Brushless motor assembly structure

A brushless motor and assembly structure technology, which is applied in the field of motor assembly structure and brushless motor assembly structure, can solve the problem of inability to use both integral and split types, screws are easily sucked into the surface of magnetic steel, hot-melt welding and fixing times High product rate and other issues, achieve the effect of reducing labor cost and raw material cost, improving assembly process, and good product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

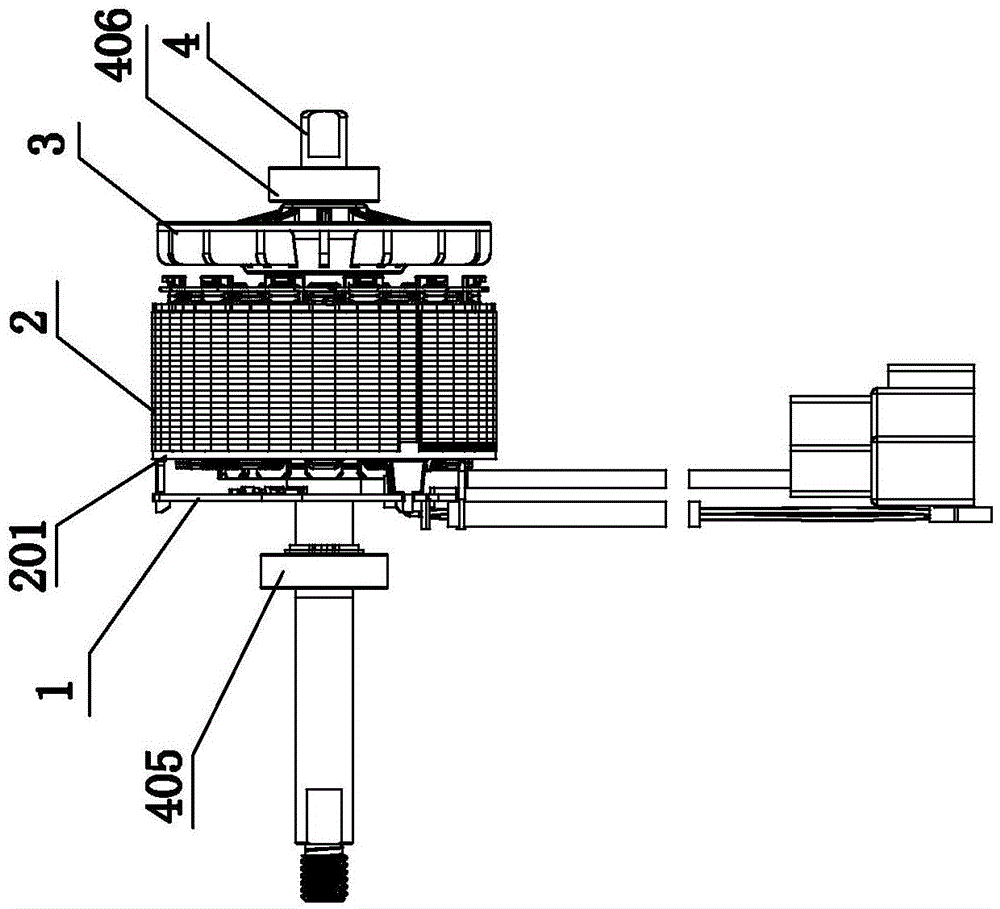

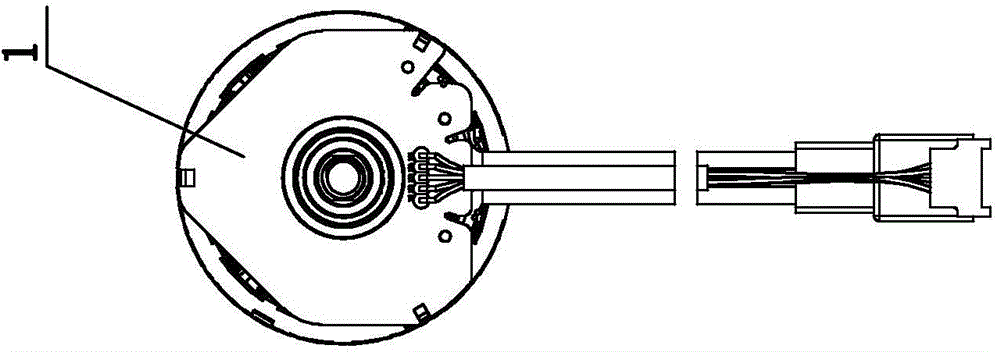

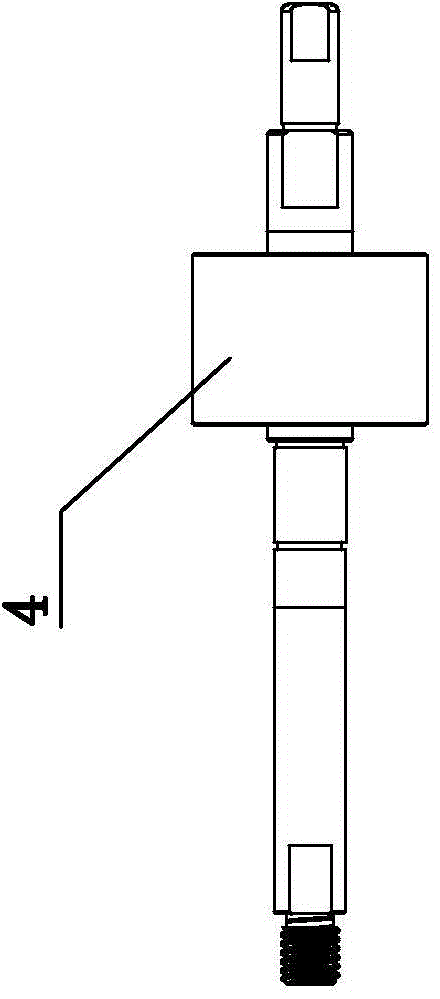

[0042] Such as Figure 1-1 to Figure 7-2 As shown, an assembly structure of a brushless motor includes a Hall plate 1, a stator assembly 2, an air blade 3 and a rotor assembly 4; the Hall plate 1 is arranged in front of the stator assembly 2, and the air blade 3 is arranged in the Behind the stator assembly 2, the fan blade 3 is fixedly connected to the stator assembly 2, and the rotor assembly 4 is rotationally connected to the stator assembly 2; the stator assembly 2 includes an insulating end plate 201, and the insulating end plate 201 is at the front end of the stator assembly 2, The rotor assembly 4 includes a rotor chip 401 and a magnetic ring 402. The rotor chip 401 is arranged in the magnetic ring 402. Eight arc-shaped grooves 403 are uniformly arranged on the outer edge of the rotor chi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com