Split stator core mounting and fixing structure and fixing method

A stator core and fixed structure technology, which is applied in the field of split stator core installation and fixed structure, can solve the problems of difficult control of stator core precision and rigidity, high requirements for products and equipment, increased compression and welding processes, etc. , to achieve the effect of low manufacturing cost, high production efficiency and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

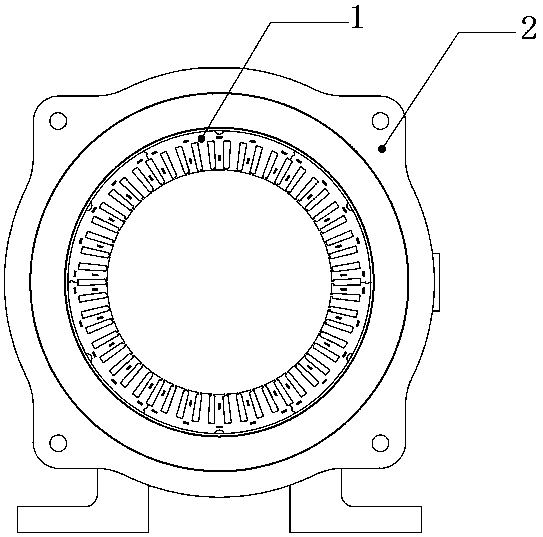

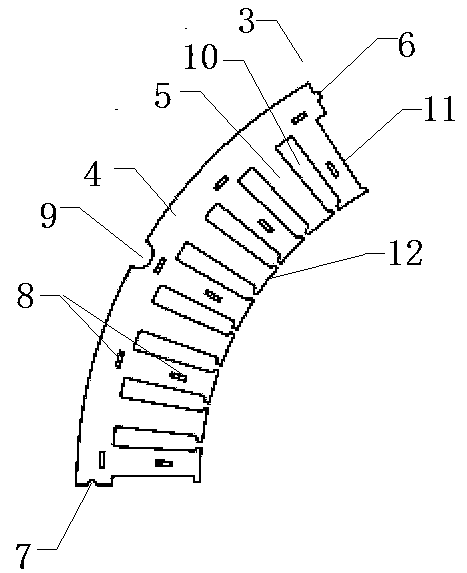

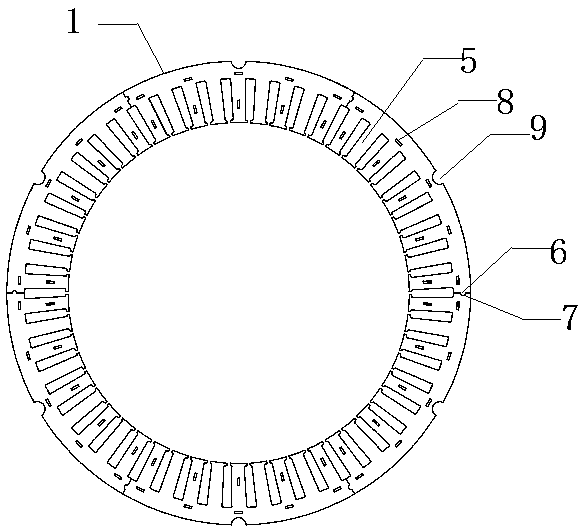

[0029] According to Figure 1 to Figure 5 The specific implementation of the present invention is further explained:

[0030] See figure 1 , A split stator core mounting and fixing structure, comprising a stator housing 2 and a full circle stator core 1. The structure of the full circle stator core 1 is as follows image 3 As shown, a plurality of split stator cores 3 are spliced together, see figure 2 , The split stator core 3 includes a plurality of stator split punches, the stator split punches include an arc-shaped yoke 4 and a number of notch teeth 5 evenly distributed on the inner ring of the yoke 4, A notch 10 is formed between two adjacent notch teeth 5, one end of the yoke 4 is provided with a process groove 7, and the other end is provided with a process boss 6 that matches the process groove 7. The outer ring of the part 4 is provided with a positioning groove 9, and the surfaces of the yoke part 4 and the notch tooth 5 are provided with a plurality of self-fastenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com