Support brackets, picking workpieces, and vehicle dashboards

A technology for supporting brackets and instrument panels, which is applied to instrument panels, vehicle parts, manufacturing tools, etc., can solve the problems of reducing the supporting strength of the supporting brackets, falling of the fastening workpiece, and losing the basic functions of the supporting brackets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

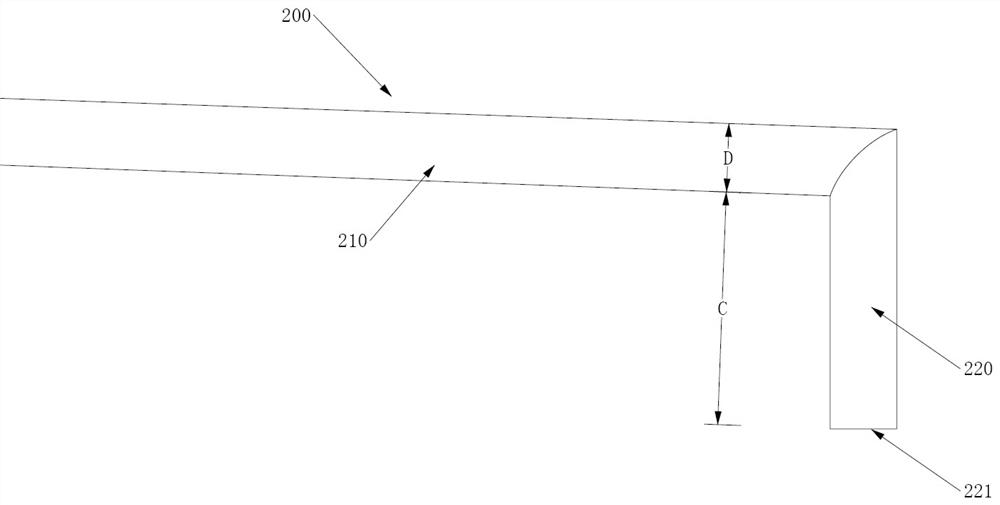

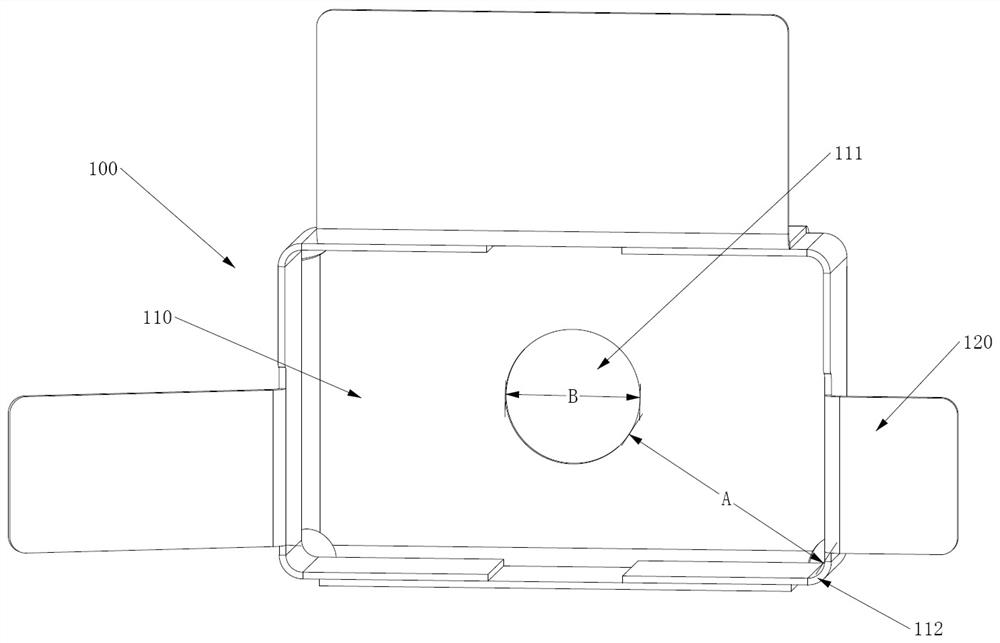

[0020] see figure 1 , which shows an embodiment of a support bracket 100 . The support bracket 100 includes a support body 110 forming a closed inner space, and a process through hole 111 is opened on the first surface of the support body 110, and the process through hole 111 is used for picking up the workpiece 200 and / or fastening the workpiece. In addition, as a conventional application of this component, the support bracket 100 can also be fixed on the component to be installed through the process through hole 111 . Most critically, in order to realize that the pick-up workpiece can freely enter and exit the process through hole 111 under the condition of carrying the fastened workpiece, attention will be paid to the design of the parameters concerned in the following,

[0021] First, the maximum size of the process via 111 is B. Wherein, for the process through hole 111, when it is a round hole, the maximum dimension B is correspondingly the diameter of the round hole; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com