Hydraulic boring head for machining engine cylinder cover seat ring guide pipe

A technology for engine cylinder heads and seat rings, which is applied to boring heads, metal processing equipment, manufacturing tools, etc., and can solve problems such as inconsistent tool travel standards in conduit holes, large tool jumps, and unstable tool processing processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The present invention will be further described below with reference to the accompanying drawings.

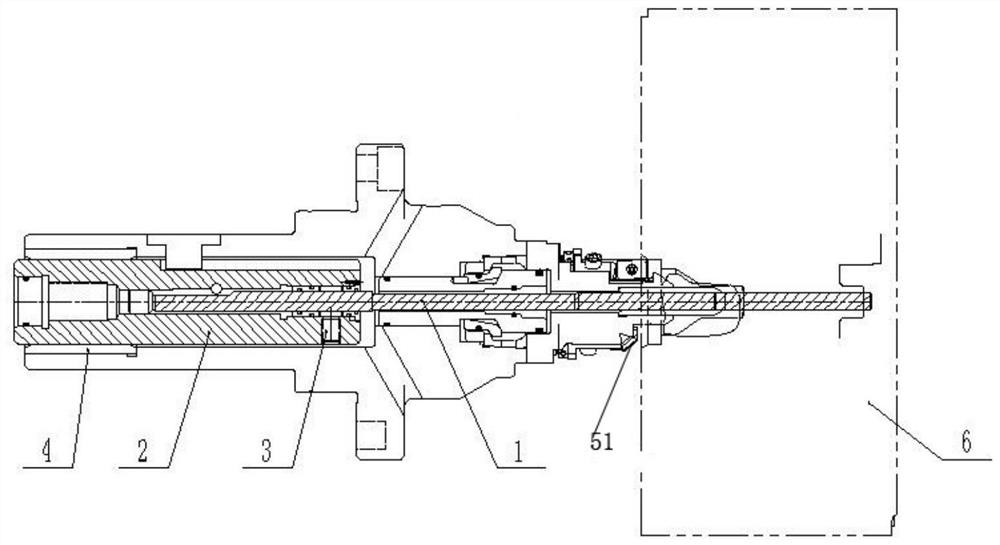

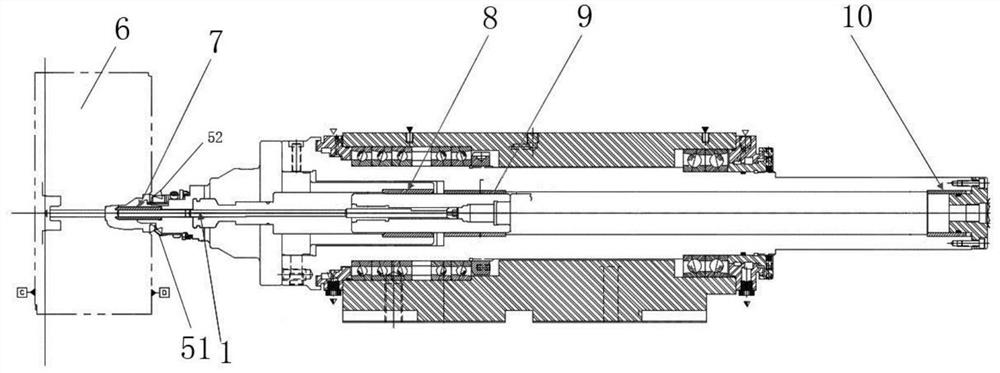

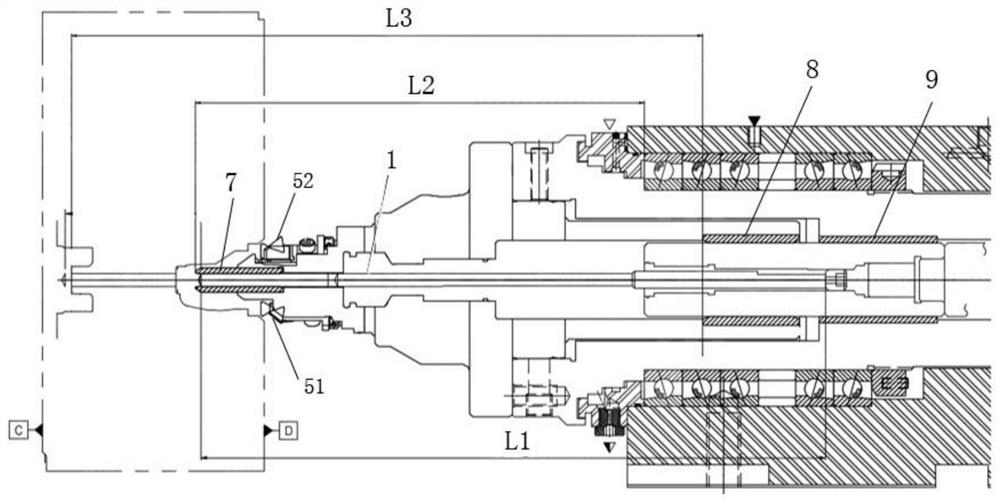

[0036]By the followingFigure 1-3The process of the existing seat hole and catheter holes will be described.

[0037]As described in the background art, the engine cylinder head is irregularly, the roundness does not meet the standard, whose reasons have the following three points: 1) Tools are fixed, side pressure screws The screw causes the tool to deviate from the center of the mandrel, causing the tool beating to be large; 2) The catheter hole tool is much constrained during the feed, and the plurality of constrained faces will cause the tube hole tool to travel Do not unify; 3) The clamping part of the tool and the tool is too long, causing the tool extremely unstable during processing. The specific reasons for the above three points are described in detail below:

[0038]1) The tool is fixed by a side pressure screw, and the side pressure screw causes the tool to deviate from the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com