Machining method of motor rotor magnetic steel ring of electric vehicle

A technology of motor rotor and processing method, which is applied in electric vehicles, motors, manufacturing stator/rotor body, etc., can solve the problems of narrowing the width of magnetic steel sheets, complex processing technology, and reducing material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the drawings.

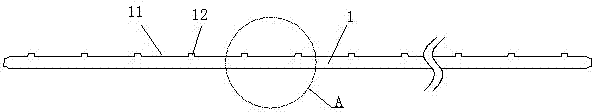

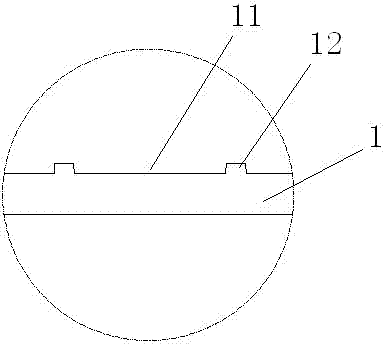

[0025] Such as Figure 1-3 As shown, the steel strip is punched into a steel plate punch 1 with an inner groove 11 after passing through the punching equipment. The inner grooves 11 are formed with a distance between the protrusions 12, and after a predetermined length is cut to form a single-layer steel plate punch . Use equipment to stack the multi-layer steel plate punching sheet 1 into a punching sheet block 2 of a predetermined height, such as Figure 4 Shown. The laminated punch block 2 is bent by an external force to form an annular cylindrical magnetic steel ring 3 through a mold, such as Figure 5-7 As shown, the cylindrical magnetic steel ring 3 that has been bent and formed is connected to form an integral structure by welding, riveting or self-fastening. Image 6 In the example in the example, welding is used for fixed connection.

[0026] Such as Figure 7-9 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com