Pipeline inner wall bionic groove surface machining device and machining method thereof

A surface processing and pipeline technology, which is applied in the field of bionic groove surface processing devices on the inner wall of pipelines, can solve the problems of reducing oil and gas transportation resistance, not obvious economic benefits, large turbulent flow resistance, etc., to avoid bending deformation and torsional deformation, structure The effect of compact design and guaranteed operation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

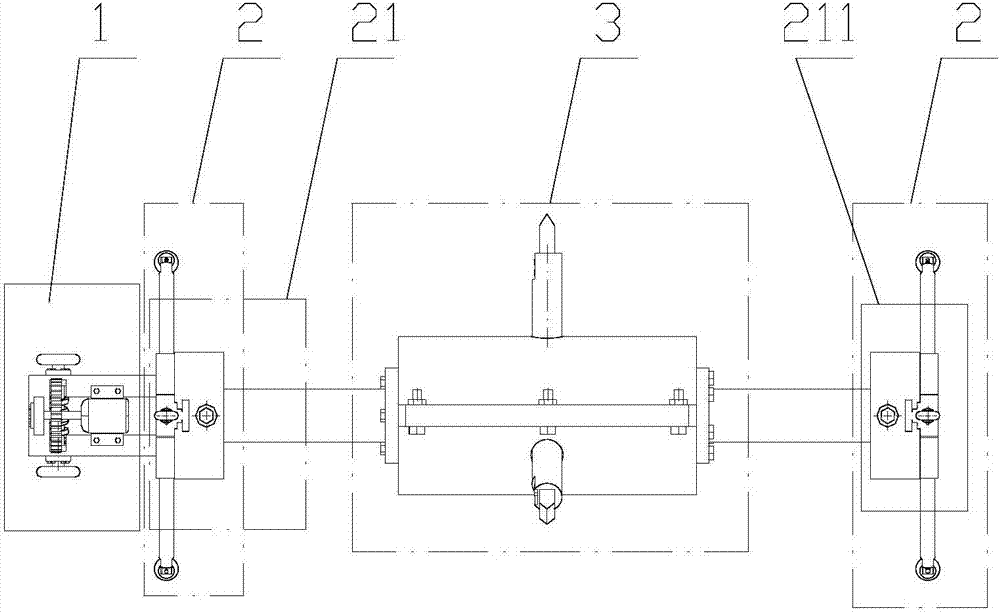

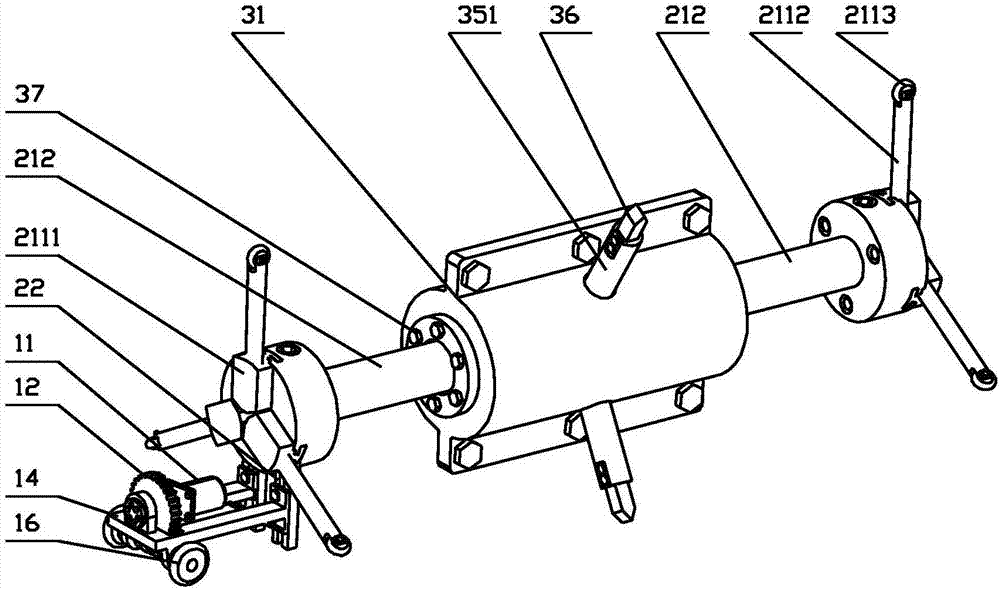

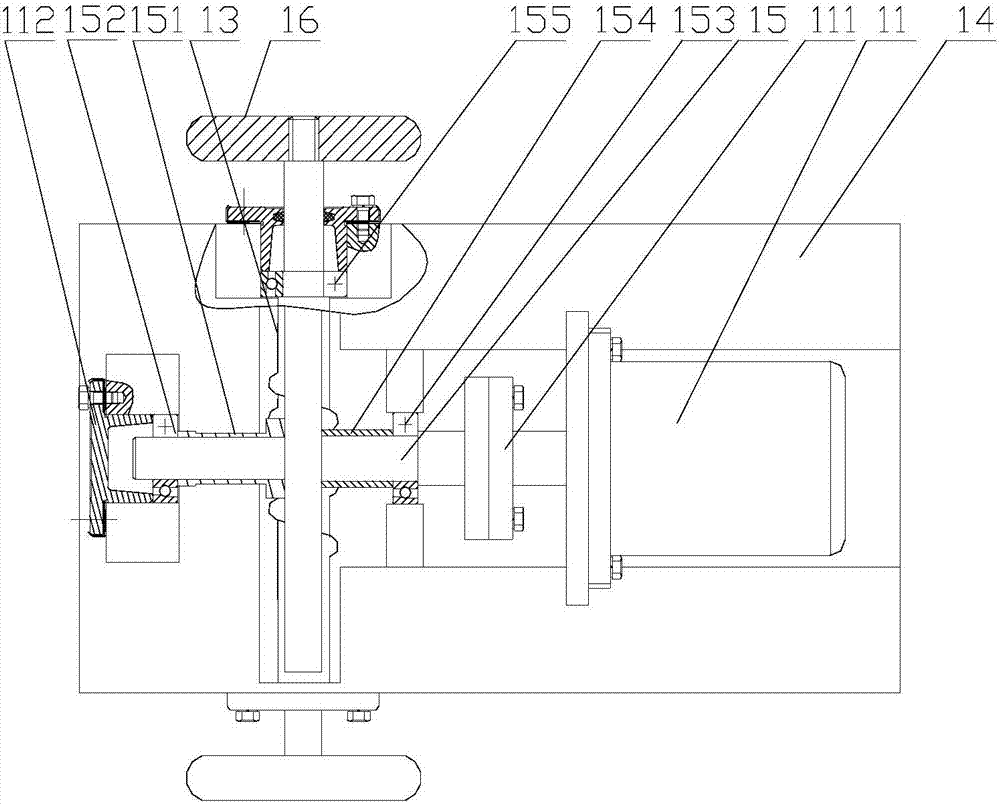

[0035] Embodiment 1 A bionic groove surface processing device for the inner wall of a pipeline according to the present invention includes a driving mechanism 1 for providing a driving force, a walking mechanism 2 for supporting the inner wall of the pipeline, and a driving mechanism 2 for processing the inner wall of the pipeline. The processing mechanism 3 and the controller for processing the bionic groove, the driving mechanism 1 is installed on the running mechanism 2 through bolts; the processing mechanism 3 is fixedly connected with the running mechanism 2 through bolts; the driving mechanism 1 and the processing mechanism 3 are both corresponding to the controller The control terminal is electrically connected; the driving mechanism 1 includes a driving motor 11, a worm wheel 12, a worm screw 13, a support frame 14, a transmission shaft 15 and a roller 16, and the driving motor 11 is installed vertically, and is fixed on the On the support frame 14; the output shaft of ...

Embodiment 2

[0045] Embodiment 2 According to the processing method of a bionic groove surface processing device for the inner wall of a pipeline described in Embodiment 1, the processing method includes the following steps:

[0046] 1) According to the diameter of the pipe to be processed, adjust the front and rear traveling mechanisms so that the three moving claws move at the same time to drive the three support rods to extend radially until the rollers can just touch the inner wall of the pipe to ensure that the entire processing device enters the pipe Part of the internal operation is balanced to ensure its stability;

[0047] 2) Adjust the bolts of the bracket under the front travel unit to move the drive mechanism radially until the rollers installed at both ends of the worm touch the inner wall of the pipeline;

[0048] 3) Place the bionic groove surface processing device on the inner wall of the pipeline completely in the pipeline to be processed to ensure its stability;

[0049]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com