Electric vehicle hub motor stator and manufacturing method thereof

A technology for in-wheel motors and electric vehicles, used in the manufacture of motor generators, electric components, and stator/rotor bodies, etc., can solve the problem of placing rivets, inconvenient welding operations, large punching area in stacking riveting process, and inconvenient slot size. To anticipate and other issues, to reduce labor costs, improve stability and safety, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

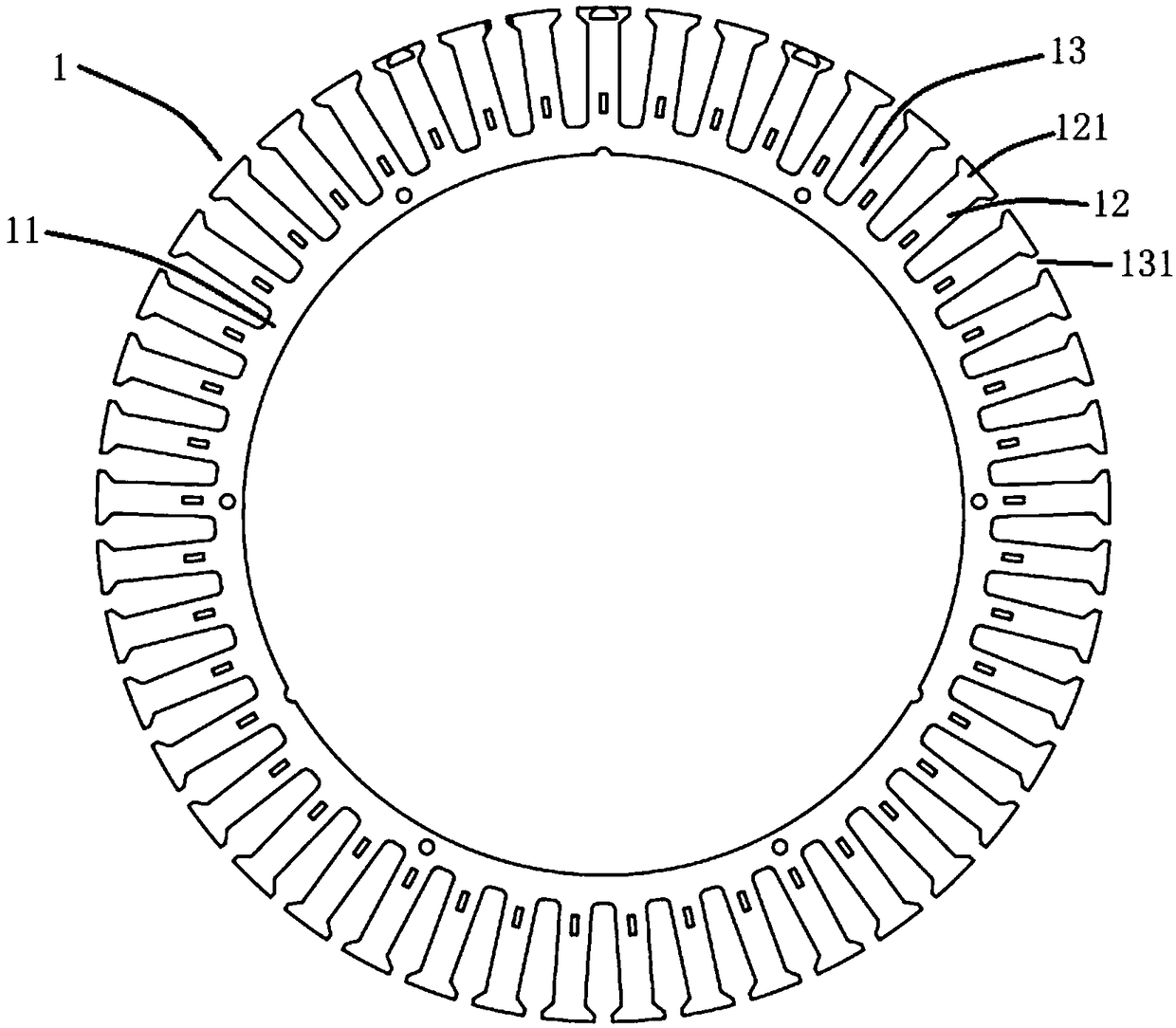

[0064] Such as figure 1 As shown, the present invention proposes a stator core of an electric wheel hub motor. The iron core 1 includes a yoke portion 11, a tooth portion 12, and a wire slot 13. The tooth portion 12 includes a tooth head 121. Two adjacent tooth portions 12 forms a slot 13, the slot 13 includes a notch 131, the notch 131 is located at the top of the slot 13, a notch 131 is formed between two adjacent tooth heads 121, and the notch 131 is trumpet-shaped .

[0065] The outer diameter of the iron core 1 proposed by the present invention is between 140-160mm, and the inner diameter of the iron core 1 is between 100-120mm.

[0066] In a preferred embodiment, the outer diameter of the stator core 1 is 158.9-159.1 mm, the inner diameter of the iron core 1 is 113-113.1 mm, the width of the yoke 11 is 4.45 mm, the width of the teeth 12 is 5 mm, and the minimum size of the notch is 2.75mm, the number of embedding grooves 13 is 45 grooves.

[0067] In another preferred...

Embodiment 2

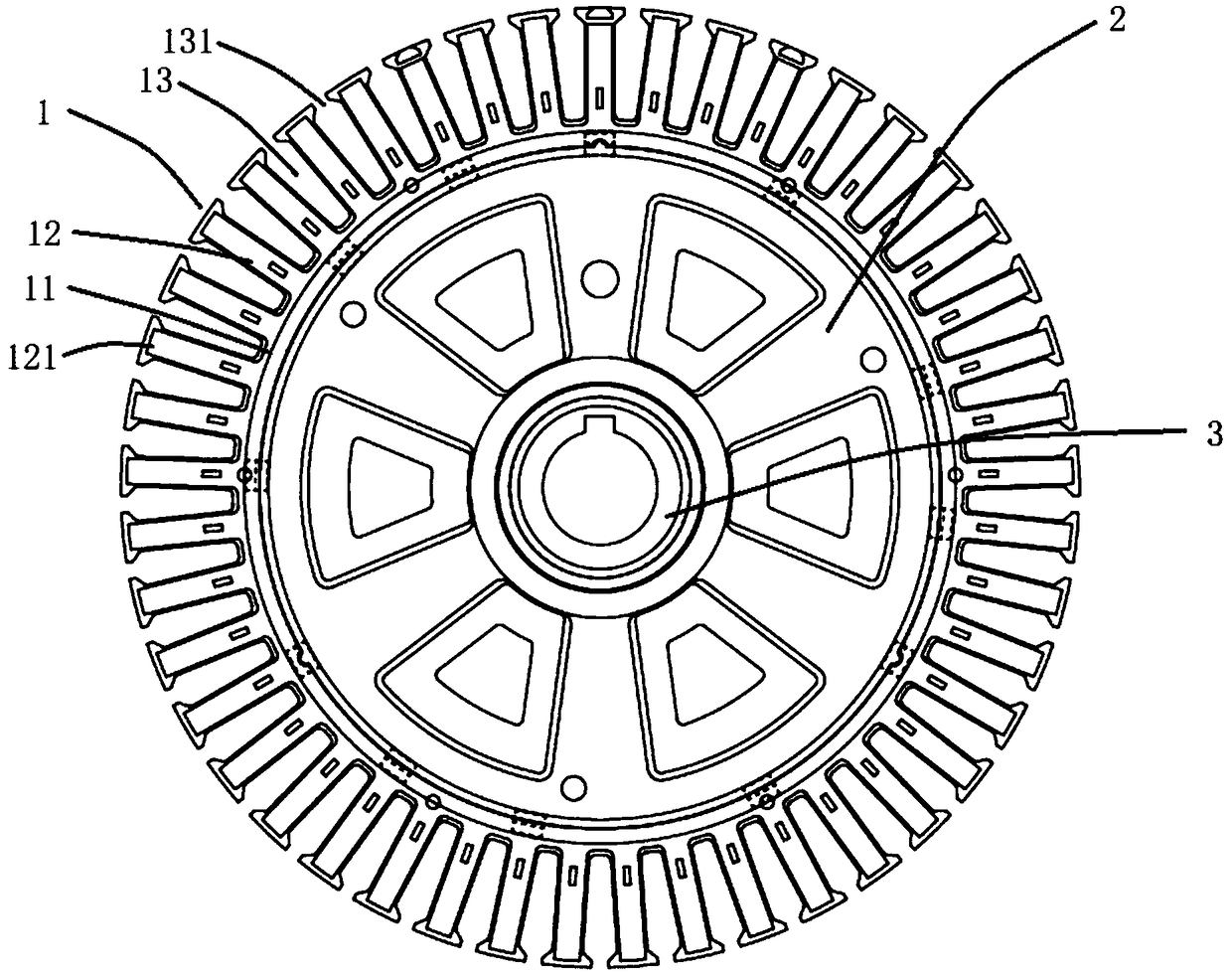

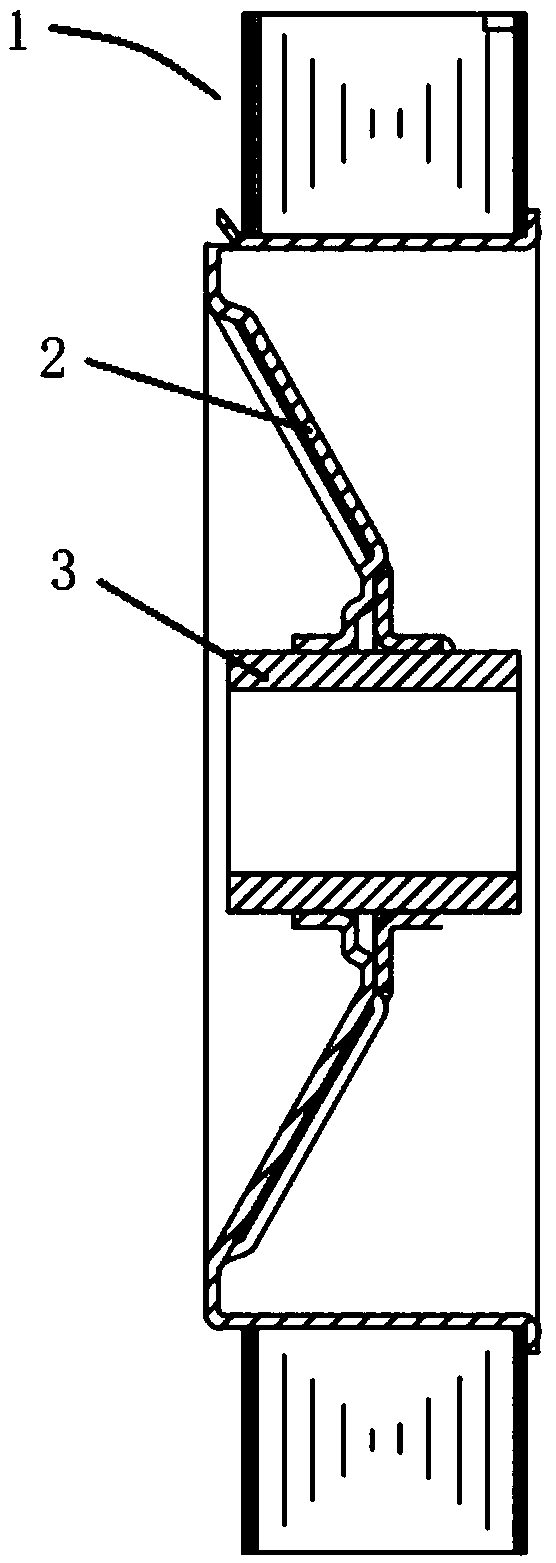

[0070] Such as Figure 1-Figure 6 As shown, it is a preferred embodiment of the stator of the electric wheel hub motor proposed by the present invention, which includes the stator core 1 described in Embodiment 1, and adopts a single bracket structure, wherein the number of brackets 2 is one piece.

[0071] In this embodiment, the stator of the electric hub motor includes an iron core 1 , a support 2 , a shaft sleeve 3 , and two insulating sheets 5 . The shaft sleeve 3 is located at the center of the bracket 2, the outer side is fixedly connected with the bracket 2, and the inner side is connected with the axle. The bracket 2 is used to fix the iron core 1, and the outer side of the bracket 2 is fixedly connected with the inner side of the iron core 1. There are two insulating sheets 5, which are arranged on the upper and lower end surfaces of the iron core 1. In this embodiment, the insulating sheet 5 is an insulating sheet with buckle feet.

[0072] The single bracket stru...

Embodiment 3

[0074] Such as figure 1 , Figure 7-Figure 11 As shown, it is another preferred embodiment of the stator of the electric wheel hub motor proposed by the present invention, which includes the stator core 1 described in Embodiment 1, and adopts a double bracket structure, wherein the number of brackets 2 is 2 pieces .

[0075] In this embodiment, the stator of the electric wheel hub motor includes an iron core 1 , two supports 2 , a shaft sleeve 3 and two insulating sheets 5 . The shaft sleeve 3 is located at the center of the bracket 2, the outer side is fixedly connected with the bracket 2, and the inner side is connected with the axle. The bracket 2 is used to fix the iron core 1, and the outer side of the bracket 2 is fixedly connected with the inner side of the iron core 1; there are two insulating sheets 5, which are arranged on the upper and lower end surfaces of the iron core 1. In this embodiment, the insulating sheet 5 is a plane insulating piece.

[0076] In this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

| Inner diameter size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com