Intelligent regulating system for grain harvesters and control method thereof

A technology of intelligent adjustment and harvesting machine, which is applied in the direction of harvesters, agricultural machinery and implements, cutters, etc., can solve the problem of affecting the quality and efficiency of operations, cannot guarantee normal operations, and cannot fundamentally guarantee the quality and efficiency of operations, etc. problem, to achieve the effect of improving operation efficiency and ensuring operation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

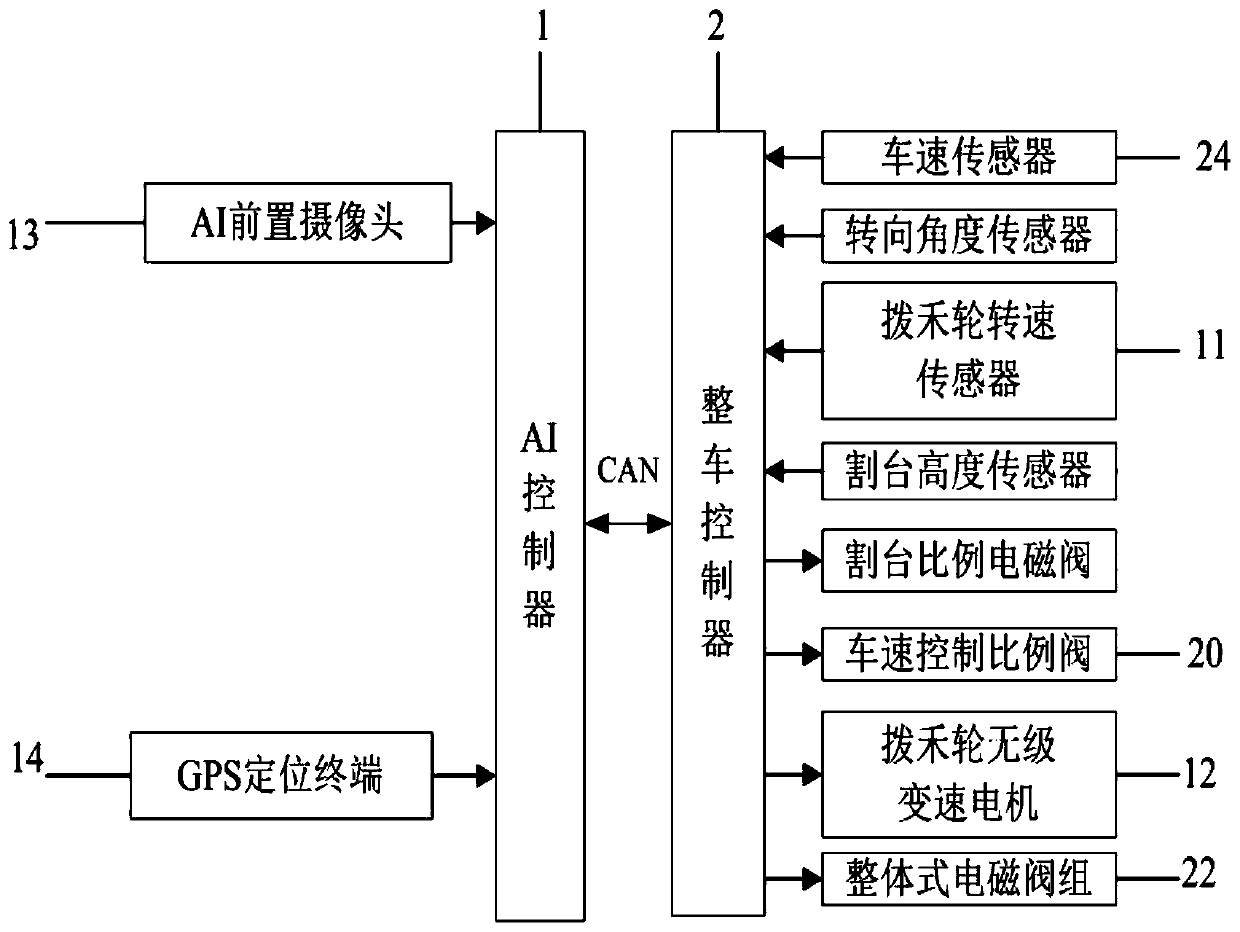

[0042] An intelligent adjustment system for a grain harvester

[0043] Such as Figure 4 As shown, below the cab 3, a reel 4, a header 21, a threshing cylinder 23, a concave plate 5, and a sieve 31 are sequentially arranged from front to back, and a fan 26 is arranged between the threshing cylinder 23 and the concave plate 5. , the rear side of the driver's cab is provided with a granary and an elevator, and the elevator is used to transport the processed crops to the granary by the sieve 31, which is the prior art.

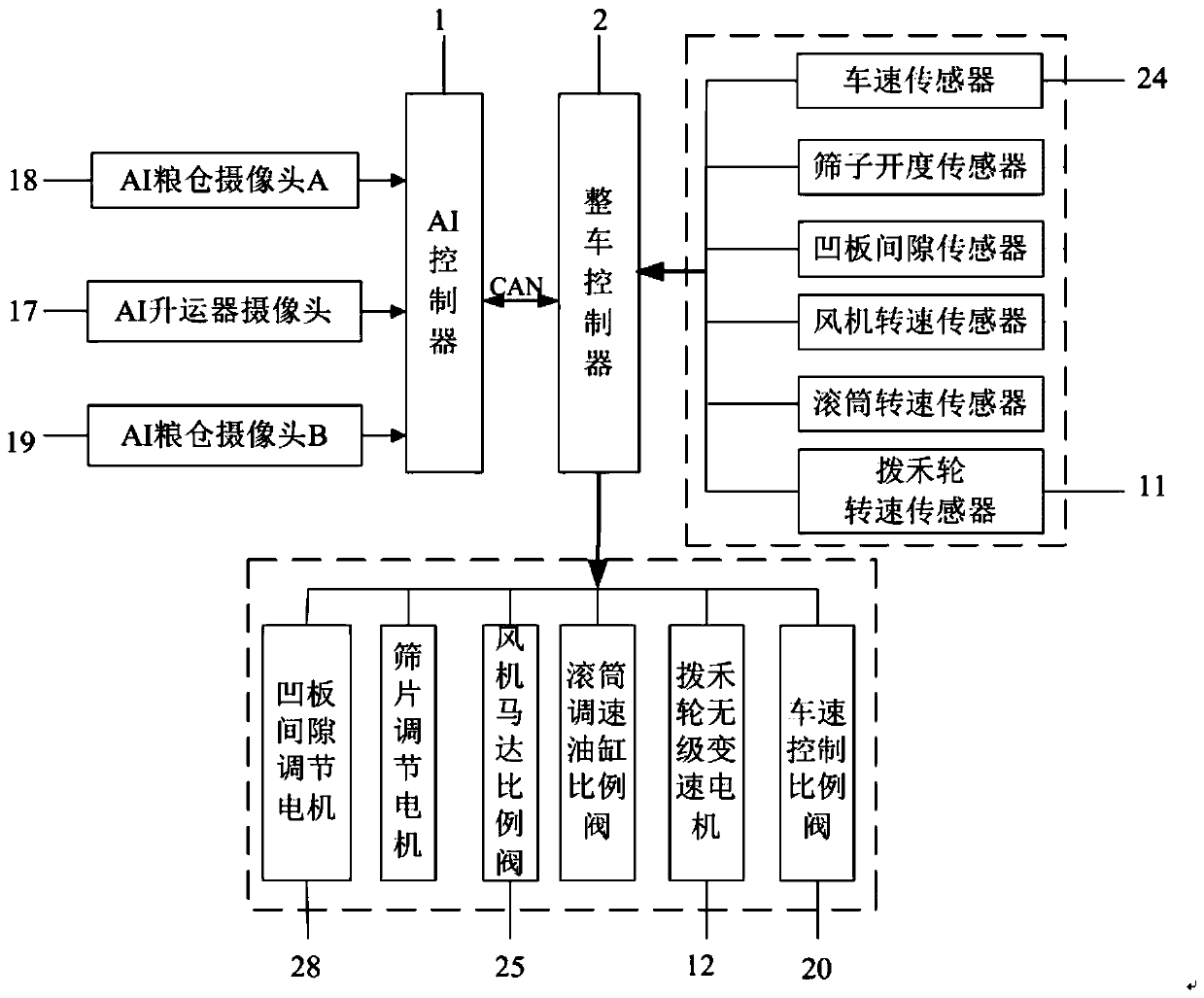

[0044]The grain detection unit includes a granary camera A18 and a granary camera B19, which are installed in the granary for taking images of the impurity content and broken rate of the grain in the granary; the reel speed sensor (fifth sensor) 11 is installed on the reel shaft , for detecting the rotating speed of reel 4 during operation; Drum speed sensor (the first sensor), is installed on the threshing drum 23, is used for detecting the real-time rotating s...

Embodiment 2

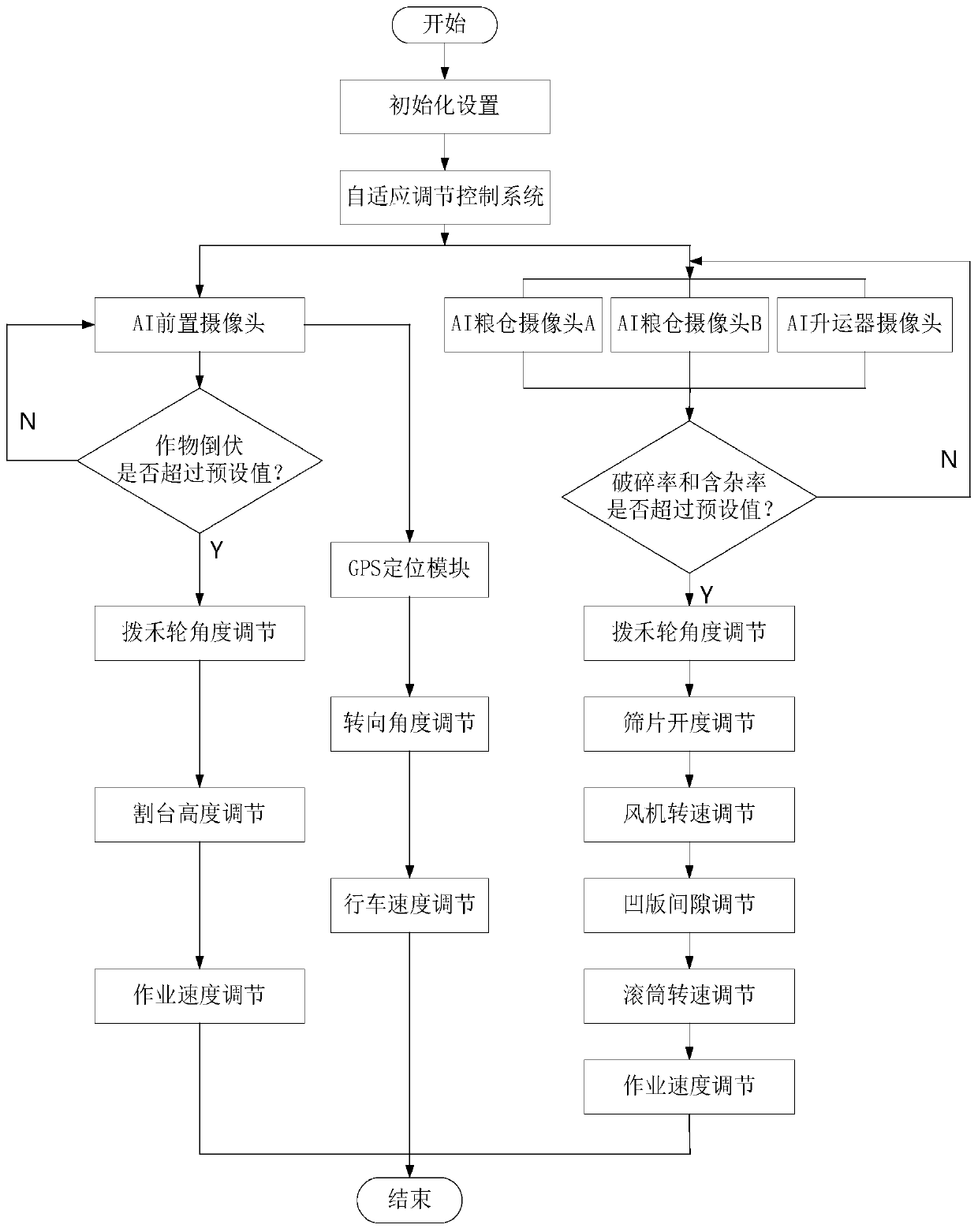

[0048] A control method for an intelligent adjustment system of a grain harvester

[0049] Such as image 3 As shown, the AI control unit calculates the grain impurity content and broken rate according to the image information acquired by the granary camera and the elevator camera (grain grain detection unit); when the impurity content and broken rate exceed the set threshold, based on the corresponding The real-time data transmitted by the sensor judges the required matching screen opening, concave plate gap, drum speed, fan speed, reel speed, and operating speed values, and transmits the above required matching values to the vehicle control unit; The car control unit adjusts the opening of the sieve, the gap between the concave plates, the rotating speed of the drum, the rotating speed of the fan, the rotating speed of the reel, and the operating speed to achieve the required matching values. Repeat the above steps of adjusting according to the impurity content of the g...

Embodiment 3

[0053] A control method for an intelligent adjustment system of a grain harvester

[0054] The driver selects the mode through the panel buttons, and there are two modes: walking mode and working mode. In the walking mode, the opening of the sieve, the gap between the concave plates, the drum speed, the reel speed, the fan speed, and the header height cannot be adjusted. The drum speed, reel speed and fan speed are zero, and the vehicle speed can be adjusted in real time. When working in the field, press the button to switch to the operation mode, and an intelligent adjustment system of the grain harvester officially starts to work. The control method in the working mode is the same as that in the second embodiment.

[0055] In the operation mode, the driver can view the specific parameter values of each component in real time through the display, such as the drum speed value, the concave plate gap, the screen opening, the fan speed, the reel speed, the operation speed and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com