Method for manufacturing bulk sheet motor iron core by using waste sheet self-buckling mode

A technology of self-fastening and scrapping, which is applied in the manufacture of motor generators, stator/rotor bodies, electrical components, etc., and can solve problems affecting the surface flatness of motor iron core loose pieces, affecting the continuity of processing, and affecting the production process, etc. , to facilitate processing, control iron loss and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

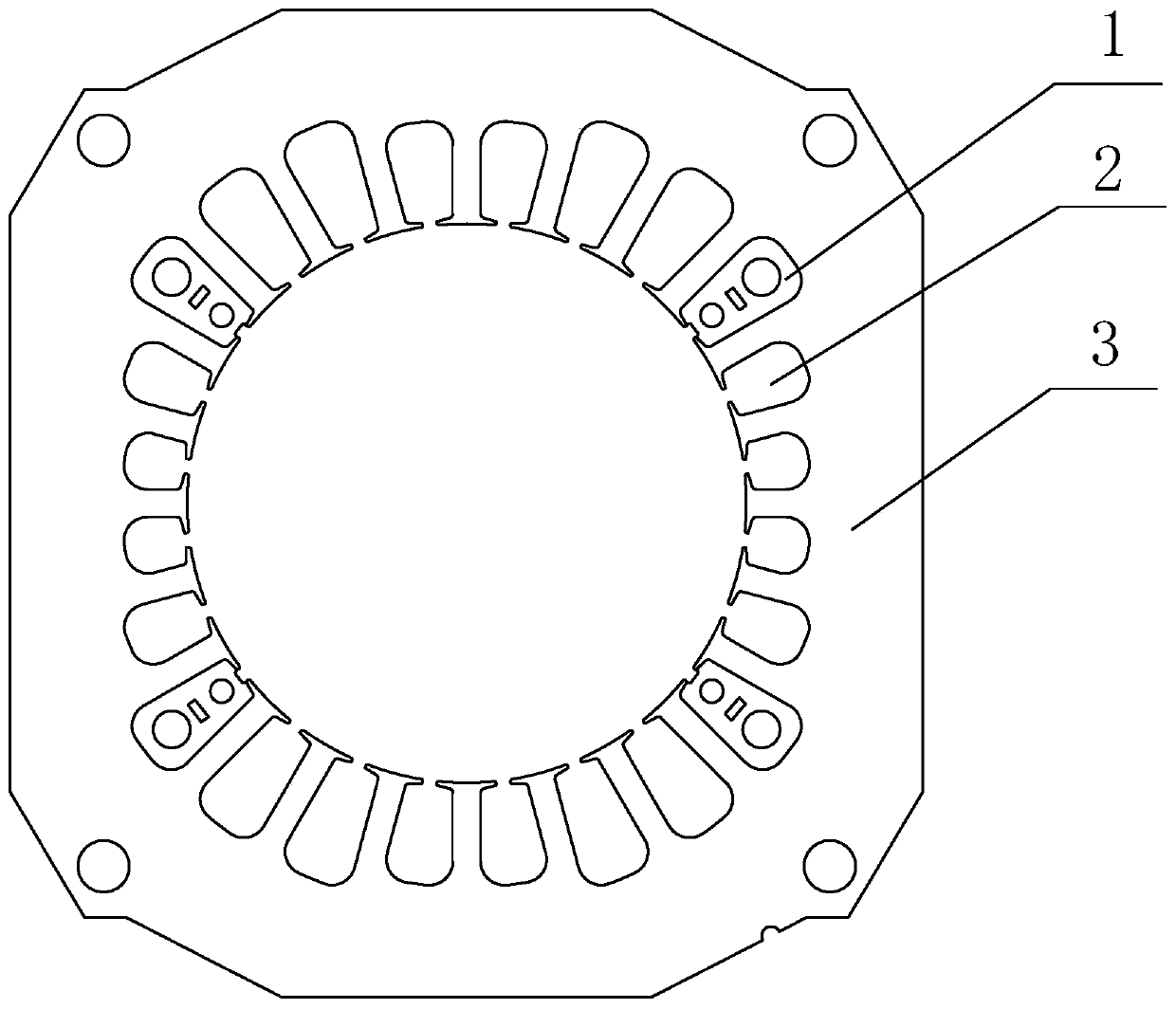

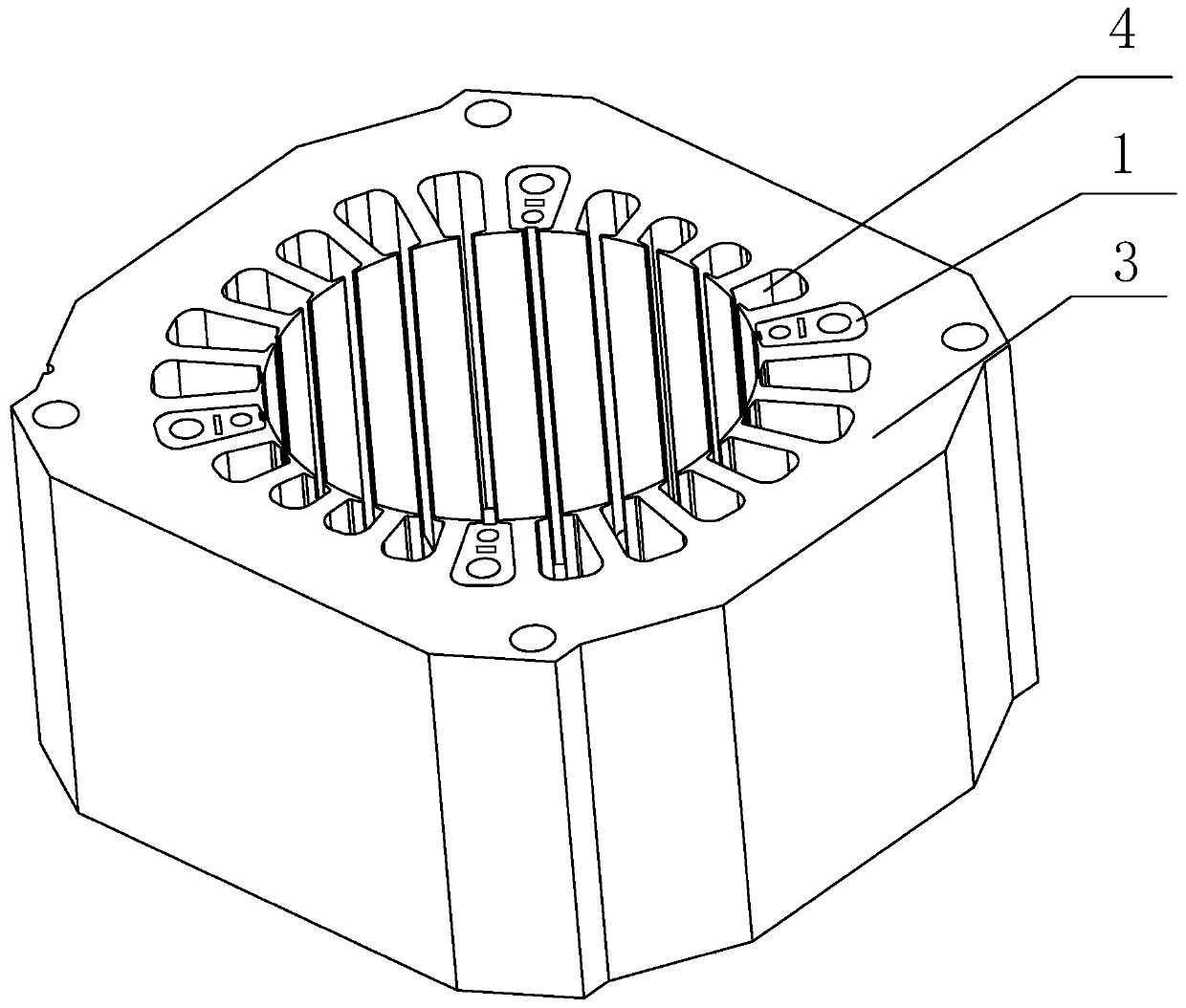

[0032] Embodiment 1: as Figure 1 to Figure 4 Shown is a method of manufacturing loose sheet motor iron cores by using the waste sheet self-fastening method. First, the steel plate is wound on the plate rolling machine, and the steel plate is uncoiled according to the width of the stator. After the steel plate is uncoiled, the surface or edge of the steel plate Unevenness occurs. Therefore, it is necessary to pass the steel plate uncoiled by the plate rolling machine through a precision leveling machine to level the surface of the steel plate. Pass the leveled steel plate into the automatic feeder, the automatic feeder sets the feeding speed according to the punching speed, automatically transports the steel plate, and transports the steel plate to the high-speed punching machine for punching.

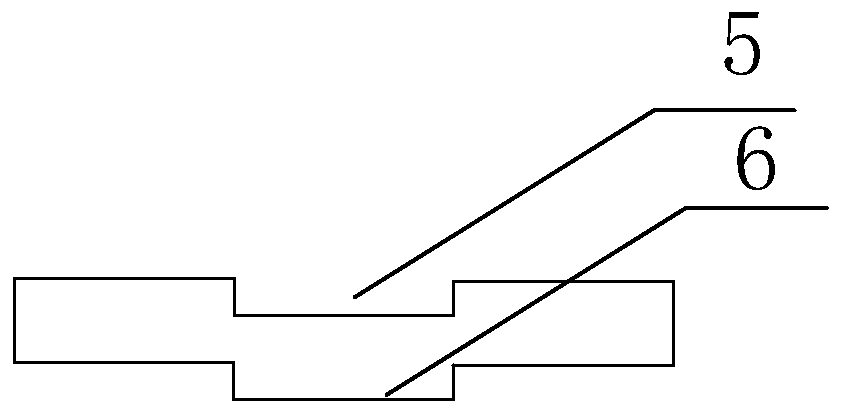

[0033] When punching, first punch out the waste pieces in the tank, use a multi-station progressive die to punch out the waste pieces-1 in the loose piece tank body 3, and punch out th...

Embodiment 2

[0040] Embodiment 2: Other structures are the same as Embodiment 1, but for a part of the motor iron core, due to the need for setting, when the yoke portion 4 of the motor iron core is also provided with a through hole in the axial direction, like this, it can be The blanking position of waste sheet two 2 is arranged in the through hole in the yoke 4, like this, for the blanking in the tank body 3, can carry out once, other blanking and processing method are the same as embodiment 1, can equally Improve the quality of the product; for the stator loose pieces with a large surface area, 6 waste pieces 22 on the yoke 4 are arranged in axisymmetric arrangement, which can increase the mutual friction and improve the stator loose pieces. between fixed effects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com