An automatic riveting machine professionally applied to the combined installation of aircraft

A combined installation and riveting machine technology, which is applied in the field of aviation passenger aircraft, can solve the problems of riveting parts that are difficult to move, heavy structure, etc., and achieve the effect of improving the success rate, good effect, and avoiding the phenomenon of burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

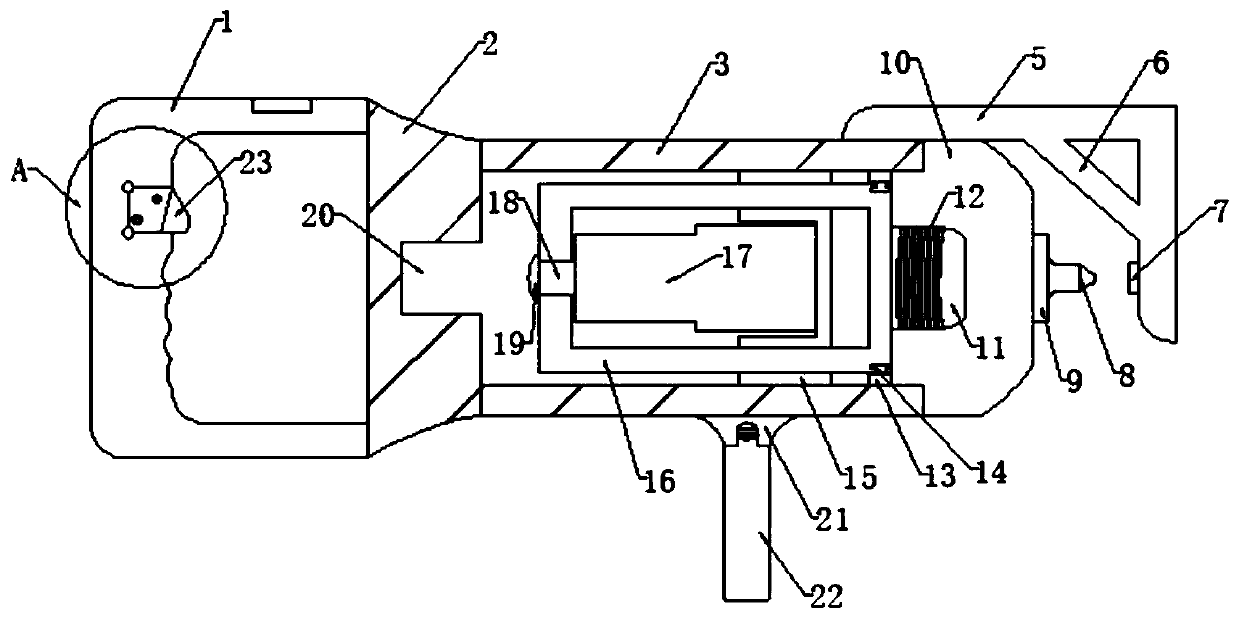

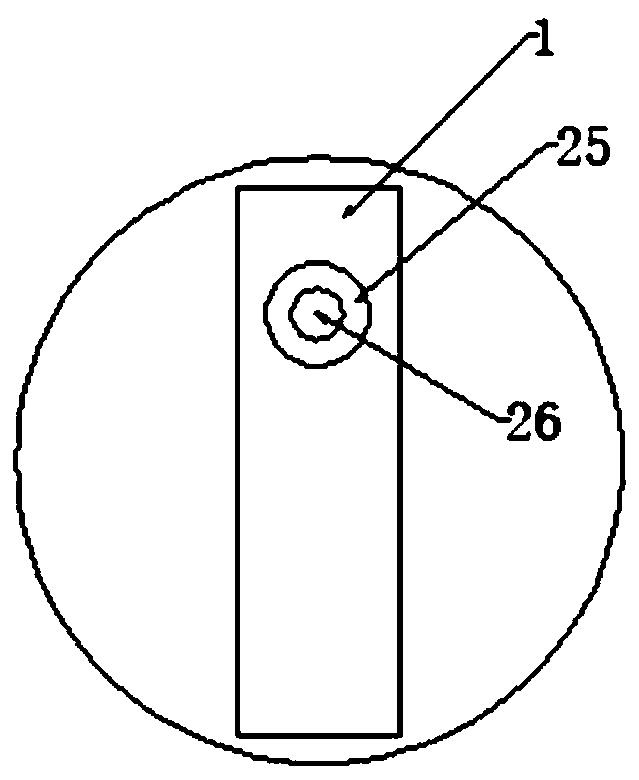

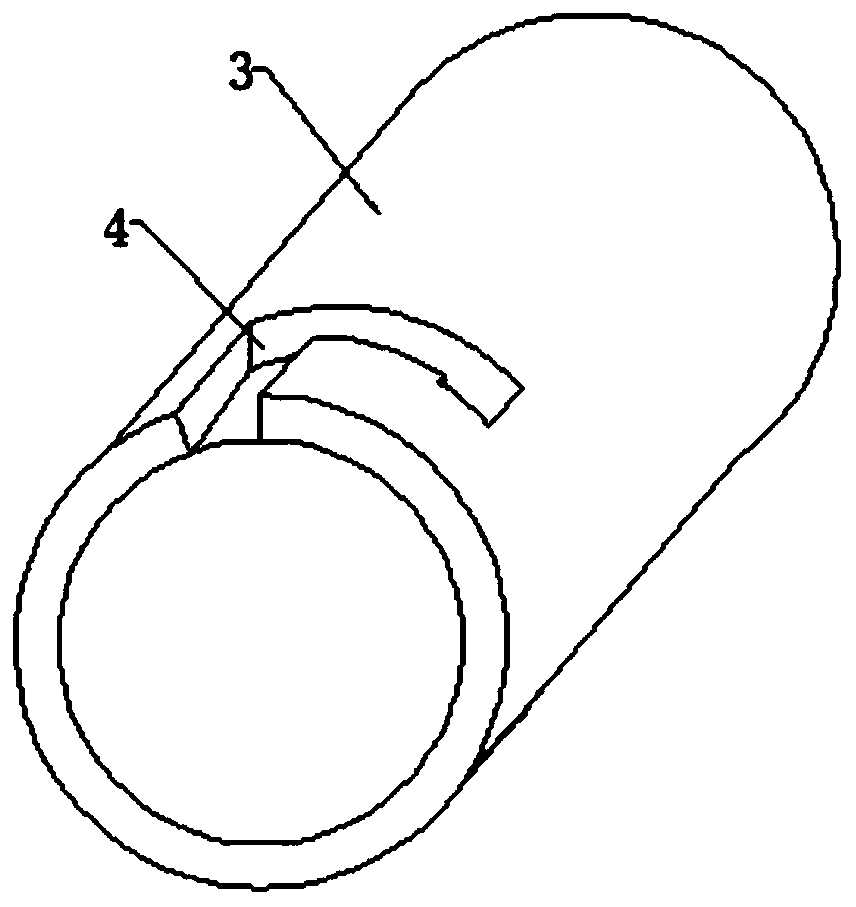

[0026] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

[0027] Such as Figure 1-5 As shown, an automatic riveting machine professionally applied to combined installation of aircraft, including a handle 1, a connecting block 2, a riveting machine shell 3, a riveting device 10 and a riveting pad 5, the handle 1 is in the shape of a 匸, and The inner side of the handle 1 is provided with a riveting switch 23, and one side of the handle 1 is provided with a connecting block 2, and the handle 1 and the connecting block 2 are tightly welded and fixed, and one end of the connecting block 2 is provided with a riveting machine shell 3, The connection block 2 is tightly welded and fixed with the riveting machine shell 3, a riveting device 10 is provided at one end of the riveting machine shell 3, a riveting pad 5 is provided at one side of the rivetin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com