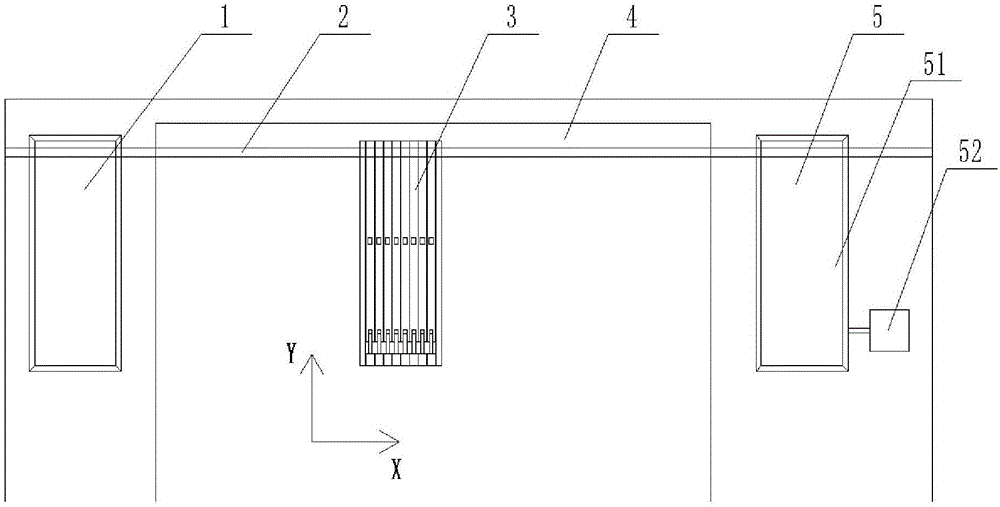

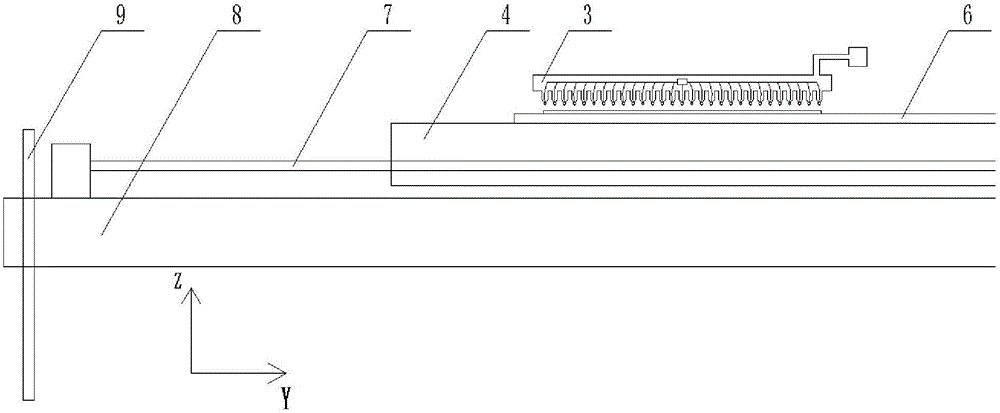

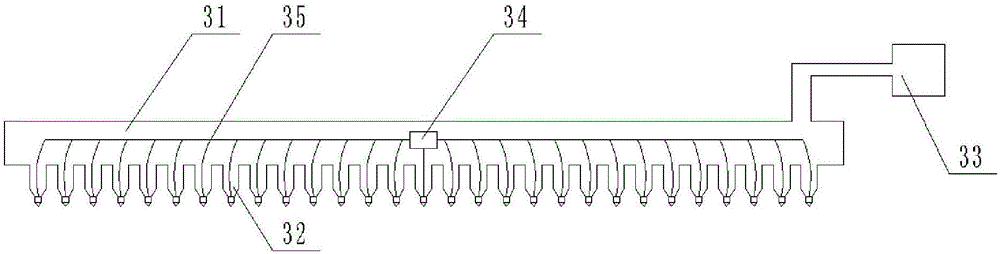

Rapid color 3D printing device

A 3D printing and printing device technology, applied in the direction of additive processing, etc., can solve the problems of inconvenient cleaning of unformed powder, powder pollution of the surrounding environment, complicated operation process, etc., to avoid excessive temperature, high printing efficiency, and flexible movement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0121] The workpiece to be printed is a mobile phone case, and it is planned to print a half-length portrait of a person on the back.

[0122] To this end, firstly, the digital information of the portrait photo to be printed is transmitted to the receiving module of the image processing module through the data cable or Bluetooth;

[0123] According to the three-dimensional or 3D effect to be obtained, such as the profile of the person's face, hair, coat, etc. in the portrait photo, where the raised parts are expected to appear, set different shades of color, and then divide the image into multiple layers according to the shade of the image, including at least one one or more substrate layers and one or more color layers;

[0124] The information of the image layer corresponding to the matrix layer is transmitted to the calculation module, and the color ratio required for printing the image layer and the corresponding working condition of the nozzle are calculated by the calcul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com