Up-and-down dual self-buckling self-sealing packaging box

A packaging box and buckle technology, applied in packaging, transportation and packaging, rigid containers, etc., can solve the problems that items cannot be stored separately, without layering, and do not meet environmental protection requirements, so as to save glue or tape and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

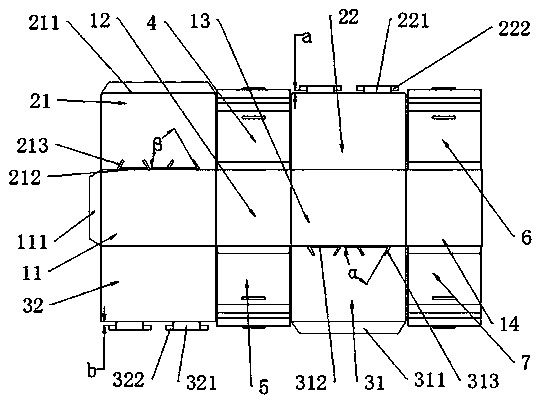

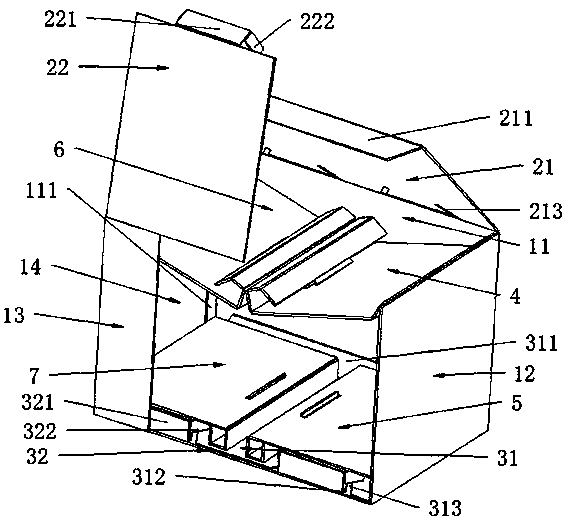

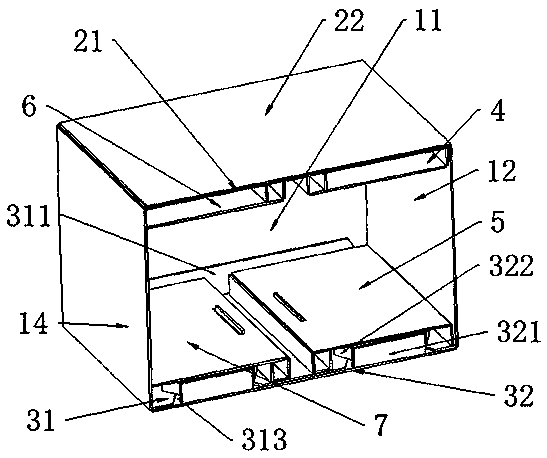

[0028] Embodiment one: see Figure 1-5 , an upper and lower double self-fastening and self-sealing packaging box, including a first side panel 11, a second side panel 12, a third side panel 13 and a fourth side panel 14 connected along the same horizontal axis and having equal widths, the first The other side of the side plate 11 is connected with a side plate 111; the upper and lower ends of the first side plate 11 are respectively connected with the first top plate 21 and the second bottom plate 32, and the upper and lower ends of the third side plate 13 are respectively connected with the second top plate 22 and the first bottom plate 31, the upper and lower ends of the second side plate 12 are respectively connected with the first upper layer plate 4 and the first lower layer plate 5, and the upper and lower ends of the fourth side plate 14 are respectively connected with the second upper layer The layered plate 6 and the second lower layered plate 7; the first side plate ...

Embodiment 2

[0035] Embodiment two: see Figure 6-7 , the first inner buckle 222 is connected to the first insertion piece 221 through the first folded plate 223, and the second inner buckle 322 is connected to the second insertion piece 321 through the second folded plate 323 The first buckle slot 213 is connected to two adjacent first slots 212 in an "I" shape, and the second buckle slot 313 is connected to two adjacent second slots 312 to form an "I" shape. I" shape structure. The slot is in the shape of an "I", which is more conducive to inserting the insert piece and the inner buckle piece into the opening and snapping into the slot, which has better sealing performance.

[0036] Further, the width of the first buckle groove 213 is greater than or equal to twice the thickness of the box body; the width of the second buckle groove 313 is greater than or equal to twice the thickness of the box body.

Embodiment 3

[0037] Embodiment three: see Figure 8 The difference between this embodiment and the second embodiment is that the shape of the first inner buckle 222 is triangular; the shape of the second inner buckle 322 is triangular.

[0038] The folding process of Embodiment 1 of the present invention is as follows:

[0039] Firstly, the first side panel 11 , the second side panel 12 , the third side panel 13 and the fourth side panel 14 are folded into a box body, and then the side panel 111 is glued or bound inside the fourth side panel 14 . Then start to fold the first upper layer board 4 and the first lower layer board 5, turn down the inner flap 41 on the inner side of the box body, then turn up the transverse support plate 42 to be horizontal, and then turn the The first vertical plate 43 , the connecting plate 44 and the second vertical plate 45 are folded into a square tube in a direction close to the inner flap 41 , and finally the insertion plate 46 is inserted into the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com