Quantized assembly and overhaul control system for locomotive

A control system and locomotive technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of unable to record and trace tightening data, and cannot guarantee the quality of bolt tightening, so as to prevent assembly errors and guarantee The effect of high quality of work and high degree of confidentiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

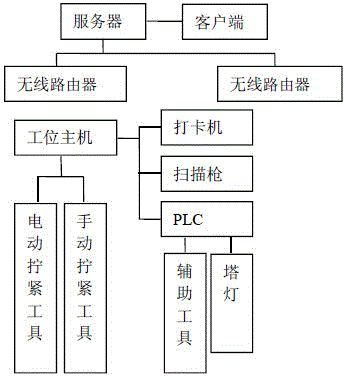

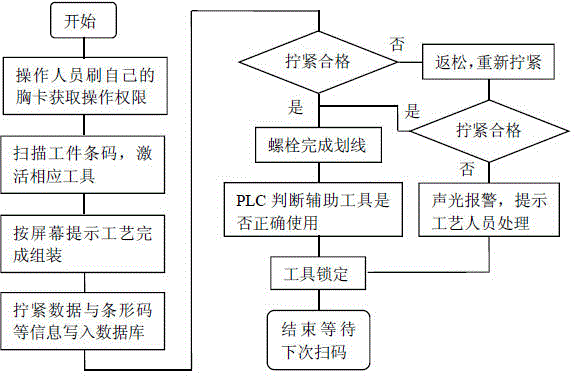

[0022] Such as figure 1 The locomotive quantitative assembly and maintenance control system shown includes a client, a server and an operation terminal, the client is a PC or an intelligent mobile terminal with networking capabilities, the server is a database server, and the The operating end includes several stations, the client is connected to the server through the network, the station performs data interaction with the server through a wireless router or wireless AP, and the station includes a station host, a card punching machine , scanning guns, PLC, electric tightening tools, manual tightening tools, tower lights and auxiliary tools, card punching machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com