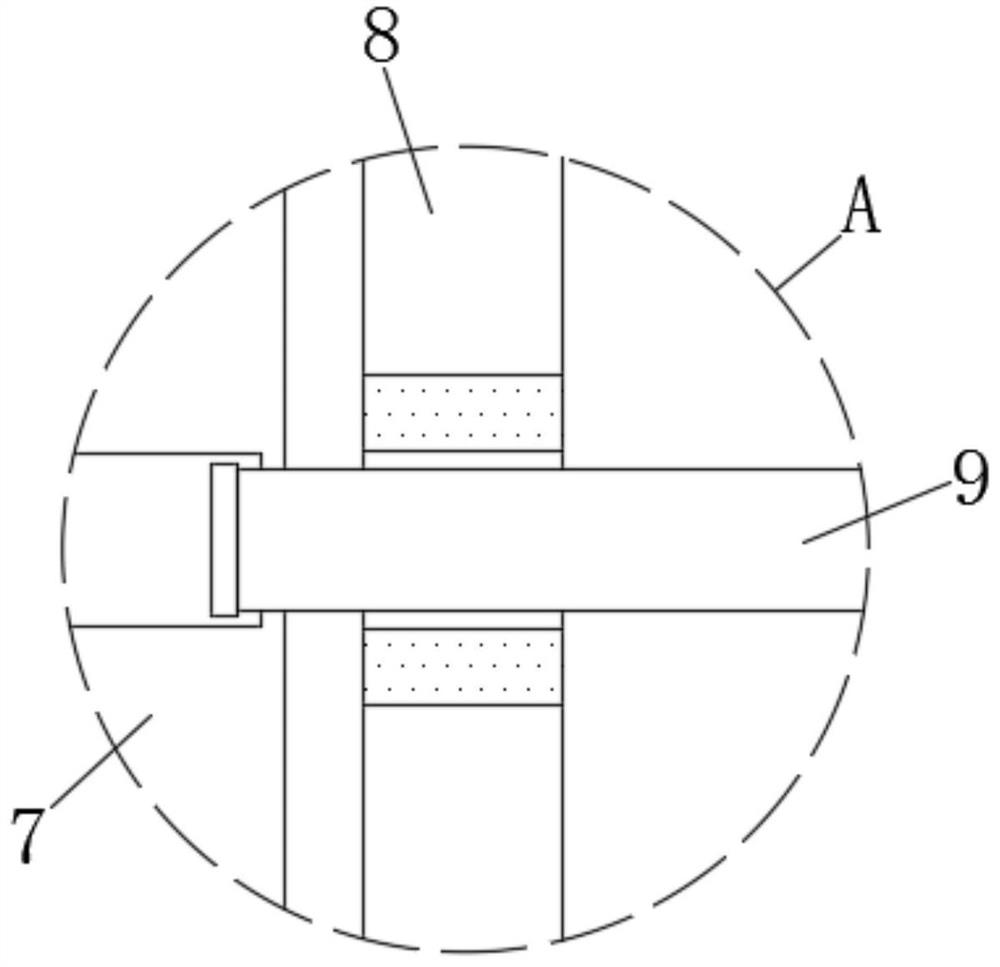

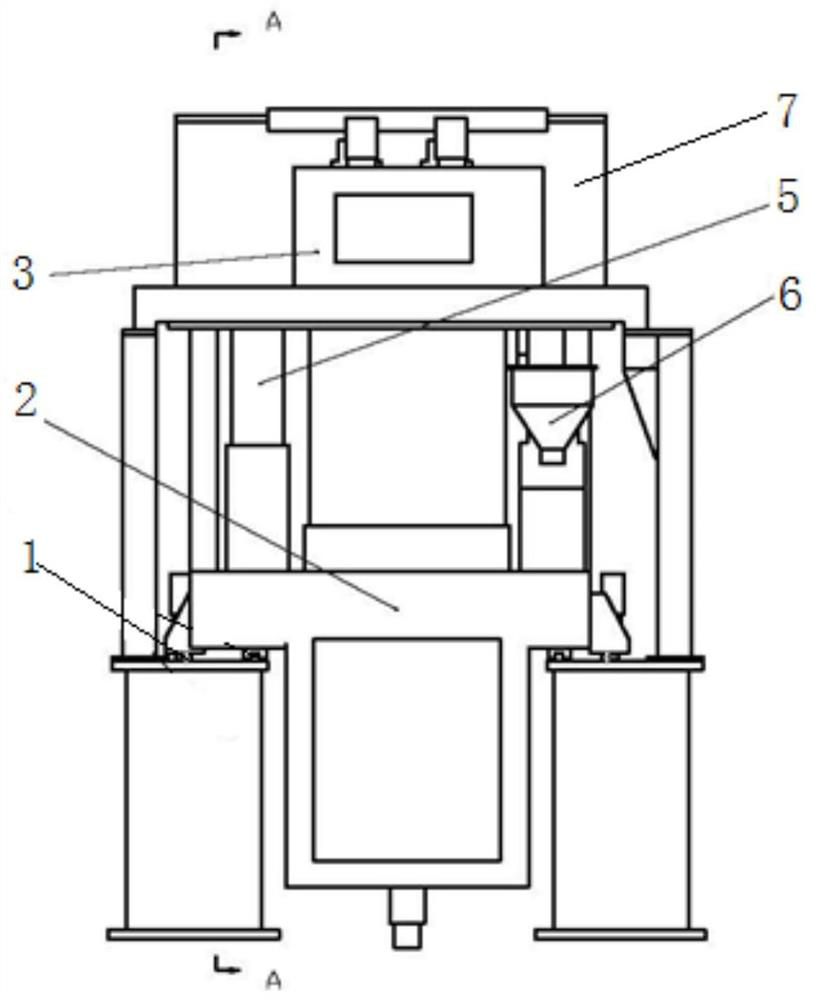

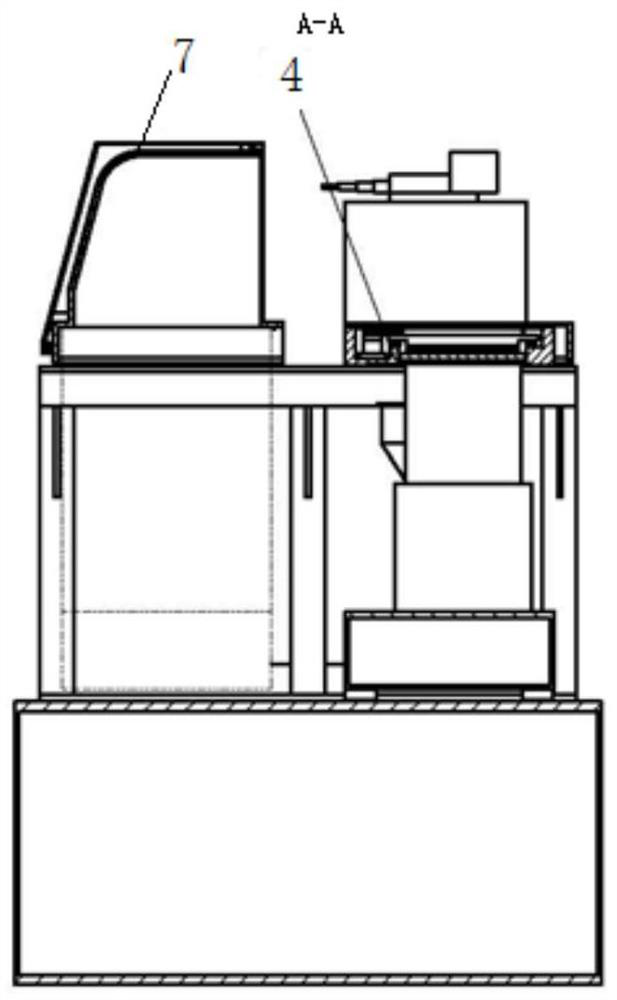

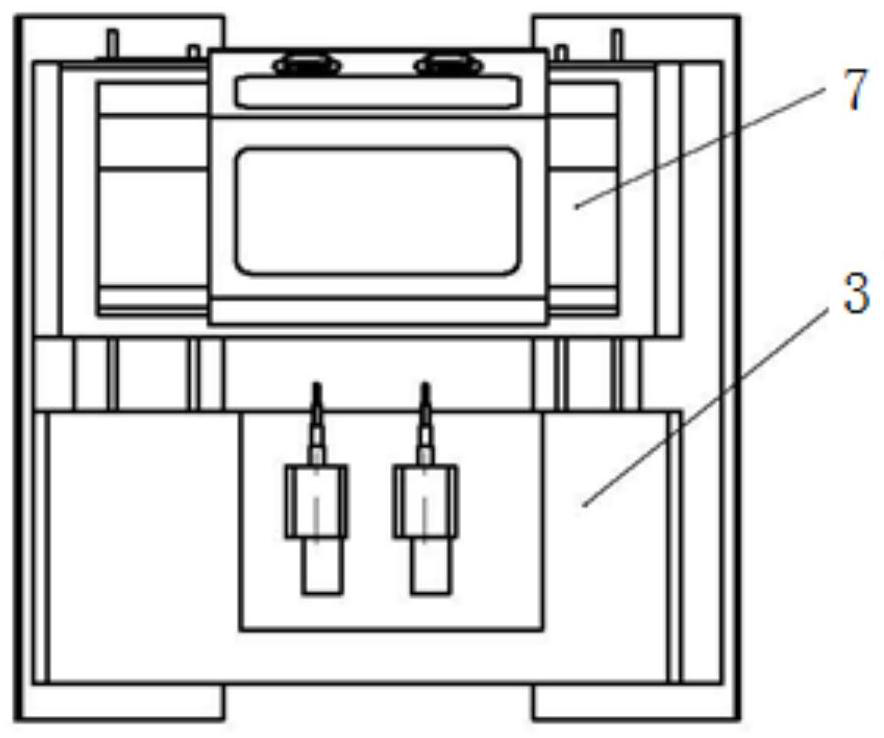

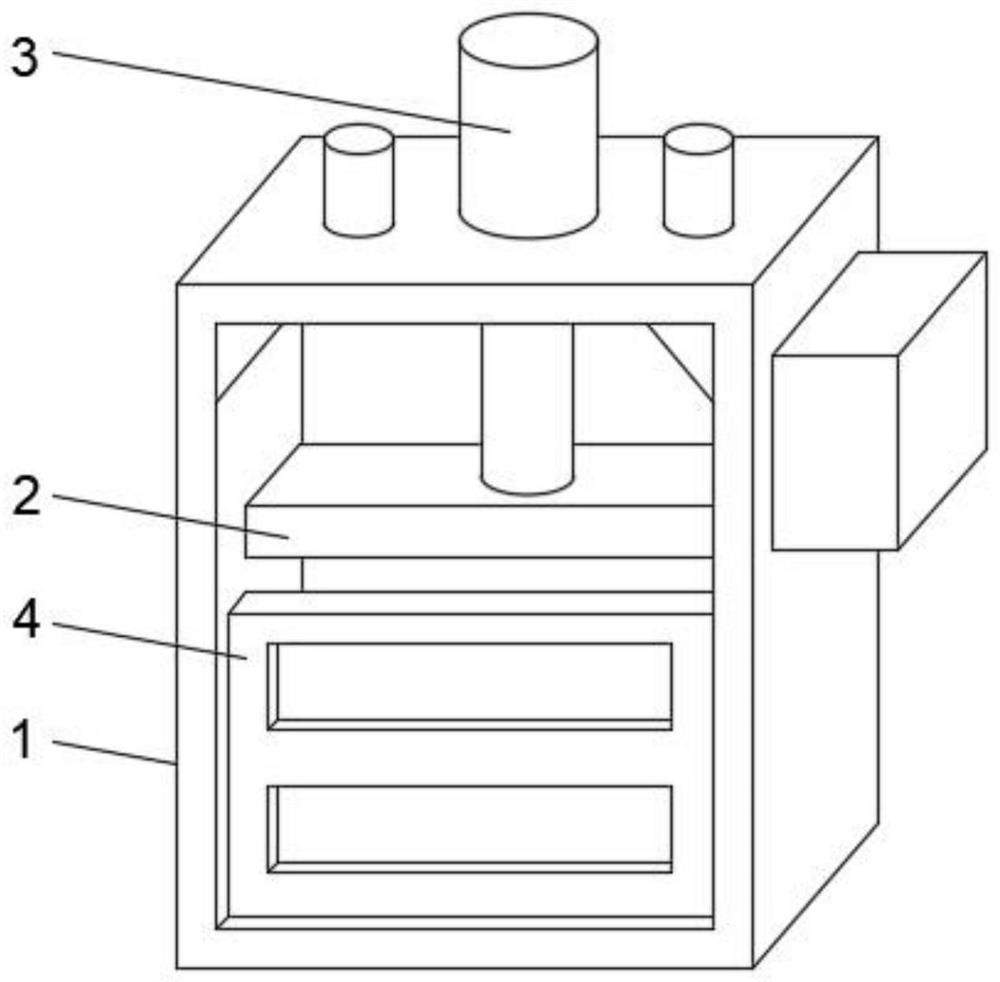

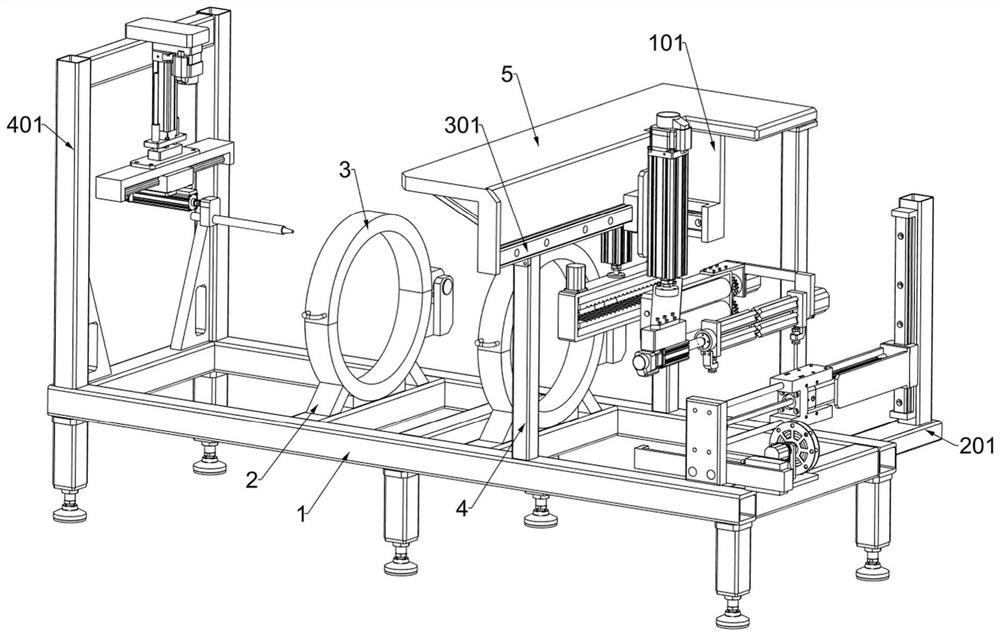

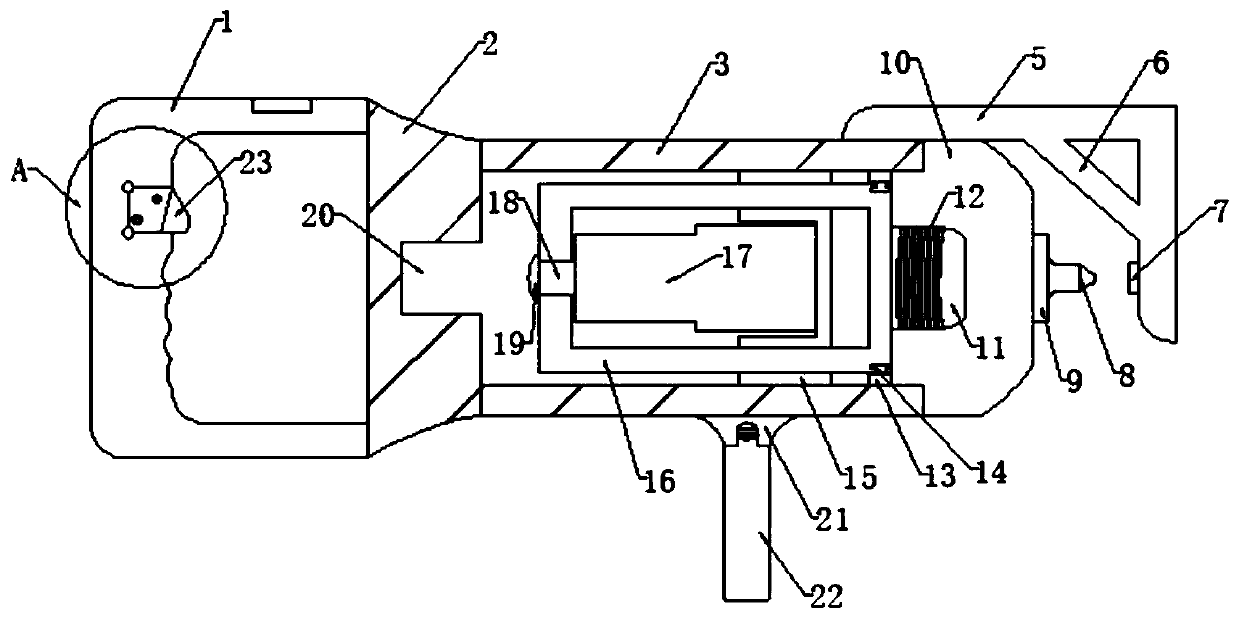

A laser selective melting forming equipment

ActiveCN109365815BSolve the problem that is difficult to take outResolve adjustmentsAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringMetal powder

The invention relates to a laser selective melting forming equipment. The equipment at least includes: a two-dimensional mobile device, a forming workbench, a forming cabin, an auxiliary cabin, a powder spreading device, a powder feeding device, a powder recovery device and a laser printer. On the other hand, the two-dimensional moving device is connected and can drive the forming worktable to move between the forming cabin and the auxiliary cabin, wherein the two-dimensional moving device includes a longitudinal drive unit for driving the forming worktable to move longitudinally, and a driving unit for driving the forming work The horizontal drive unit for the horizontal movement of the table. In the sealed state of the forming cabin, the laser printer melts the metal powder on the forming workbench into predetermined parts. The excess powder recovery device is used to recover excess metal powder. The two-dimensional moving mechanism drives the forming The workbench moves from the forming cabin to the auxiliary cabin, and the auxiliary cabin is provided with a pick-up window for removing the parts on the forming workbench.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

A seedling box for cultivating high-quality small sweet potato seedlings

ActiveCN113439589BImprove survival rateIntegrity guaranteedClimate change adaptationTransplantingEnvironmental geologyTransplanting

The invention belongs to the technical field of seedling raising boxes, in particular to a seedling raising box for cultivating high-quality small sweet potato seedlings, comprising a box body, a box cover, a slide plate and a first support plate; hole; the inner wall of the through hole is fixedly connected with a rubber tube; the inside of the rubber tube is provided with a first air cavity; A second air cavity is opened inside in the vertical direction; the second air cavity is connected to any adjacent first air cavity design through a conduit; the other end of the conduit passes through the second handle side wall design; the first A first one-way valve is fixedly connected to the connection between the second air chamber and the conduit inside the handle; the second air chamber is connected to the external design through the air inlet; the second one-way valve is fixedly connected to the inner wall of the air inlet; The invention has a simple structure, can protect the integrity of the root system of the small sweet potato seedlings in the transplanting process, and improves the survival rate of the small sweet potato seedlings transplanted.

Owner:杭州市临安区农林技术推广中心

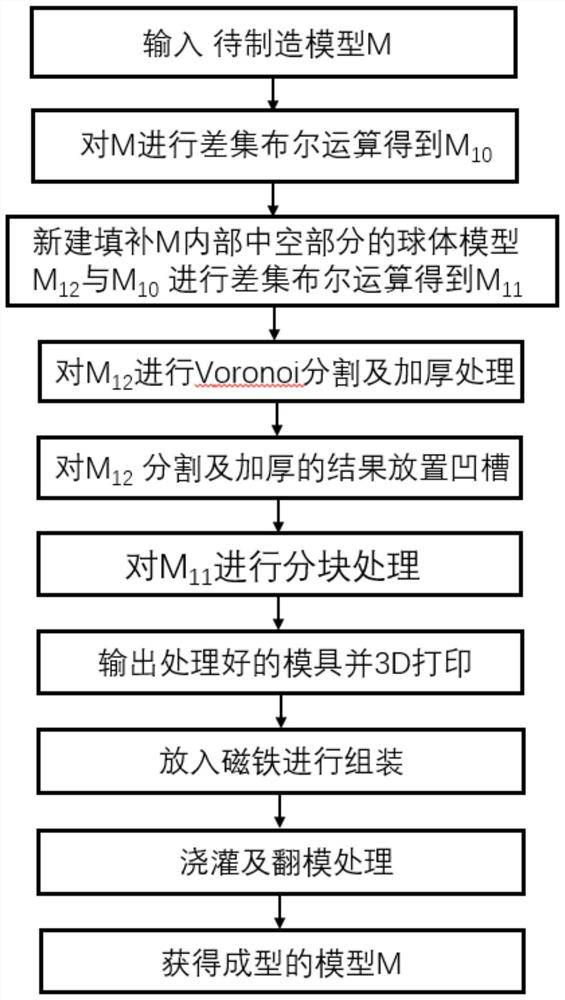

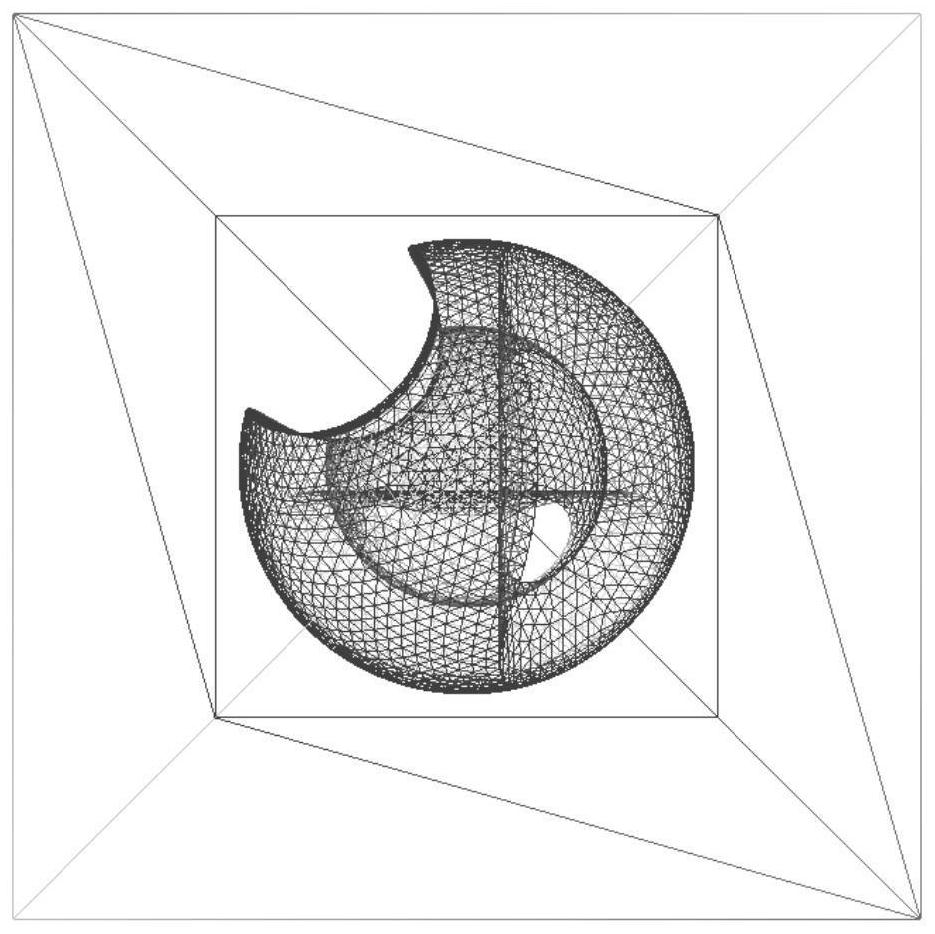

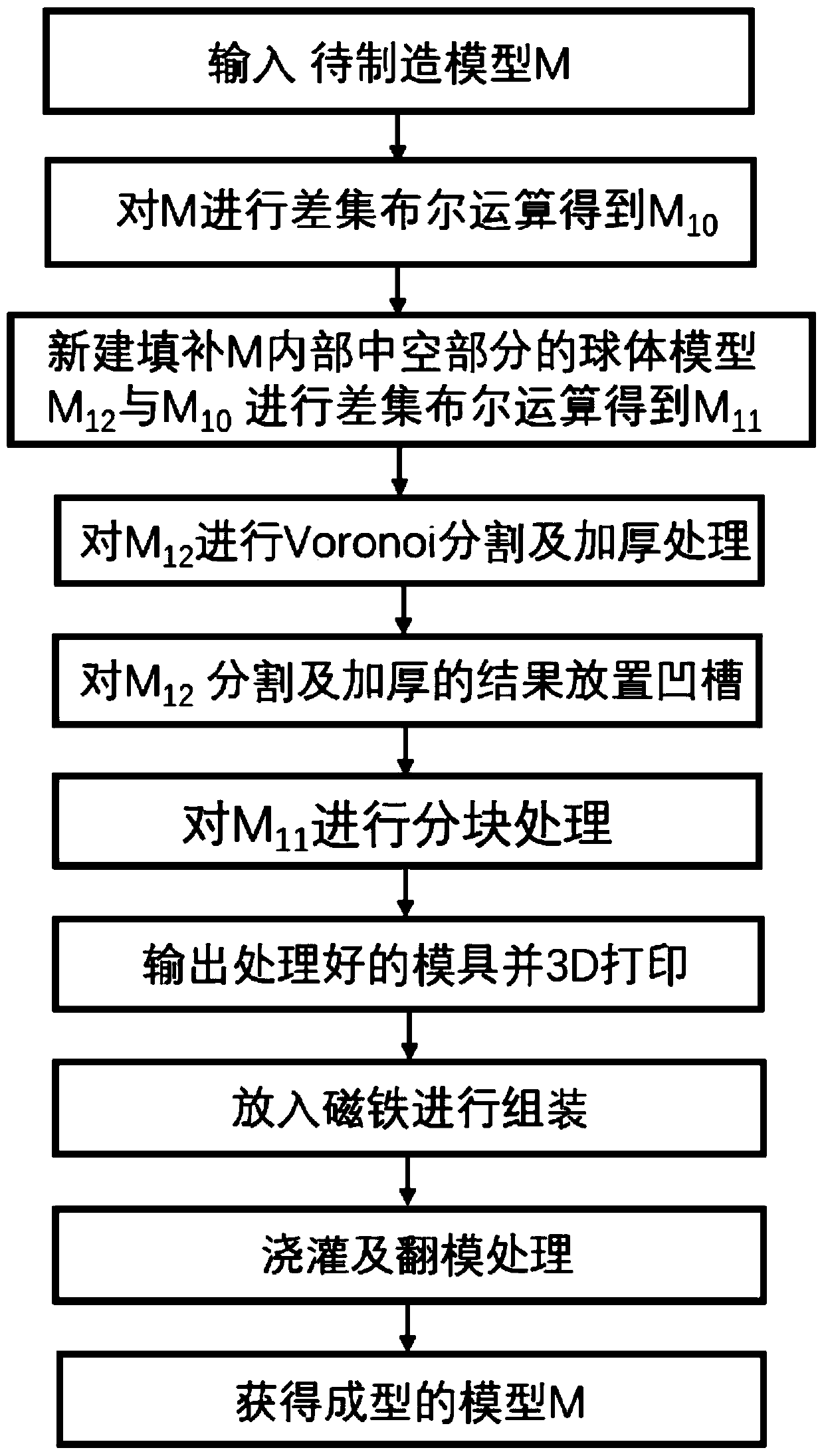

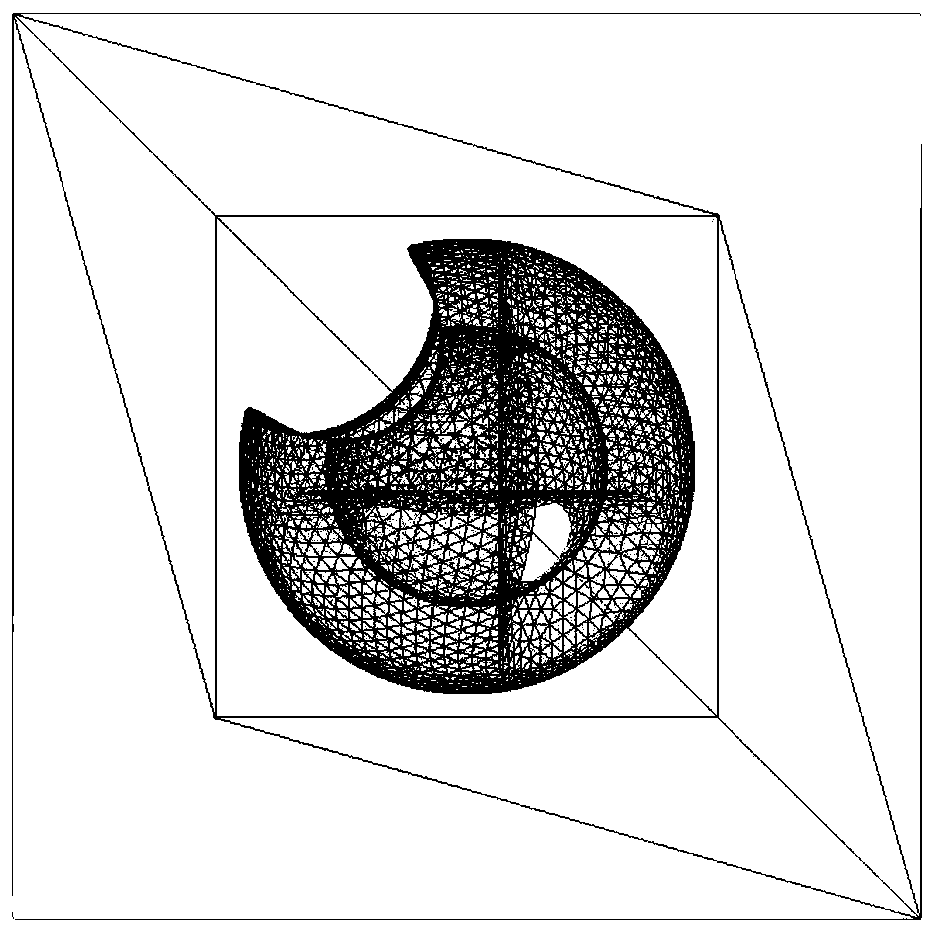

A Design and Release Method of Complicated Mold Based on Magnetic Force

ActiveCN111284016BSolve the problem that is difficult to take outEasy to disassembleAdditive manufacturing apparatus3D object support structuresMagnetic tension forceProcess engineering

The invention provides a complex mold design and demoulding method based on magnetic force, comprising the following steps: inputting the model to be manufactured, and obtaining an initial model after difference operation; creating an internal model of the model to be manufactured; performing difference between the initial model and the internal model After the calculation, the external model is obtained; the internal model is divided to form mold modules that can be taken out; grooves are provided on the splicing surface of each mold module, and magnets are placed in the grooves; the external model is divided and processed at the same time. The hole is used to obtain the pouring port of the material; set the mold entity, put the magnet in the groove position for assembly, pour through the pouring port after assembly, and perform demoulding after cooling and solidification; the method of splitting and splicing is adopted, which is convenient for disassembly and assembly, and the design flexible.

Owner:SHANDONG UNIV

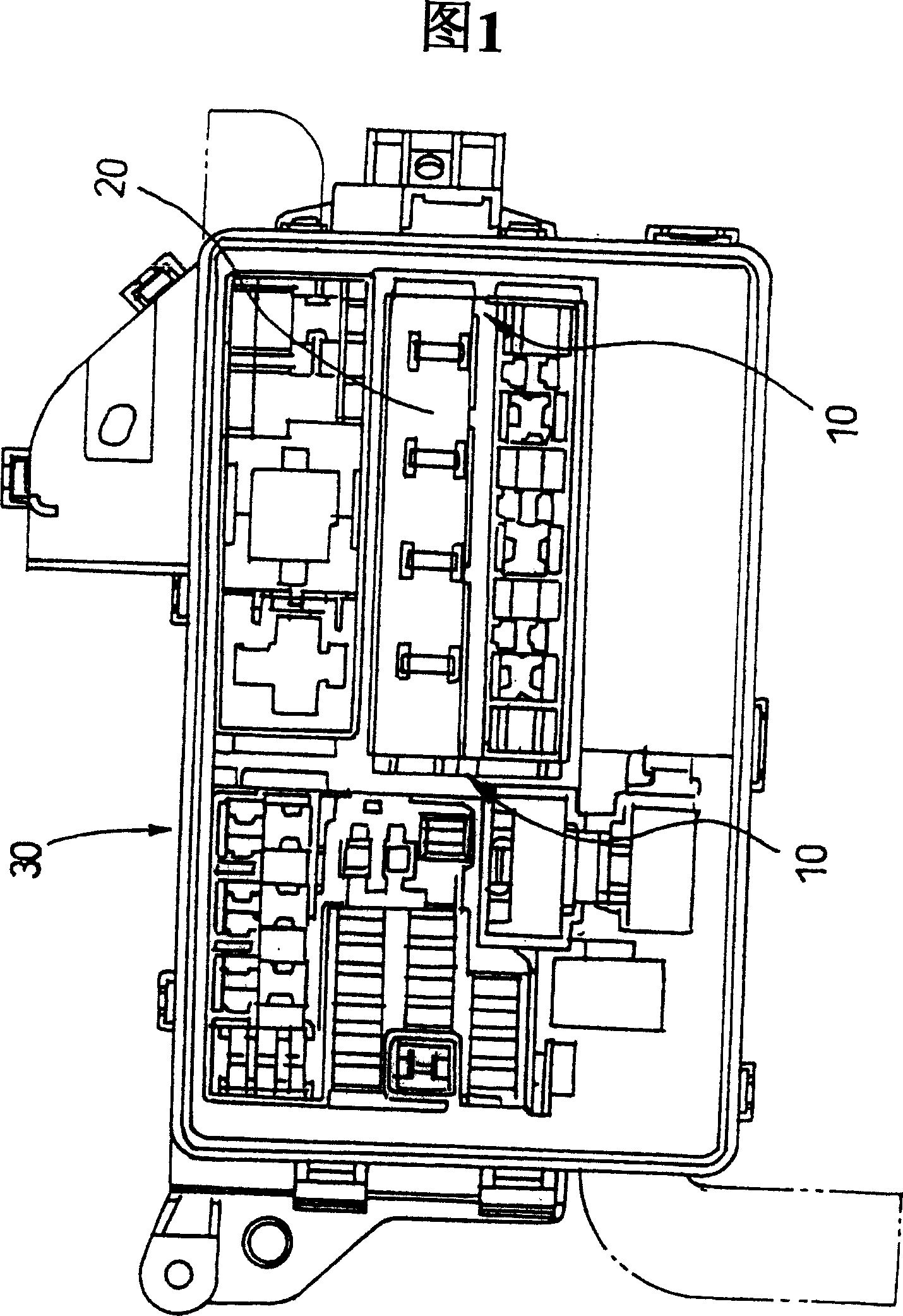

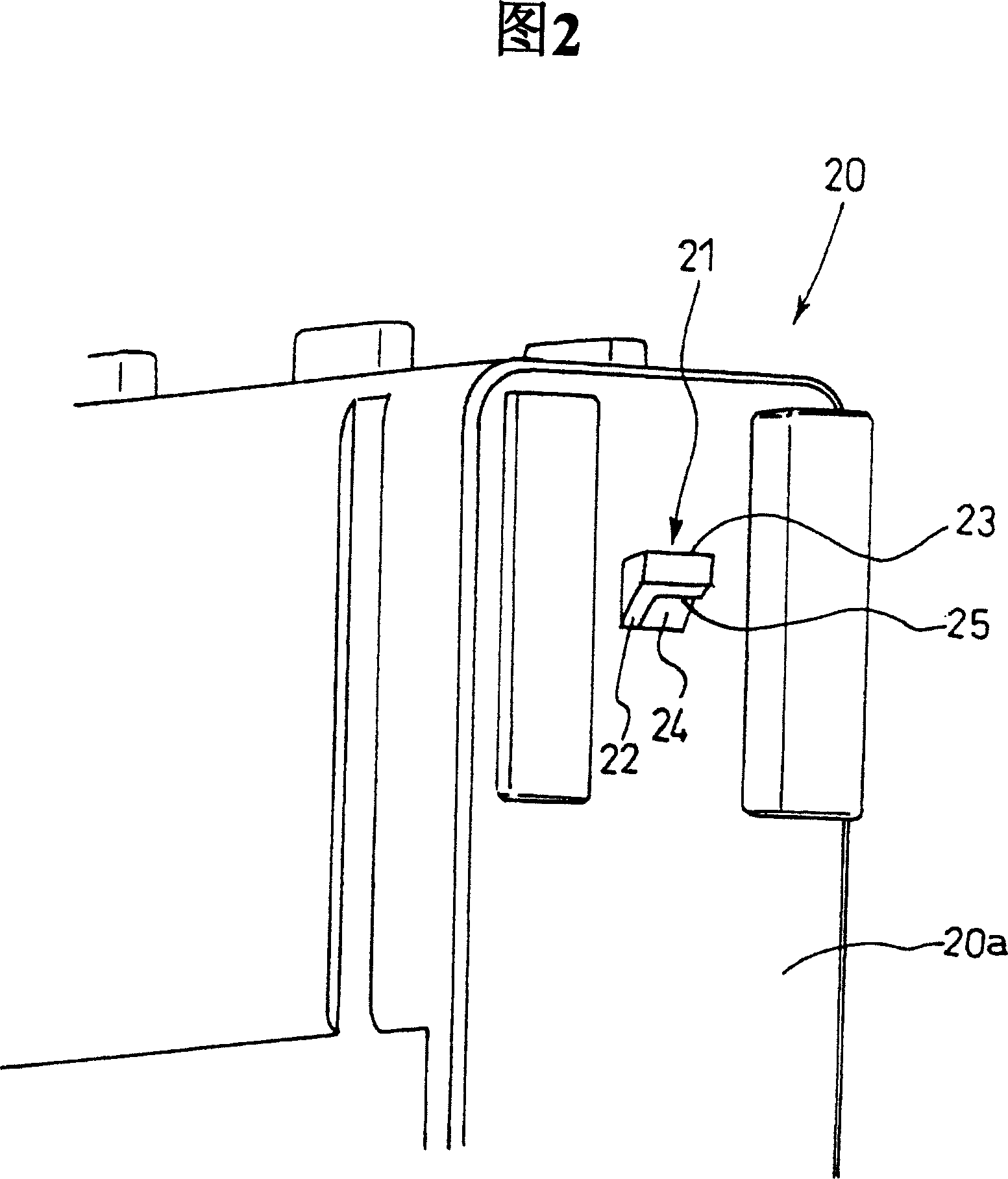

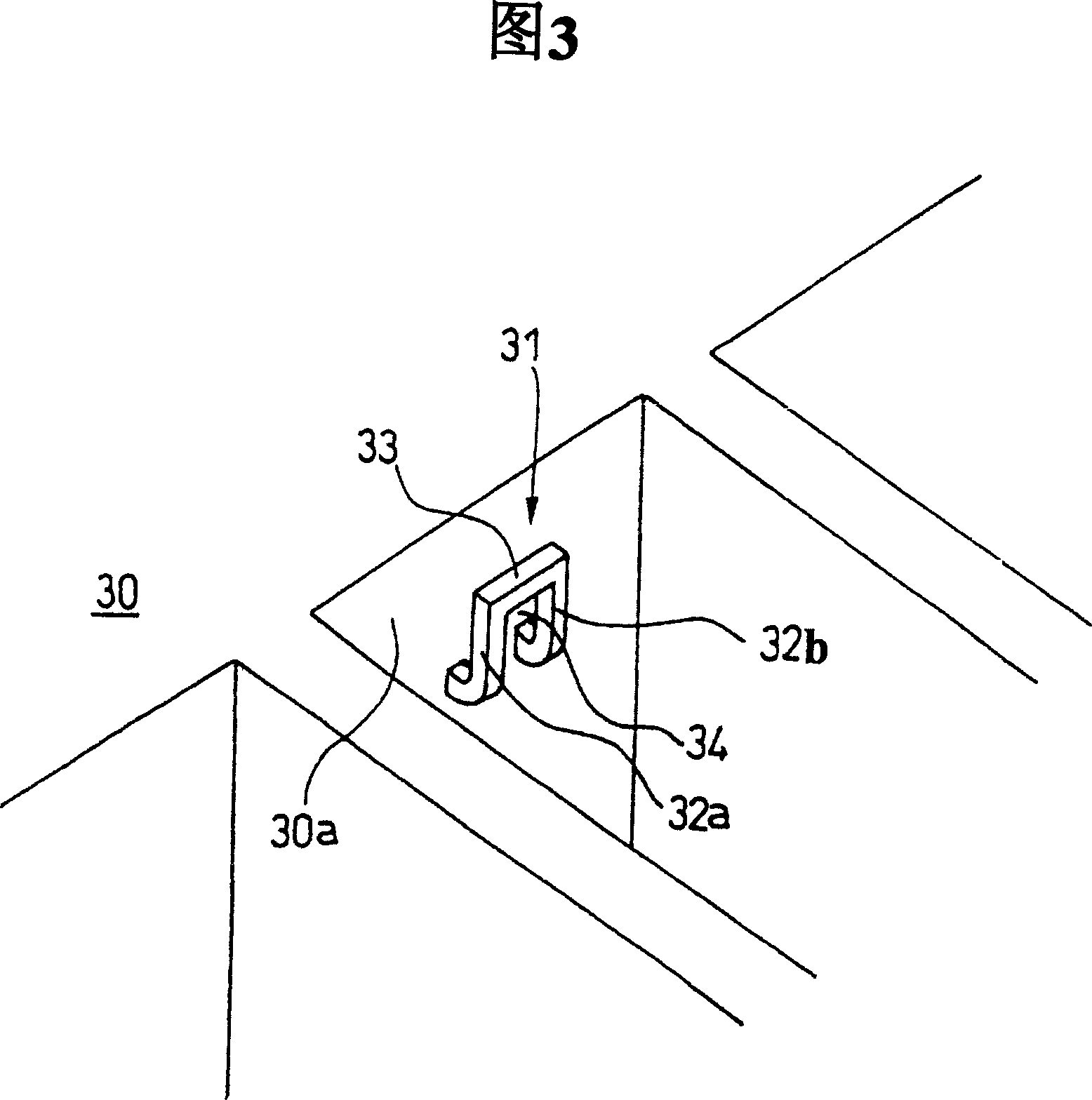

Locking structure

ActiveCN1327750CSolve the problem that is difficult to take outUnlock stateSnap-action fastenersRelay bases/casings/coversEngineeringElectrical and Electronics engineering

Owner:YAZAKI CORP

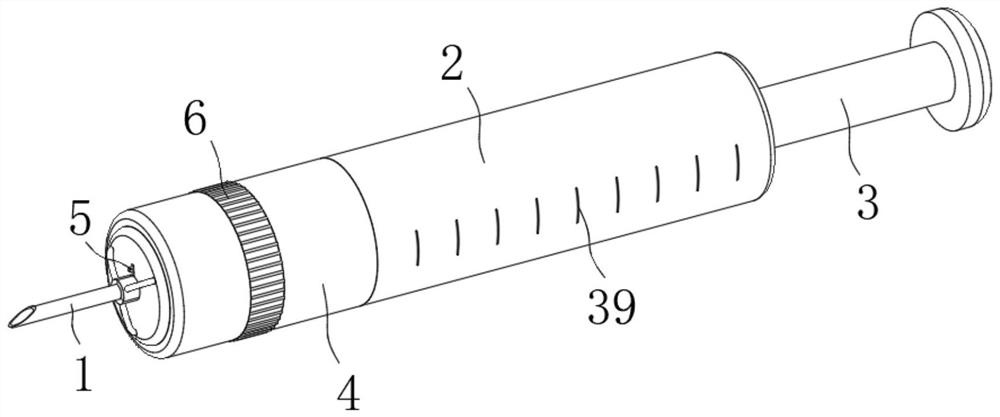

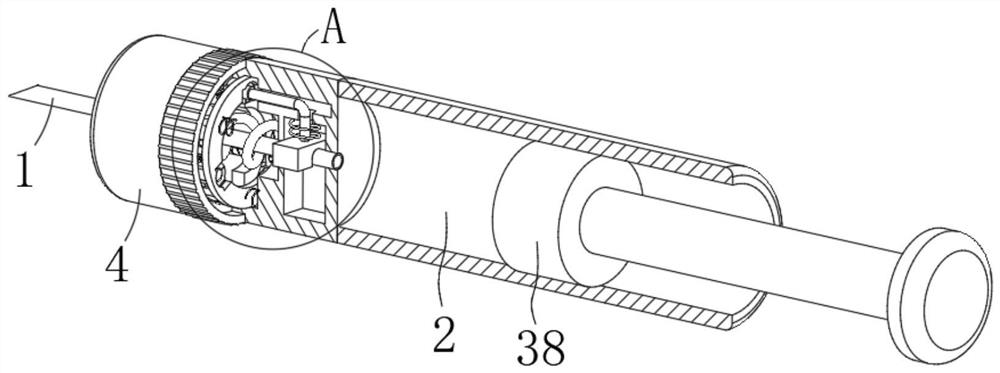

Animal epidemic disease immune injection device and method thereof

ActiveCN114515210ASolve the problem that is difficult to take outPrevent the phenomenon of breaking in the bodyInfusion syringesClimate change adaptationAnimal bodyBiomedical engineering

The invention discloses an animal epidemic disease immune injection device and an animal epidemic disease immune injection method, relates to the field of animal injection, and solves the problem that a needle head is broken in an animal body and is difficult to take out due to the fact that an animal frequently reacts violently when an existing animal epidemic disease immune injection device is used for injection. Comprising a needle head, a fixing device, a telescopic device and a tube body used for storing injection liquid, an injection part used for pushing the injection liquid into the needle head is arranged in the tube body, and a device tube is fixedly connected to the tube body. The linkage telescopic device quickly draws the needle out of the animal body, the phenomenon that the needle is broken in the body due to continuous strenuous movement of the animal is prevented, the device is easy and quick to operate, capable of being repeatedly used and convenient to install, the phenomenon that the needle is broken in the animal body and difficult to take out is effectively prevented, and use is safer and more reliable.

Owner:连云港市畜牧兽医站

Computer hard disk production packaging box convenient for hard disk taking and placing

InactiveCN112693727ASolve the problem that is difficult to take outEasy to fixInternal fittingsMechanical engineeringEngineering

The invention relates to the technical field of packaging boxes, in particular to a computer hard disk production packaging box convenient for hard disk taking and placing. The computer hard disk production packaging box comprises a packaging box body, a clamping groove is formed in the front end face of the packaging box body, a placing groove is formed in the front end face of the packaging box body, and a limiting block is fixedly connected to the left end of the inner side wall of the placing groove. Elastic pieces are fixedly connected to top end and the bottom end of the inner side wall of the placing groove, a hard disk is arranged in the placing groove, a pull rope is fixedly connected to the bottom end of the inner wall side of the placing groove, a clamping ring is fixedly connected to the inner side of the pull rope, a mounting hole is formed in one side of the packaging box body, a connecting block is fixedly connected to the front end face of the packaging box body, and a buckle is fixedly connected to the front end face of the connecting block. According to the computer hard disk production packaging box convenient for hard disk taking and placing, by arranging the elastic pieces, the pull rope, the clamping ring and the buckle, packaging and fixing are quite convenient, the packaging efficiency of the device is greatly improved, and the problem that the hard disk in the packaging box is difficult to take out is solved; and the computer hard disk production packaging box is quite convenient to use, easy to operate, simple in process and low in cost.

Owner:陕西优民惠科技有限公司

An intelligent storage device for oil storage

ActiveCN114212400BWith filter functionSolve the problem that is difficult to take outLarge containersTank wagonsOil and greaseLiquid state

Owner:南通科达化工机械制造有限公司

Waste extrusion device convenient to use

The invention provides a waste extrusion device convenient to use, and relates to the field of waste treatment. The waste extrusion device comprises an extrusion box, an opening and closing door is installed at the front end of the extrusion box, a hydraulic rod is installed at the top end of the extrusion box in a penetrating mode, an extrusion disc is installed at the bottom end of the hydraulic rod, and a hydraulic cylinder is installed on one side of the extrusion box; the hydraulic cylinder is in transmission connection with the hydraulic rod, a plurality of sets of extrusion blocks are installed at the bottom end of the extrusion disc, the extrusion blocks are arranged in a hexagonal prism frustum shape, six sets of movable plates are installed on the outer sides of the extrusion blocks, rotating shafts are installed on one sides of the movable plates, and the movable plates are movably connected with the extrusion blocks through the rotating shafts; and a conveying telescopic rod is installed at the position, close to the bottom end, of one side of each movable plate, a plurality of blocking covers are installed on the inner sides of the conveying telescopic rods, and an extrusion bag is installed at the bottom end of each conveying telescopic rod. The waste extrusion device convenient to use effectively solves the problems that in the waste extrusion process, due to high extrusion force, the connecting force between formed waste and the bottom end of the extrusion box is too high, and consequently, the waste is difficult to take out.

Owner:万佳欣

A processing device and processing method for metal materials used for die-casting

ActiveCN114012637BSolve the problem that it is difficult to take out after breakingSolve the problem that is difficult to take outWork holdersMetal-working hand toolsMetallic materialsEngineering

Owner:江苏凌广新材料科技有限公司

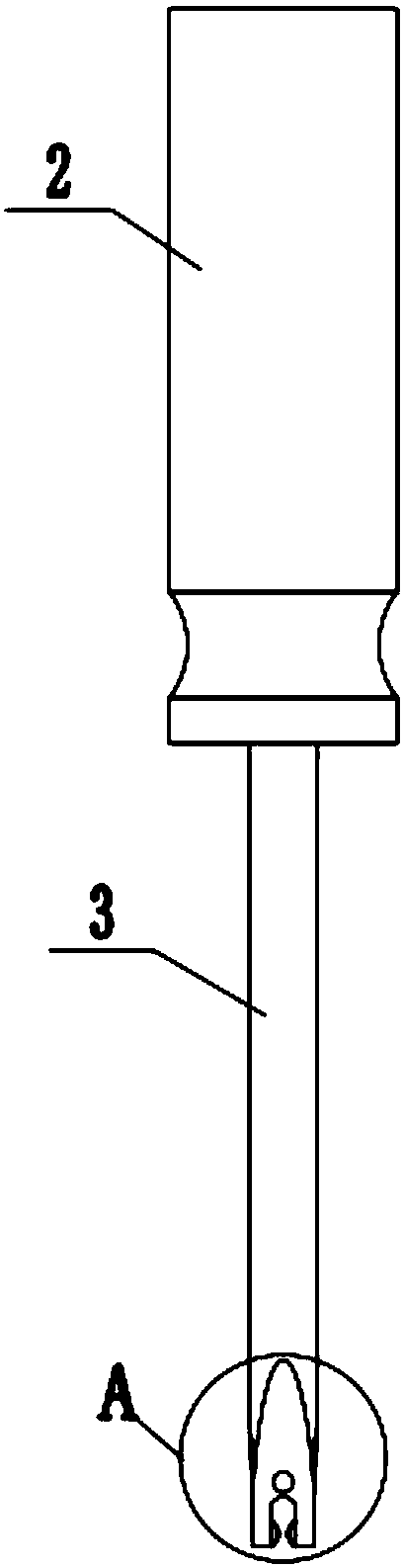

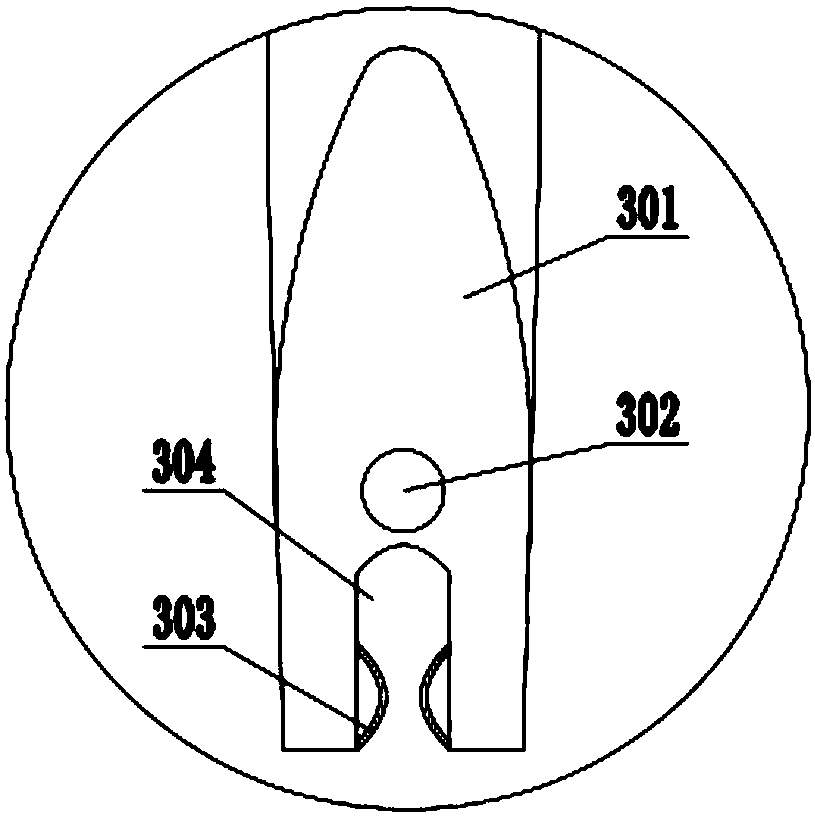

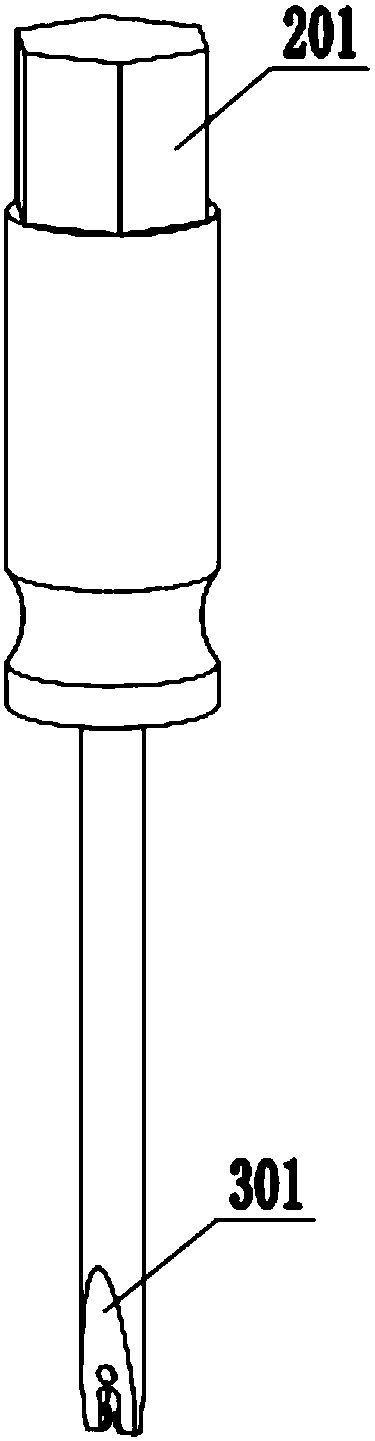

Multifunctional screwdriver

PendingCN108214410AAchieve tighteningSolve the problem that the steel wire tightening cannot be completedMulti-purpose toolsEngineeringUsability

The invention discloses a multifunctional screwdriver which comprises a handle and a toolbar connected with the handle. A linear tool bit is arranged at the lower end of the toolbar. The multifunctional screwdriver is characterized in that a tool edge is arranged in the middle of the lower end of the tool bit, an elastic metal piece is arranged on the inner wall of each of two sides of the tool edge, the two elastic metal pieces are opposite in position, each elastic metal piece is of an externally-convex arc structure, and a cylindrical steel wire hole is formed in the upper end of the tool edge and is a through hole. The tool bit of the screwdriver is provided with the tool edge and the steel wire hole, so that functions of clamp-type tools are replaced, the problem that a steel wire cannot be tightened by using a common screwdriver when a clamp is forgotten to carry is solved, and convenience is brought to mounting and maintaining; due to lever laws, the process of tightening the steel wire is quite labor-saving, so that the problem of labor consumption when sharp-nose pliers are used to mesh and tighten thick steel wires is solved, operating efficiency is improved, working intensity is relieved, and the multifunctional screwdriver is high in usability.

Owner:陈旭澎

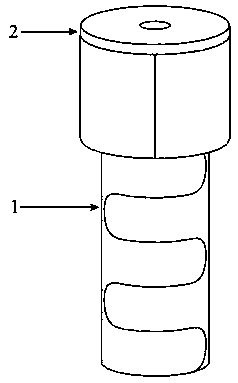

A kind of ceramic spring forming device and preparation method of ceramic spring

InactiveCN103707390BReduce defectsSolve the problem of declining reliabilityCeramic shaping apparatusMaterial defectCeramic molding

The invention provides a forming device and a manufacturing method of a ceramic spring, and relates to the ceramic spring. The forming device of the ceramic spring is provided with a melt spinning forming device, a spring winding forming device, a driving mechanism and a support table. The melt spinning forming device is provided with an upper sealing cover, a mandril, a charging basket, a spinneret plate and a lower sealing cover; the spring winding forming device comprises a chuck body, three arc-shaped clamp plates and a chuck driving mechanism, and the chuck driving mechanism is provided with a big bevel gear and three bevel pinions; the driving mechanism is provided with an electric motor and a controller. The method includes the steps of (1) obtaining a continuous polycarbosilane filament; (2) forming a polycarbosilane spring in a wound mode; (3) carrying out oxidative crosslinking processing; (4) carrying out high-temperature presintering; (5) taking out the ceramic spring; (6) carrying out high-temperature final sintering to obtain a ceramic spring finished product. Thus, the continuous polycarbosilane filament which is small in defect, uniform, compact and controllable in thickness can be obtained, the use reliability declining problem of the ceramic spring due to material defects is effectively solved, and the process is simple and easy to achieve.

Owner:XIAMEN UNIV

Tool for taking out floating valve element of drilling tool

InactiveCN110080706ASolve the problem that is difficult to take outSimple structureBorehole/well accessoriesEngineeringMechanical engineering

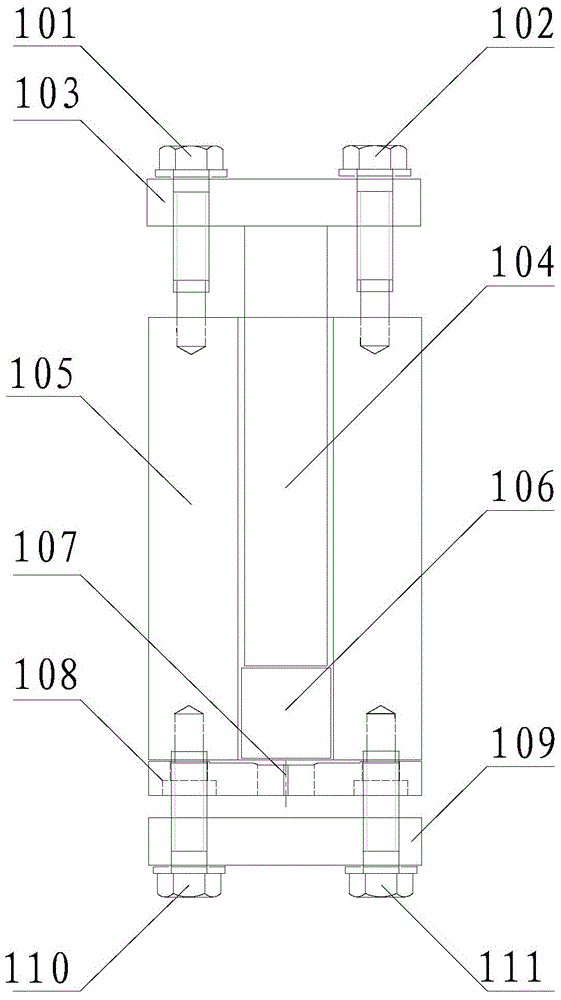

The invention discloses a tool for taking out a floating valve element of a drilling tool. The tool comprises an adjustable support, two hooks, a lead screw, an auxiliary nut and a baffle board, two through holes are formed in the two sides of the adjustable support, the lower parts of the two hooks are hooked on a step of the floating valve element, the upper parts penetrate through the corresponding through holes, extend upwards and are locked by hook nuts, the lower part of the lead screw vertically penetrates through the middle part of the adjustable support and extends downwards, the leadscrew is in transmission connection with the auxiliary nut, the auxiliary nut is arranged at the lower end of the adjustable support and detachably and fixedly connected with the adjustable support through a limiting pin, a baffle is rotatably installed at the lower end of the lead screw and abuts against the step face of a floating valve connector body to serve as a support, and the baffle is limited on the lead screw through a locking nut; and the distance between the baffle and the adjustable support can be adjusted by rotating the lead screw, the adjustable support can drive the two hooksto move upwards, and then the floating valve element is taken out. The tool is simple in structure, convenient to use, safe, reliable and wide in application range.

Owner:CNPC BOHAI DRILLING ENG

Magnetic force-based complex mold design and demolding method

ActiveCN111284016ASolve the problem that is difficult to take outEasy to disassembleAdditive manufacturing apparatus3D object support structuresMagnetic tension forceProcess engineering

The invention provides a magnetic force-based complex mold design and demolding method. The method comprises the following steps of inputting a to-be-manufactured model, and performing difference setoperation to obtain an initial model; creating an internal model of the to-be-manufactured model; performing difference set operation on the initial model and the internal model to obtain an externalmodel; performing segmentation on the internal model to form mold modules which can be taken out; forming a groove in a splicing surface of each mold module, wherein the grooves are used for containing magnets; performing segmentation on the external model, and meanwhile, digging holes to obtain material pouring ports; and setting mold entities, putting the magnets in the grooves for assembly, performing pouring through the pouring ports after assembly, and performing demolding after cooling and solidification. By adopting a mode of splicing after segmentation, disassembly and assembly are facilitated and the design is flexible and variable.

Owner:SHANDONG UNIV

Metal material machining device and method for die-casting formation

ActiveCN114012637ASolve the problem that it is difficult to take out after breakingSolve the problem that is difficult to take outWork holdersMetal-working hand toolsMetallic materialsManufactured material

The invention belongs to the field of metal material machining, and relates to a metal material machining device and method for die-casting formation. The device comprises a rack, two bases, a locking ring, a supporting column, a first fixing plate and a supporting column are connected to the middle of the rack, a broken material treatment system is connected to the right portion of the rear side of the rack, and a winding system is connected to the right portion of the first fixing plate; a pushing and ejecting system ejects the part of the metal material into a pulling system, the pulling system clamps one end of the metal material to carry out multiple times of horizontal pulling, and then the broken metal material is pulled out for the second time through the broken material treatment system and then is wound through the winding system. According to the device, manual pipe taking is replaced with a mechanical mode, the efficiency is improved, meanwhile, the problem that a copper pipe is broken and difficult to take out during pulling is solved, the taken-out copper pipe is flattened and rolled to solve the problem that the long copper pipe is inconvenient to transfer, and the rough smelting effect is improved when the recycled copper pipe serves as a die-casting raw material to be smelted.

Owner:江苏凌广新材料科技有限公司

An automatic riveting machine professionally applied to the combined installation of aircraft

The invention discloses an automatic press riveting machine specially applied to aircraft combination and installation. The machine comprises a handle, a connecting block, a press riveting machine shell, a press riveting head and a press riveting pad, wherein the handle is in a left-square-bracket shape, a press riveting switch is arranged on the inner side of the handle, the connecting block is arranged on one side of the handle, the handle is tightly welded and fixed to the connecting block, one end of the connecting block is provided with the press riveting machine shell, the connecting block is tightly welded and fixed to the press riveting machine shell, and the press riveting head is arranged at one end of the press riveting machine shell. The press riveting pad is arranged on one side of the press riveting machine shell, the press riveting pad is a movable pad, and an L-shaped sliding groove is formed in one side of the press riveting machine shell. The press riveting cushion isembedded into the press riveting machine shell through the sliding groove and is tightly attached and fixed to the press riveting machine shell. The automatic press riveting machine specially appliedto aircraft combination and installation can achieve handheld press riveting so that a part of complex or large parts can be subjected to press riveting by moving the press riveting machine, and combination and installation are facilitated for workers.

Owner:晨龙飞机(荆门)有限公司

Electrostatic spinning tubular support collecting device and electrostatic spinning equipment

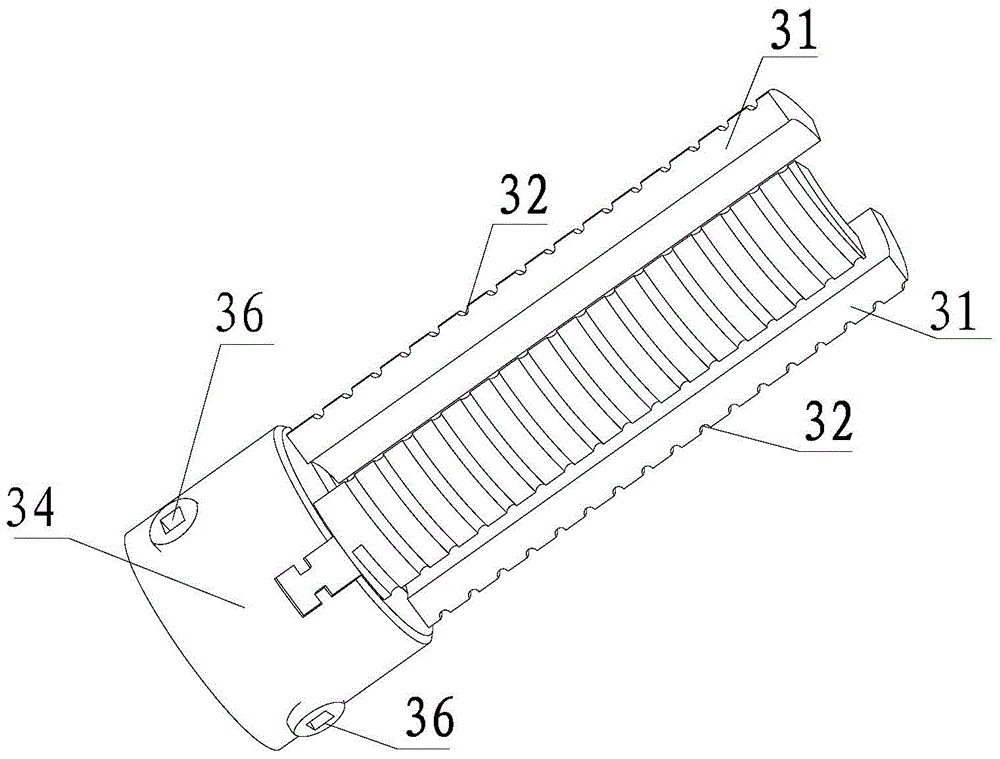

ActiveCN108866645AEasy to take outSolve the problem that is difficult to take outFilament/thread formingFiberElectrospinning

The invention relates to the technical field of electrostatic spinning, and in particular to an electrostatic spinning tubular support collecting device and an electrostatic spinning device. The collecting device comprises a support frame and a collector rotatable connected with the support frame, the collector comprises a split tubular structure and a coupling used for restraining the split tubular structure, wherein the coupling is detachably connected to the two ends of the split tubular structure; one end of the split tubular structure is connected with a transmission mechanism, and the transmission mechanism is connected with a driving motor; the split tubular structure is of a conductive structure, a negative voltage is applied to the split tubular structure, and a fiber formed by the splitting of a charged jet released from a positive voltage end is directionally collected on the outer surface of the split tubular structure due to the action of an electric field force. The splittubular structure of the invention is a cylinder under the fixing of the coupling, the split tubular structure is split after the constraint of the coupling is loosened, a tubular bracket can be easily taken out without damaging the original appearance of the tubular bracket, and the problem that it is difficult to take out the tubular bracket is solved.

Owner:FOSHAN QINGZI PRECISION MEASUREMENT & CONTROL TECH

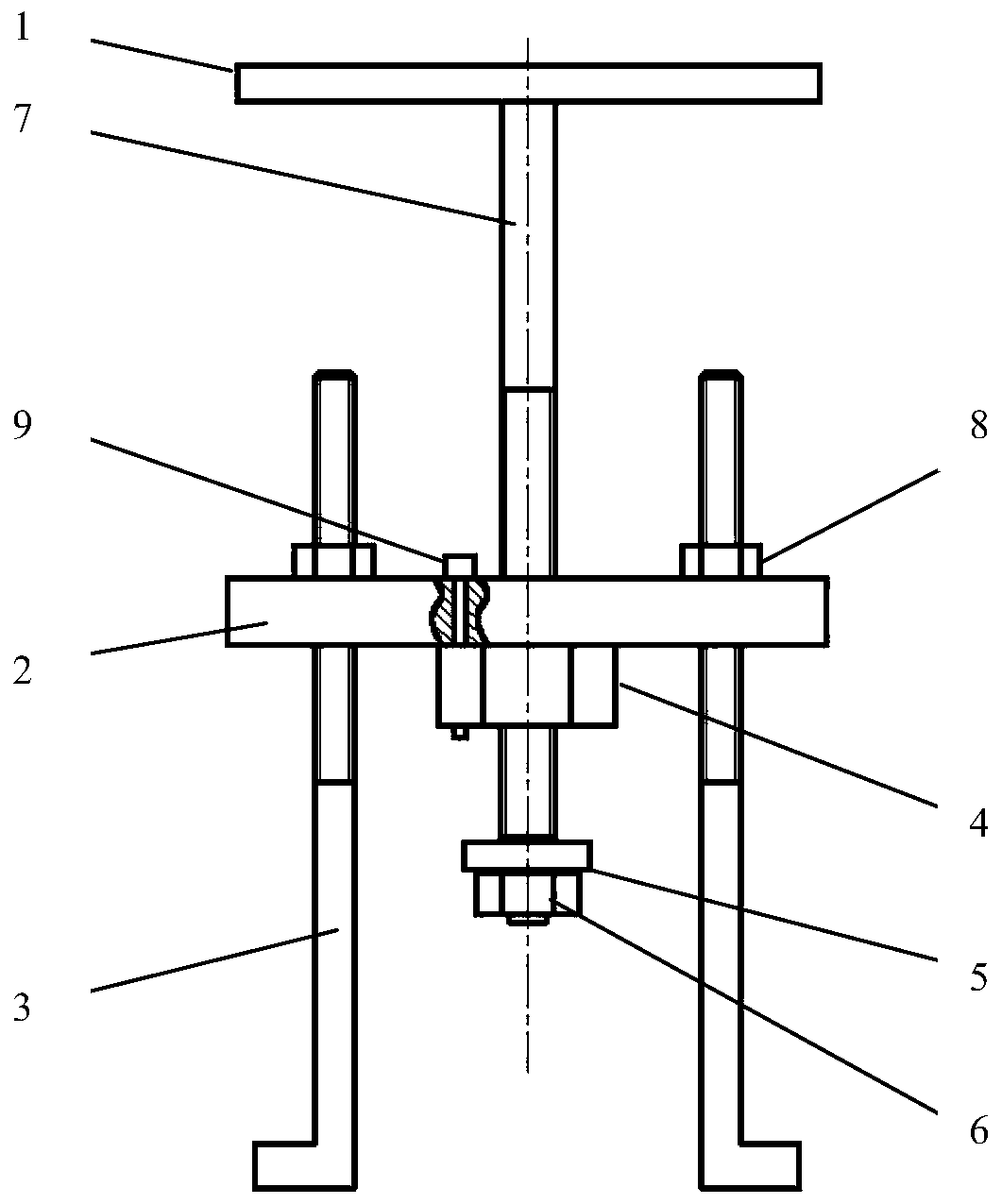

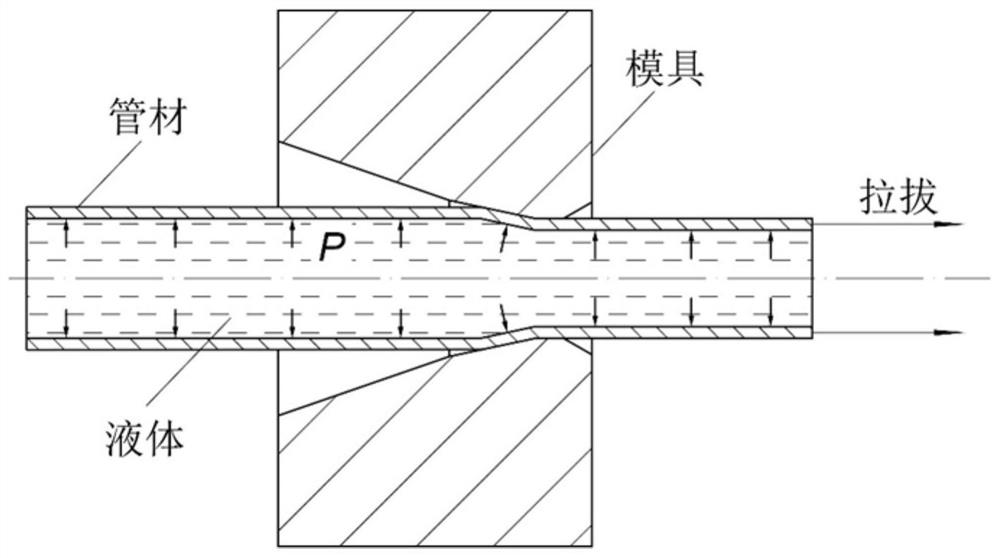

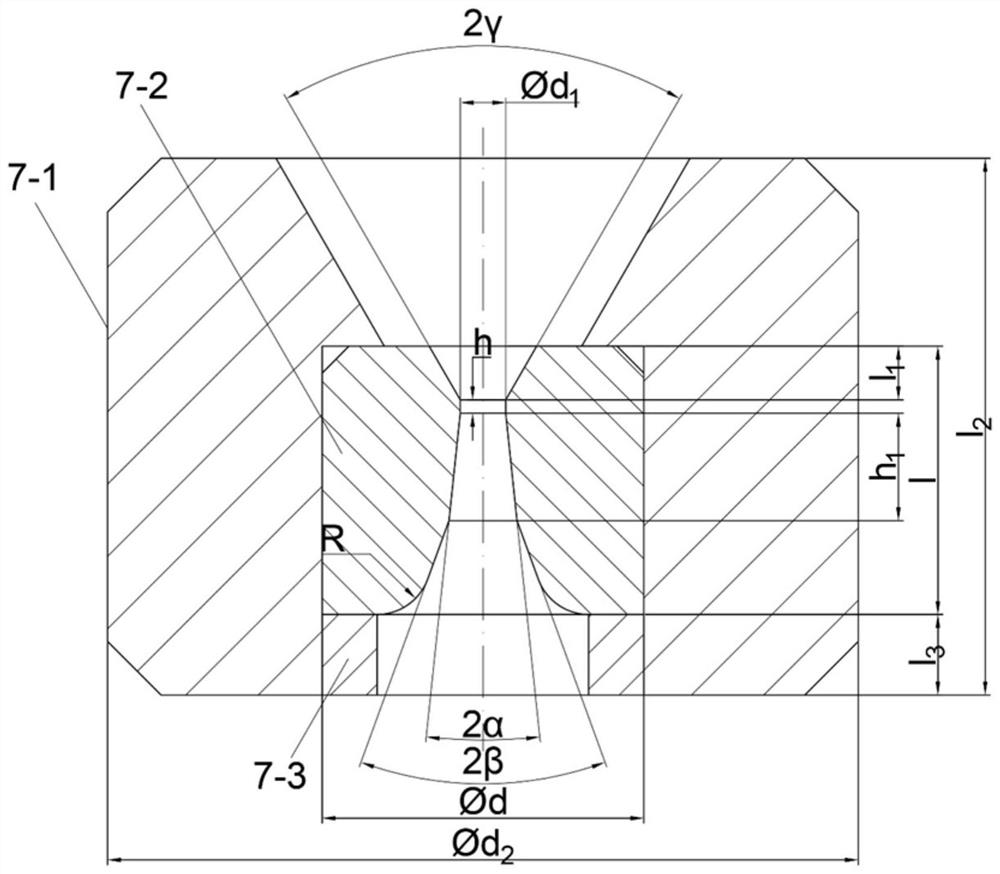

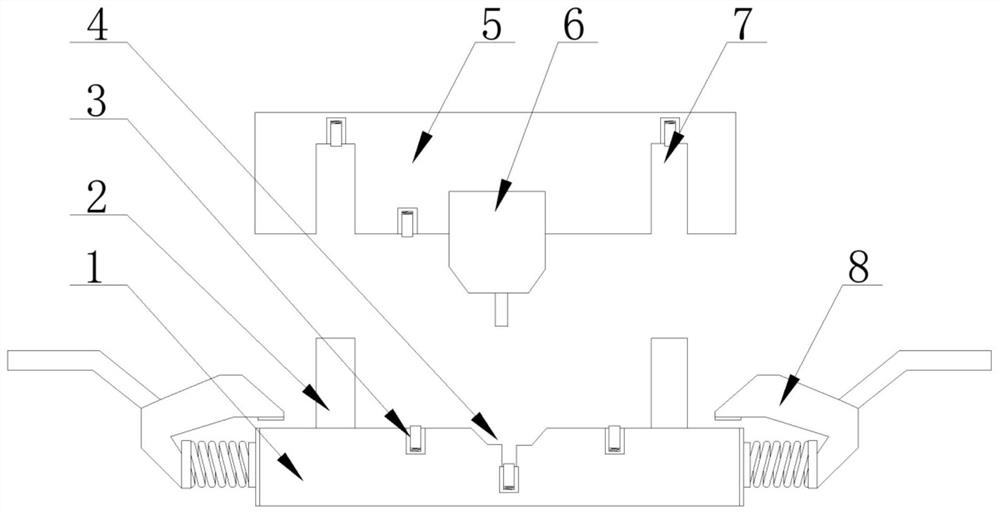

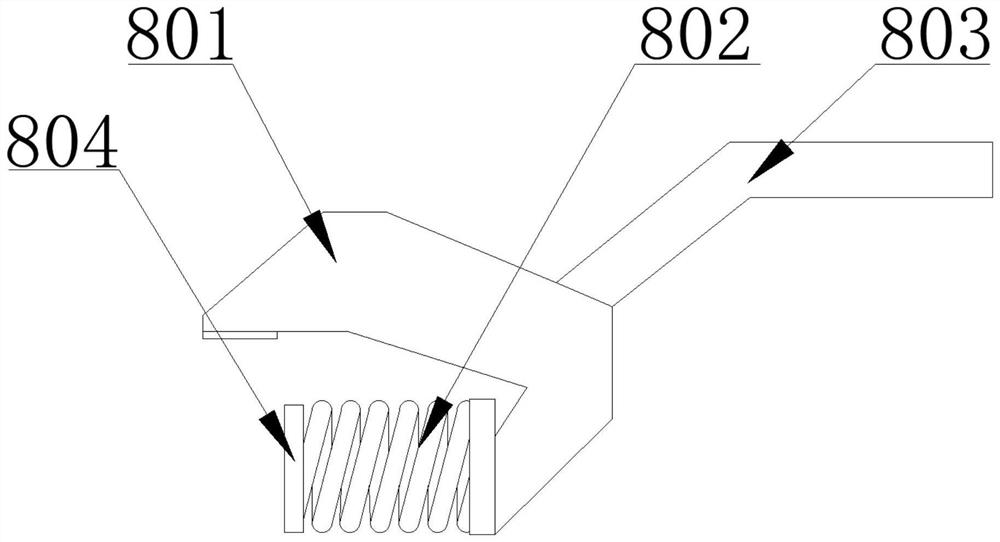

A liquid-filled drawing device and method for a miniature thin-walled metal tube

ActiveCN111495996BSolve the problem that is difficult to take outIncrease productivityDrawing diesTube drawingEngineering

The invention belongs to the technical field related to the drawing of miniature thin-walled metal tubes, and discloses a liquid-filled drawing device and method for miniature thin-walled metal tubes. The liquid-filled drawing device includes a forming component and a pressure control component, and the forming component is symmetrical Structure, which is used to fix the miniature thin-walled metal tube blank and guide it during the drawing process; the two ends of the forming component are respectively connected to the pressure control component through the liquid pipeline; the pressure control component is used to provide pressure liquid through the liquid pipeline For forming components, and used to control the pressure value of the pressure liquid in the micro thin-walled metal tube; The pulling part and the floating part are respectively used for fixing the two ends of the miniature thin-walled metal tube blank, and the miniature thin-walled metal tube blank is connected with the liquid pipeline. The invention can reduce the generation of cracks in drawing, improve the forming limit, improve the efficiency and quality, and reduce the cost.

Owner:HUAZHONG UNIV OF SCI & TECH

High-strength stamping die for steel

InactiveCN112453212AEffectively fixedEasy to fixShaping toolsMetal-working feeding devicesEngineeringMechanical equipment

The invention discloses a high-strength stamping die for steel, in particular to the field of manufacturing of mechanical equipment. The high-strength stamping die comprises a fixed die and a moving die, wherein the fixed die and the moving die are used for stamping; a first stamping head is mounted on the surface of the fixed die; a second clamping slot is formed in the center of the fixed die; elastic pressing clips are mounted at the two ends of the fixed die in a sliding manner; first clamping slots are formed in the two ends of the bottom face of the moving die and are matched with the first stamping head; a second stamping head is fixedly mounted on a position where the bottom face of the moving die corresponds to the second clamping slot; a plurality of round holes are formed in theopposite sides of the fixed die and the moving die; and ejector pins are movably mounted in the round holes. According to the high-strength stamping die disclosed by the invention, by using the elastic pressing clips, a stamping piece can be effectively and firmly fixed to the fixed die in a descending process of the moving die, displacement of workpieces caused by vibration due to operation of machines is prevented, and the stamping piece withdraws from the surfaces of the workpieces slowly through pressure of the moving die when the moving die approaches the stamping piece, and manual operation is not required, and the problem that the yield rate caused by displacement of the stamping piece is reduced is solved.

Owner:无锡质诚胜精密机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com