Patents

Literature

39 results about "Self-buckling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A column can buckle due to its own weight with no other direct forces acting on it, in a failure mode called self-buckling. In conventional column buckling problems, the self-weight is often neglected since it is assumed to be small when compared to the applied axial loads. However, when this assumption is not valid, it is important to take the self-buckling into account. Elastic buckling of a "heavy" column i.e., column buckling under its own weight, was first investigated by Greenhill at 1881.

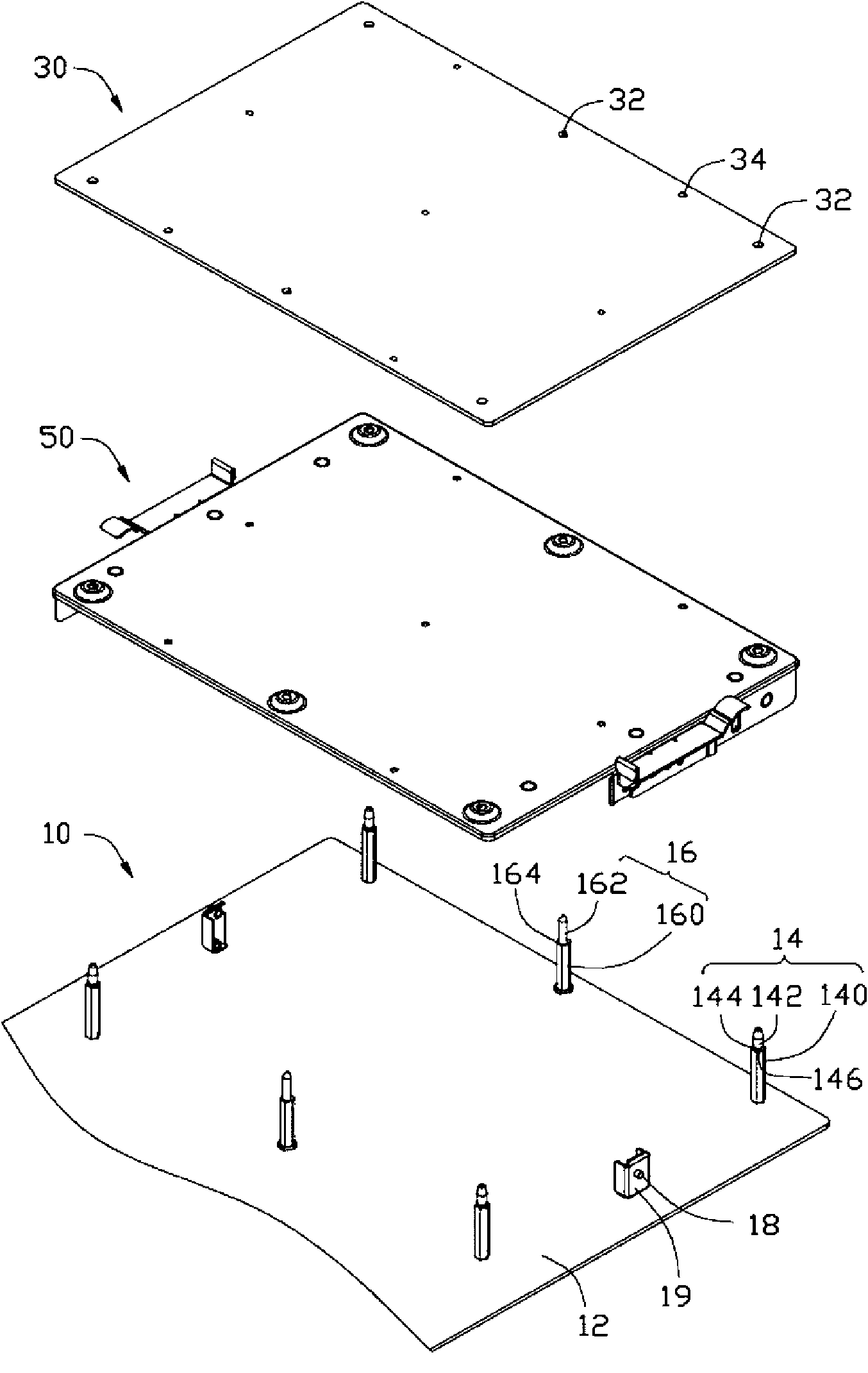

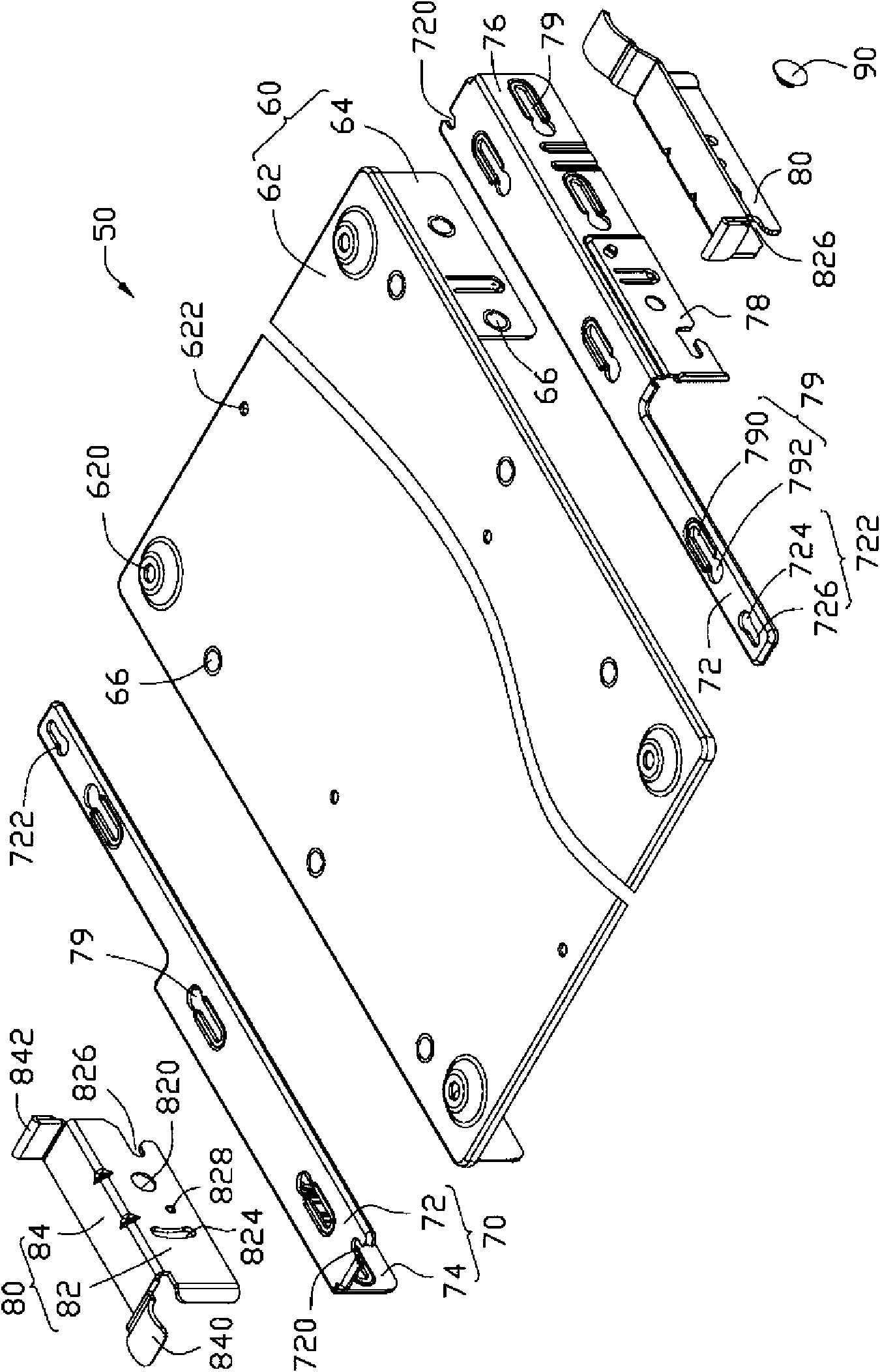

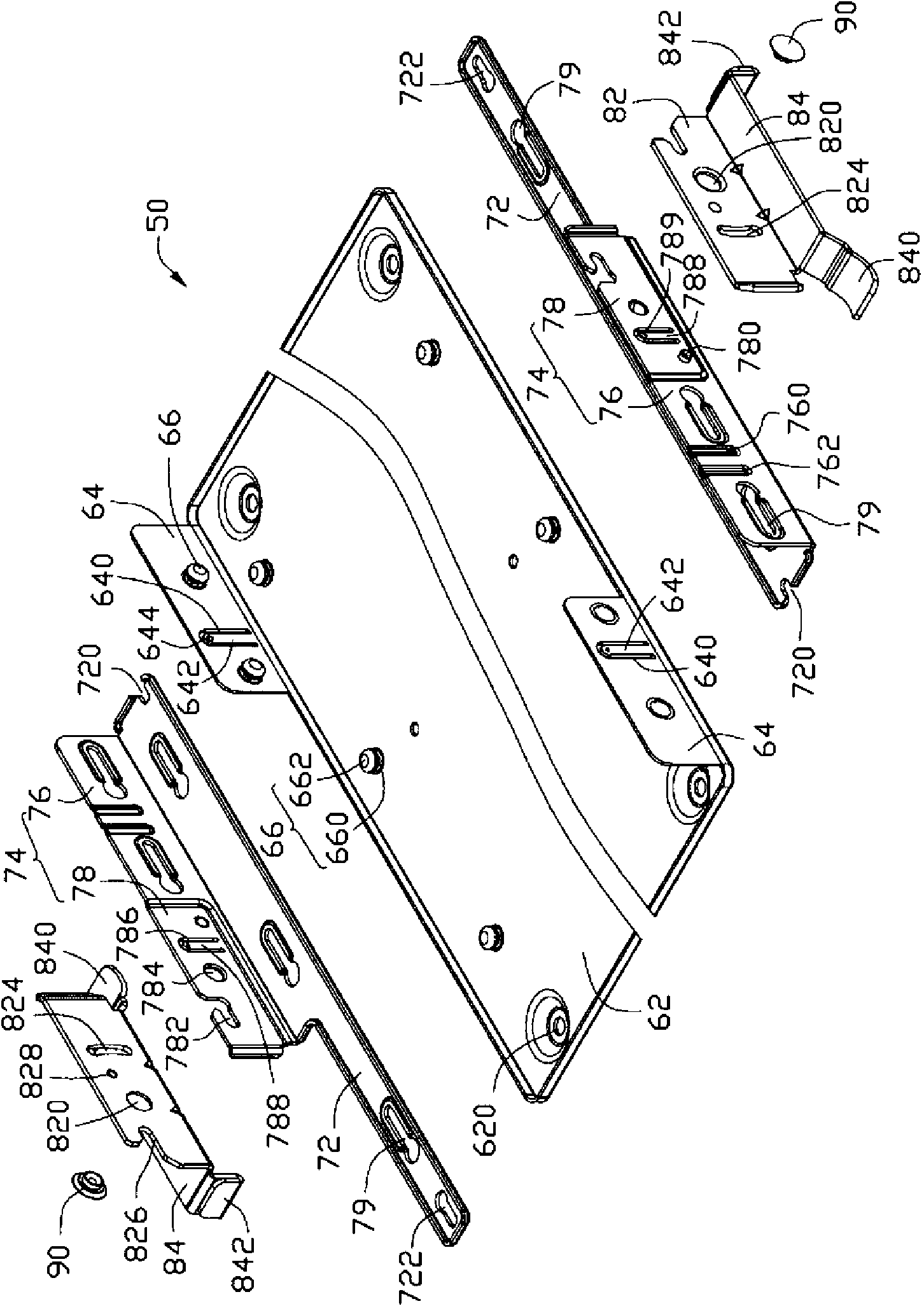

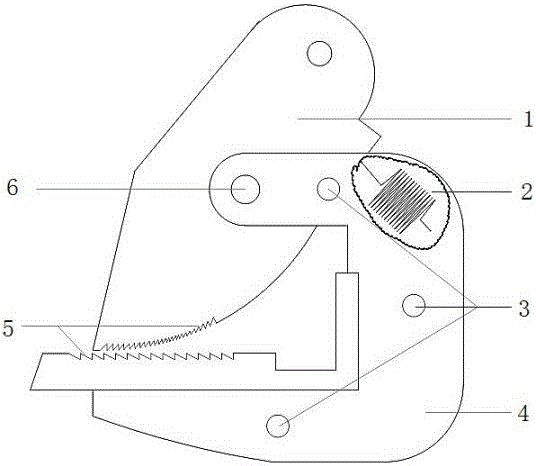

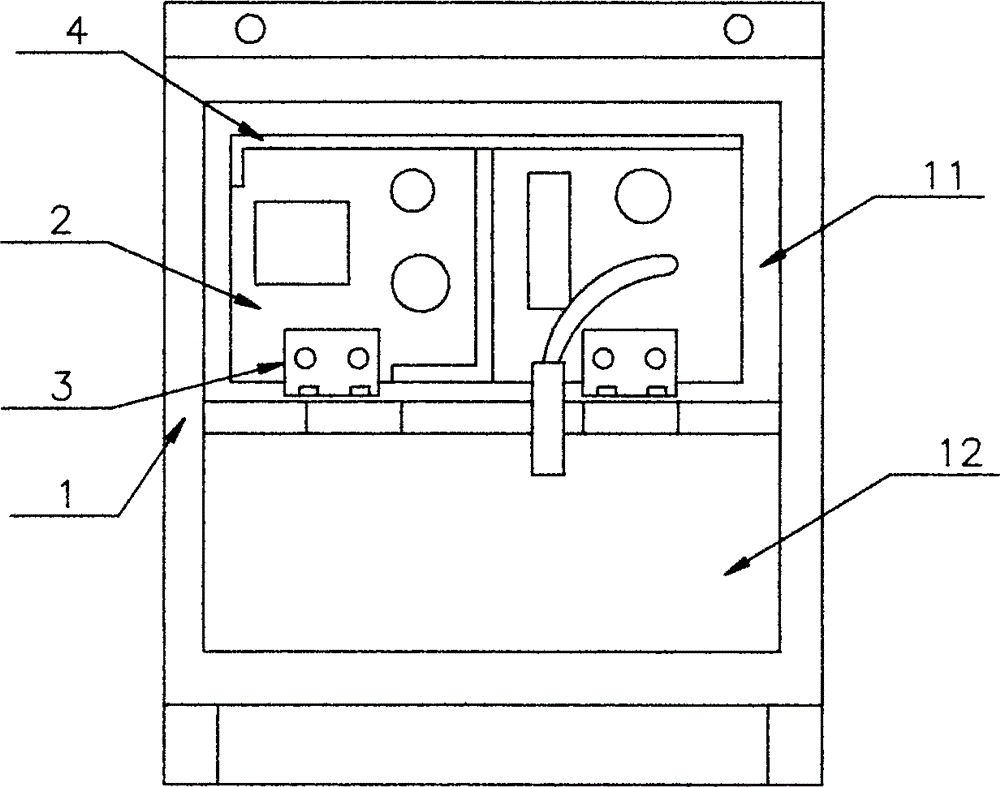

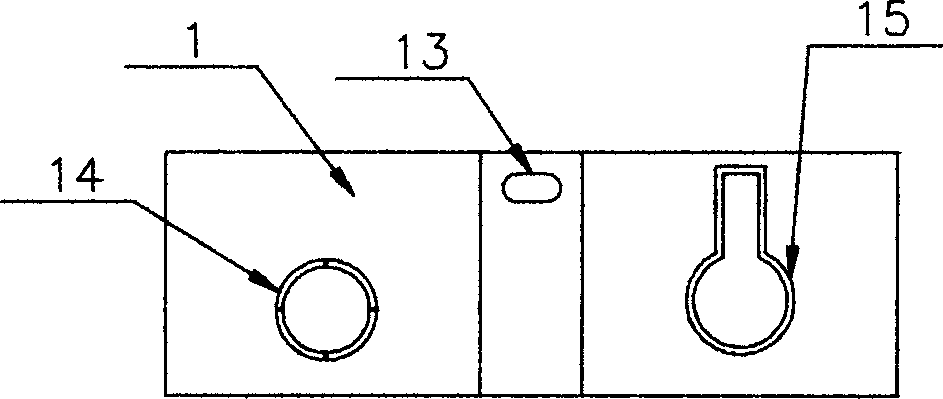

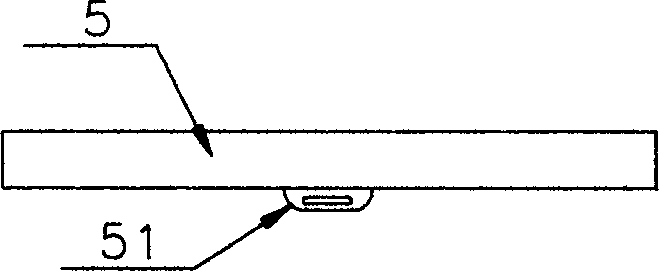

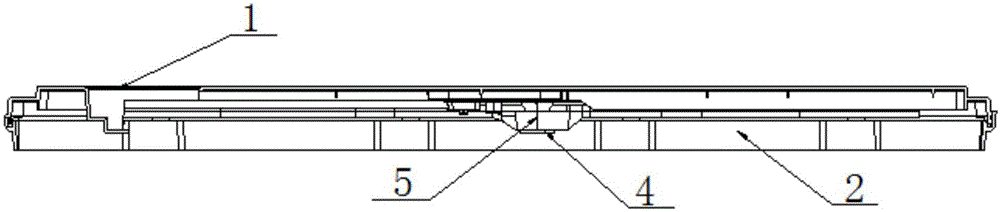

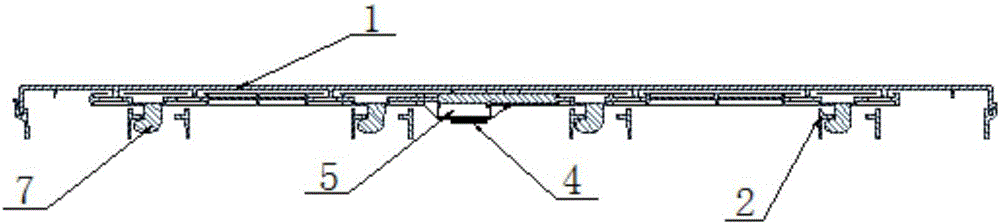

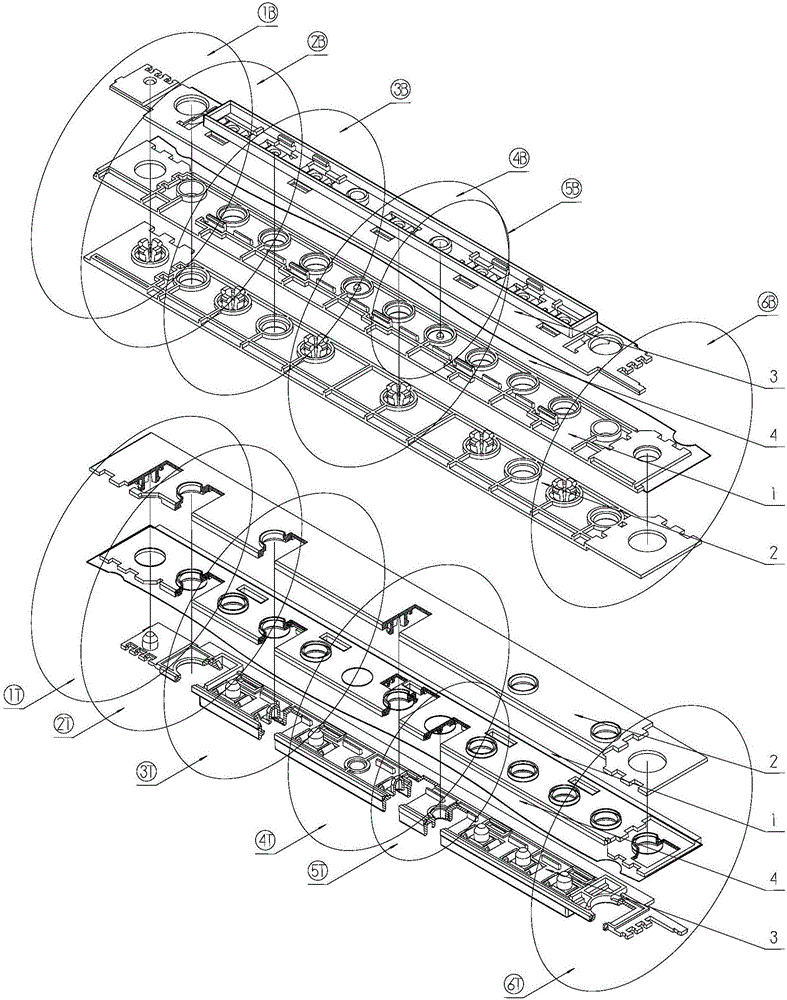

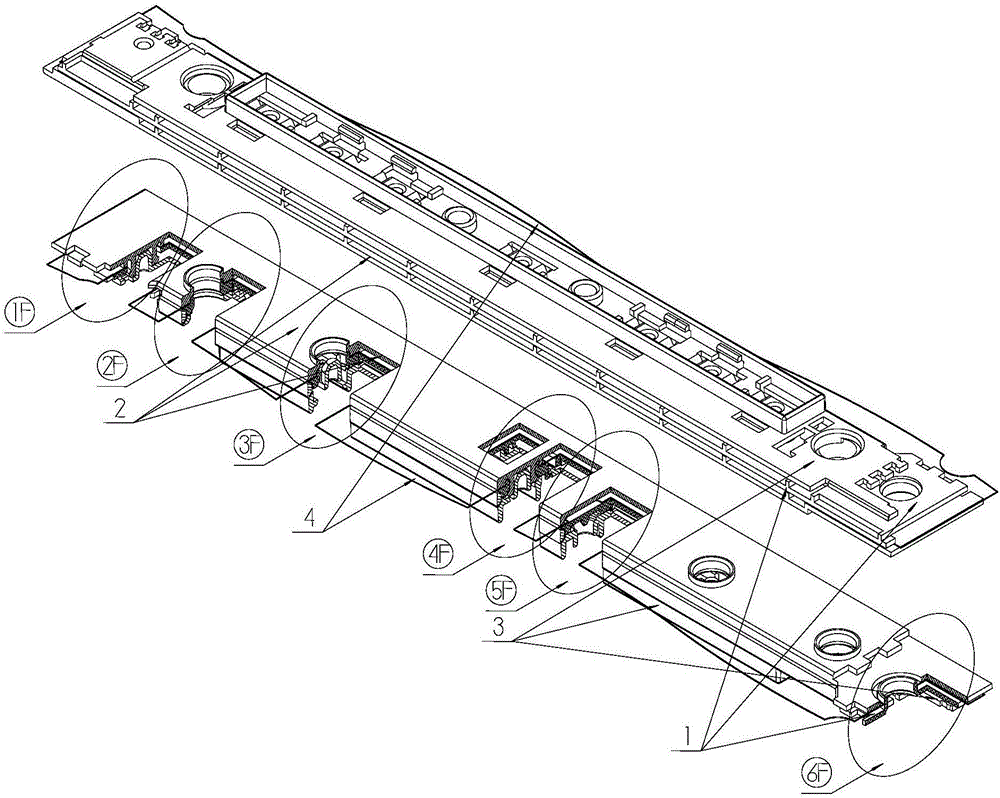

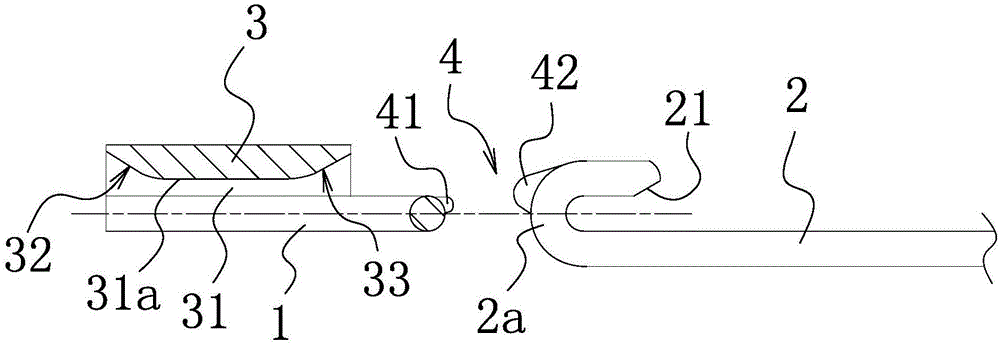

Server and buckling mechanism thereof

InactiveCN102073354ARealize disassemblyEasy to assemble and disassembleServersDigital processing power distributionSelf-bucklingMechanical engineering

The invention relates to a server comprising a base plate, a circuit board and a buckling mechanism, wherein the buckling mechanism is used for detachably installing the circuit board on the base plate and comprises a bracket and a sliding part, wherein the bracket is provided with a connecting pin; the connecting pin comprises a rod body and an end part, wherein the rod body is connected with the bracket, the end part is formed on the tail end of the rod body, and the end part is bigger than the rod body; the sliding part is provided with a clamping groove and a sliding groove, wherein the sliding groove corresponds to the connecting pin; the clamping groove comprises a circular hole and a limit groove, the circular hole faces to the sliding groove, the limit groove is communicated with the circular hole, and the diameter of the circular hole is larger than the width of the limit groove; the sliding groove comprises an opening and a slot, wherein the opening faces to the clamping groove, the slot is communicated with the opening, the opening is larger than the end part of the connecting pin, and the slot is smaller than the end part of the connecting pin but not smaller than the rod body of the connecting pin; the end part of the connecting pin penetrates through the opening of the sliding groove; and the sliding part slides towards a first direction relative to the bracket to enable the rod body of the connecting pin to be clamped into the slot of the sliding groove, therefore, the disassembly and the assembly of the circuit board can be realized through the self buckling matching of the buckling mechanism, without screws, screwdrivers, and the like, and the advantages of simpleness and convenience are achieved.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

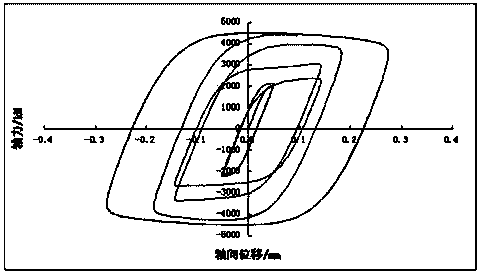

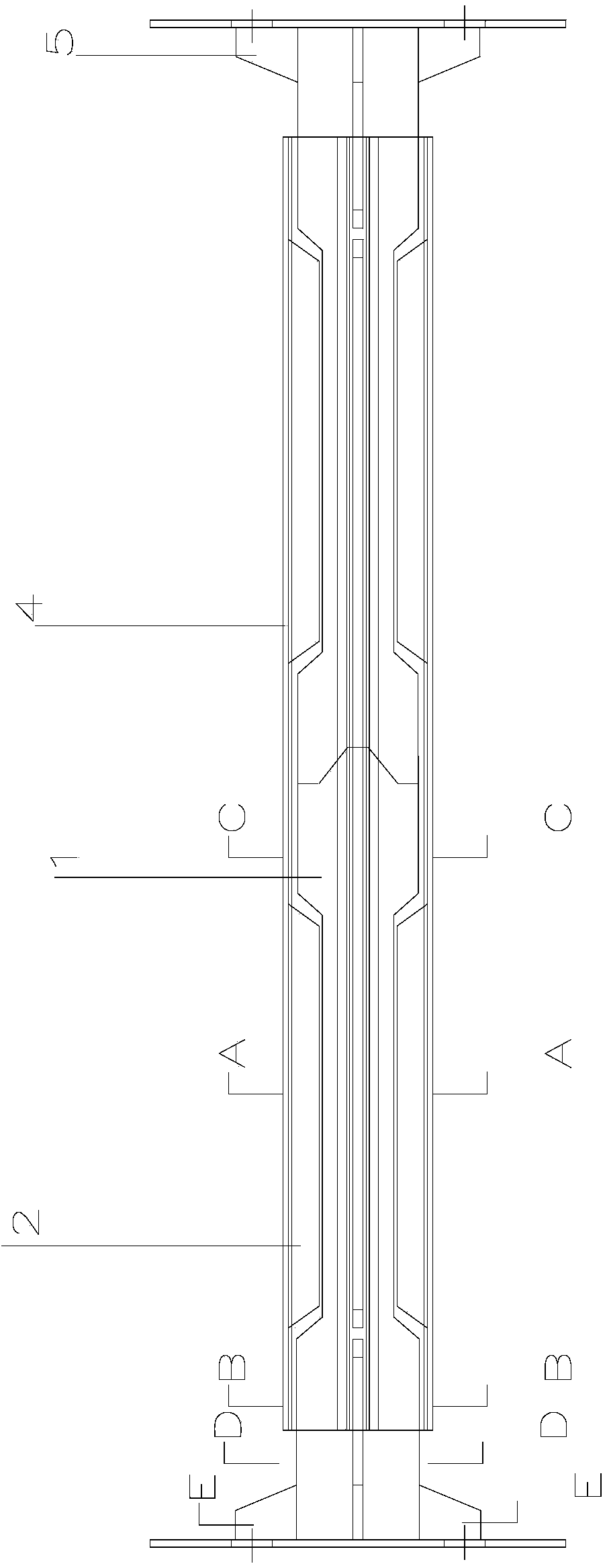

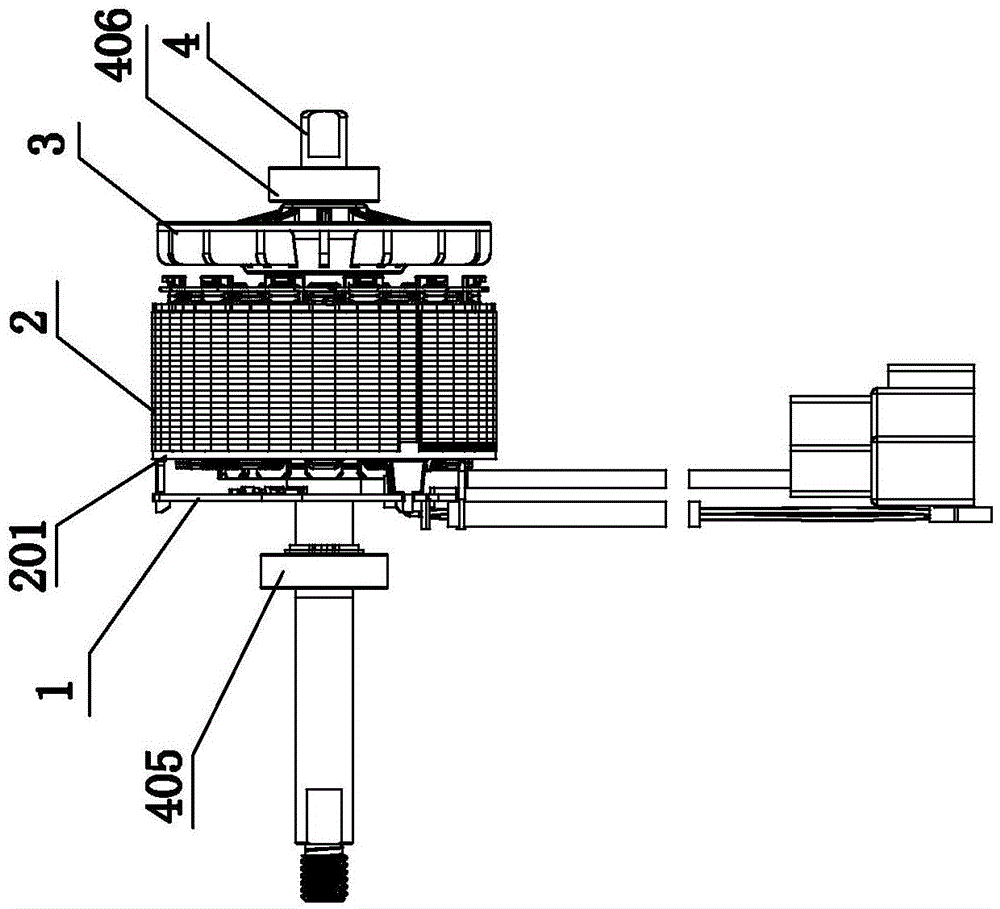

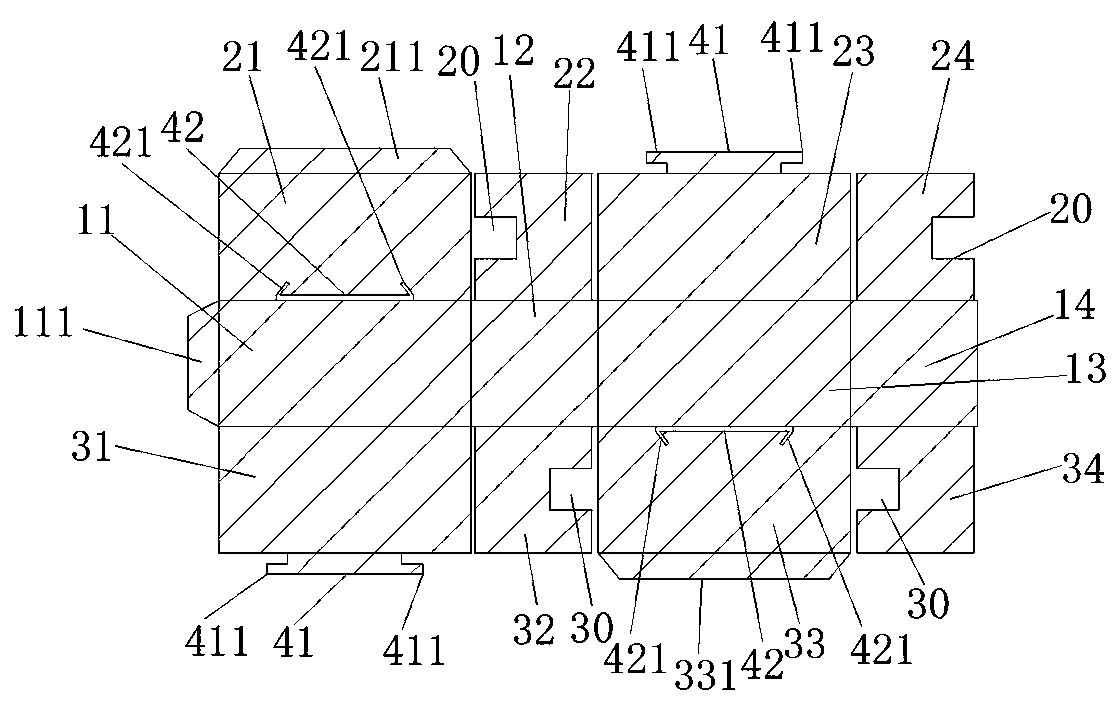

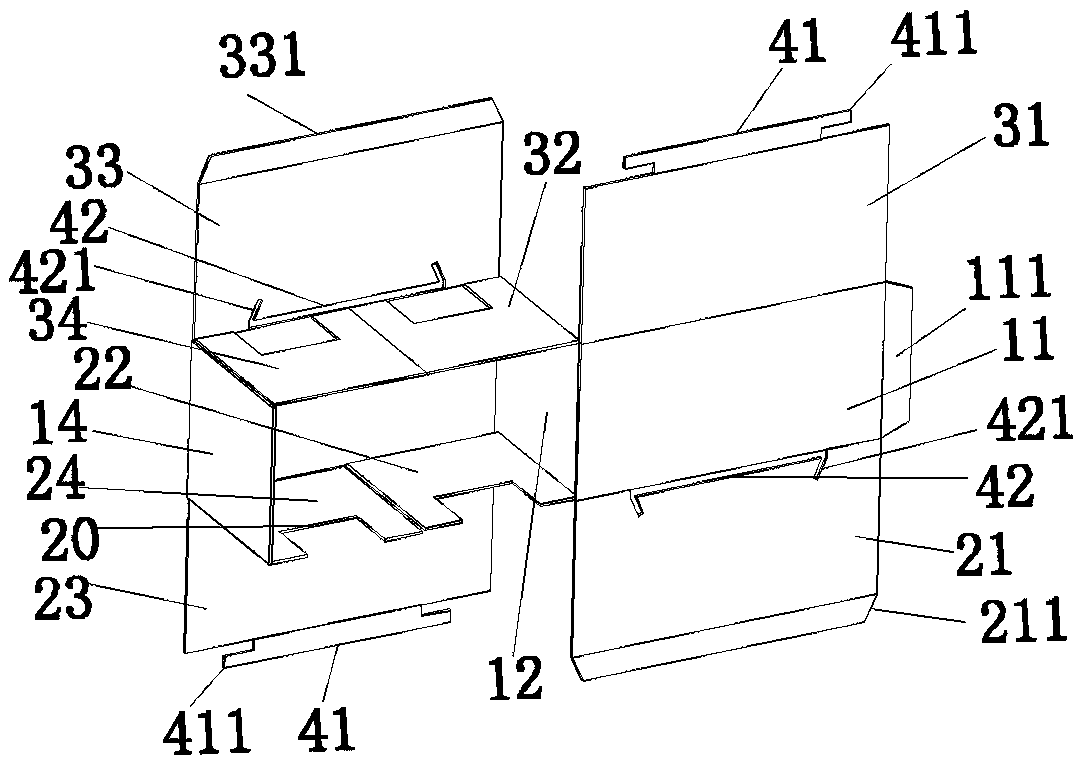

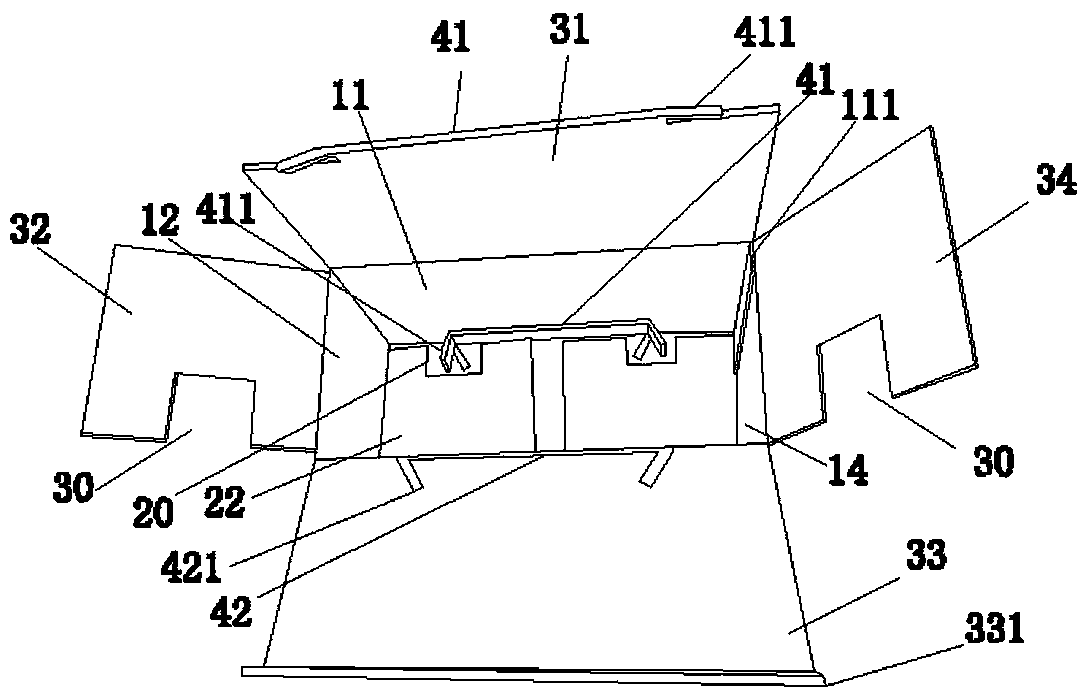

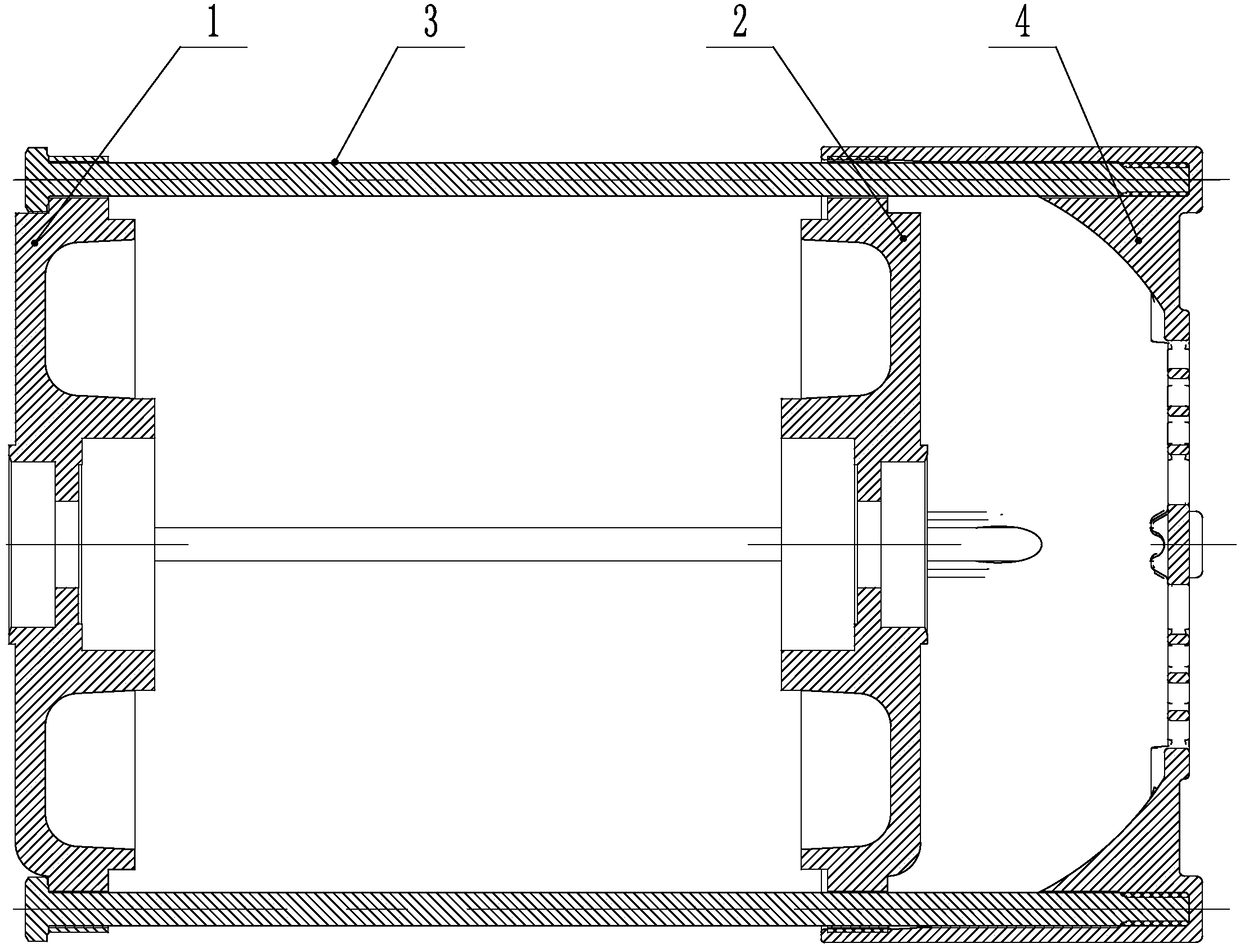

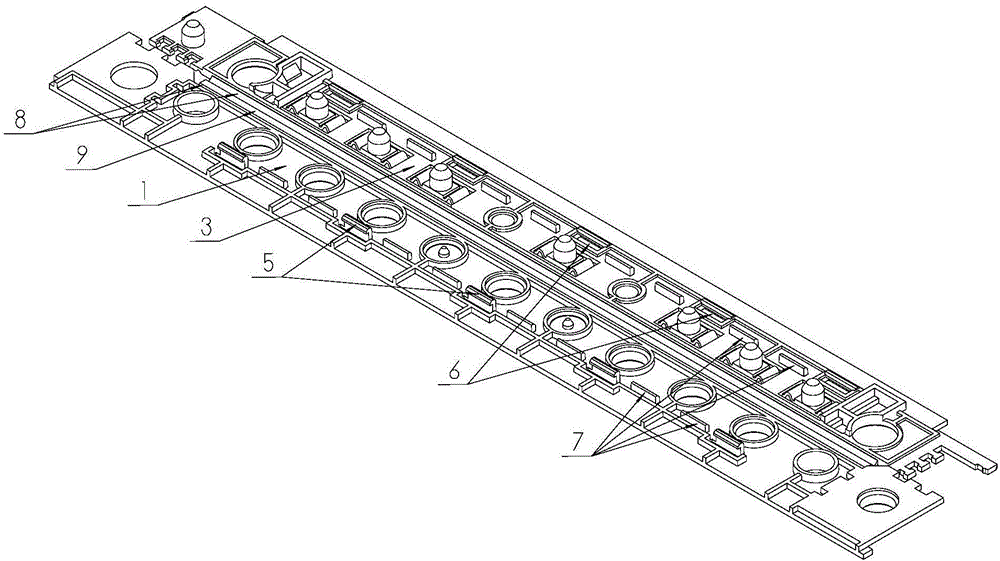

All-steel four-steel pipe multistage mountable overlong buckling-restrained brace

The invention discloses an all-steel four-steel pipe multistage mountable overlong buckling-restrained brace, and belongs to a novel energy dissipation and seismic mitigation component. On the basis of the traditional buckling-restrained brace, the steel core and the outer restraining component are manufactured and transported in stages and mounted at the construction site. By using the peripheral restraining mechanisms of four hollow steel pipes, the weight of the overlong buckling-restrained brace is effectively reduced so as to solve the difficulties that the general buckling-restrained braces are overlong to cause overlarge self-weight and the initial deflection cannot satisfy the existing requirements. The working section of the steel core is changed from one section to a plurality of sections, so that the stress of the steel core is more uniform and reasonable; the sections are connected to ensure that the length can be up to 30-50 meters; the all-steel four-steel pipe multistage mountable overlong buckling-restrained brace can be applied to the air cooling platform and special structures such as the large-scale industrial buildings and the like to improve the functionality of the buildings through increasing the structural rigidity, and can also be used for protecting the main structure under the design intensity, severe intensity and super-large earthquakes through self-buckling energy consumption.

Owner:BEIJING UNIV OF TECH

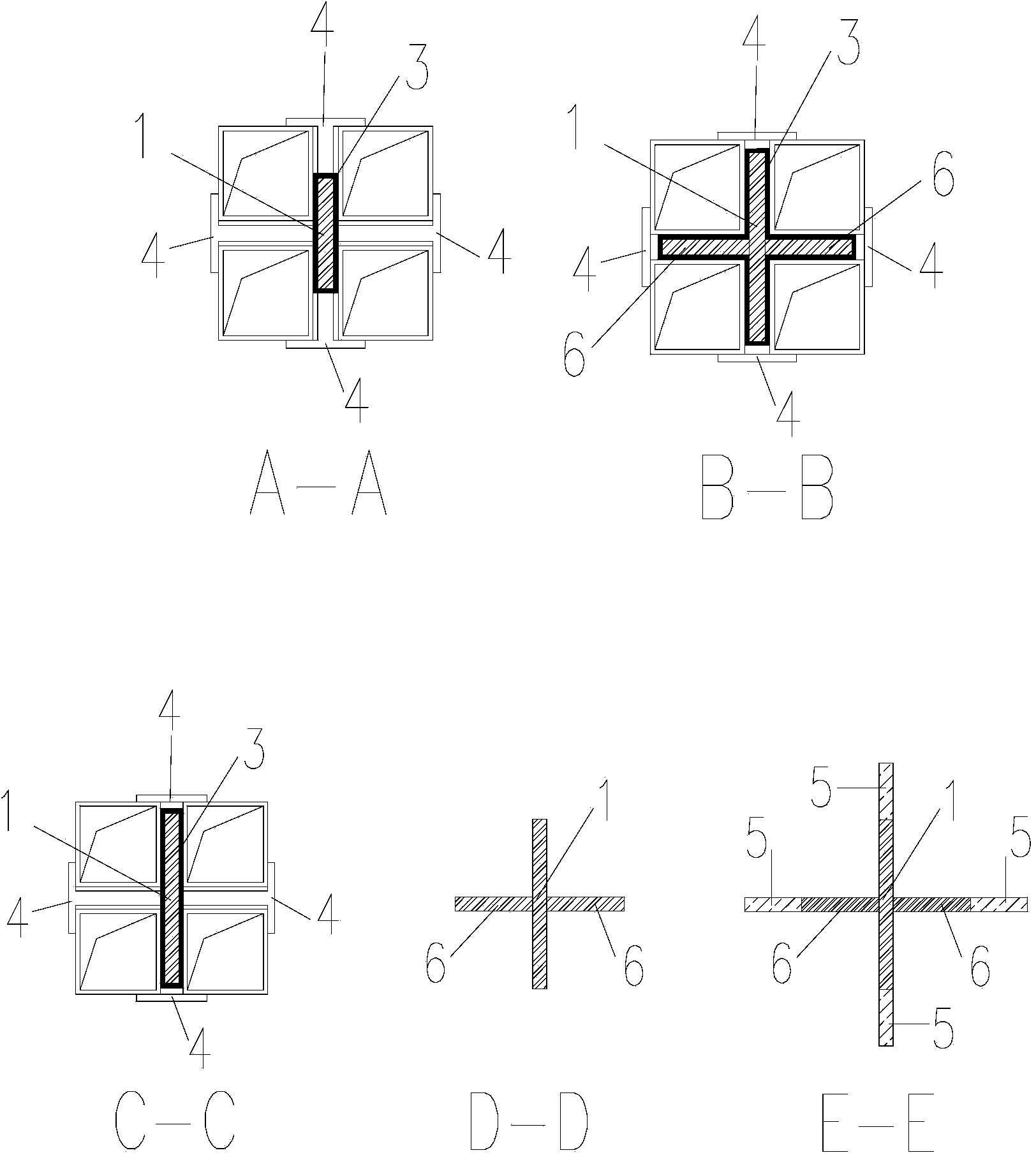

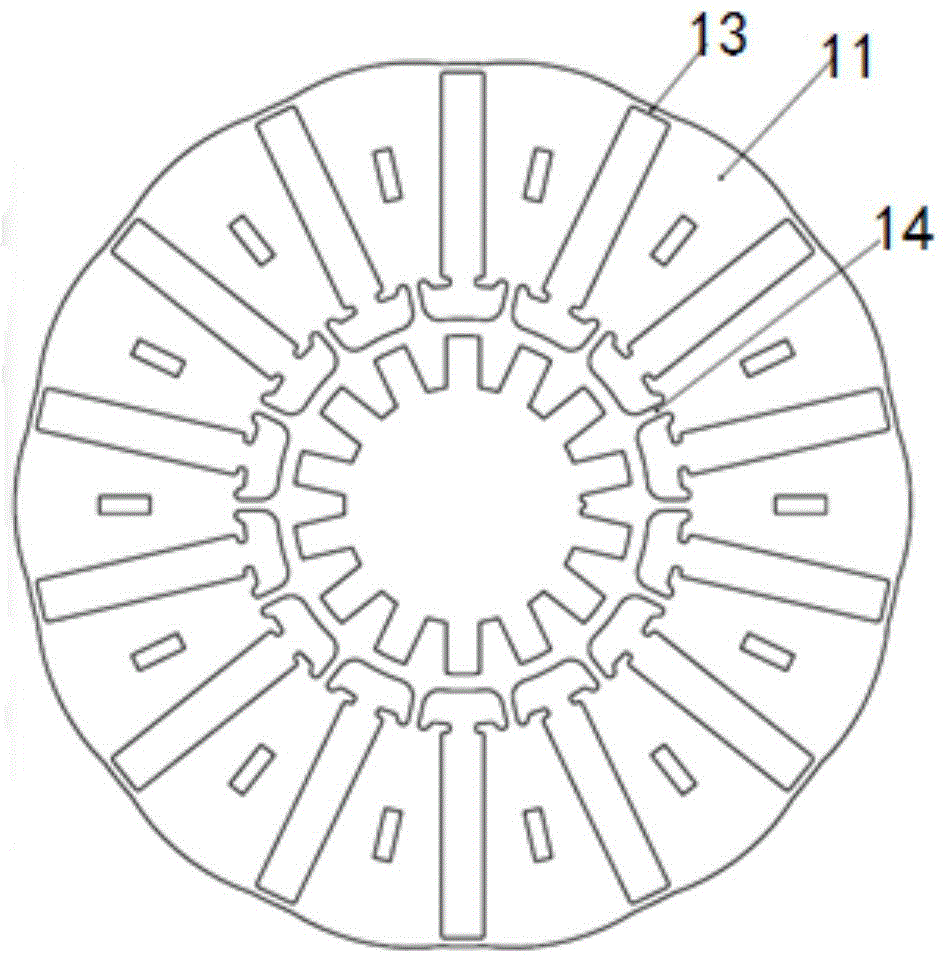

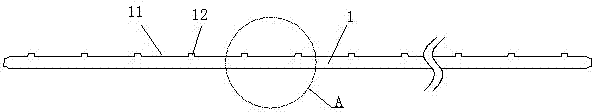

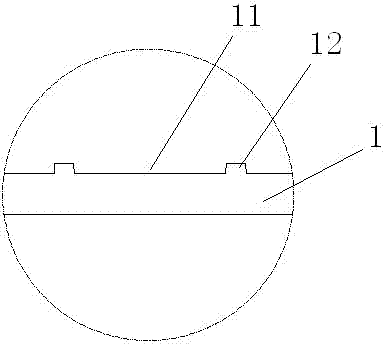

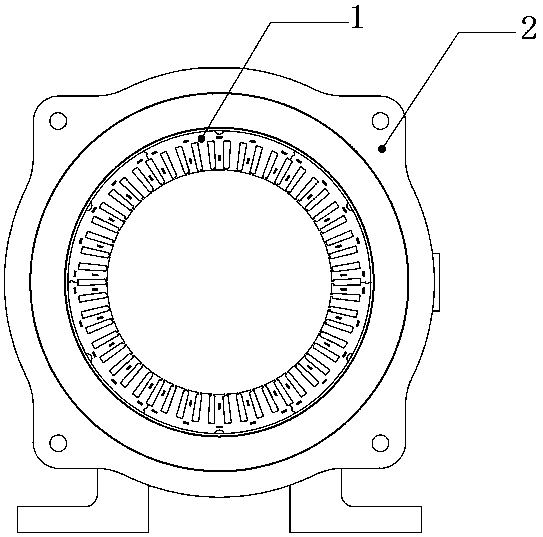

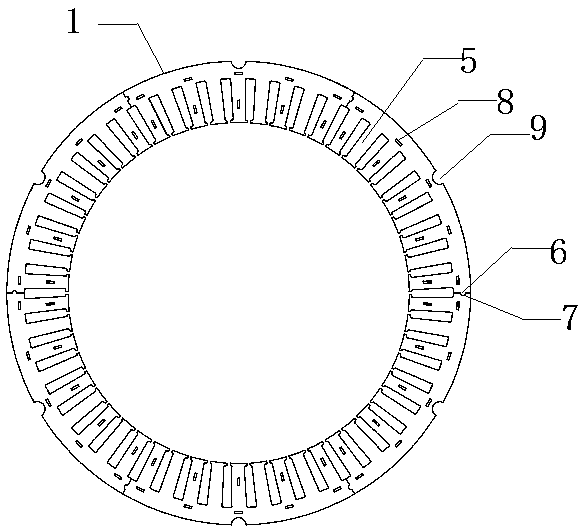

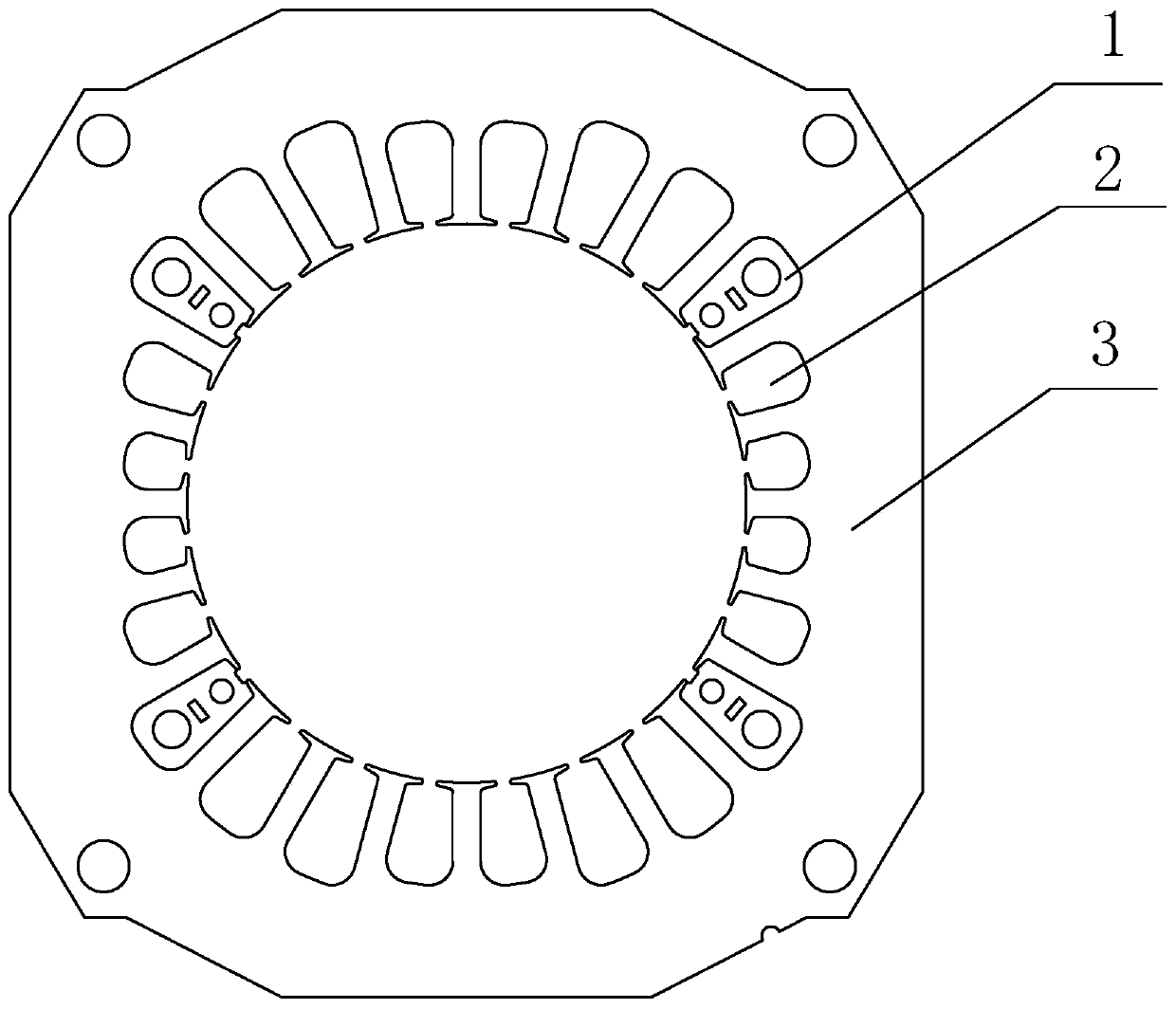

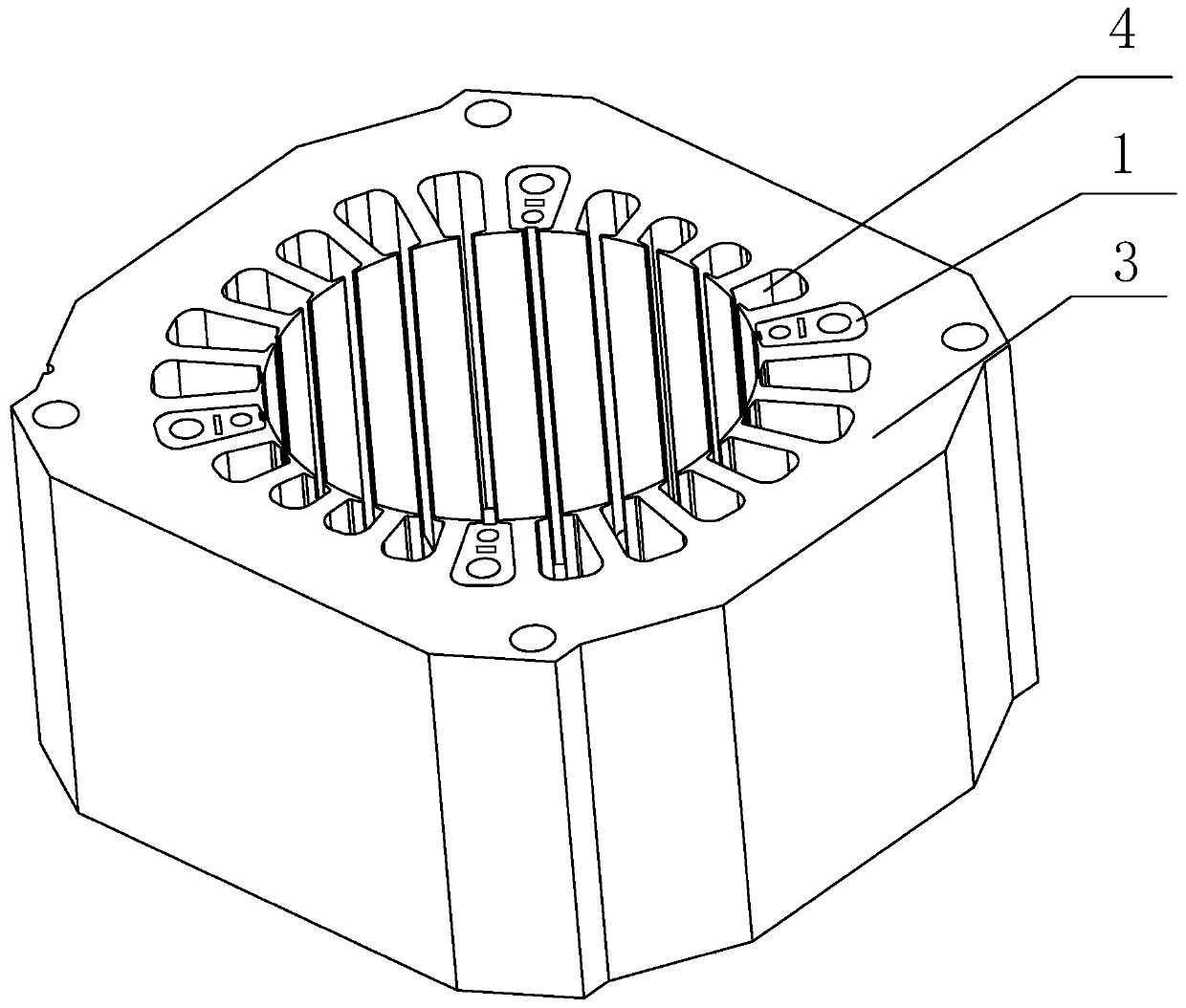

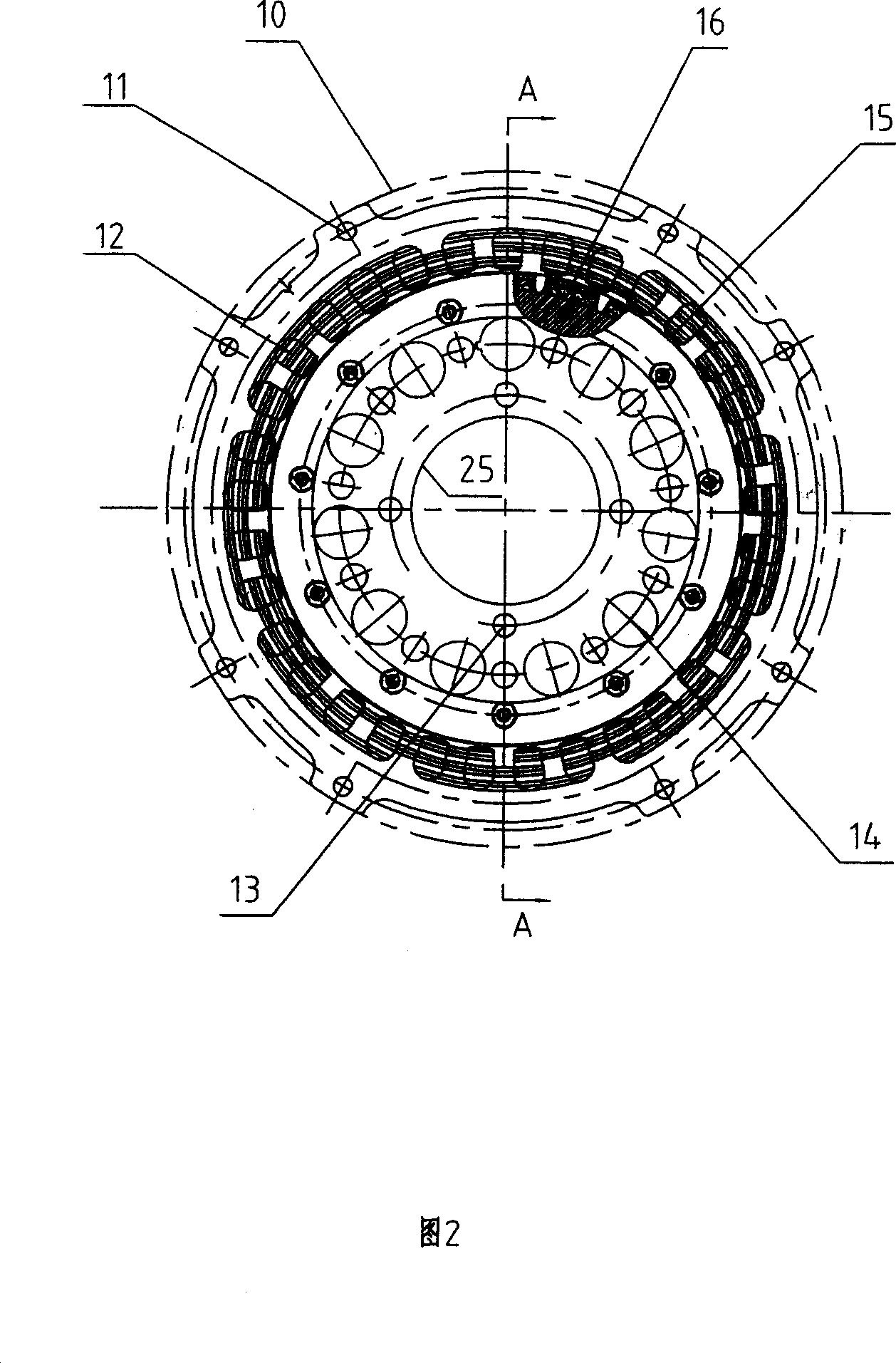

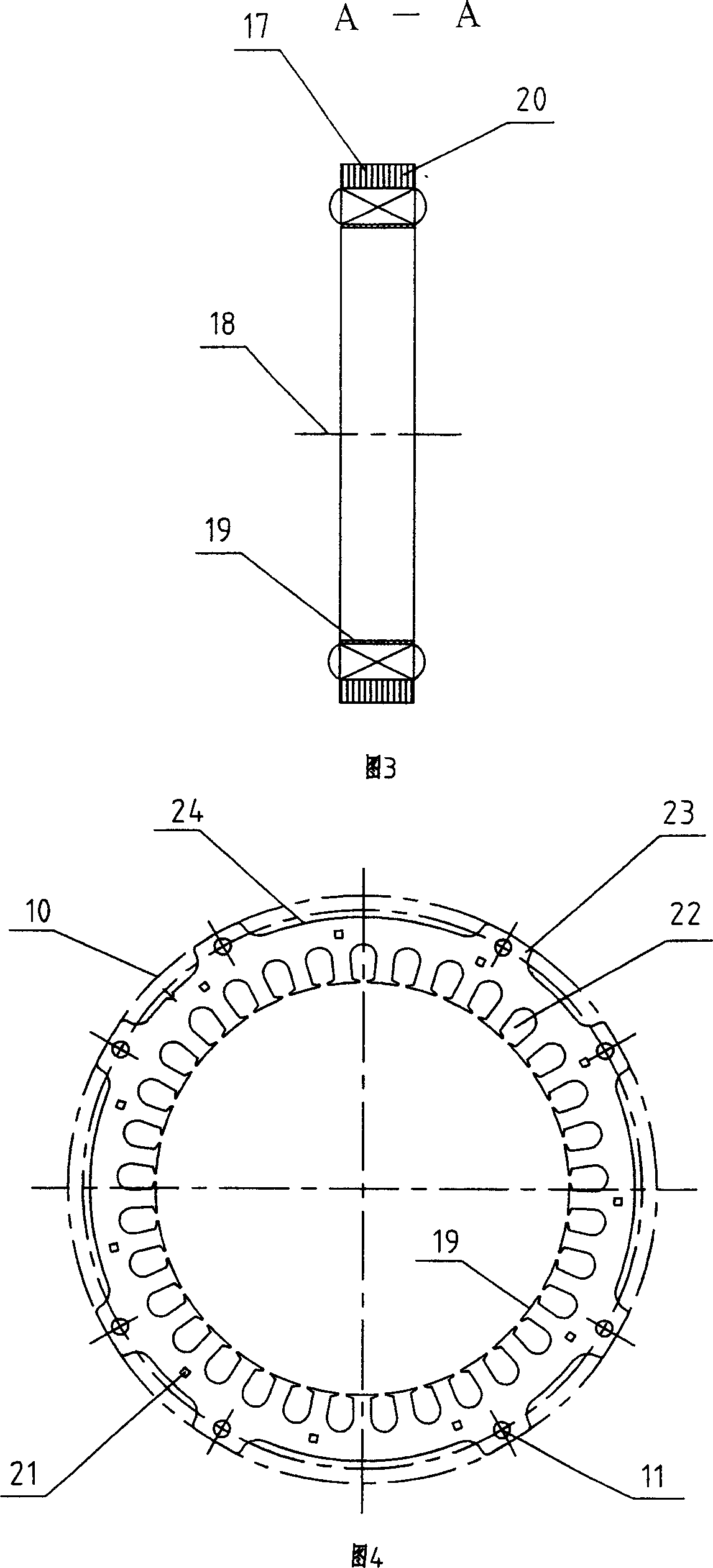

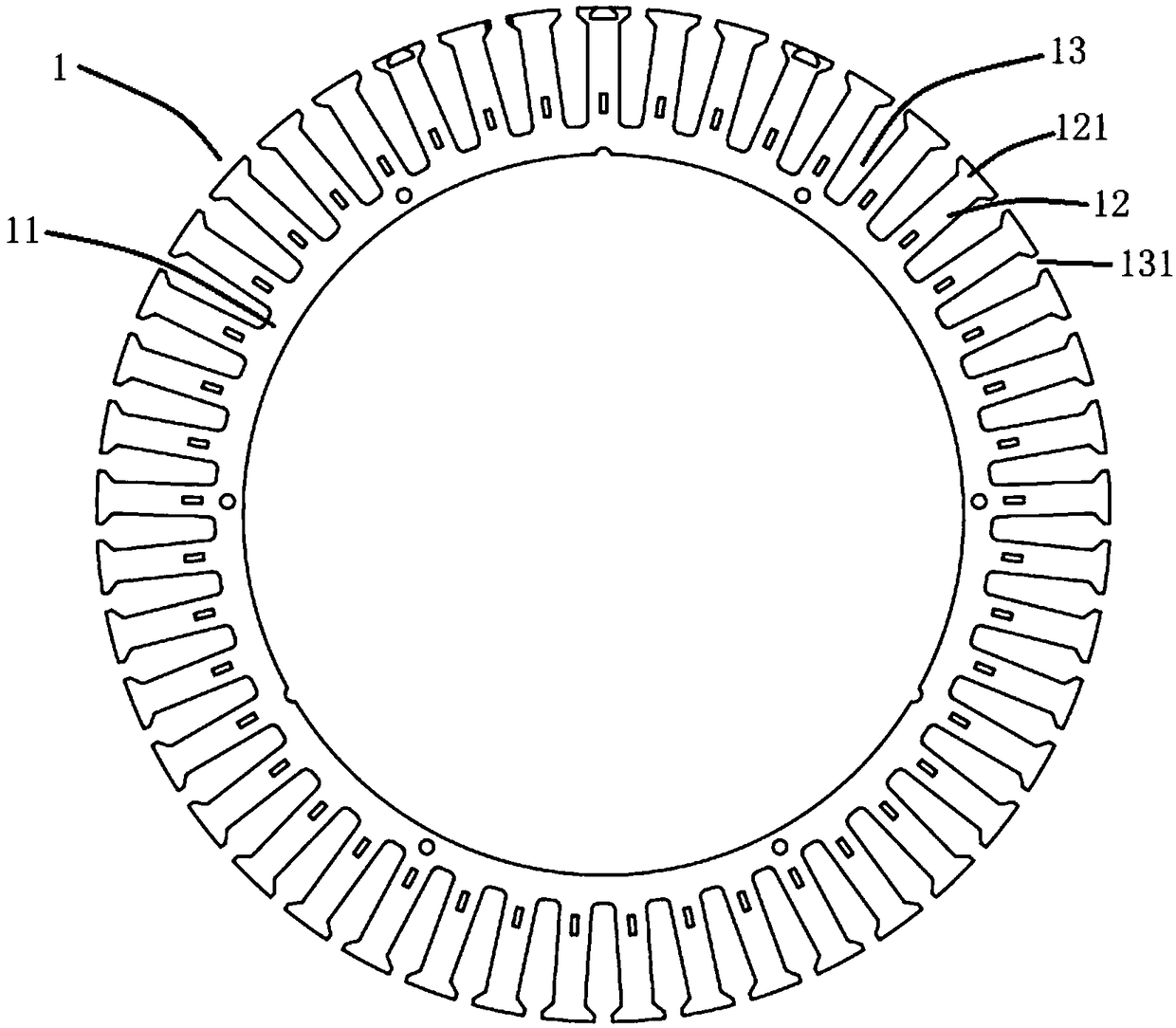

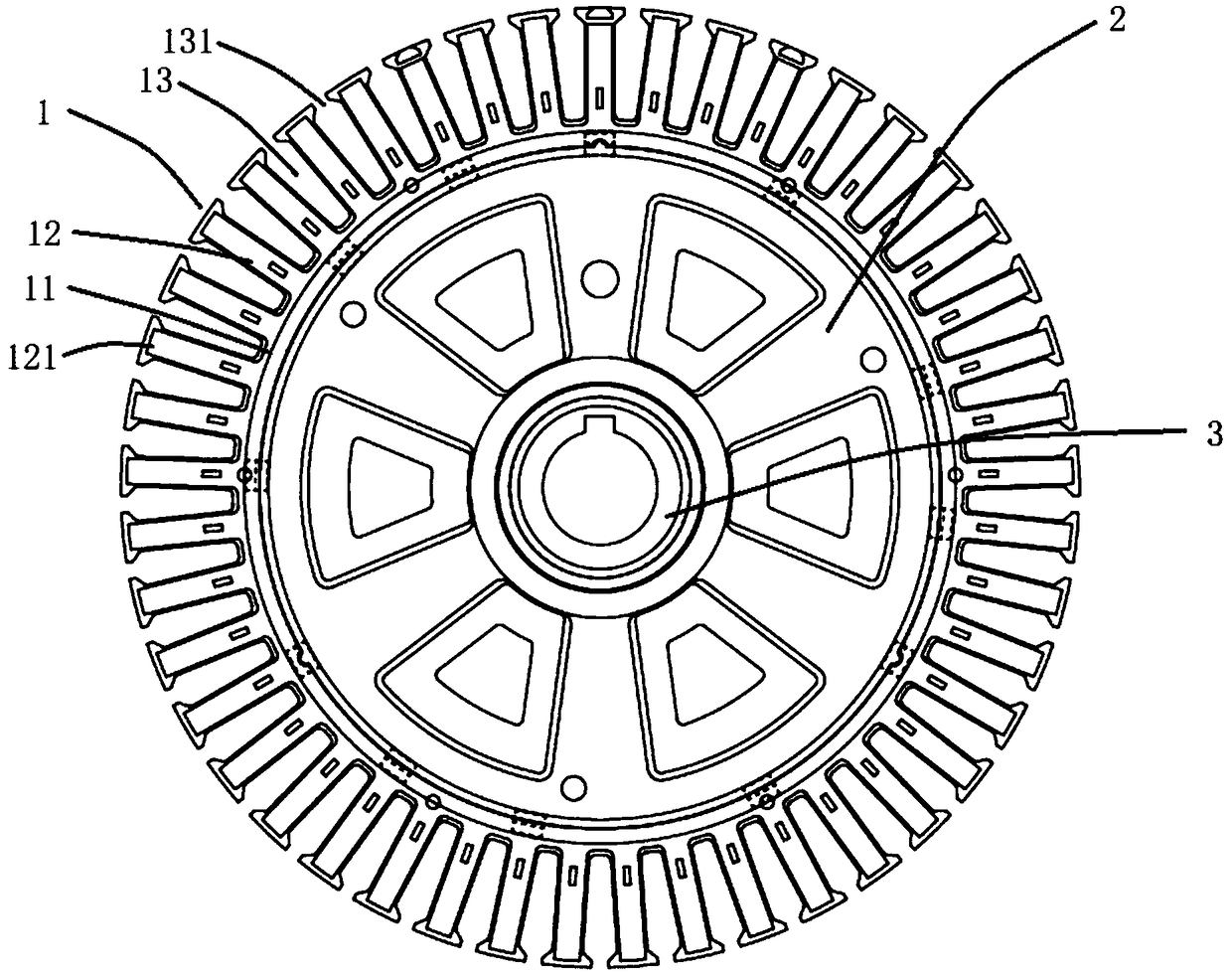

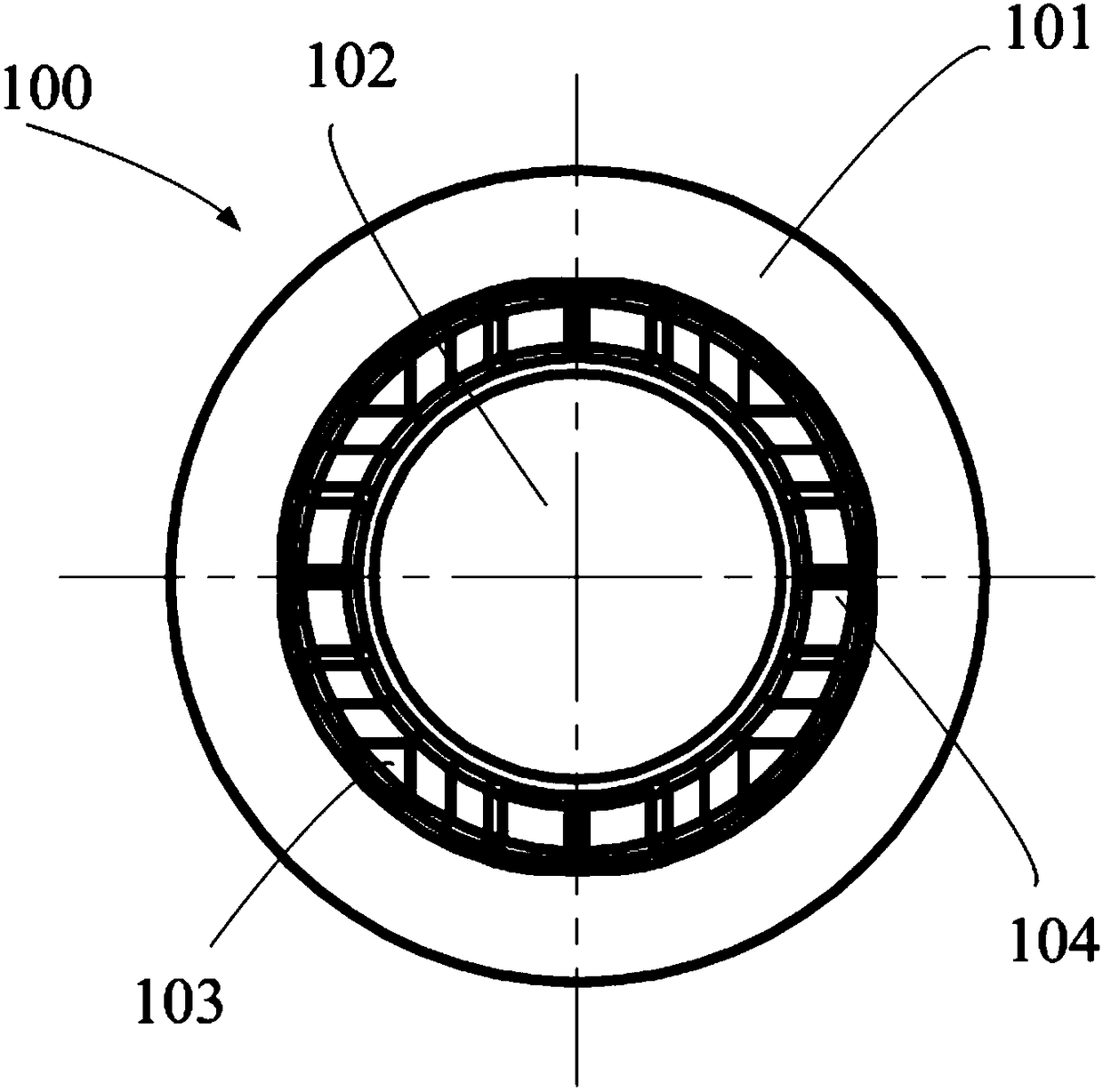

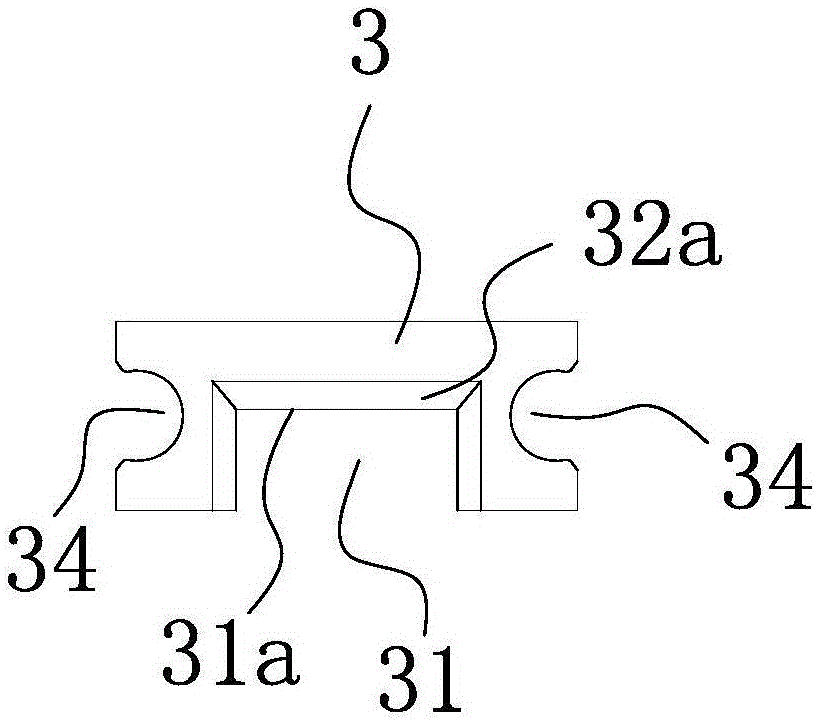

Split type stator core structure and splicing method

The invention discloses a split type stator core structure and a splicing method. The structure includes a full circular stator core; The full circular stator core includes multiple stator core splitstructures that can be spliced together into a full circle; each of the stator core split structures includes multiple stator split punching sheets; each of the stator split punching sheets includes an arc yoke portion and multiple notch teeth; the multiple notch teeth are uniformly distributed on the inner ring of the yoke portion; notches are formed between the adjacent notch teeth; one end of the yoke portion is provided with a process groove, and the other end is provided with a process boss; the outer ring of the yoke potion is provided with a positioning groove and a first welding groove; and the yoke portion and the notch teeth are provided with multiple self-buckling points, and the multiple stator split punching sheets are overlapped with each other by the self-buckling points toform the stator core split structures. The split type stator core structure is high in the utilization rate of materials, enables the stamping force to be greatly reduced, and be mass-produced by a small-tonnage high-speed punching machine; and the size, form and location tolerance and structure strength of the split type stator core structure are conveniently controlled by the positioning grooveand by performing welding on each of the first welding grooves.

Owner:宁波菲仕自动化技术有限公司

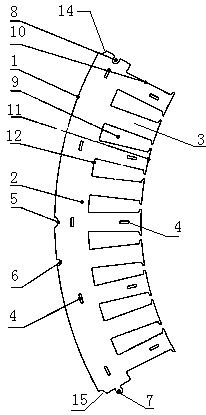

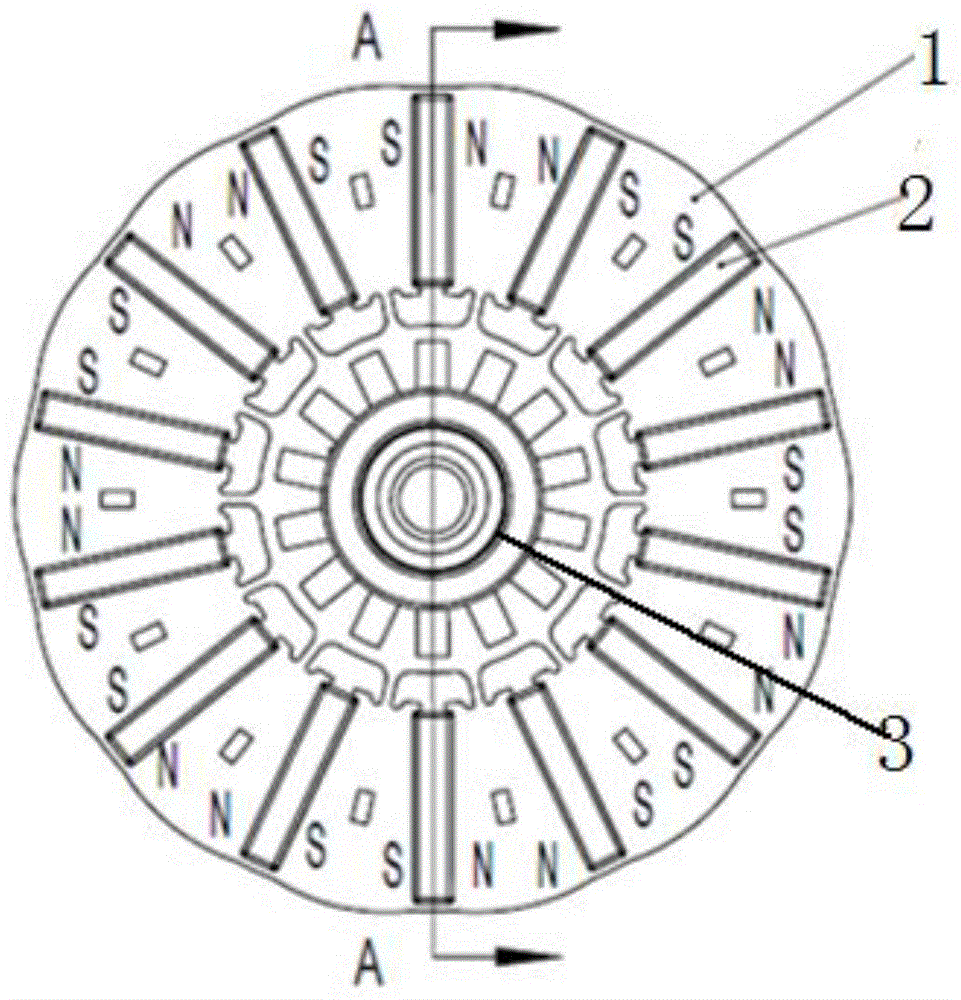

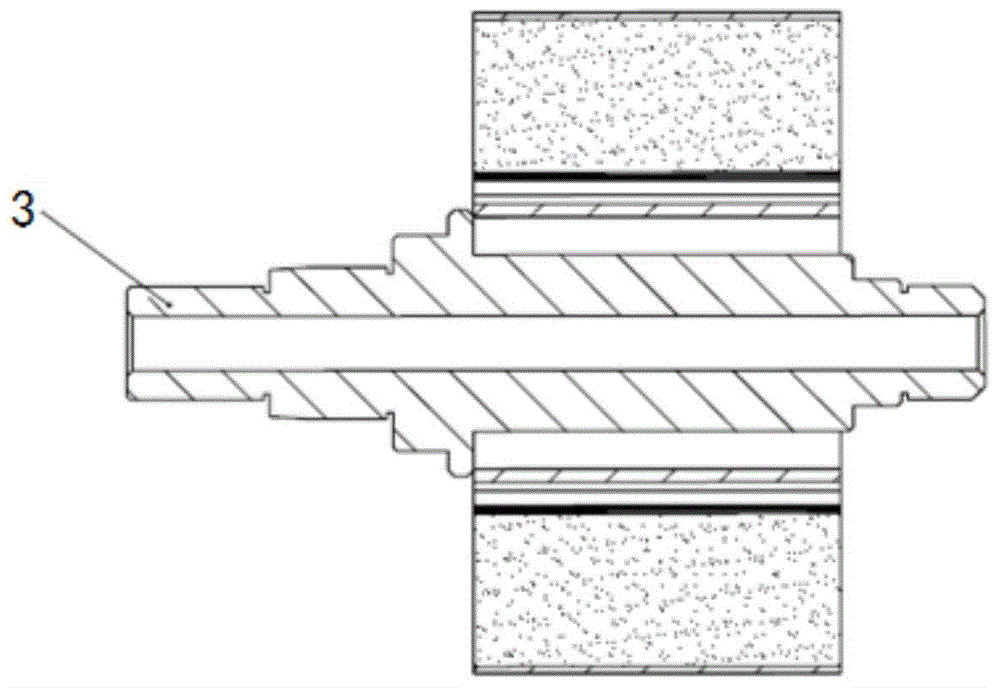

Brushless motor rotor structure employing built-in magnetic steel tangential magnetization

PendingCN105391203AReduce Flux LeakageSmall torqueMagnetic circuit rotating partsBrushless motorsPunching

The invention provides a brushless motor rotor structure employing built-in magnetic steel tangential magnetization, and the structure comprises a rotating shaft, a rotor core, and magnetic steels. The magnetic steels are inset in the rotor core, and the rotor core is fixed on the rotating shaft. The rotor core is formed by the alternate superposing of first rotor punching sheets and second rotor punching sheets through a self-buckling riveting mechanism, wherein the first and second punching sheets are provided with magnetic steel grooves. The magnetic steel is inserted into the magnetic steel grooves in a tangential manner. The structure can effectively reduce magnetic leakage of a motor.

Owner:NEW ANANDA DRIVE TECHN SHANGHAI

Machining method of motor rotor magnetic steel ring of electric vehicle

InactiveCN103036372AImprove fitNo changeElectric machinesManufacturing stator/rotor bodiesPunchingEngineering

The invention discloses a machining method of a motor rotor magnetic steel ring of an electric vehicle. A punching disc is punched by steel plate strips after materials are obtained, wherein the punching disc is provided with a concave groove. The punching disc is cut into single-layer steel plate punching discs after the length of the punching disc is predetermined. A multi-layer steel plate punching disc is pressed into a punching disc block with predetermined height in an overlying mode through equipment. The annular cylindrical magnetic steel rings are formed by bending the punching disc block which is pressed in the overlying mode through external force. The cylindrical magnetic steel rings which are formed in a bending mode are connected into a whole in a welding mode or in a riveting mode or in a self-buckling mode.

Owner:CHANGYING XINZHI TECH CO LTD

Split stator core mounting and fixing structure and fixing method

PendingCN109560625AReduced dimensional accuracy requirementsReduced stiffness requirementsMagnetic circuit stationary partsIn process controlSelf-buckling

The invention discloses a split stator core mounting and fixing structure and a fixing method. The structure comprises a stator casing and a full-circular stator core. The full-circular stator core comprises a plurality of split stator cores. Each split stator iron includes a plurality of stator split punches. Each stator split punch includes a yoke portion and a plurality of slot teeth distributed on the inner ring of the yoke portion. The yoke portion is provided with a process groove at one end, and is provided with a process boss at the other end. The outer ring of the yoke portion is provided with a positioning groove. The plurality of stator split punches are mutually riveted by a self-buckling point to form the split stator core. The plurality of split stator cores are spliced intothe full-circular stator core. The inner wall of the stator casing is provided with a positioning boss. The stator casing sleeves the full-circular stator core and the positioning boss is embedded inthe positioning groove on the full-circular stator core. The structure does not need welding forming, does not has high requirements for the dimensional accuracy and rigidity of the split stator core,is convenient in process control, and has high production efficiency, simple production equipment and low manufacturing cost.

Owner:宁波菲仕自动化技术有限公司

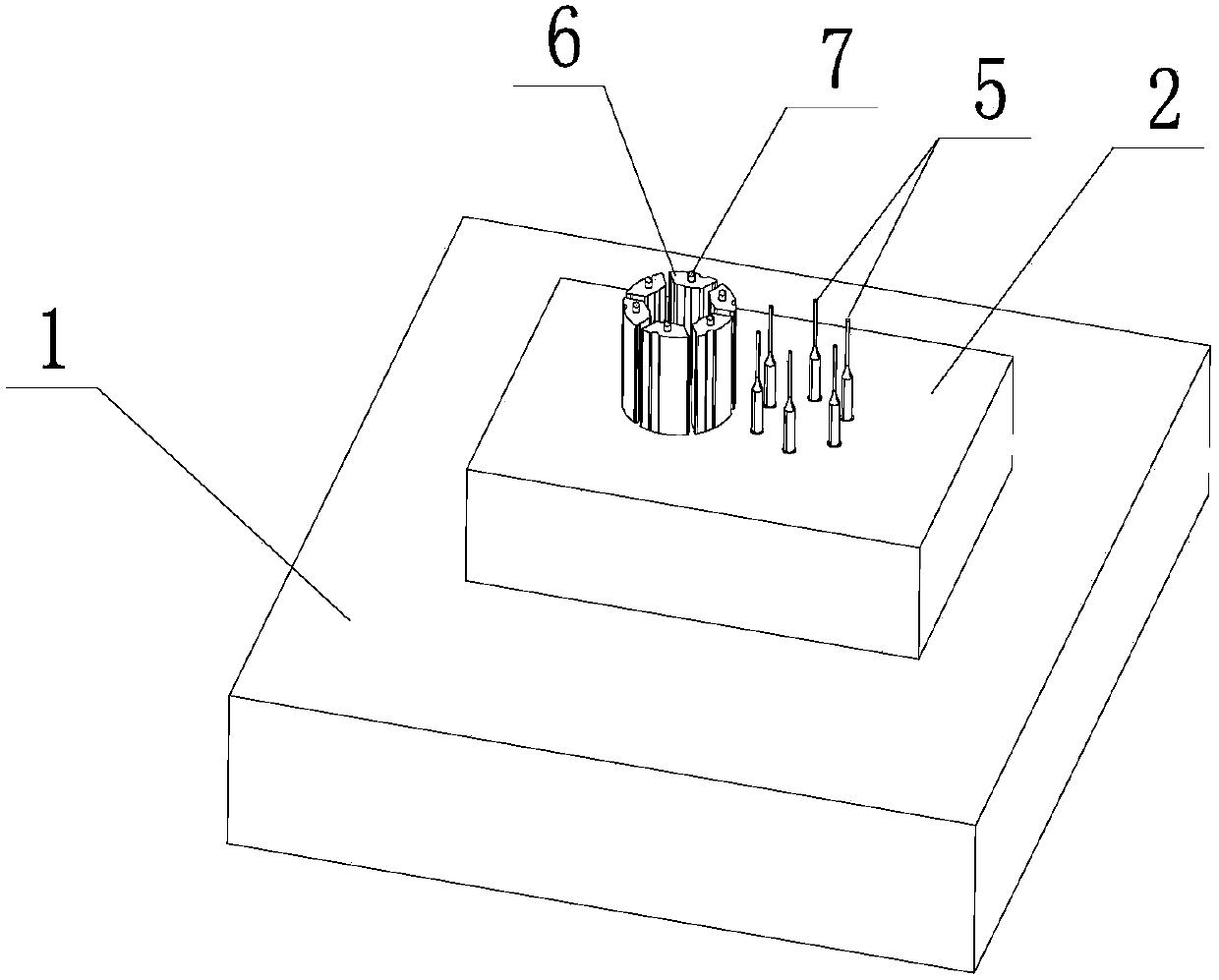

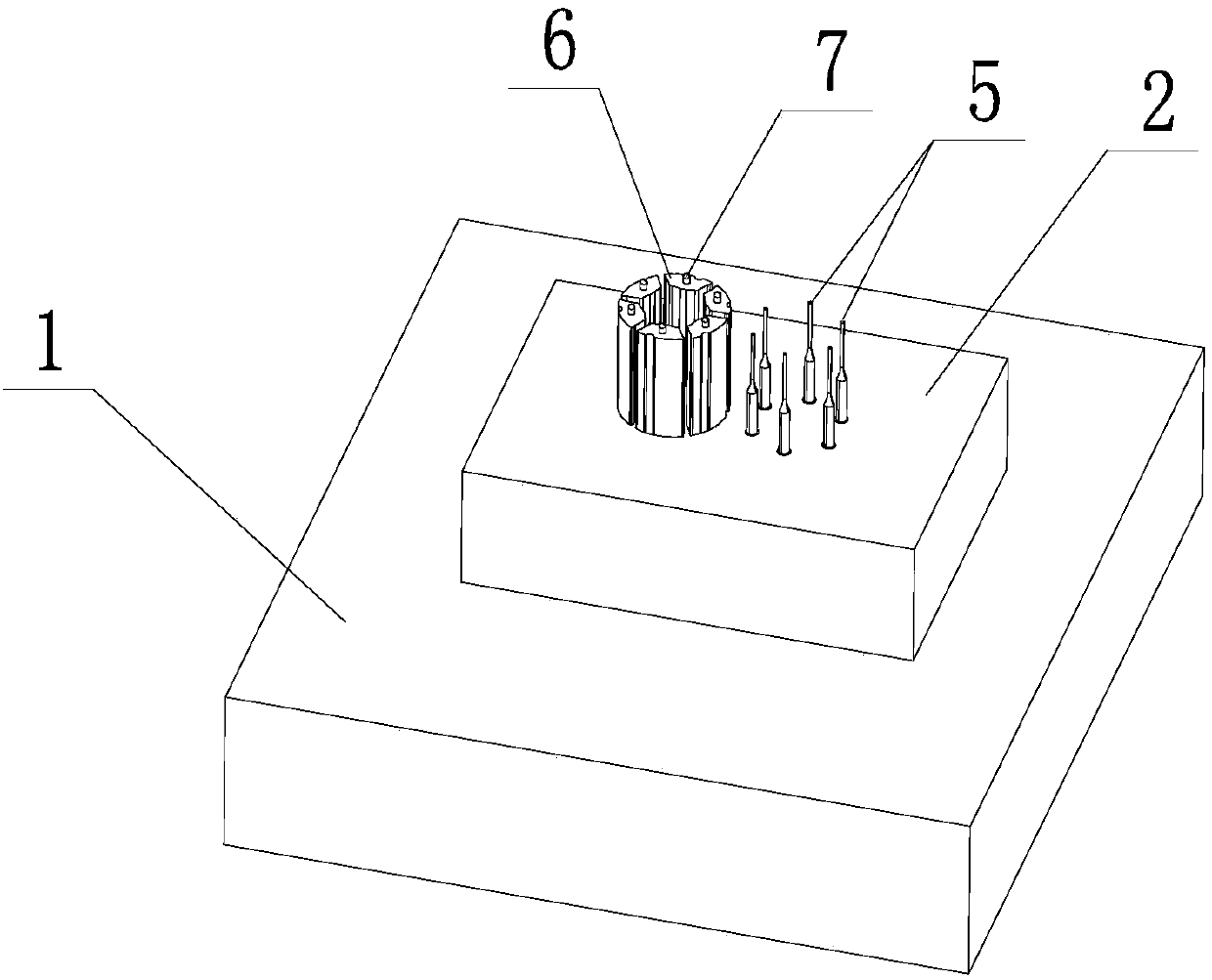

Combination die used for preparing colorful curbstones

The invention discloses a combination die used for preparing colorful curbstones. The combination die comprises an outer sleeve die, an inner sleeve die and a water discharging hole die; the outer sleeve die is of a groove-shaped structure, and comprises a first front wall, a first back wall, a first left side wall, a first right side wall and a first bottom wall; the first left side wall is provided with a left concave part; the first right side wall is provided with a right convex part; and the right convex part is matched with the left concave part; the inner sleeve die comprises a second front wall, a second back wall, a second left side wall, a second right side wall and a second bottom wall; the second bottom wall is provided with a bottom convex part; the water discharging hole die is matched with the bottom convex part of the inner sleeve die; and surface layers of the colorful curbstones are made of colorful concrete, and inner layers of the colorful curbstones are made of common concrete. The colorful curbstones, which are prepared using the combination die, possess following advantages: intensity is high; color is magnificent; the colorful curbstones are not easy to fade, and are capable of glowing, and realizing water discharging; and self-buckling connection of the colorful curbstones is realized. In addition, solid waste is recycled, so that production cost is reduced, and the combination die can be widely used for preparing the colorful curbstones.

Owner:许春雷

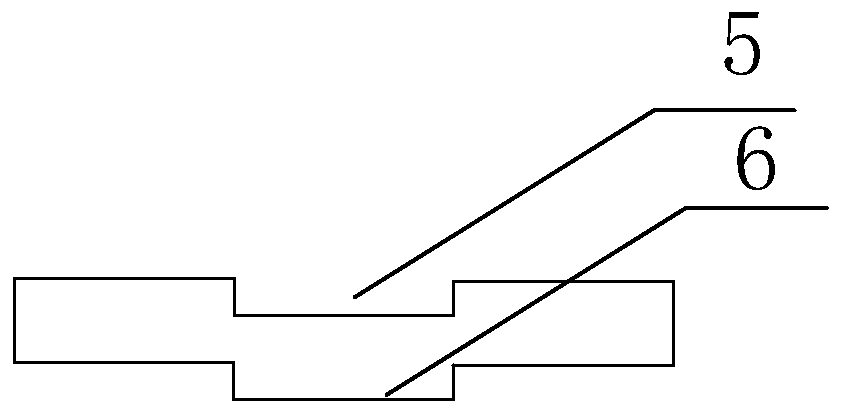

Method for manufacturing bulk sheet motor iron core by using waste sheet self-buckling mode

ActiveCN110138156AAvoid deformationGuaranteed flatnessManufacturing stator/rotor bodiesPunchingEngineering

The invention discloses a method for manufacturing a bulk sheet motor iron core by using a waste sheet self-buckling mode, and belongs to the technical field of motor manufacturing. The bulk sheets ofthe stator are connected together as a whole by setting the buckling point process of the waste sheets in the punching groove, the waste sheet self-buckling process in the punching groove and the reverse pressure self-buckling process and the like so as to facilitate processing. The production efficiency can be improved by changing the manual arrangement process of the bulk sheets of the stator so that the deformation phenomenon of the bulk sheets of the stator in the processing course can be prevented, the flatness of the bulk sheets of the stator can be maintained, the product accuracy canbe ensured, the iron loss can be controlled, the magnetic permeability of the material can be improved and the overall performance of the motor can be improved.

Owner:浙江信戈制冷设备科技有限公司

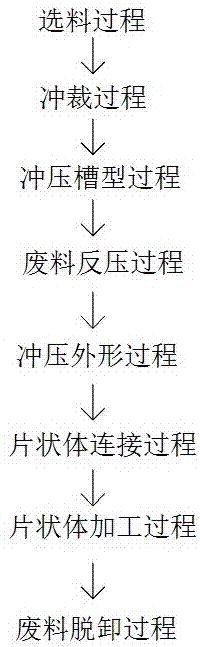

Self-stacking manufacturing process of punched sheet body

ActiveCN108011476AImprove efficiencyIncrease profitManufacturing stator/rotor bodiesPunchingMachining process

The invention, which belongs to the technical field of mechanical manufacturing, discloses a self-stacking manufacturing process of a punched sheet body. The process is implemented as follows: carrying out a material selection process; carrying out a punching process; carrying out a groove type punching process; carrying out a waste back-pressure process; carrying out an appearance punching process; carrying out a sheet body connection process; carrying out sheet body processing; and carrying out a waste removing process. According to the invention, self-buckling is carried out after sheet body punching and thus the sheet body punched out by a punching die is bukcled inside the die automatically, so that the production efficiency is improved, the material losses are reduced, the productioncost is lowered, and the utilization rate of raw materials is increased.

Owner:CHANGYING XINZHI TECH CO LTD

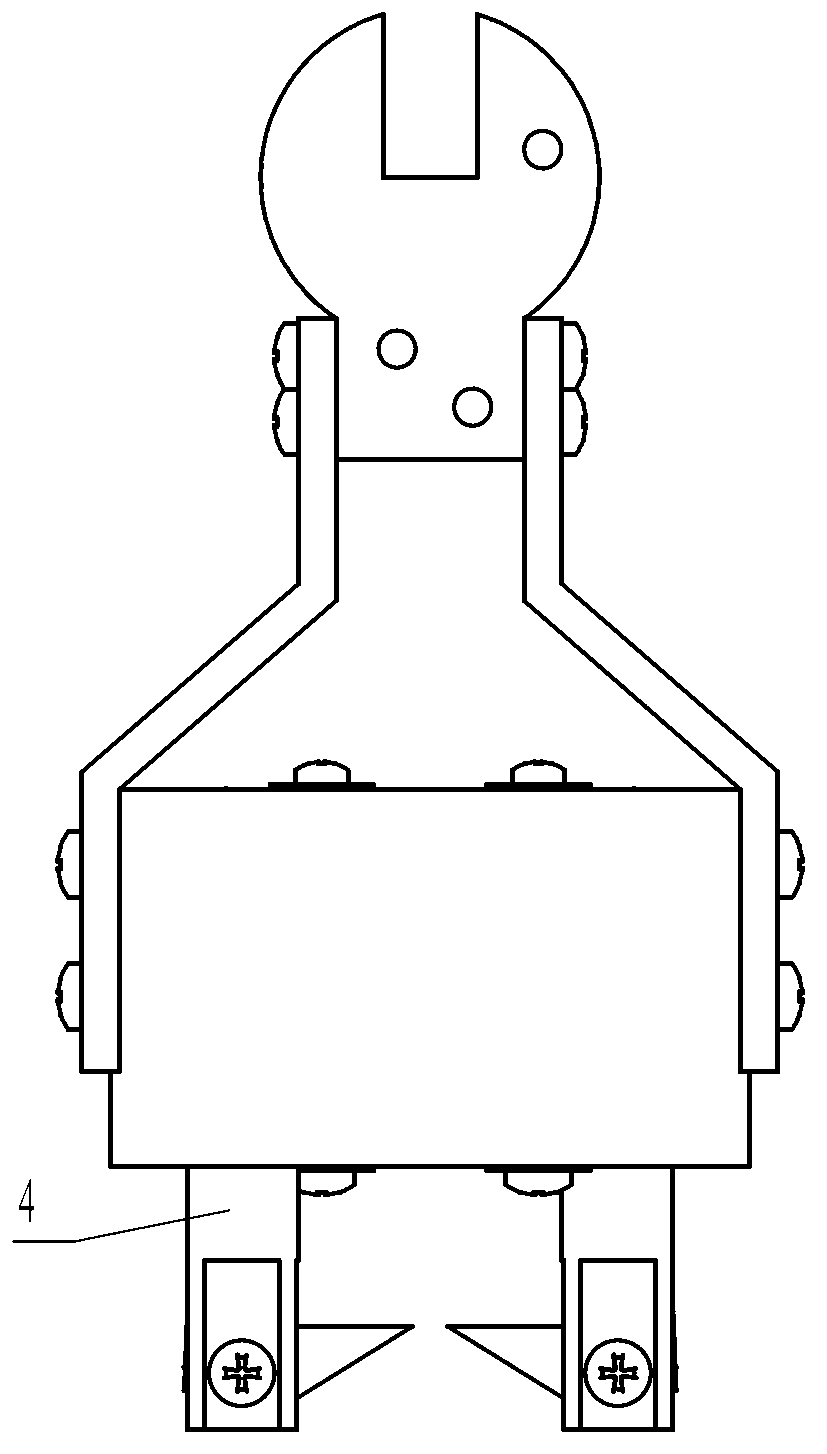

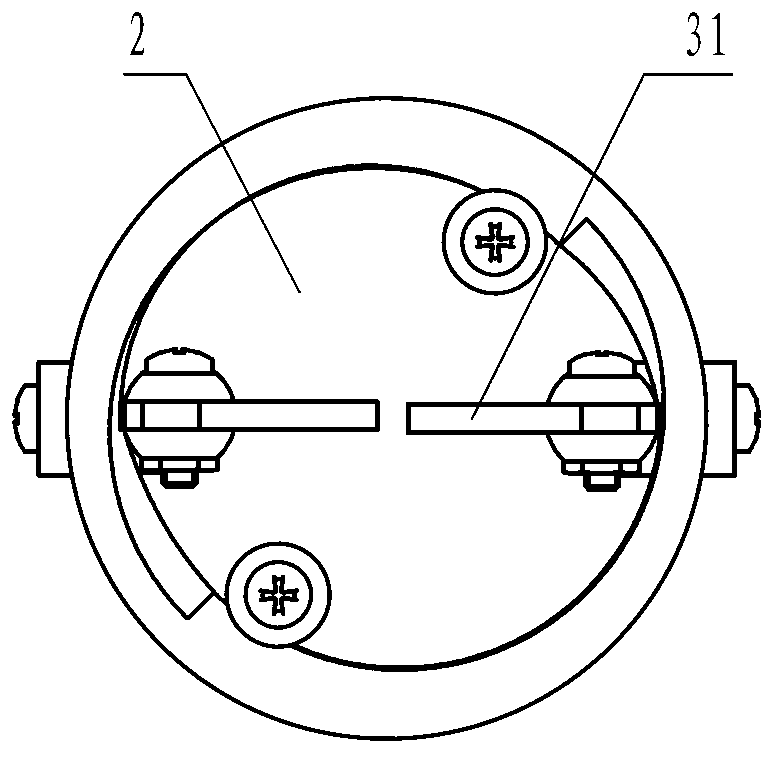

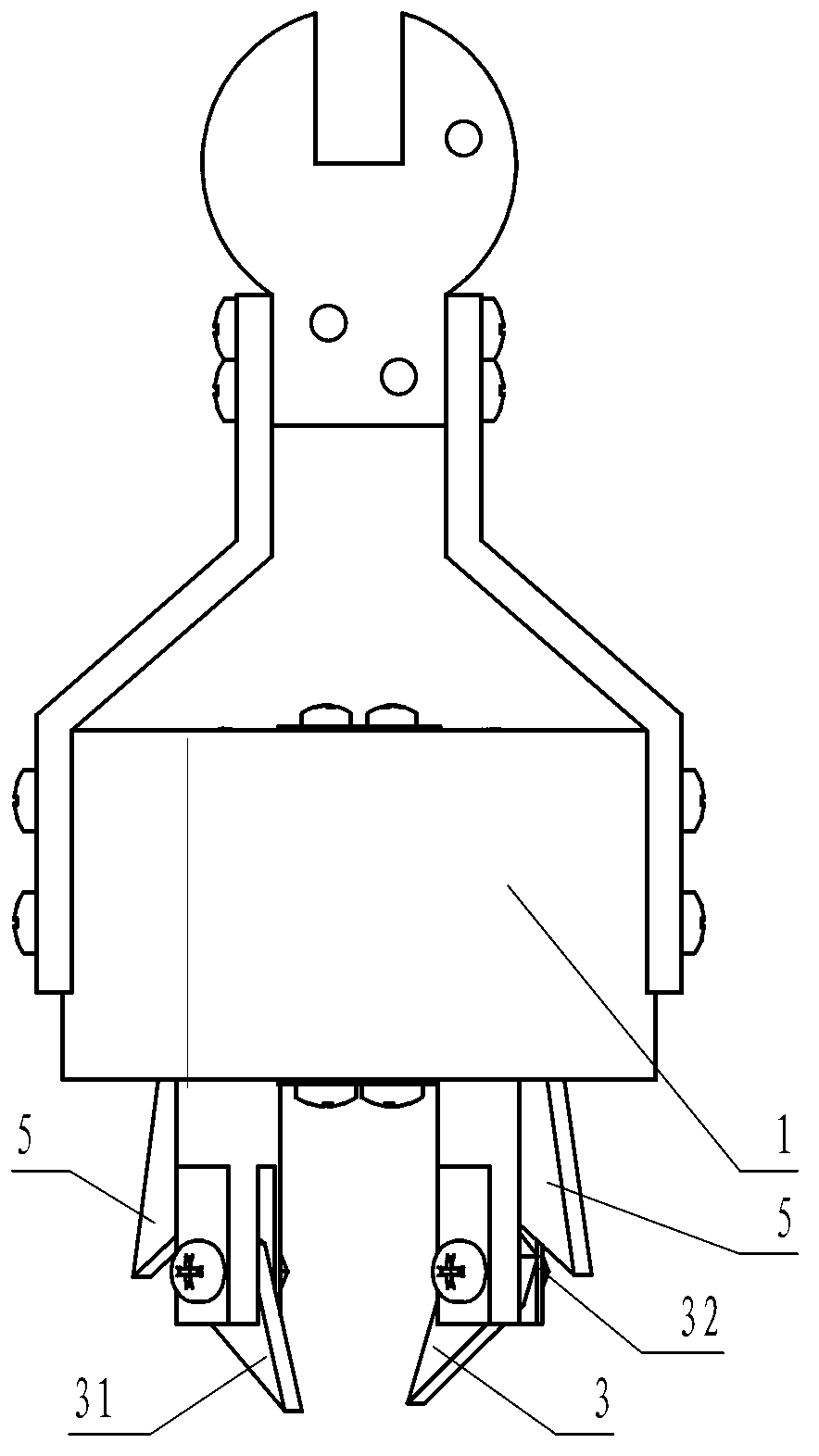

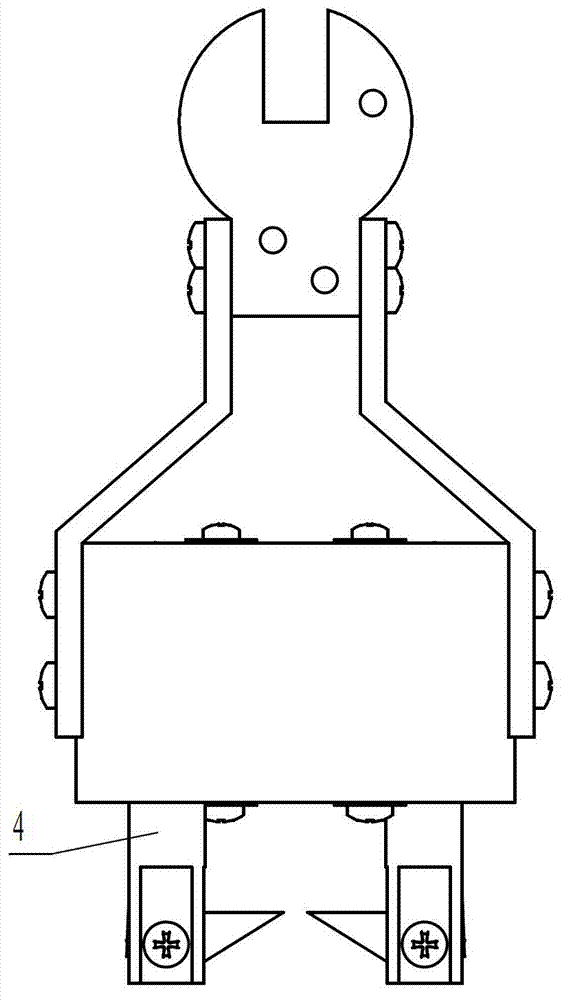

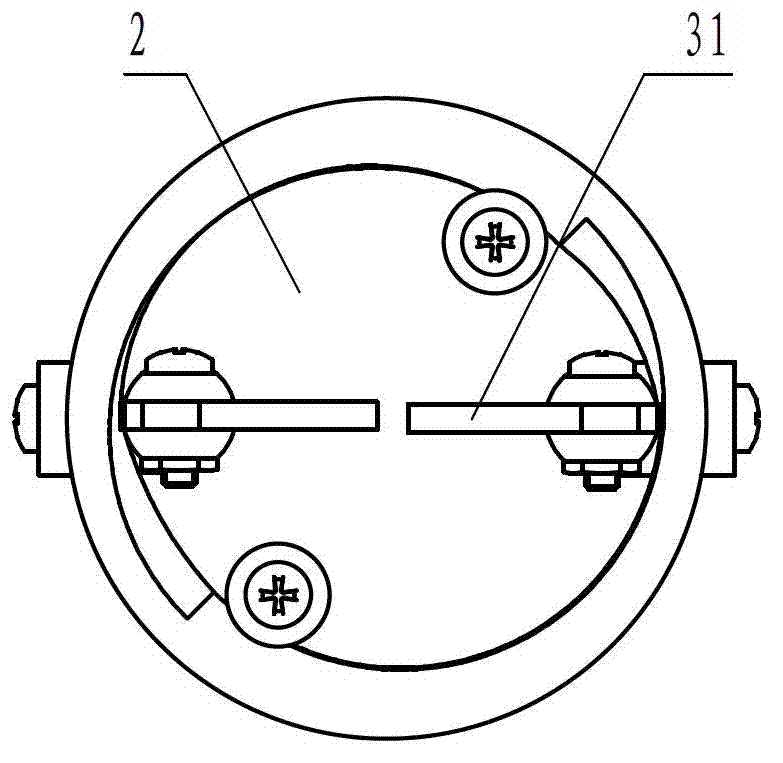

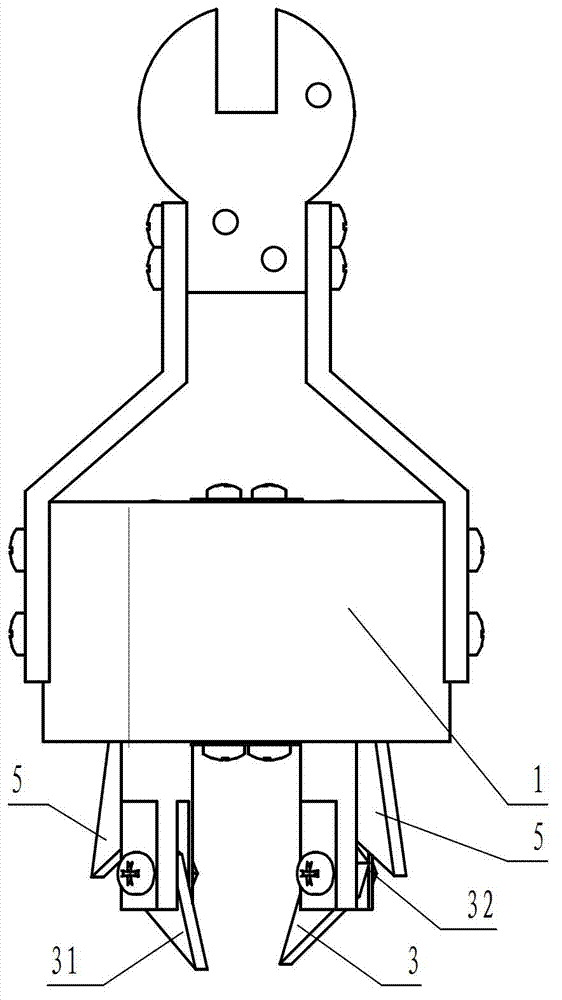

Self-buckling type anti-sliding steel plate tong with night warning function

InactiveCN106348162ASimple and fast operationImprove hoisting efficiencySafety gearButton batteryArchitectural engineering

The invention discloses a self-buckling type anti-sliding steel plate tong with a night warning function. The self-buckling type anti-sliding steel plate tong comprises tong teeth, a self-buckling spring, a plurality of warning lamps, a tong jaw, a tooth-attached anti-sliding adhesive tape and a high-strength bolt, wherein the top of the tong jaw is connected with the tong teeth through the high-strength bolt; the tooth-attached anti-sliding adhesive tape is arranged on a contact surface of the tong teeth and the tong jaw; the self-buckling spring is connected between the tong teeth and the tong jaw; the warning lamps are arranged on the two sides of the tong jaw; the warning lamps are powered by the built-in button cells; six warning lamps in total are arranged on the two sides of the tong jaw; three warning lamps are respectively arranged on each side. The self-buckling type anti-sliding steel plate tong is simple in operation, capable of greatly increasing the hoisting efficiency, capable of meeting the requirement of safe use and capable of guaranteeing the safety and reliability of the hoisting process.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

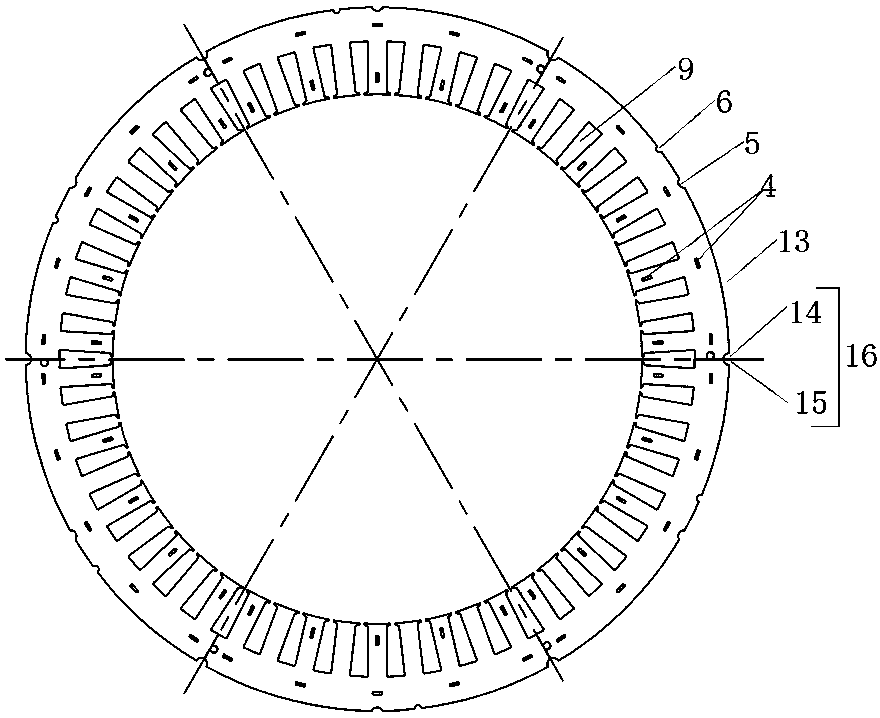

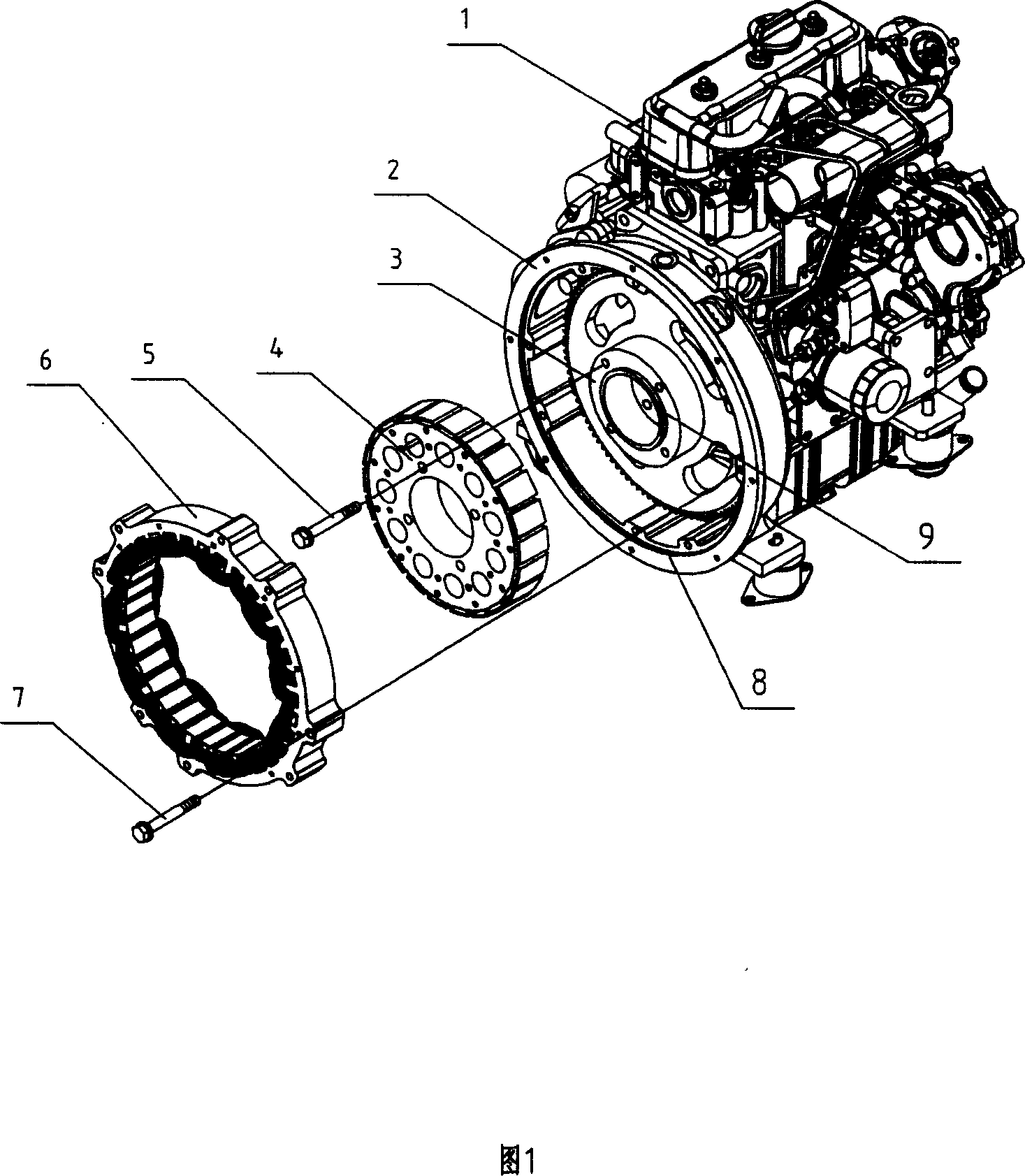

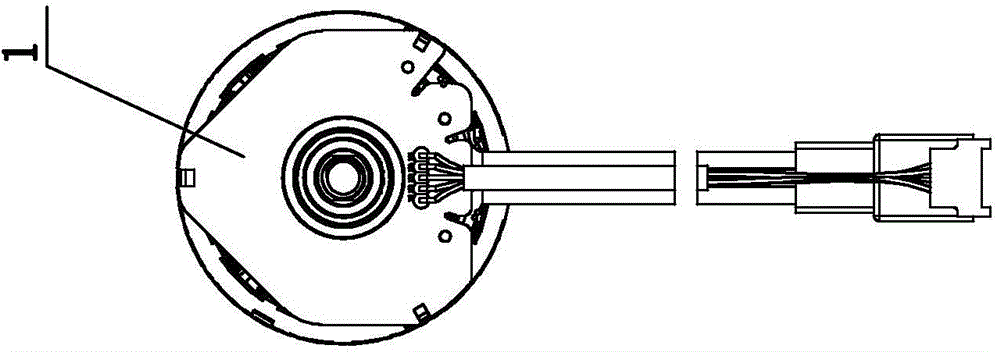

Stator of multipole internal rotor permanent magnet generator

InactiveCN101005216AAchieve thinningAchieve lightweightMagnetic circuit stationary partsManufacturing stator/rotor bodiesMiniaturizationSelf-buckling

Through self-buckling slot for stator, punch pieces of stator are stacked to form stator body. Neck groove of stator are prepared on inner side face of stator faced to rotor. Number of the neck groove is equal to number of permanent magnet taken in by rotor. Multiple stator windings are inserted in neck groove. Characters are that boltholes are setup on stator in direction parallel to line of rotation axis. Through the boltholes, one end face of stator is fixed on stator seat of engine assembly directly. The invention realizes high output efficiency, and high output power, easy to produce generator with larger power, as well as stability, durability, and reliability. Features are: no chassis, simple structure, compact, thin, light weight, and miniaturization.

Owner:WUXI KIPOR POWER CO LTD

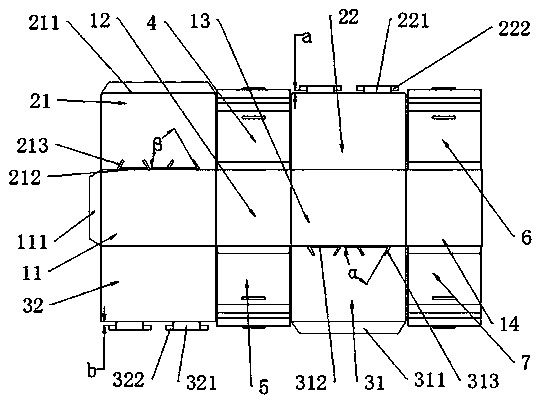

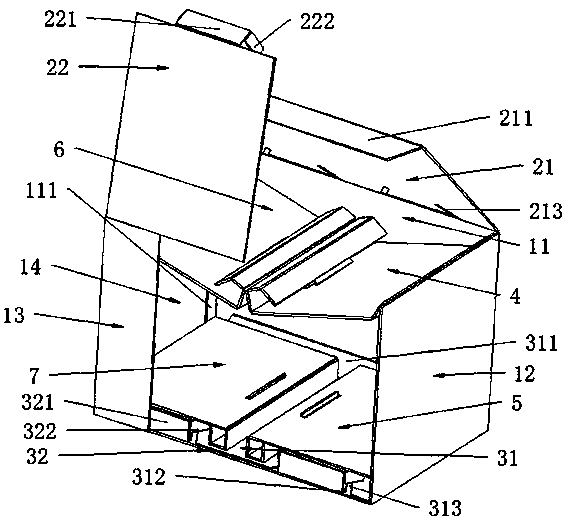

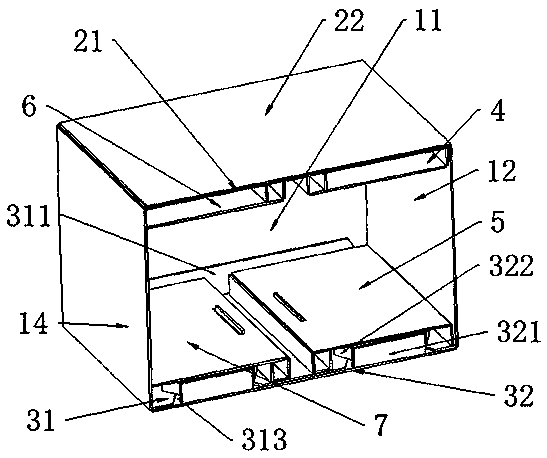

Safety protection equipment assembling box

InactiveCN105899007AEasy to installBeautiful installationCasings/cabinets/drawers detailsWeak currentSelf locking

The invention relates to a safety protection equipment assembling box, and relates to the safety protection industry and the technical field of weak current engineering. The safety protection equipment assembling box is characterized in that the bottom of a box body is provided with a self-buckling hole, the bottom of a box cover is provided with a self-locking buckle, the box cover is interlocked to the self-buckling hole through the self-locking buckle, the box body is provided with a partition plate, the partition plate divides the box body into a power supply portion and a wiring portion, the power supply portion is internally provided with a power supply board, the power supply board is provided with rapid binding posts, the side surface of the box body is provided with a preformed hole, and the bottom of the box body is provided with a reserved cable hole and a reserved network camera hole. The safety protection equipment assembling box adopts an integral design, is convenient to install and beautiful, and saves the installation material cost and the labor cost; and the flame resistance is high, and the protection capability is high.

Owner:JIANGSU YUANZHILING INTELLIGENT TECH CO LTD

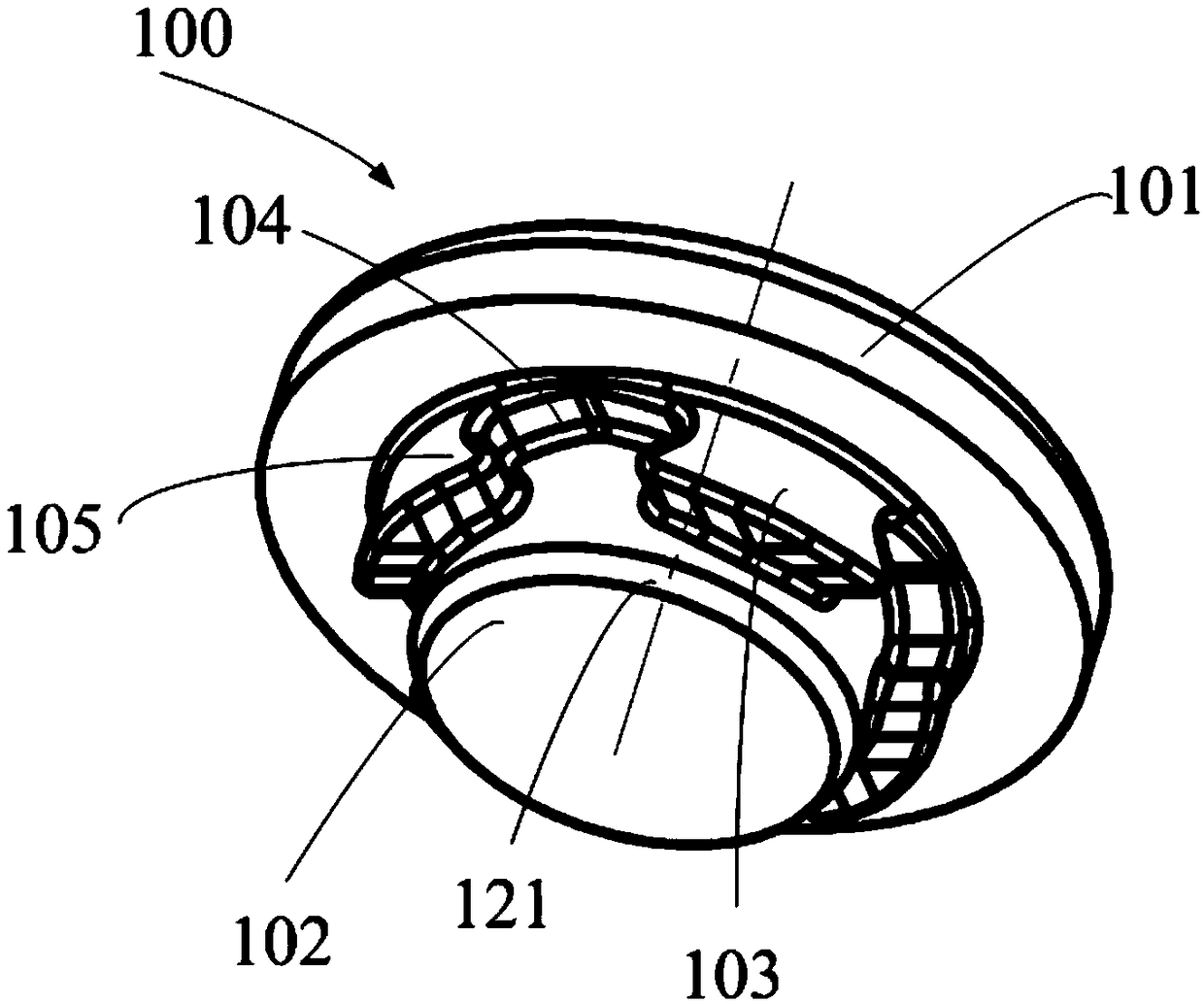

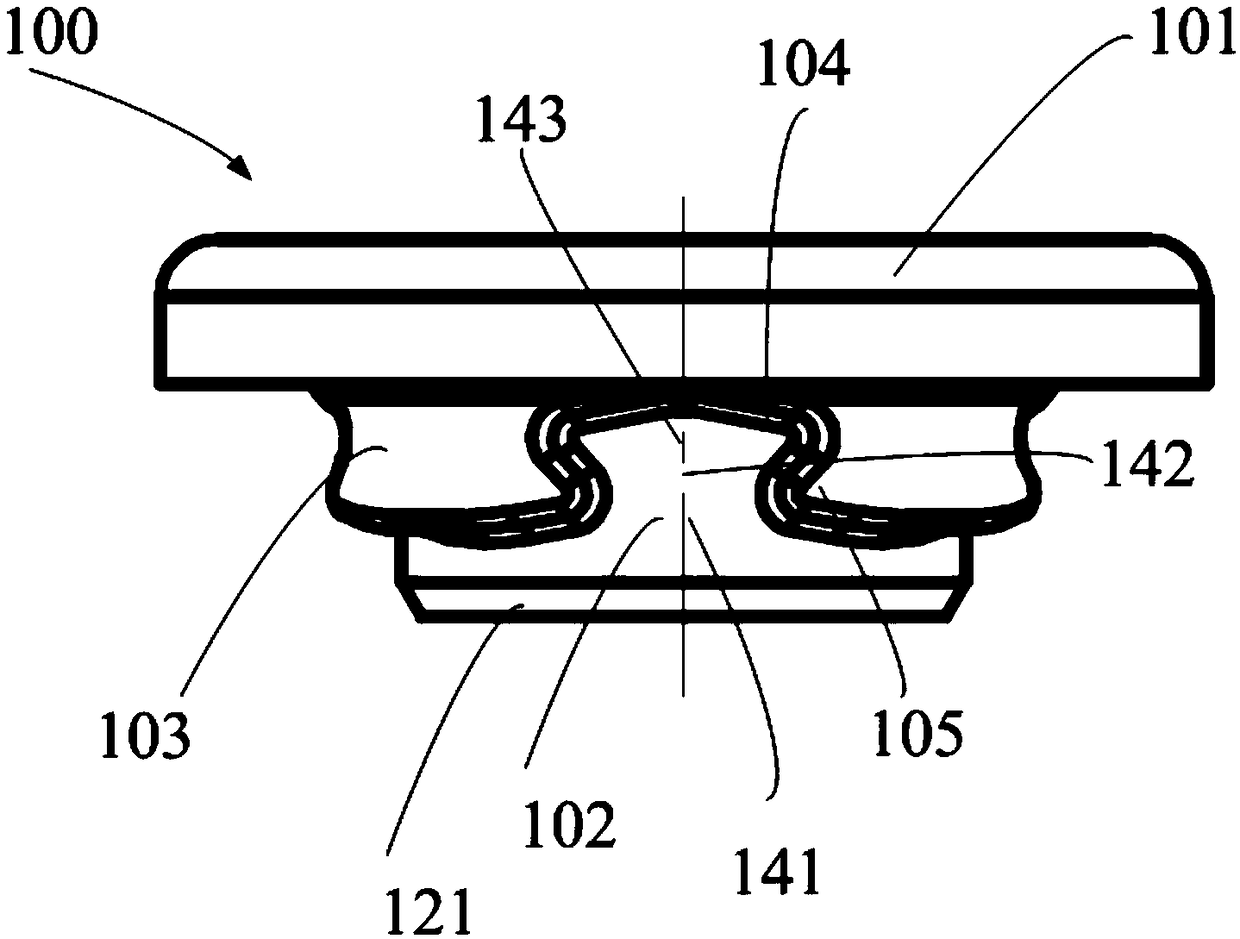

Electric vehicle hub motor stator and manufacturing method thereof

PendingCN108964298ALess consumablesImprove production efficiencyMagnetic circuit stationary partsManufacturing stator/rotor bodiesPunchingEngineering

The invention discloses an electric vehicle hub motor stator comprising an iron core and a bracket. The bracket is used for fixing the iron core. The iron core comprises a yoke part, tooth parts and wire embedding slots. The wire embedding slot is formed between two adjacent tooth parts. The electric vehicle hub motor stator is characterized in that the stator iron core is made by the winding process, the outer diameter size of the iron core is 140-160 mm, and the inner diameter size of the iron core is 100-120 mm. According to the electric vehicle hub motor stator, the consumption material isless and the manufacturing efficiency is higher than those of the same level product under the condition that the product performance reaches the standard through reasonable design of the size of thestator inner diameter and outer diameter and the size of the yoke. Compared with the stator iron core with the same outer diameter, the stator iron core has larger inner diameter, forming and installing of the bracket are facilitated, the iron core material is saved and the stability of the bracket and the convenience of installation and maintenance are enhanced. The original single punching or double riveting process is replaced by the winding and self-buckling process of the stator core so as to reduce the material loss and improve the production efficiency.

Owner:CHANGYING XINZHI TECH CO LTD

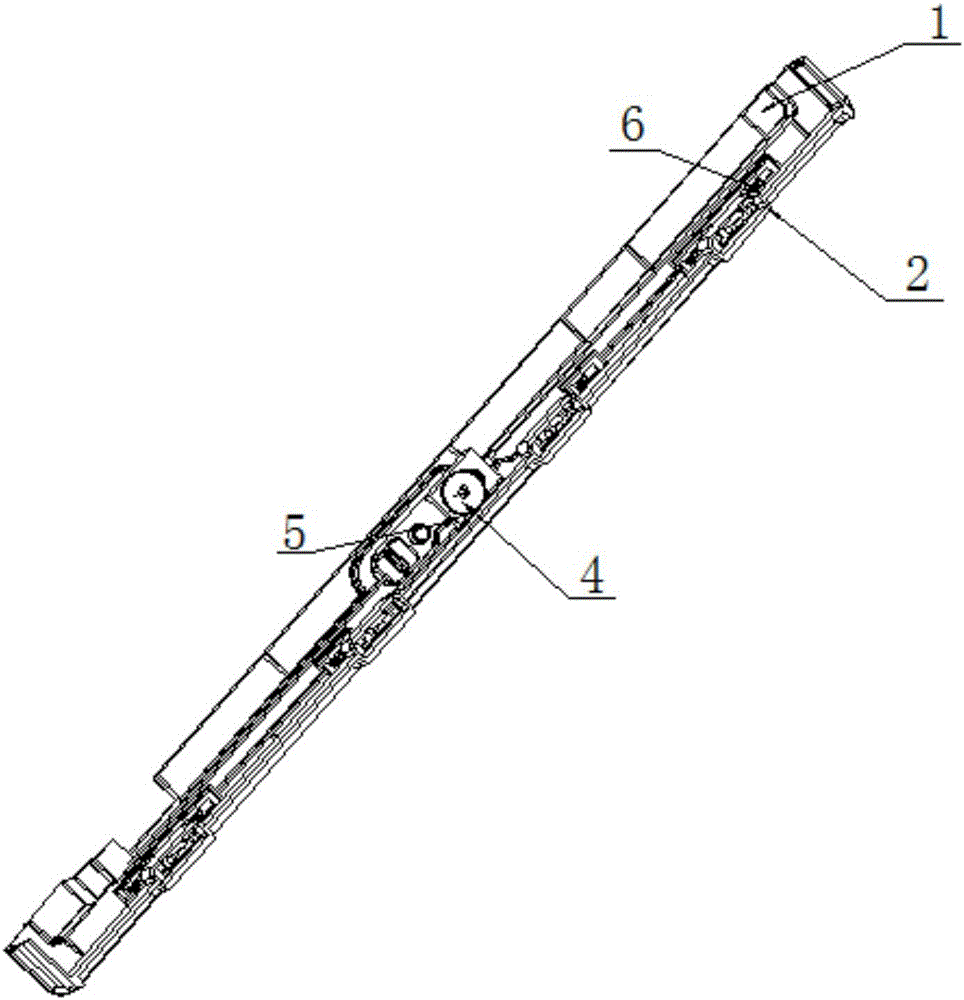

One-way self-buckling type rotating wheel sliding lock bar

Owner:WSELE ELECTRICAL

Brushless motor assembly structure

InactiveCN104836354ASolve the problem of large jumpSolve balance problemsMagnetic circuit rotating partsStructural associationBrushless motorsMotor vibration

A brushless motor assembly structure belongs to the technical field of motor equipment assembly. The brushless motor assembly structure comprises a Hall plate, a stator assembly, and a rotor assembly. The stator assembly comprises an insulating end plate, and the Hall plate is fixed to the stator in a self-buckling way through the insulating end plate. The rotor assembly comprises a rotor chip and a magnetic ring. The outer edge of the rotor chip is uniformly provided with 4-12 arc grooves, the area between every two adjacent arc grooves is in clearance fit with a corresponding inner hole of the magnetic ring, 4-12 clearance sections are formed, and the clearance portions are filled with anaerobic glue water. The middle of each clearance section at the outer edge of the rotor chip is provided with a convex arc surface, the total number of the convex arc surfaces is 4-12, the height of the convex arc surfaces is 0.06 mm, and the convex arc surfaces are in tight fit with the corresponding inner holes of the magnetic ring. By adopting the brushless motor assembly structure of the invention, the following beneficial effects are achieved: the surface of the magnetic ring does not jump after bonding, the motor vibration is small, the air gap of a motor is normal, the magnetic ring does not crack, the Hall plate and the stator assembly are fixed in a plugging way, the production efficiency is improved, the defective rate is reduced, and the integrity of the structure is achieved.

Owner:YUYAO ACTUATOR ELECTRIC MOTOR CO LTD

Self-buckling packing carton

The invention relates to a self-buckling packing carton. The self-buckling packing carton comprises a first side plate, a second side plate, a third side plate and a fourth side plate rotationally connected transversely in sequence; the edge, relative to the second side plate, of the first side plate is rotationally connected with a combination plate; the upper edge and the lower edge of the firstside plate are rotationally connected with a first top plate and a first base plate; the upper edge and the lower edge of the second side plate are rotationally connected with a second top plate anda second base plate; the upper edge and the lower edge of the third side plate are rotationally connected with a third top plate and a third base plate; the upper edge and the lower edge of the fourthside plate are rotationally connected with a fourth top plate and a fourth base plate; self-sealing pieces are arranged at the top and the bottom of a packing carton; the self-sealing pieces compriseinsertion plates and slots; bendable buckle plates extend from two ends of the insertion plates; the slots are matched with the insertion plates; the edge, relative to the third side plate, of the third top plate is connected with the insertion plates; the slots are formed in the first top plate; the edge, relative to the first side plate, of the first base plate is connected with the insertion plates; and the slots are formed in the third base plate.

Owner:FUJIAN YILONG PACKING PROD CO LTD

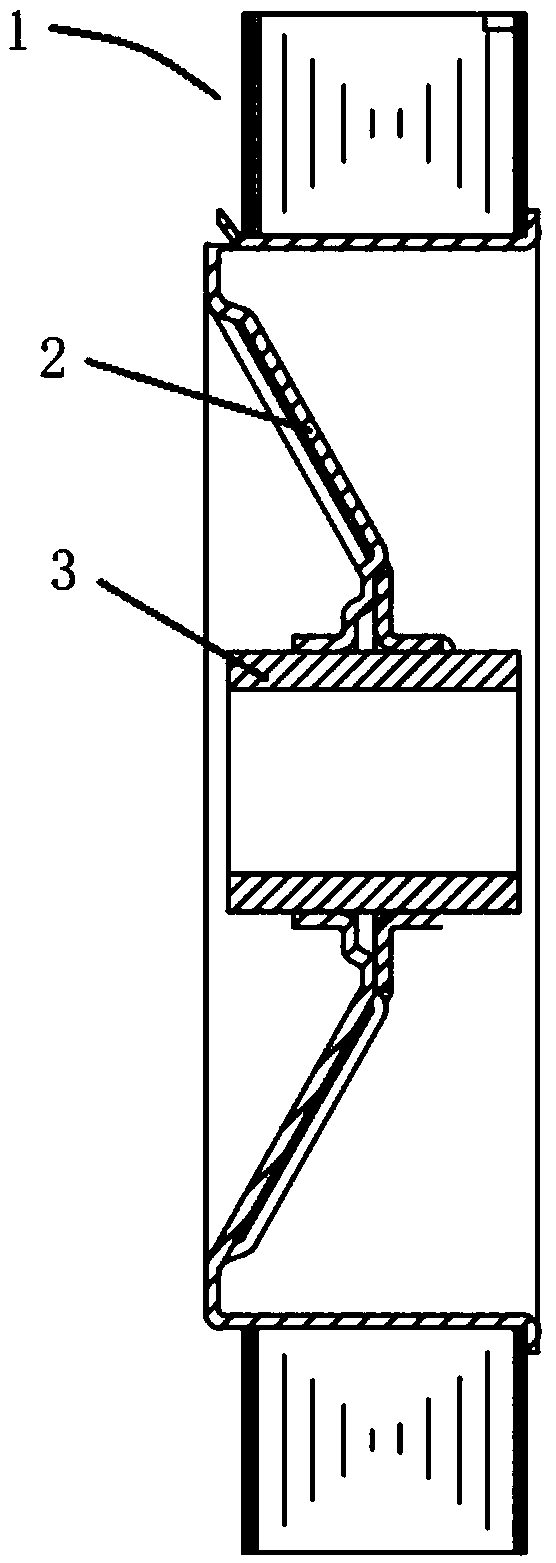

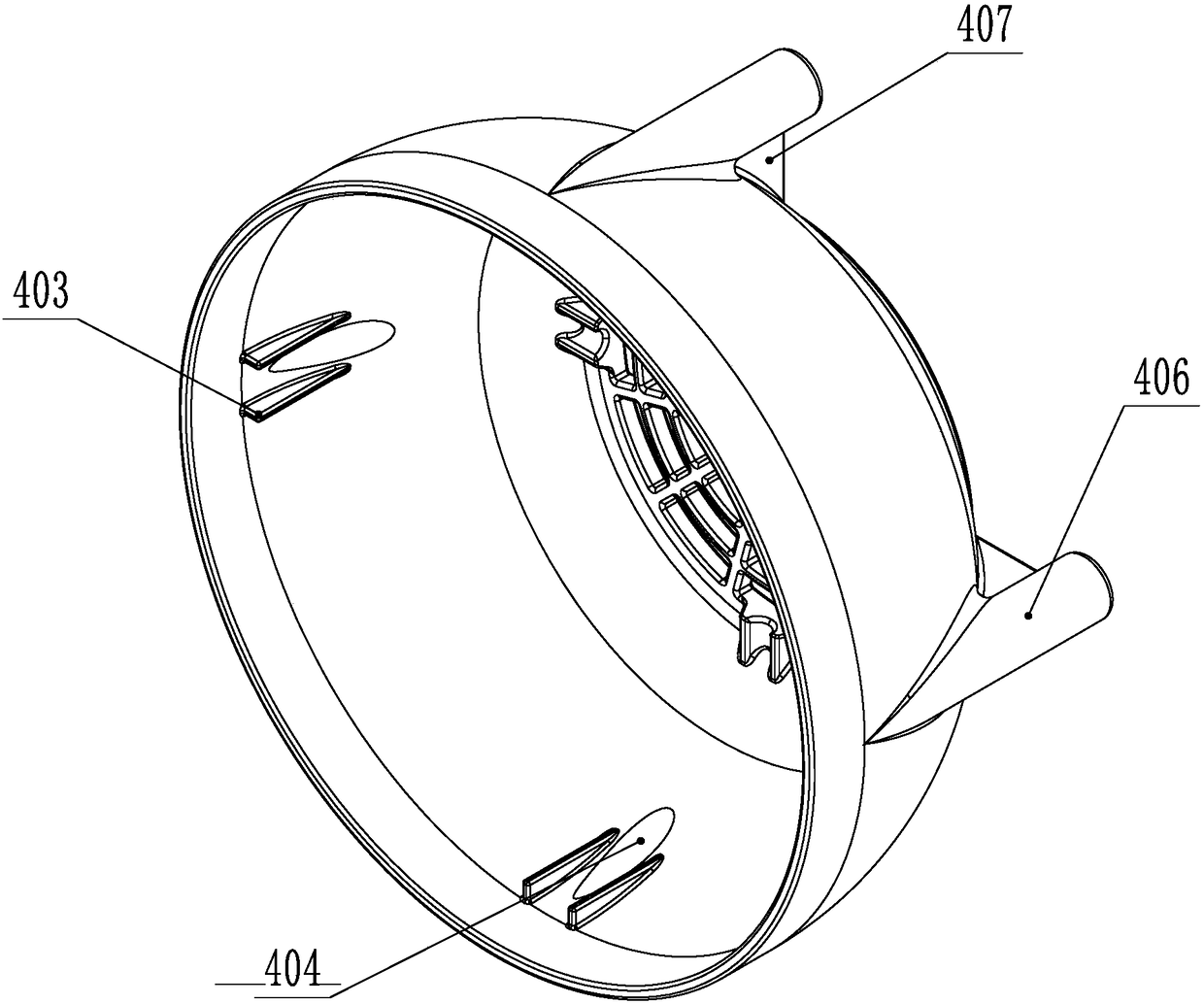

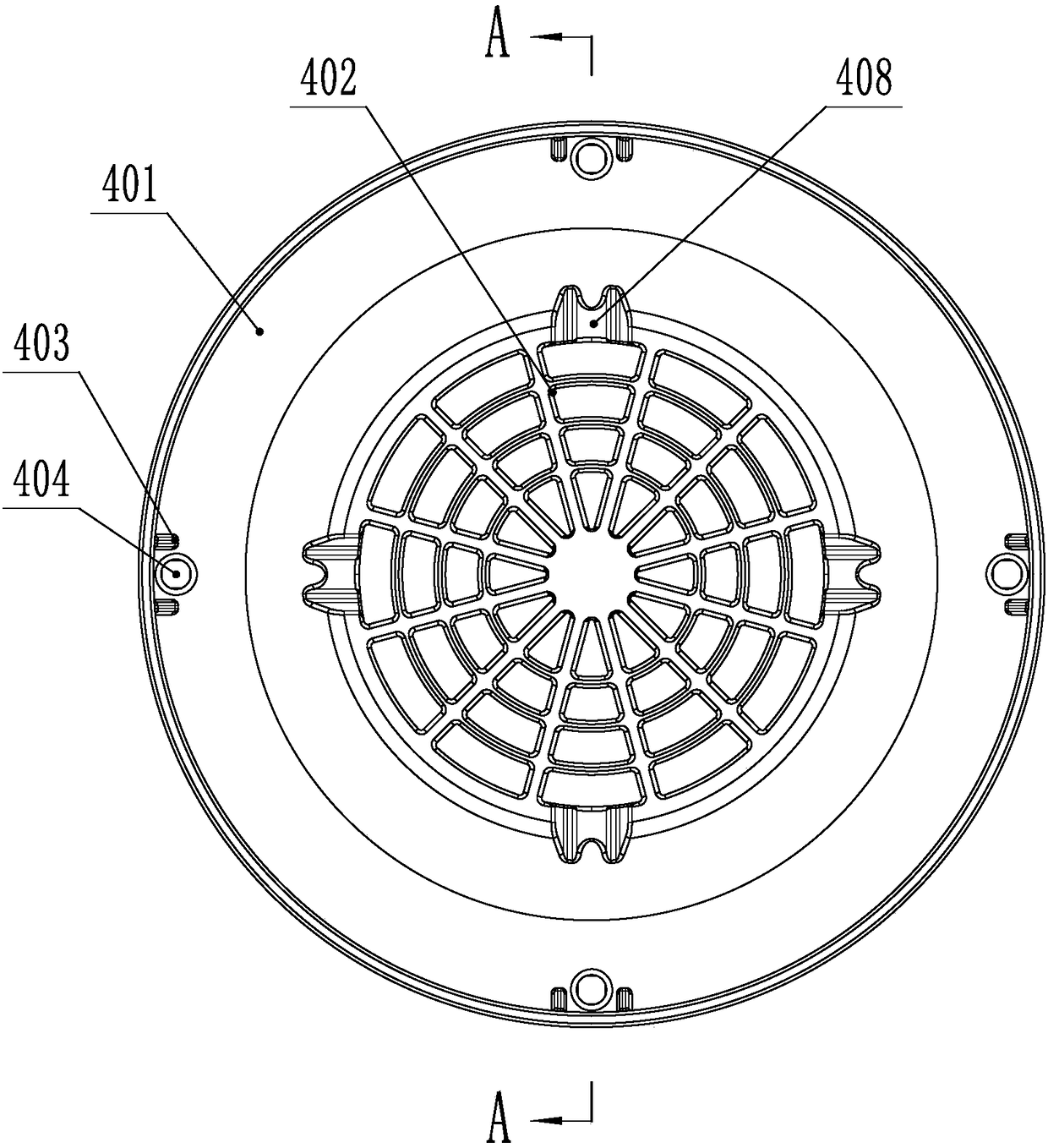

Pull-rod-self-bucking type motor fan cover

ActiveCN108258836AInstalled and disassembledReduce vibrationManufacturing dynamo-electric machinesSupports/enclosures/casingsMotor vibrationEngineering

The invention, which relates to the motor field, provides a pull-rod-self-bucking type motor fan cover. A common fan cover is in contact with an end cover directly; and the vibration value and the noise value of the motor are increased by fan cover vibration and noises, so that the overall quality of the motor is reduced. The pull-rod-self-bucking type motor fan cover comprises a fan cover ring and an inlet window. A pull rod is screwed into a thread hole formed at a rear end cover from a front end cover of a motor; a plurality of pull rod holes for pull rod entrance are formed in the rear part in the inner wall of the fan cover ring; and a self-buckling piece for automatic tight buckling of the pull rod after entrance is arranged in each pull rod hole. The pull rod passes through the thread hole of the rear end cover, moves forward, and enters the pull rod hole and then is buckled and fixed automatically by the self-buckling pieces. When the fan cover is installed, the pull rod holesof the fan cover are aligned at the pull rod for insertion; and the self-buckling pieces and the pull rod are in an automatic buckling and fixation relationship. On the basis of the self-buckling piece mode, fixation between the fan cover and the pull rod is realized quickly to realize installation and fixation of the fan cover and the motor. When the fan cover is dismounted, the rear end of the fan cover ring is hooked and is pulled back to realize separation of the self-buckling pieces from the pull rod. Therefore, quick dismounting is realized; and the vibration and the noises can be effectively reduced.

Owner:WOLONG ELECTRIC GRP CO LTD

Riveting part

Owner:PEM CHINA

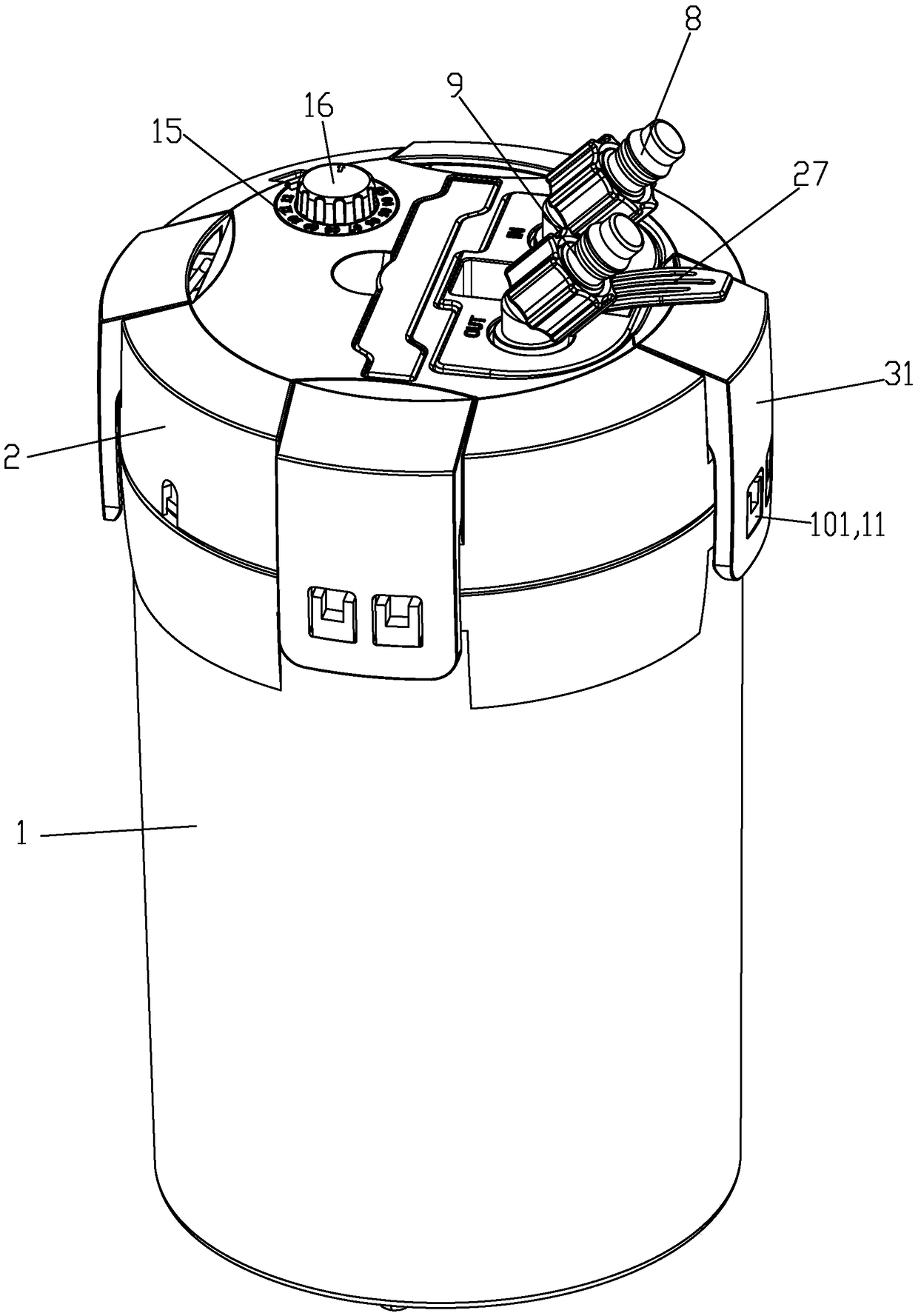

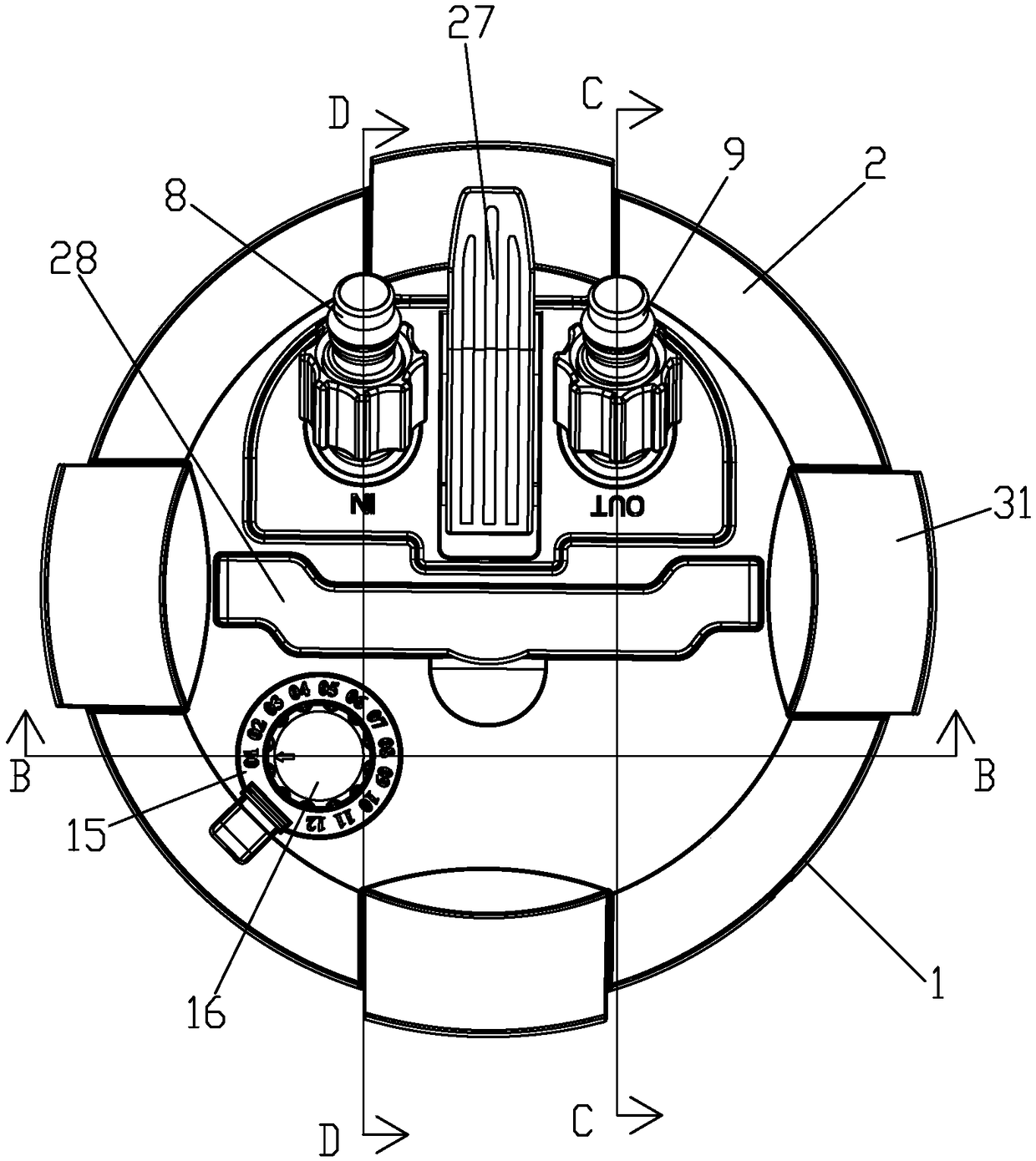

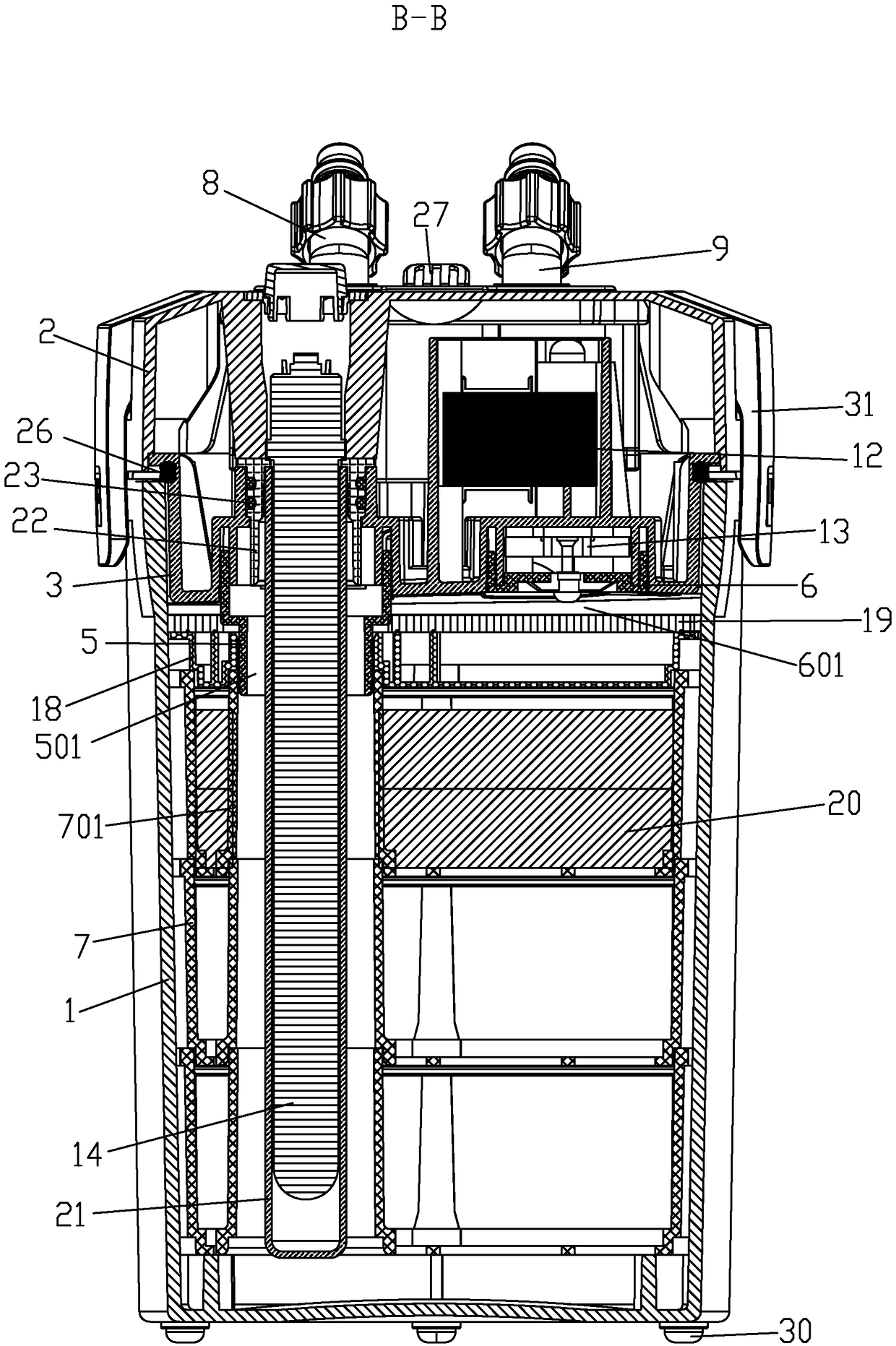

External filtering barrel convenient to assemble and disassemble

PendingCN109430150AEasy to assemble and disassembleAvoid forgettingPisciculture and aquariaImpellerSelf-buckling

The invention discloses an external filtering barrel convenient to assemble and disassemble. According to the technical scheme, the external filtering barrel is characterized by comprising a barrel body, a surface cover is arranged on the upper side of the barrel body, a filtering device is arranged in the barrel body, a water inlet nozzle and a water outlet nozzle which are communicated with theinterior of the barrel body are arranged on the surface cover, a water pump assembly for sucking water into the filtering device from the water inlet nozzle to be filtered and then sucking the water out of the water outlet nozzle is arranged on the barrel body, the water pump assembly comprises a motor base, a motor arranged on the motor base and an impeller driven by the motor to rotate, a waterinlet insert communicated with the water inlet nozzle and the water outlet insert communicated with the water outlet nozzle are arranged on the motor base, and the water inlet insert and the water outlet insert are locked at the bottom of the motor base through elastic self-buckling type structures. The water inlet insert and the water outlet insert are locked at the bottom of the motor base through the elastic self-buckling type structures, the motor base is pressed down in the installation process, the water inlet insert and the water outlet insert can be automatically locked on the motor base, and assembling and disassembling are convenient.

Owner:中山市创星电器有限公司

Up-and-down dual self-buckling self-sealing packaging box

PendingCN109051164AReduce manufacturing costMeet the requirements of packagingRigid containersPackage recyclingHorizontal axisEngineering

The invention relates to an up-and-down dual self-buckling self-sealing packaging box. The up-and-down dual self-buckling self-sealing packaging box comprises a first side plate, a second side plate,a third side plate and a fourth side plate which are connected along the same horizontal axis in sequence and have the same width; the other side of the first side plate is connected with a side connecting plate; the upper end and the lower end of the first side plate are respectively connected with a first top plate and a second bottom plate; the upper end and the lower end of the third side plate are respectively connected with a second top plate and a first bottom plate; the upper end and the lower end of the second side plate are respectively connected with a first upper layering plate anda first lower layering plate; the upper end and the lower end of the fourth side plate are respectively connected with a second upper layering plate and a second lower layering plate; the first sideplate, the first top plate and the second bottom plate are positioned on the same vertical axis and have the same length; the second side plate, the first upper layering plate and the first lower layering plate are positioned on the same vertical axis and have the same length; the third side plate, the second top plate and the first bottom plate are positioned on the same vertical axis and have the same length; and the fourth side plate, the second upper layering plate and the second lower layering plate are positioned on the same vertical axis and have the same length.

Owner:FUJIAN YILONG PACKING PROD CO LTD

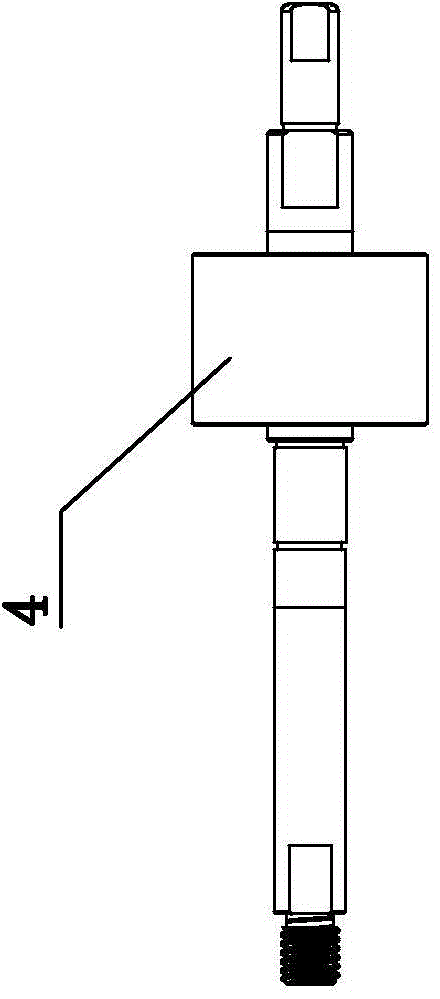

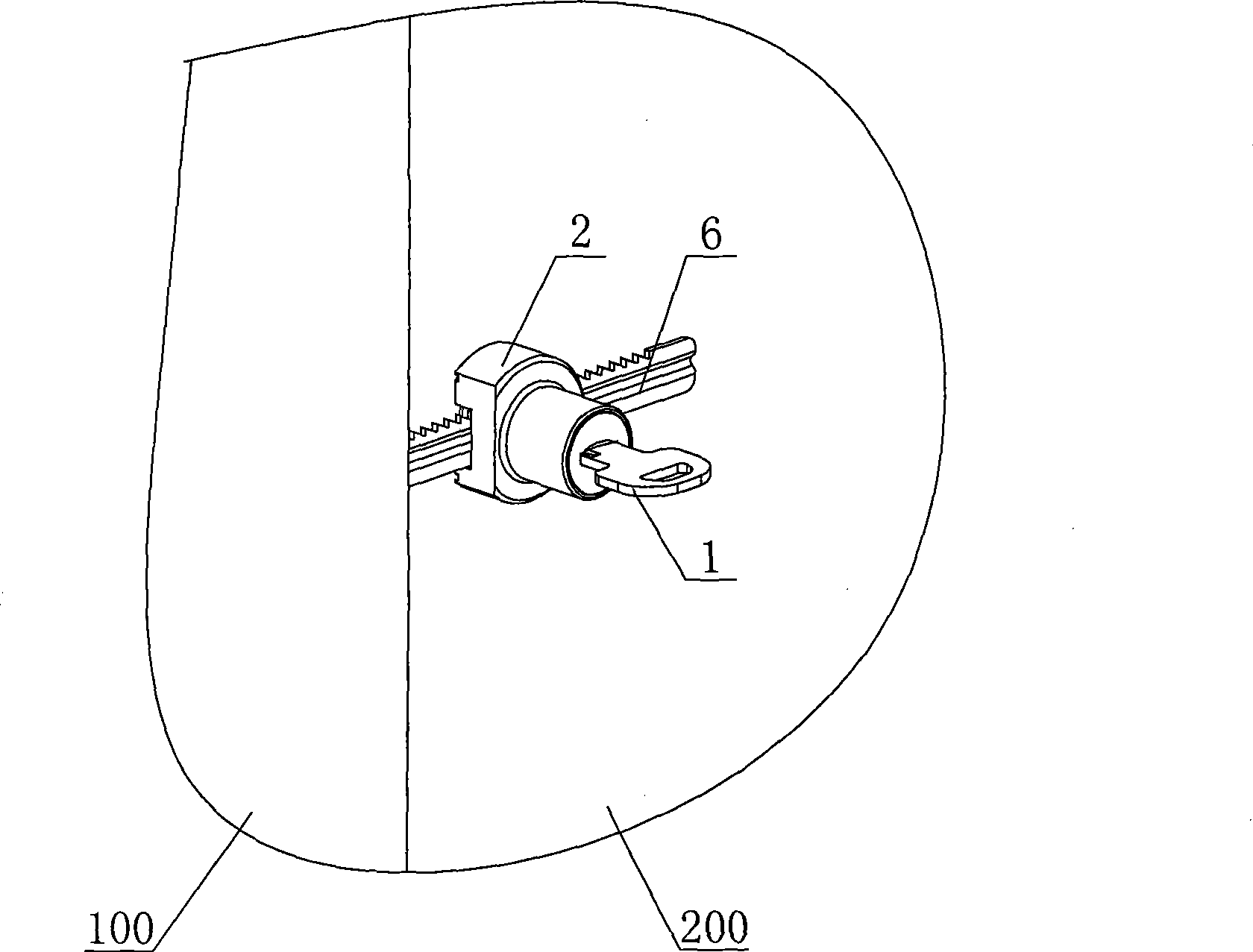

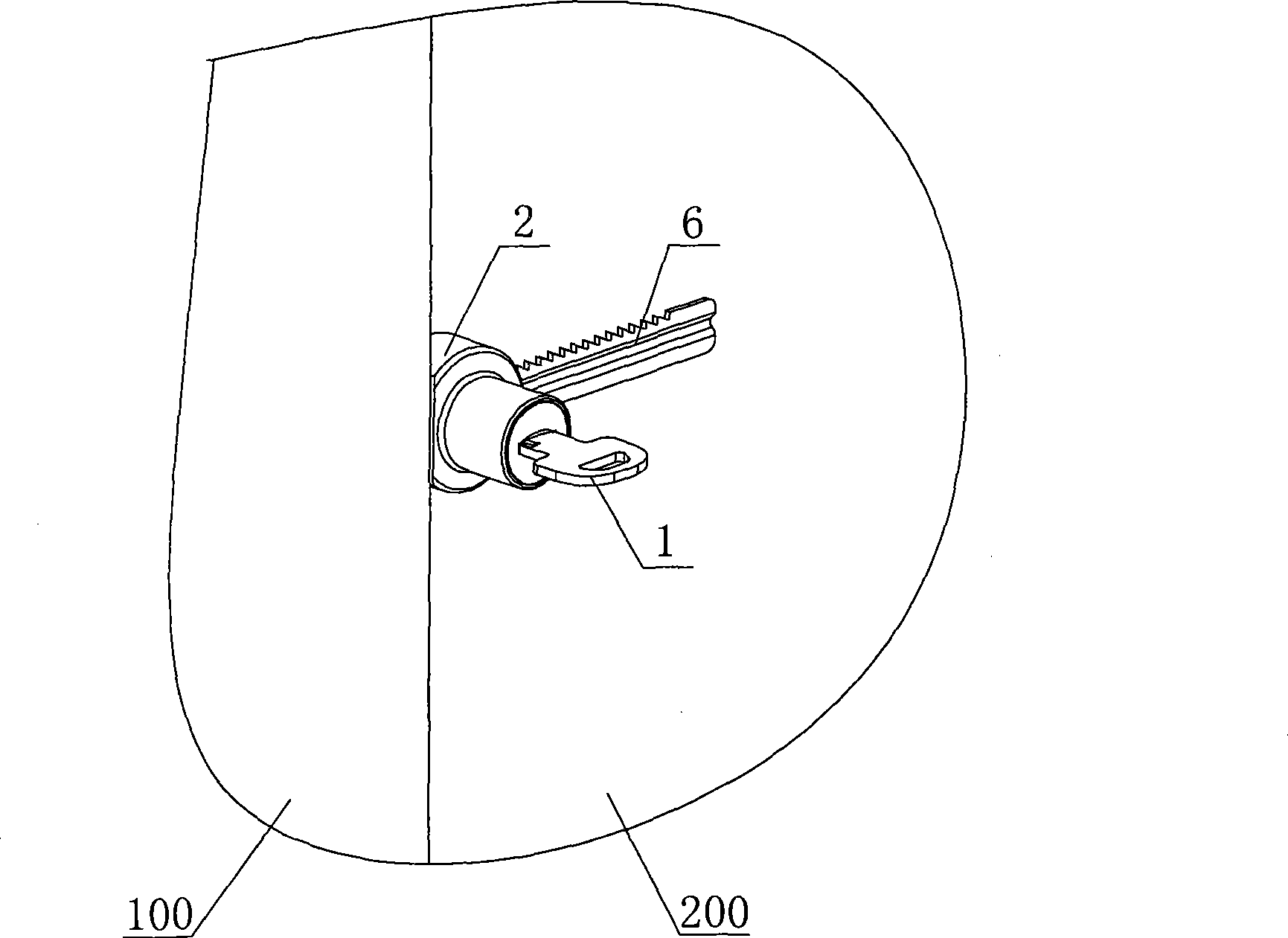

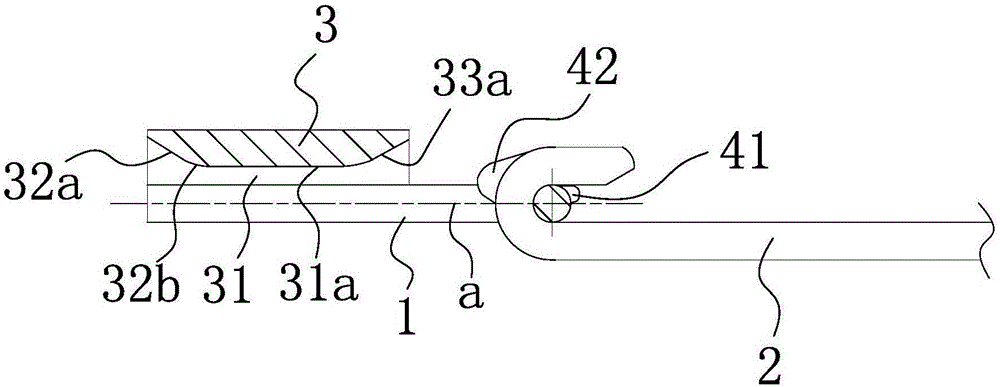

Self-buckling and self-unlocking high-voltage insulation handling rod connector

ActiveCN103258684AWith self-deductionFunctionalContact operating partsAir-break switch detailsEngineeringHigh pressure

The invention discloses a self-buckling and self-unlocking high-voltage insulation handling rod connector. According to the self-buckling and self-unlocking high-voltage insulation handling rod connector, a connecting ring is arranged on the insulation handling rod connector, a connecting shaft capable of rotating around the inner cavity of the connecting ring is arranged in the connecting ring, two tongue pieces are symmetrically arranged on the connecting shaft, two connecting pillars are symmetrically arranged on the connecting shaft, the tongue pieces are hinged to the two connecting pillars in a vertical swinging mode respectively and are in a closed state normally, and the tongue pieces can be opened automatically when being squeezed upward and can return to the original position automatically after being opened and be interlocked. The self-buckling and self-unlocking high-voltage insulation handling rod connector is reliable in use, a working head is completely mechanical and the replaceable working head enables one insulation rod or one handling rod to be multi-functional, and meanwhile, the occurrence of the situation that an operator needs to try several times to enable a hook to be hooked onto an operating position is reduced, and unsafe factors such as incomplete switching or insecure connection due to long-time lifting of the rod, miscontact with other phases and frequent confliction between the working head and a switch are eliminated.

Owner:STATE GRID CORP OF CHINA +3

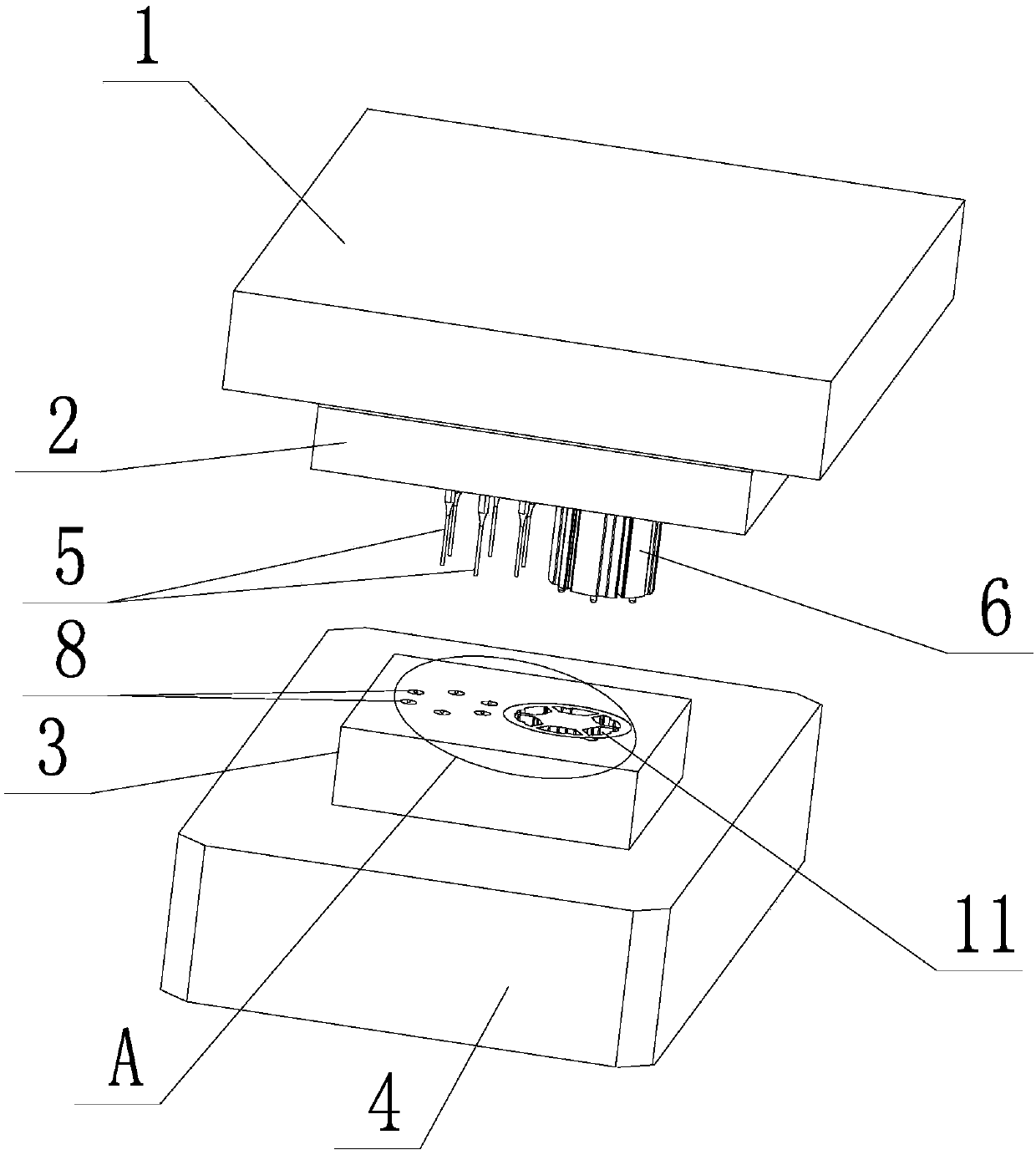

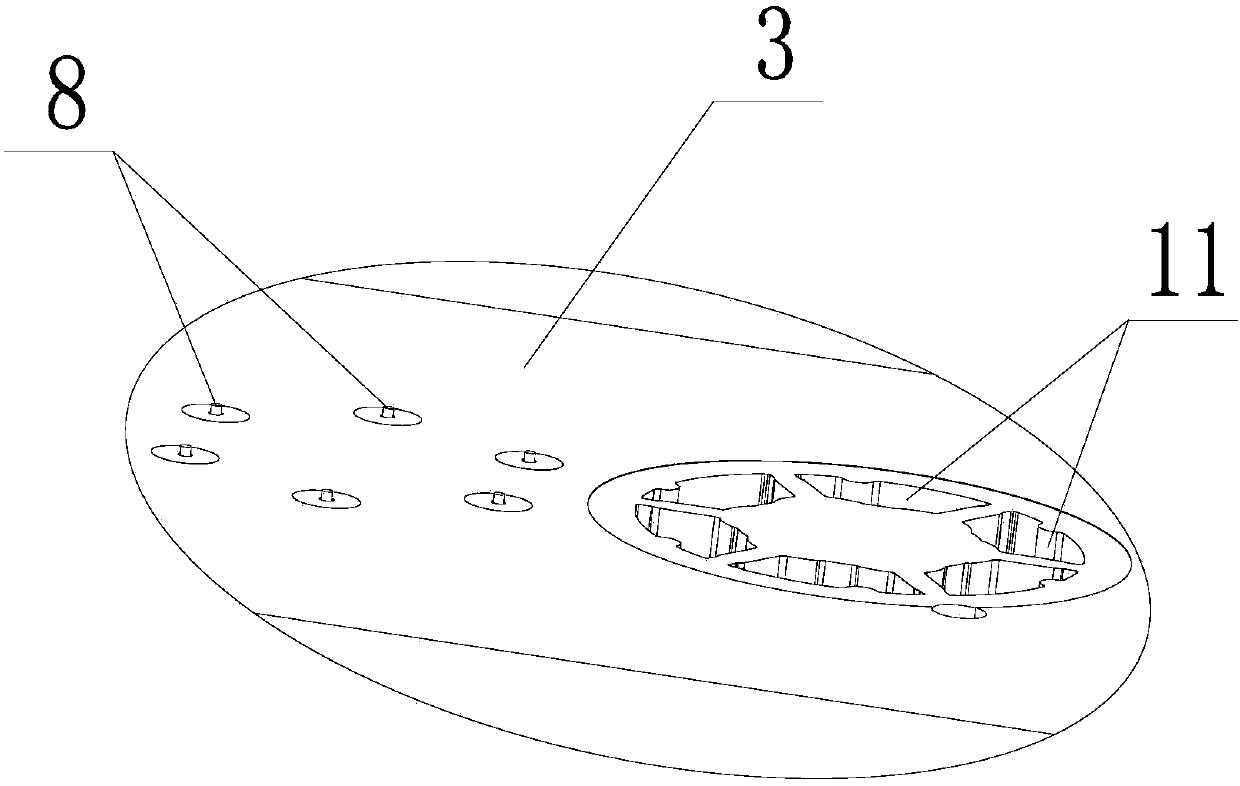

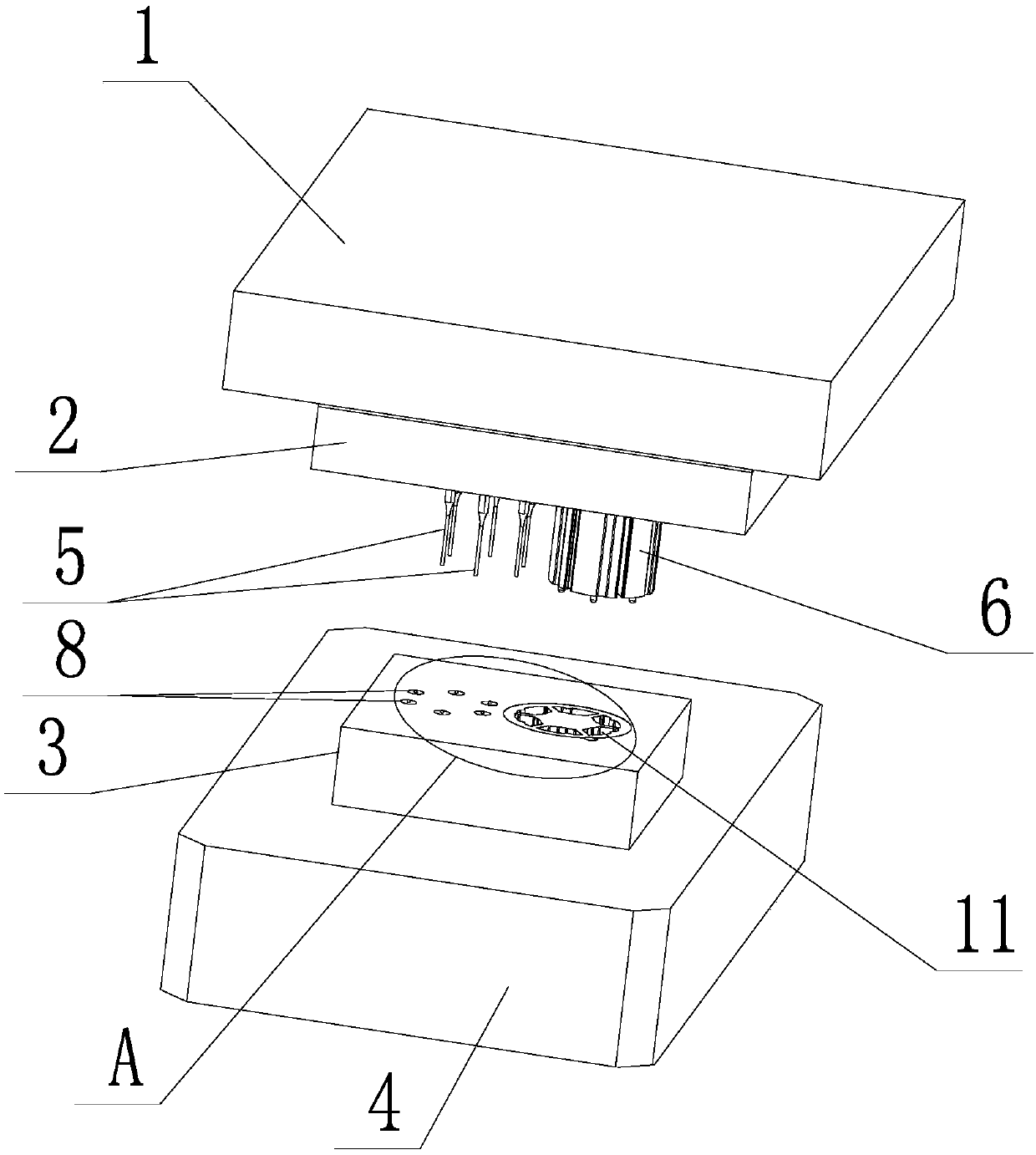

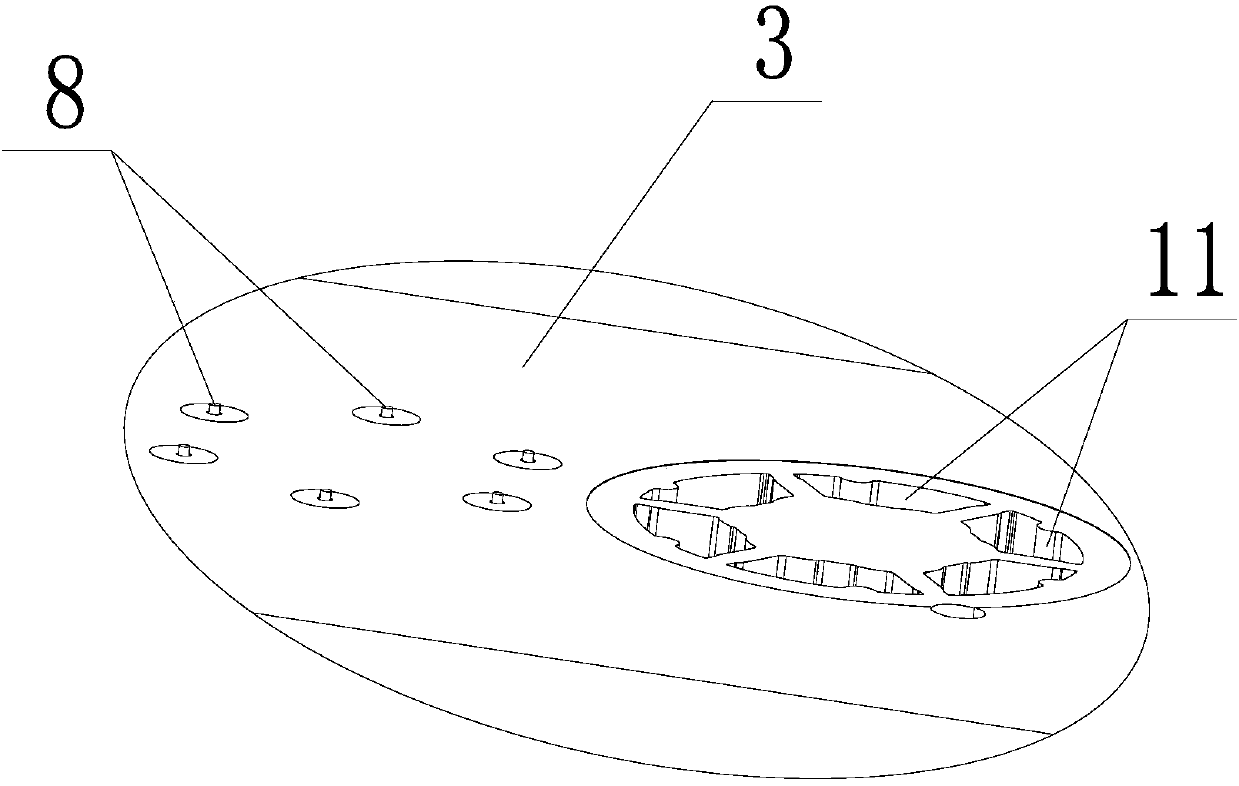

A new type of waste recycling device

ActiveCN106335094BReasonable structural designEasy to useMetal working apparatusSelf-bucklingMachining process

The invention relates to the technical field of machining, in particular to a novel waste material recycling device. The novel waste material recycling device comprises an upper mold plate, a convex cushion plate, a middle mold plate and a lower mold plate. According to the novel waste material recycling device, before waste materials leave a material strip in the material strip machining process, the waste materials are provided with self-buckling points in a printed manner, the waste materials can be automatically buckled and pressed together when the waste materials break away from the material strip, the multiple waste materials can break away from the material strip and the device as a whole, and therefore the workpiece machining efficiency and quality is improved. In addition, the novel waste material recycling device is reasonable in structural design, convenient to use and suitable for use and popularize.

Owner:无锡飞展模具制造有限公司

Self-locking self-unlocking high-voltage insulation operating rod connector

ActiveCN103258684BFunctionalImprove use reliabilityContact operating partsAir-break switch detailsEngineeringHigh pressure

The invention discloses a self-buckling and self-unlocking high-voltage insulation handling rod connector. According to the self-buckling and self-unlocking high-voltage insulation handling rod connector, a connecting ring is arranged on the insulation handling rod connector, a connecting shaft capable of rotating around the inner cavity of the connecting ring is arranged in the connecting ring, two tongue pieces are symmetrically arranged on the connecting shaft, two connecting pillars are symmetrically arranged on the connecting shaft, the tongue pieces are hinged to the two connecting pillars in a vertical swinging mode respectively and are in a closed state normally, and the tongue pieces can be opened automatically when being squeezed upward and can return to the original position automatically after being opened and be interlocked. The self-buckling and self-unlocking high-voltage insulation handling rod connector is reliable in use, a working head is completely mechanical and the replaceable working head enables one insulation rod or one handling rod to be multi-functional, and meanwhile, the occurrence of the situation that an operator needs to try several times to enable a hook to be hooked onto an operating position is reduced, and unsafe factors such as incomplete switching or insecure connection due to long-time lifting of the rod, miscontact with other phases and frequent confliction between the working head and a switch are eliminated.

Owner:STATE GRID CORP OF CHINA +3

Clip connecting edge and connecting reinforcement

InactiveCN106704322ASimple production processEasy to assembleElongated constructional elementsSheet joiningAdhesiveEngineering

The invention provides a clip connecting edge and a connecting reinforcement which respectively use a clip connecting unit and a connecting reinforcement unit as a basic structure and a functional unit. The clip connecting edge comprises a three-part basic structure including an inner skeleton, an outer skeleton and an inflated edge (face), wherein a main function and a use requirement are achieved and met by using a continuous bending self-buckling structure, an expansion buckle structure and the like; and a reinforcement connecting frame structure is obtained by connecting and mounting a standard common interactive connection unit, a linear connection or a right-angle, linear reinforcement unit in various connecting edges; and then, a product such as a door, window, box, cabinet, desk and shelf is obtained via assembly. Compared with a traditional wire craft product, the whole assembling process can be achieved without secondary processing or use of fasteners, adhesives, and the like; the production process is simple; the assembly is convenient; product style is various; the functions are complete; the structure is light and strong; the cost is low; and the whole product can be made of only one plastic, so as to be more convenient to recycle and utilize, and environmentally friendly.

Owner:上海帝陈塑胶工业有限公司

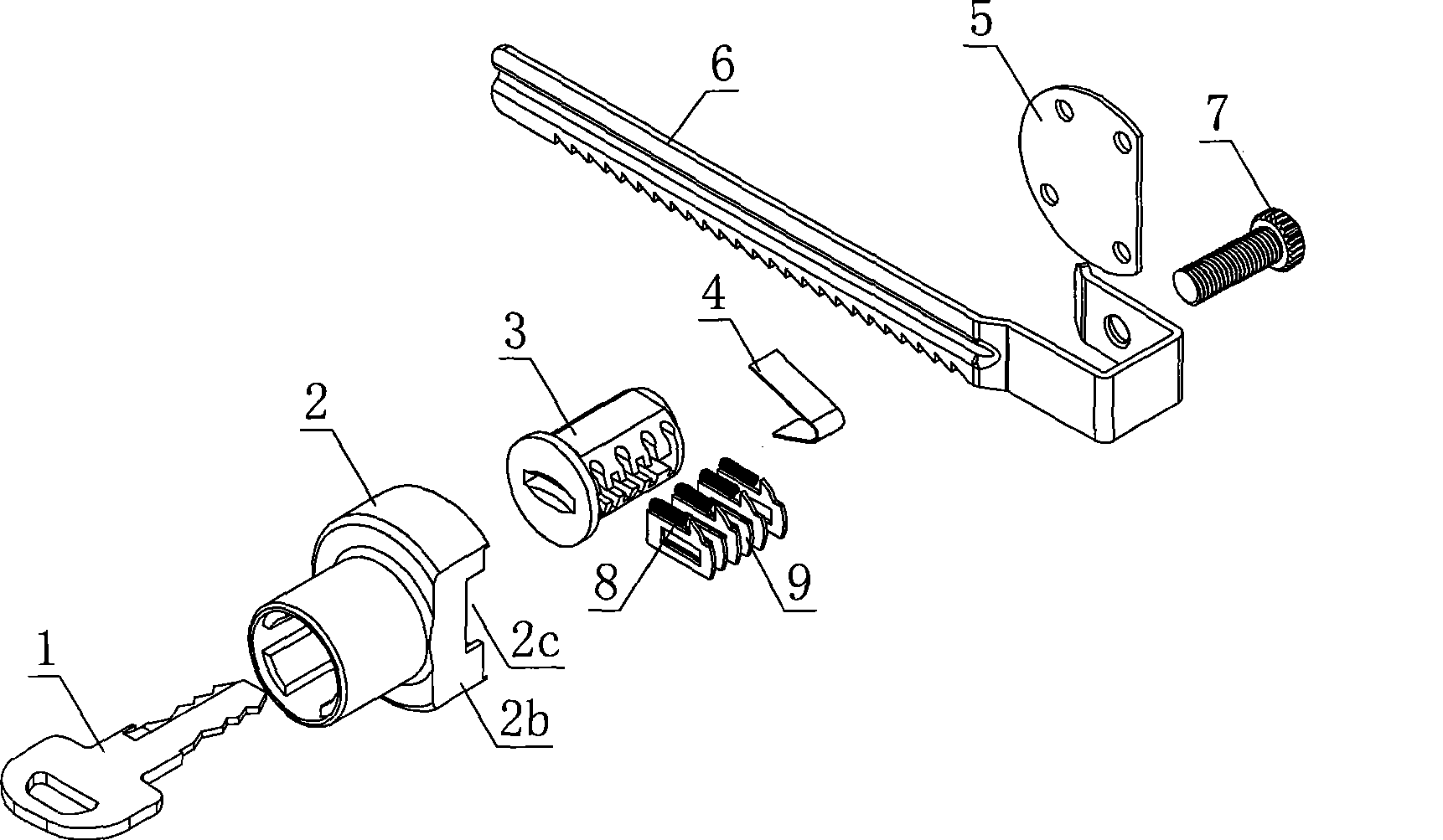

Self-buckling type slide anti-theft lock with anti-push pressure and pick-proof functions

The invention discloses a clinching type sliding antitheft lock with anti-bulldozing and anti-prying functions, comprising a key, a lock shell and a lock plunger, wherein, the lock shell is provided with a lock plunger hole for the lock plunger to pass through, the lock shell consists of a base and a lock sleeve which are connected mutually, a cavity is formed between the base and the lock sleeve and internally provided with a lock core, a spring, a film threading and a lock plunger shrapnel, the mounting positions of the spring and the shrapnel are matched with the position of the lock core, and the lock shell is provided with an anti-bulldozing and anti-prying mechanism. The antitheft lock is provided with the anti-bulldozing and anti-prying mechanism, thus avoiding the generation of malposition clearance between door plates when external force is applied on the door plate of a horizontal sliding door, preventing the front and back movement of the door plate in opposite directions, eliminating the safety hazard that objects in the horizontal sliding door can be stolen and effectively improving the safe coefficient when the antitheft lock is used.

Owner:许皓程

Using method of novel waste recovery device

InactiveCN107791311AEasy to useReasonable structural designMetal working apparatusEngineeringSelf-buckling

The invention relates to the technical field of machining, in particular to a using method of a novel waste recovery device. The novel waste recovery device comprises an upper template, a convex baseplate, a middle template and a lower template. According to the using method of the novel waste recovery device, in the machining process of a material belt, self-buckling points are made on waste before the waste leaves the material belt; the waste can be pressed together automatically when the waste leaves the material belt, so that lots of waste is escaped from the material belt and the device overall; in this way, the machining efficiency and quality of workpieces are improved. In addition, the novel waste recovery device has the advantages of rational structural design and easy use, and isapplicable for promotion.

Owner:无锡飞展模具制造有限公司

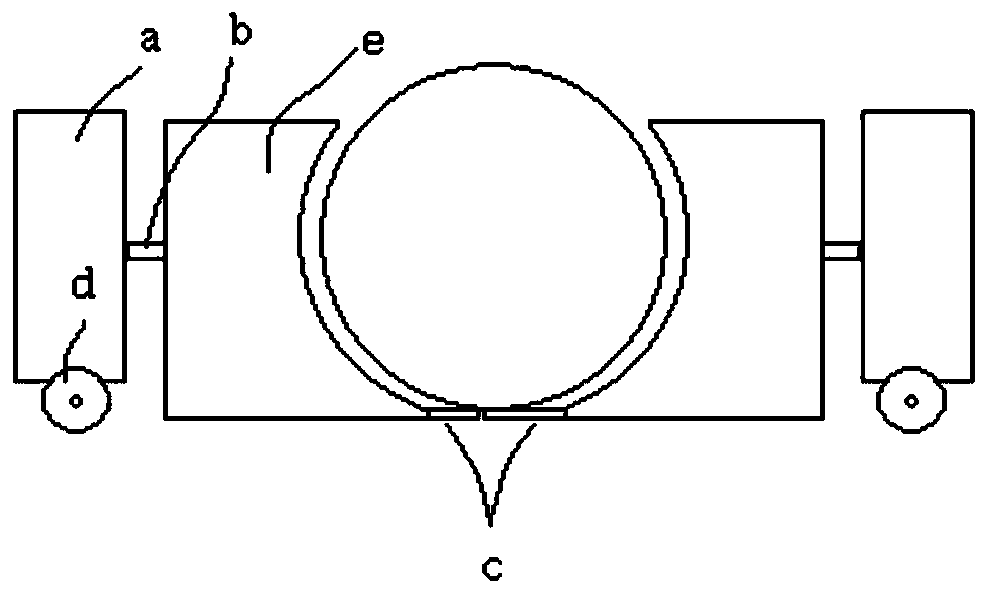

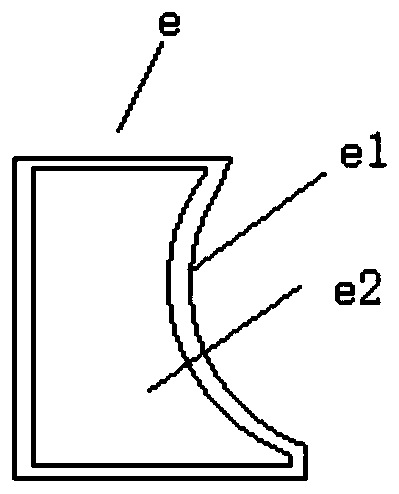

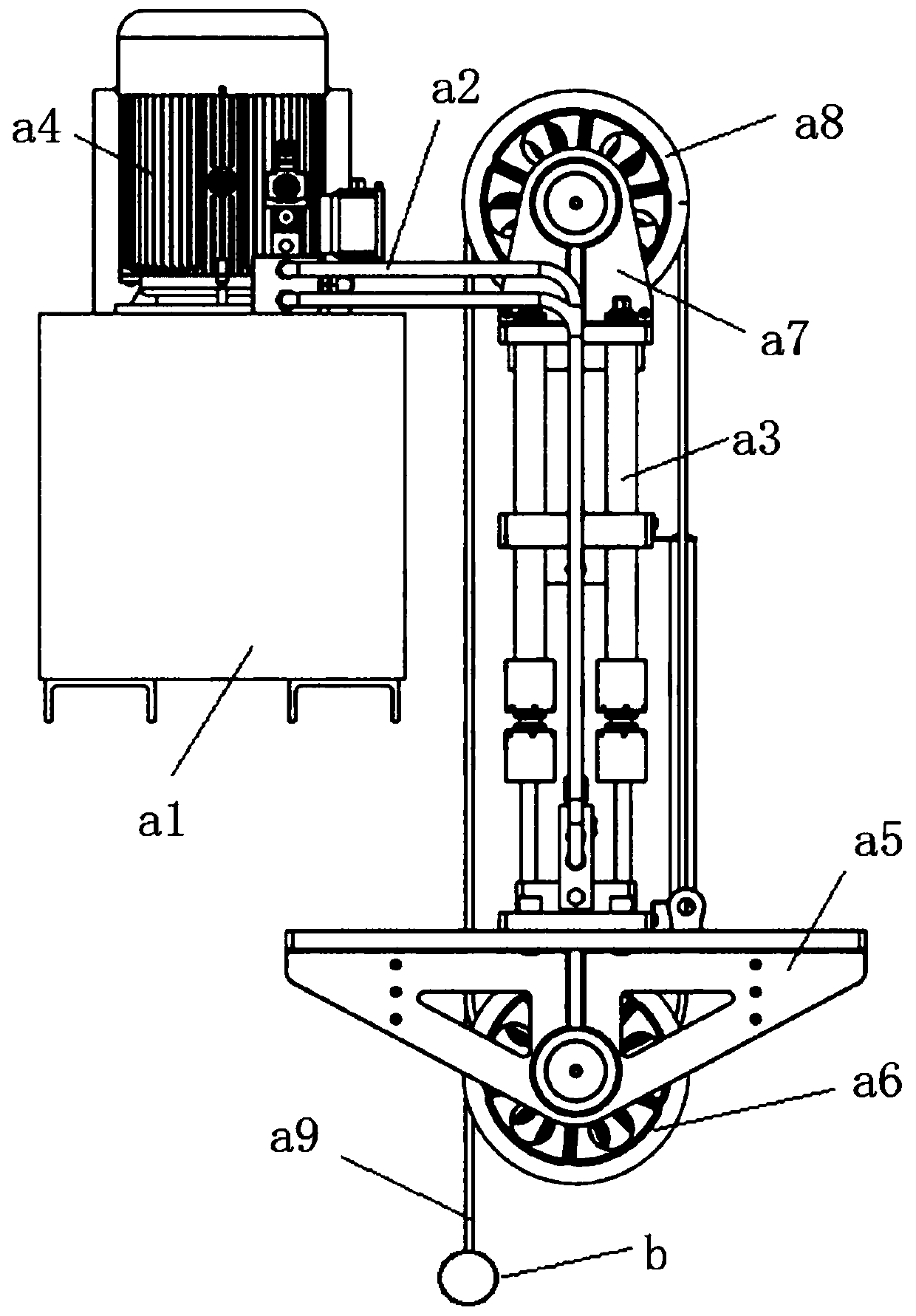

Wheel moving device for vehicle maintenance

ActiveCN110435612ARealize the unlocking processAchieve riseVehicle manoeuvring devicesDrive wheelEngineering

The invention belongs to the field of mechanical maintenance, and particularly relates to a wheel moving device for vehicle maintenance. By means of the wheel moving device, vehicle wheels are convenient to lock, lift and move. The wheel moving device comprises a pair of lifting assemblies and a pair of fixing assemblies used for fixing the wheels, wherein a self-driving wheel is arranged at the bottom of the lifting assemblies; the lifting assemblies are connected with the fixing assembly at one side through a fixing shaft to lift and adjust the fixing assemblies; arc-shaped grooves oppositeto the outer contour of the wheels are formed in one side of the fixing assemblies; and a self-buckling assembly is arranged at the bottom between the grooves of the pair of fixing assemblies. According to the wheel moving device, the locking and lifting of the wheels are achieved, the wheels can be moved through the self-driving wheels, and the vehicle is convenient to maintain.

Owner:常州常氢时代新能源有限公司

Self-locking combination wall panel

ActiveCN103174255BSimple construction processEasy to transportSynthetic resin layered productsBuilding componentsCalcium silicateSteel bar

Owner:查晓雄

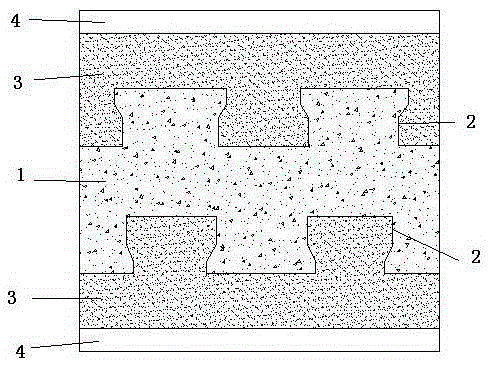

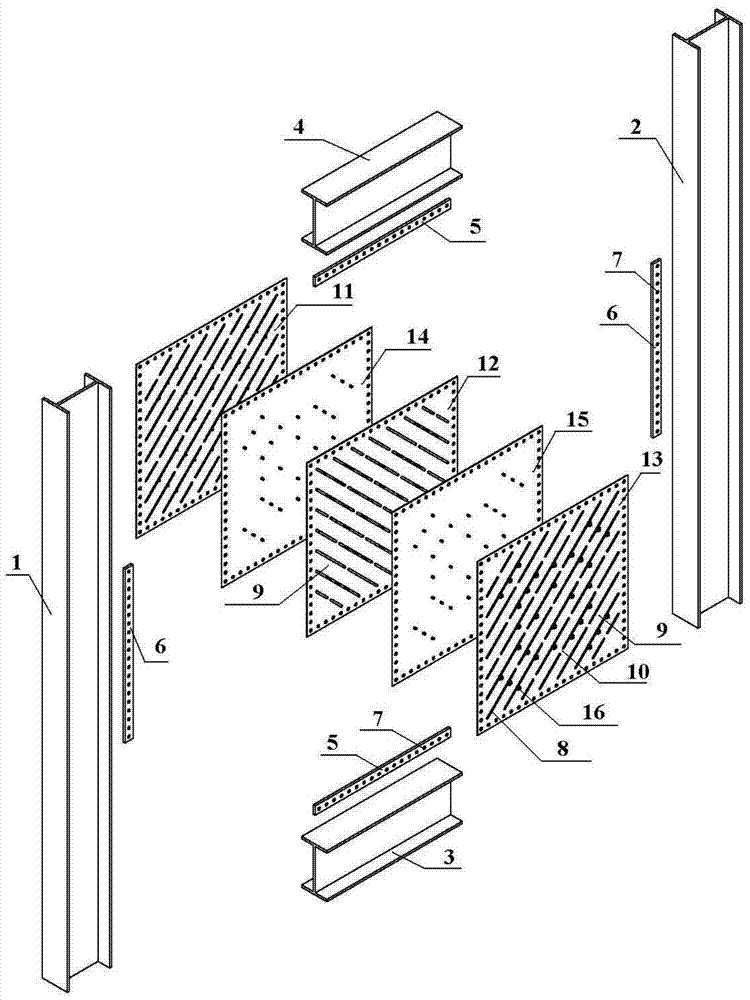

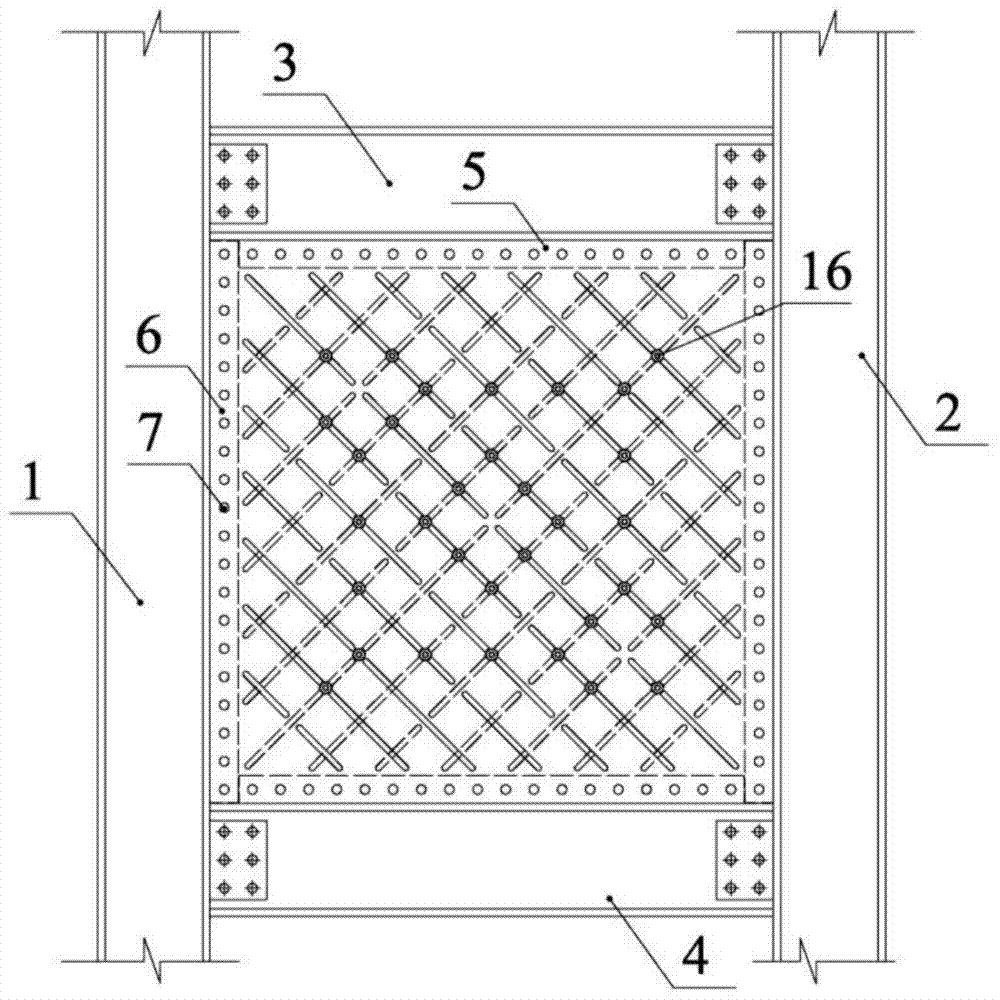

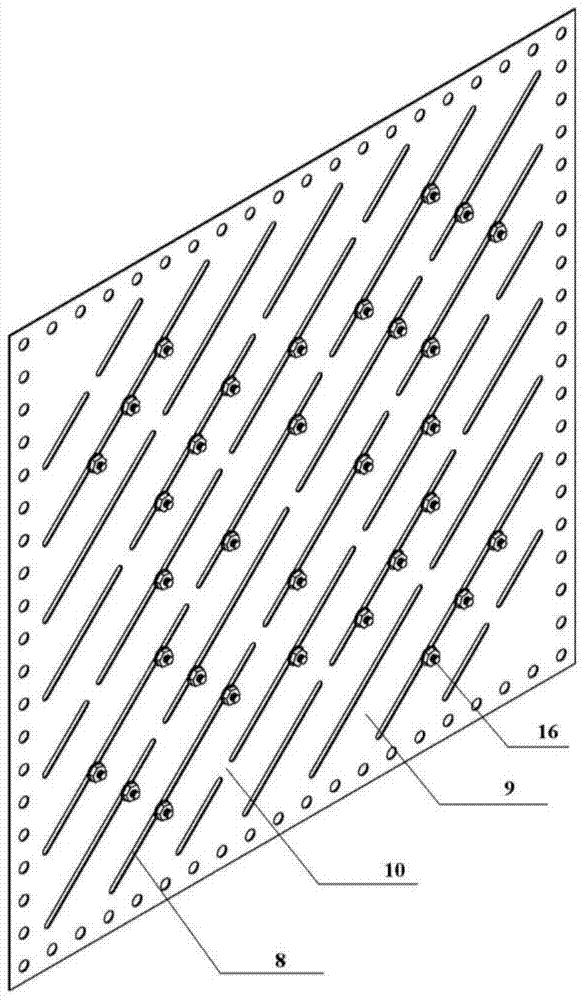

A multi-layer self-buckling-resistant steel plate shear wall

The invention relates to a multi-layer self-buckling steel plate shear wall, comprising: multi-layer steel plates with oblique grooves, friction-reducing layers are arranged between adjacent steel plates; The direction of the groove is opposite; the fastener penetrates through the steel plate and the anti-friction layer to fasten all the steel plates and the anti-friction layer into a wall; the wall is also fixedly connected to the frame column and / or frame beam through the fastener The connecting plate on the top is connected; between the inclined grooves is the inter-groove plate strip. Under the action of reciprocating horizontal earthquake load, the inter-groove plate strips in the same direction are respectively in the state of unidirectional tension or compression. The stiffness of the inter-strips provides support for the inter-slabs of the other layers of compression grooves, restricts their buckling, and achieves self-buckling prevention.

Owner:SHANDONG UNIV

Self-buckling structure of brassiere back buckle, brassiere and self-buckling method of brassiere back buckle

ActiveCN105124786AReduce the difficulty of wearingPracticalElectrotherapyBrassieresSelf-bucklingElectrical and Electronics engineering

The invention relates to a self-buckling structure of a brassiere back buckle, a brassiere and a self-buckling method of the brassiere back buckle, in order to solve the problems of being inconvenient to wear and the like in the prior art. The self-buckling structure of the brassiere back buckle comprises metal back buttons formed with button holes and metal back hooks which can be inserted into the button holes and can be buckled with the metal back buttons, wherein sliding bases are arranged on the metal back buttons; guide through slots are formed in the sliding bases and the slot bottoms of the guide slots are magnetic guide surfaces; the magnetic guide surfaces are parallel with the mean surface of the button holes in a length direction and the magnetic guide surfaces are located on the inner side of the mean surface of the button holes in the length direction; magnetic driving structures, which are capable of driving the metal back hooks to move on the magnetic guide surfaces so as to buckle the metal back hooks on the metal back buttons when the metal back hooks are located inside the guide through slots and are adsorbed on the magnetic guide surfaces, are arranged between the metal back buttons and the metal back hooks; and the magnetic force of the magnetic driving structures is more than the magnetic force of the magnetic guide surface. The brassiere back buckle disclosed by the invention has aligning and self-buckling functions, and the brassiere back buckle is strong in practicability.

Owner:余莉娅

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com