Split type stator core structure and splicing method

A stator core, split-type technology, applied in the field of split-type stator core structure and splicing, can solve the problems of restricting the application and promotion of stator split-type structure products, product size, shape and position tolerance and strength control difficulties, etc. , to achieve the effect of ensuring the installation requirements of the interference, reducing the difficulty of processing, and strengthening the structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

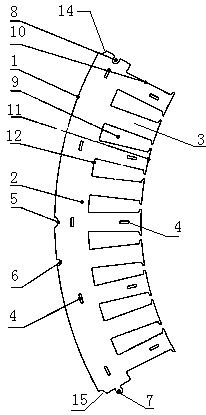

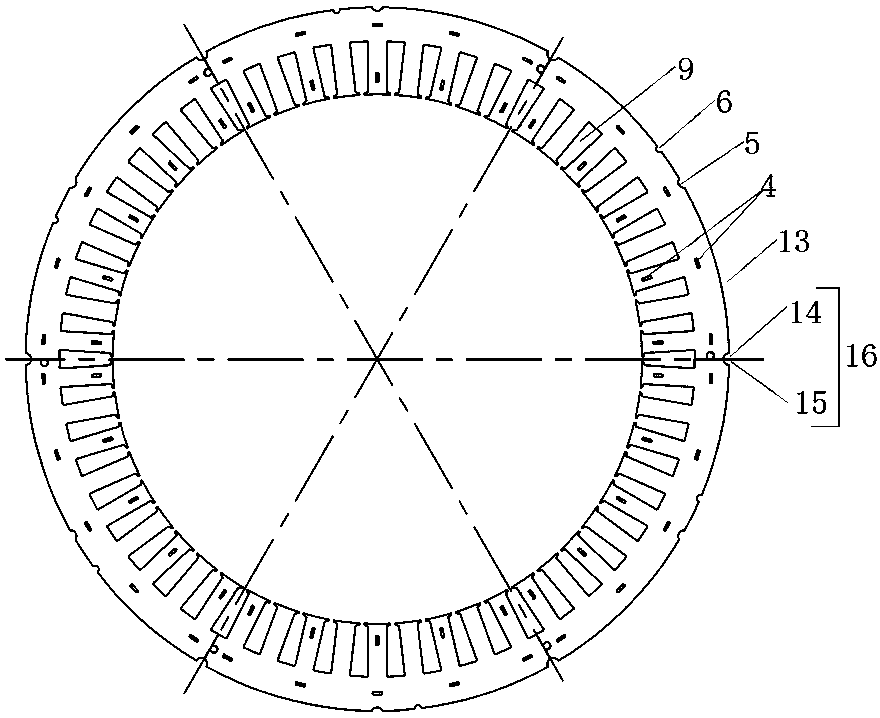

[0026] The following is based on Figure 1 to Figure 2 The specific embodiment of the present invention is further described:

[0027] A split stator core structure, including a full circle stator core 13, the structure of the full circle stator core 13 is as follows figure 2 As shown, the full circle stator core 13 includes a plurality of stator core split structures that can be spliced together into a full circle, such as figure 1 As shown, the stator core split structure includes a plurality of stator split punches 1, and the stator split punches 1 include an arc-shaped yoke 2 and several notch teeth 3, and the plurality of notch teeth 3 are uniform Distributed and fixed on the inner ring of the yoke 2, a notch 9 is formed between adjacent notch teeth 3, one end of the yoke 2 is provided with a process groove 8, and the other end is provided with a process groove 8. The matching process boss 7, the outer ring of the yoke 2 is provided with a positioning groove 6 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com