Vamp hot press molding equipment and use method thereof

A technology for hot-press forming and shoe uppers, which is applied in mechanical equipment, footwear, applications, etc., and can solve problems such as easy adhesion of shoe uppers to the support plate, increased difficulty in removing shoe uppers, and easy burns to operators, etc. Achieve the effects of improving the effect of hot pressing forming, rapid cooling, and improving the quality of forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

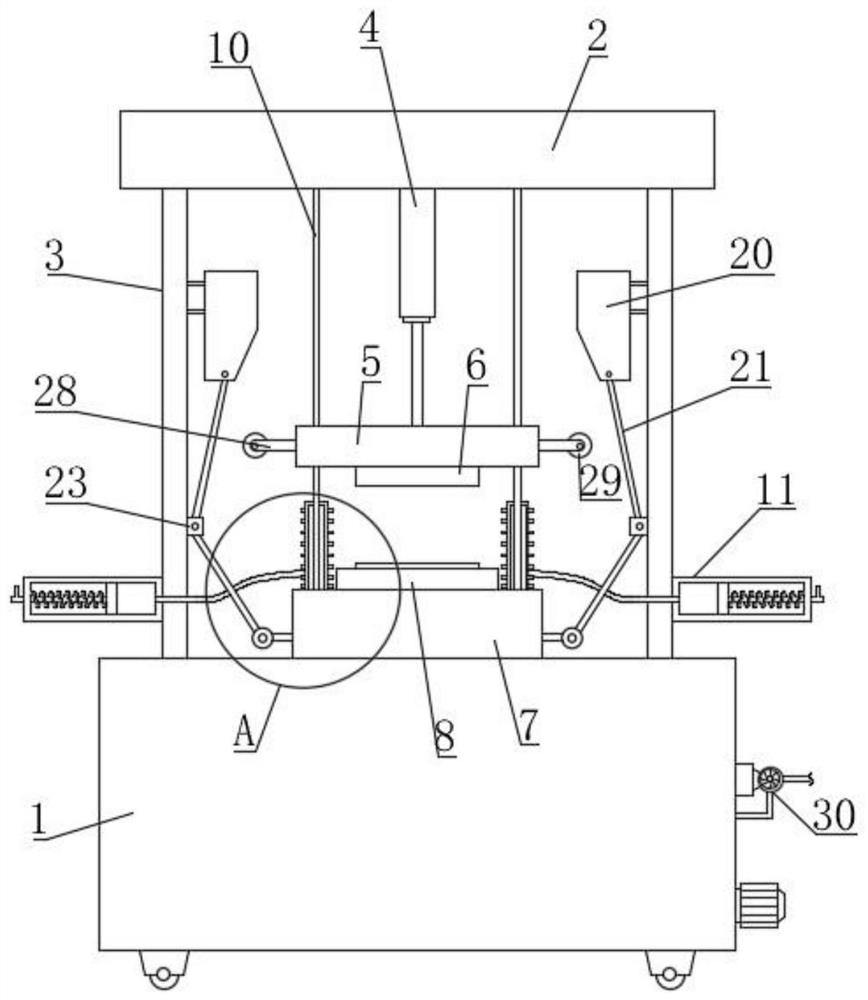

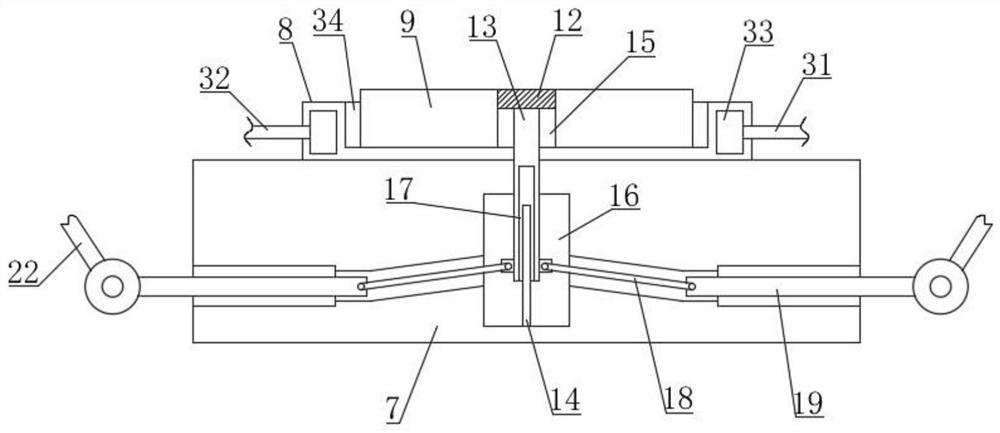

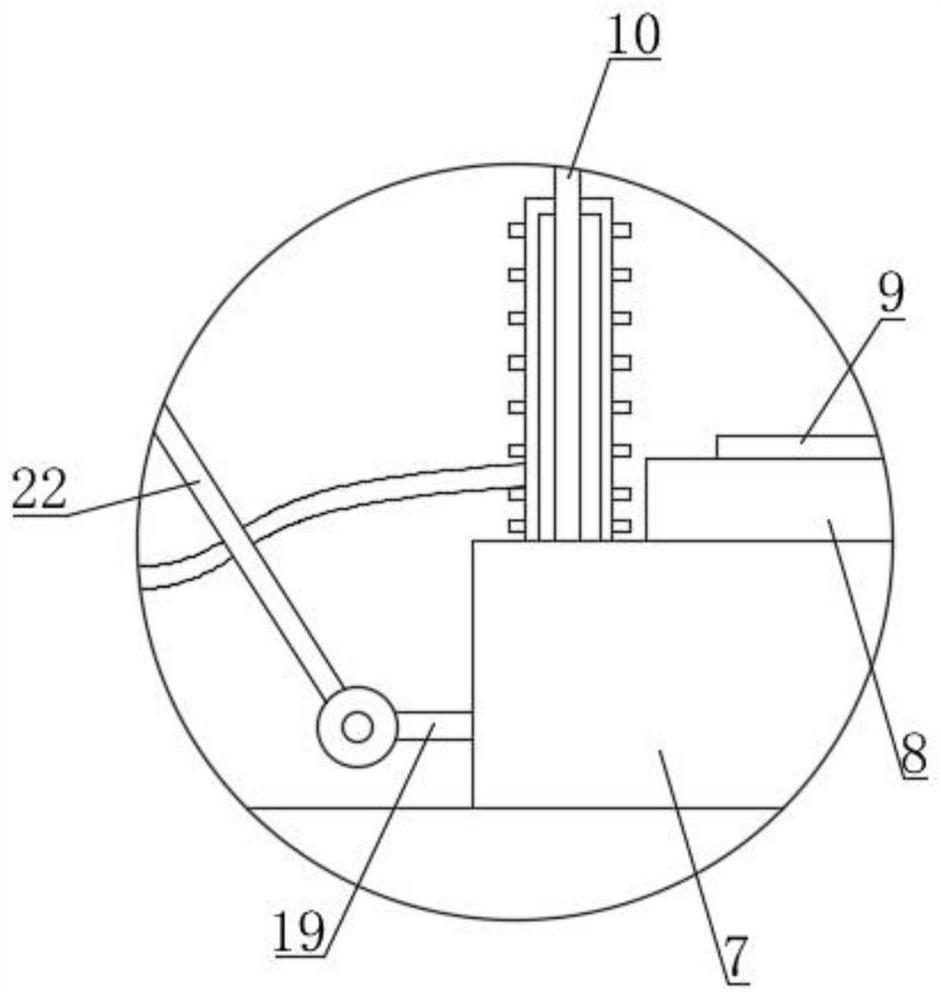

[0046] like Figure 1-5 As shown, a shoe upper thermoforming equipment proposed by the present invention includes a fixed box 1, a top plate 2, a vertical plate 3, a lifting cylinder 4, a connecting seat 5, a pressing plate assembly 6, a fixing seat 7 and a supporting plate 9, and the fixed The bottom of the box 1 is equipped with traveling wheels, which are driven by electricity. The equipment can be easily moved by setting the traveling wheels. The top plate 2 is horizontally set above the fixed box 1. The top sides of the fixed box 1 are fixed with vertical plates by bolts. 3. The top of the vertical plate 3 is fixedly connected with the top plate 2 by bolts, and the bottom of the top plate 2 is fixedly installed with a lifting cylinder 4, and the bottom end of the lifting cylinder 4 is connected with the connecting seat 5, and the lifting cylinder 4 is used to raise and lower the connecting seat 5 , the fixed base 7 is fixedly installed on the top of the fixed box 1 by bol...

Embodiment 2

[0049] like Figure 6-8 As shown, the difference between this embodiment and Embodiment 1 is that a liquid storage chamber 35 is provided in the fixed box 1, and a liquid suction pump 30 is fixedly installed on the fixed box 1 through a mounting seat, and the liquid suction pump 30 is provided with an input pipe and Output pipe, the other end of the input pipe is communicated with the liquid storage chamber 35, the other end of the output pipe is connected with the liquid inlet pipe 31, the other end of the liquid outlet pipe 32 is communicated with the liquid storage chamber 35, and the liquid suction pump 30 connects the liquid storage chamber 35 The cooling liquid in the cooling chamber is delivered to the liquid inlet pipe 31, and the cooling liquid after absorbing heat in the cooling chamber 33 flows back into the liquid storage chamber 35 through the liquid outlet pipe 32; a temperature sensor is installed in the liquid storage chamber 35, and the temperature sensor is us...

Embodiment 3

[0053] like Figure 9-10 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that an anti-shock assembly 11 is installed between the connecting seat 5 and the fixed seat 7, the anti-shock assembly 11 is located on both sides of the cooling table 8, and the anti-shock assembly 11 Multiple sets are provided on each side, and the anti-shock assembly 11 includes an elastic bellows 1101, a vent pipe 1102, a connecting cylinder 1103, a piston 1104, a second spring 1105, a movable rod 1106, and a limit protrusion 1107; the elastic bellows 1101 is vertically The connecting cylinder 1103 is arranged horizontally and fixed on the vertical plate 3 by bolts, the piston 1104 is movably arranged in the connecting cylinder 1103, and the connecting cylinder 1103 limits the position of the piston 1104 so that the piston 1104 is connected Sliding inside the cylinder 1103, the movable rod 1106 is horizontally arranged on the piston 1104, and the other end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com