Multifunctional screwdriver

A screwdriver and multifunctional technology, applied in the field of multifunctional screwdrivers, can solve the problems of laborious needle-nose pliers, forgetting to carry pliers, and ordinary screwdrivers cannot complete wire tightening, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

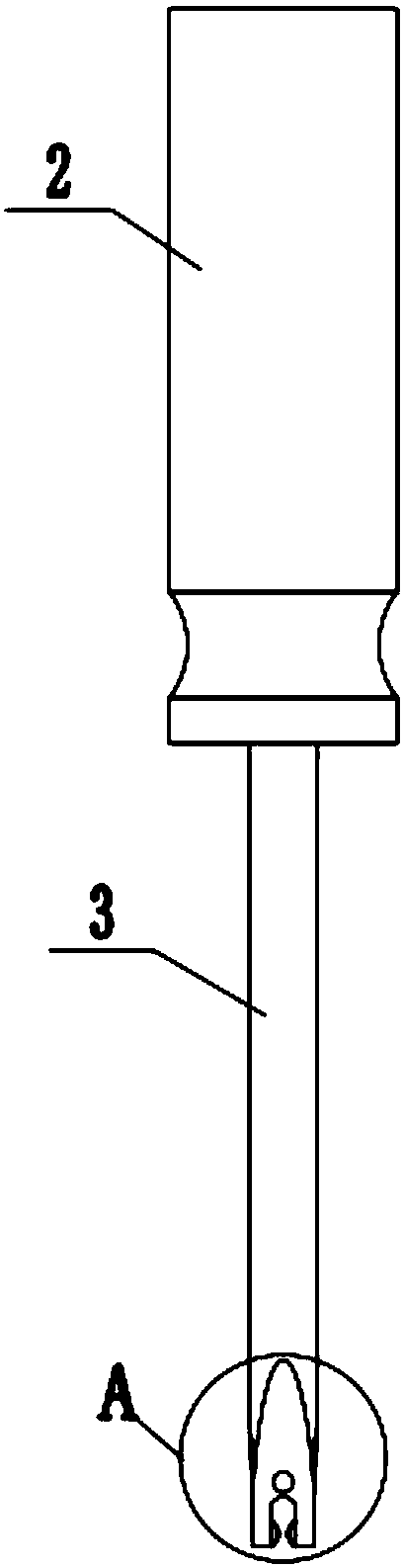

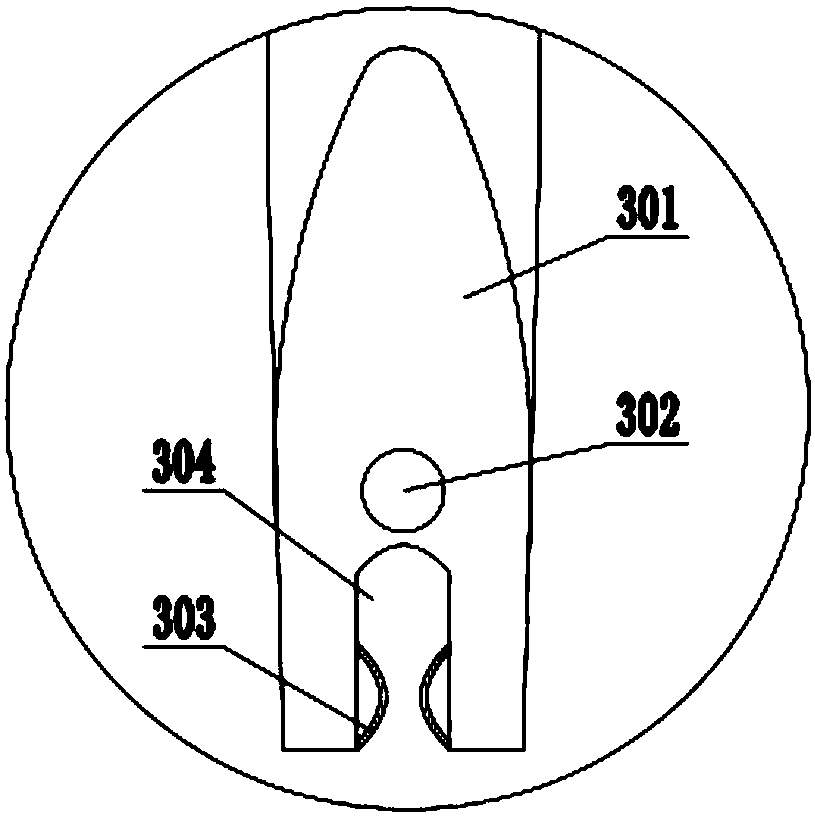

[0032] Such as Figure 1-2 As shown, a multifunctional screwdriver includes a handle 2 and a knife bar 3 connected to the handle 2. The lower end of the knife bar 3 is provided with a straight knife head 3014, and the middle part of the lower end of the knife head 301 is provided with a knife edge 304. The upper end of the knife edge 304 is a concave arc structure, and the upper end of the knife edge 304 is a concave arc structure. In the process of tightening the iron wire with a screwdriver, the knife edge 304 can be better matched with the iron wire, which not only allows the clip The holding is more reliable, and the force-bearing area is increased, which prevents damage to the iron wire during the tightening process and ensures the service life of the iron wire.

[0033] Elastic metal sheet 303 is all provided with on the inner wall of both sides of described knife edge 304, two elastic metal sheet positions are opposite, and described elastic metal sheet 303 is the circu...

Embodiment 2

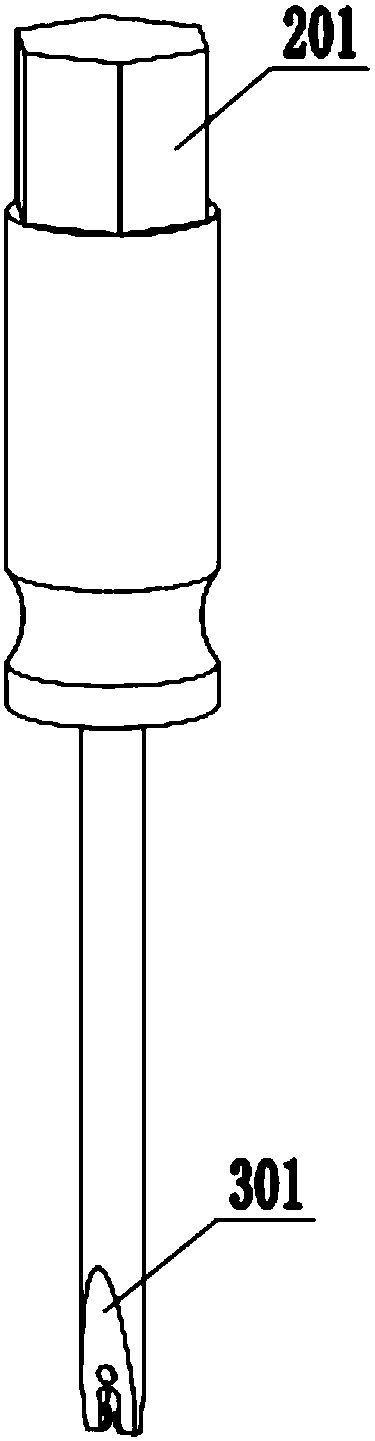

[0035] Such as Figure 3-6 As shown, a multifunctional screwdriver also includes a hammer 1, the hammer 1 includes a hammer body 104, the two ends of the hammer body 104 are hammer heads 101, and the middle part of the lower end of the hammer body 104 is provided with a connecting sleeve 103 , the inner cavity of the connecting sleeve 103 is a prismatic structure, the middle part of the hammer body 104 is provided with a tool bar hole 102, and the tool bar hole 102 is a through hole, and the tool bar hole 102 communicates with the connecting sleeve 103 , The upper edge of the tool holder hole 102 is provided with a chamfer 105 structure. Such as Figure 7 , when withdrawing the screw, the chamfered part of the knife bar hole 102 can be fixed at the screw head, the knife bar 3 passes through the knife bar hole 102 to unscrew the screw, and the knife bar hole 102 can guide and fix the knife bar 3 It solves the problem that due to the long-term use of the screw, the groove at t...

Embodiment 3

[0039] Such as Figure 8 As shown, the inner wall of the connecting sleeve 103 is provided with internal threads, the upper end of the handle 2 is provided with external threads, and the connecting sleeve 103 is threadedly connected with the handle 2 . The threaded connection can ensure the firmness of the connection between the hammer 1 and the handle 2, avoid slipping during use, and ensure the safety of use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com