Self-buckling packing carton

A packaging box and carton technology, applied in the field of packaging boxes, can solve problems such as troublesome and troublesome packaging process, and achieve the effect of improving sealing and strength and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

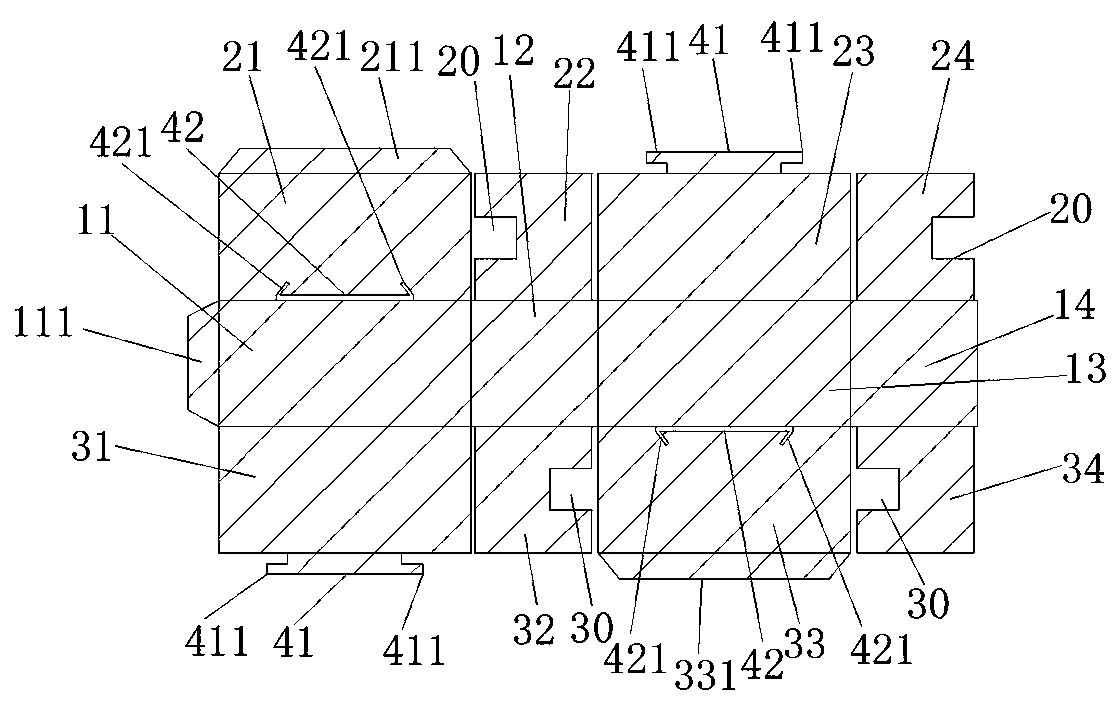

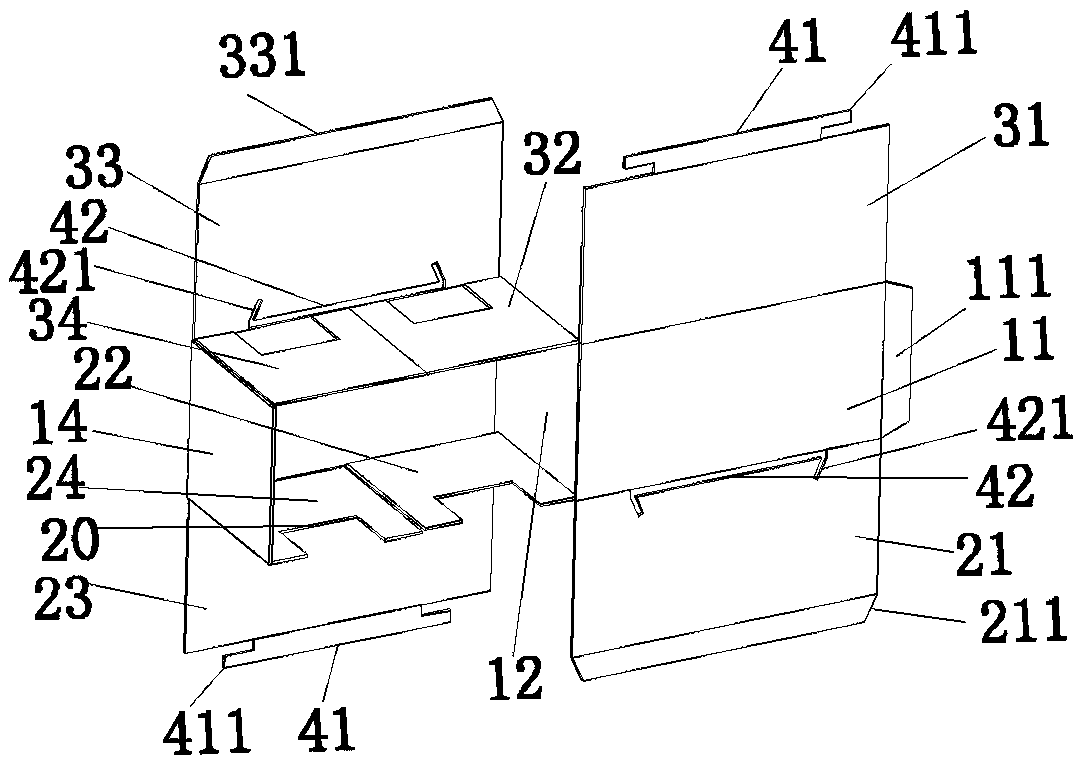

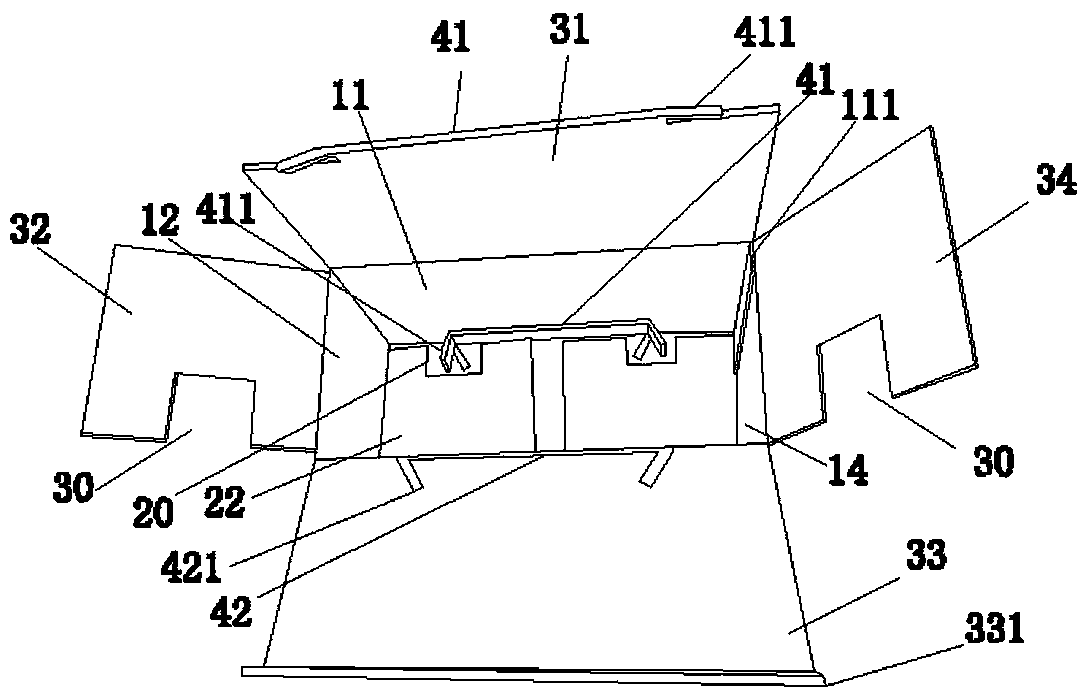

[0027] see Figure 1 to Figure 4 , a kind of self-fastening package packaging carton, including the first side panel 11, the second side panel 12, the third side panel 13 and the fourth side panel 14 which are connected in turn in the horizontal direction; the first side panel 11 is relative to the One side of the second side plate 12 is rotatably connected with a connecting plate 111, and the upper and lower sides of the first side plate 11 are respectively rotatably connected with the first top plate 21 and the first bottom plate 31; The lower edge is respectively rotatably connected with the second top plate 22 and the second bottom plate 32; the upper edge and the lower edge of the third side plate 13 are respectively rotatably connected with the third top plate 23 and the third bottom plate 33; The lower edge is respectively connected with the fourth top plate 24 and the fourth bottom plate 34 in rotation; the top and the bottom of the packaging carton are provided with a...

Embodiment 2

[0036] see Figure 2 to Figure 5 The difference between this embodiment and the above-mentioned first embodiment is that the slot 42 is rectangular, and the two ends of the slot 42 are provided with vertical to the slot 42 and matched with the pinch plate 411 Buckle groove 421.

[0037] The assembly process of this embodiment is as follows:

[0038] The first side panel 11, the second side panel 12, the third side panel 13 and the fourth side panel 14 are folded into a square, the joint plate 111 is bonded to the inner surface of the fourth side panel 14, and the second bottom panel 32 and the fourth side panel are folded. Four base plates 34 make them fold towards the square space, fold the third base plate 33, and insert the second tongue 331 in the gap between the second base plate 32, the fourth base plate 34 and the first side plate 11, then fold the first base plate 31 1. Bend the buckle plate 411 on the first bottom plate 31 in half, and then insert the insert plate 4...

Embodiment 3

[0041] see Figure 2 to Figure 4 as well as Figure 6 The difference between this embodiment and the above two embodiments is that the slot 42 is rectangular, and the width of the slot 42 is twice the thickness of the cardboard of the packaging box; there is no buckle groove 421 at both ends of the slot 42 .

[0042] The assembly process of this embodiment is as follows:

[0043]The first side panel 11, the second side panel 12, the third side panel 13 and the fourth side panel 14 are folded into a square, the joint plate 111 is bonded to the inner surface of the fourth side panel 14, and the second bottom panel 32 and the fourth side panel are folded. Four base plates 34 make them fold towards the square space, fold the third base plate 33, and insert the second tongue 331 in the gap between the second base plate 32, the fourth base plate 34 and the first side plate 11, and then fold the first base plate 31 , bend the gusset 411 on the first bottom plate 31 inwards so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com