Laser equipment and laser scanning galvanometer array calibrating method

A technology of scanning galvanometer and laser equipment, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of not being able to realize large-area scanning and marking, reduce manufacturing accuracy requirements, and ensure operation quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

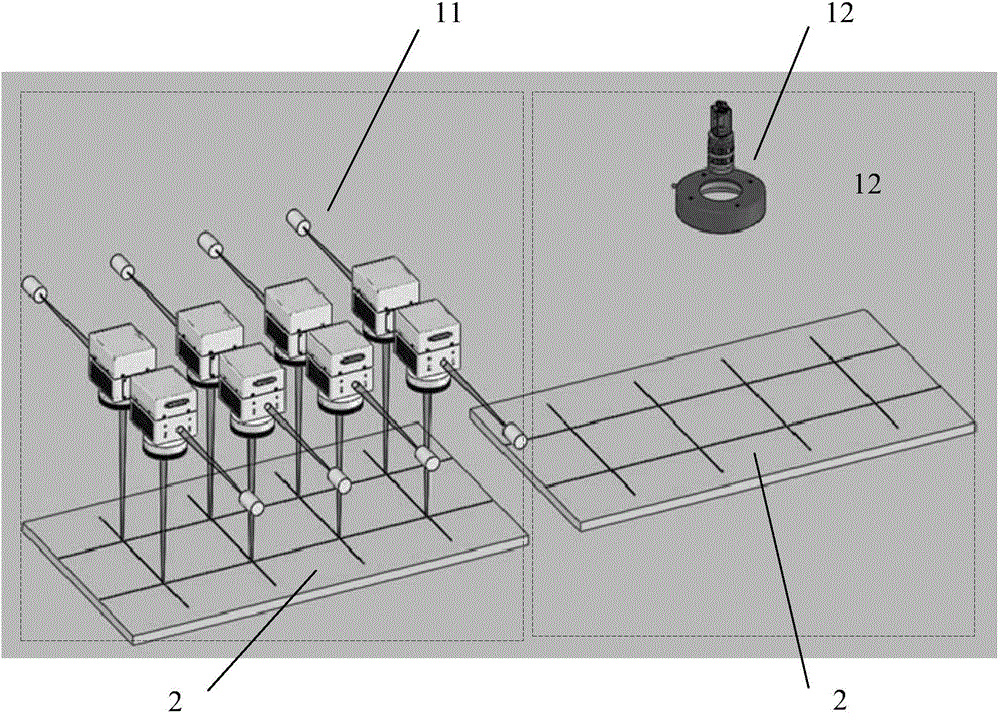

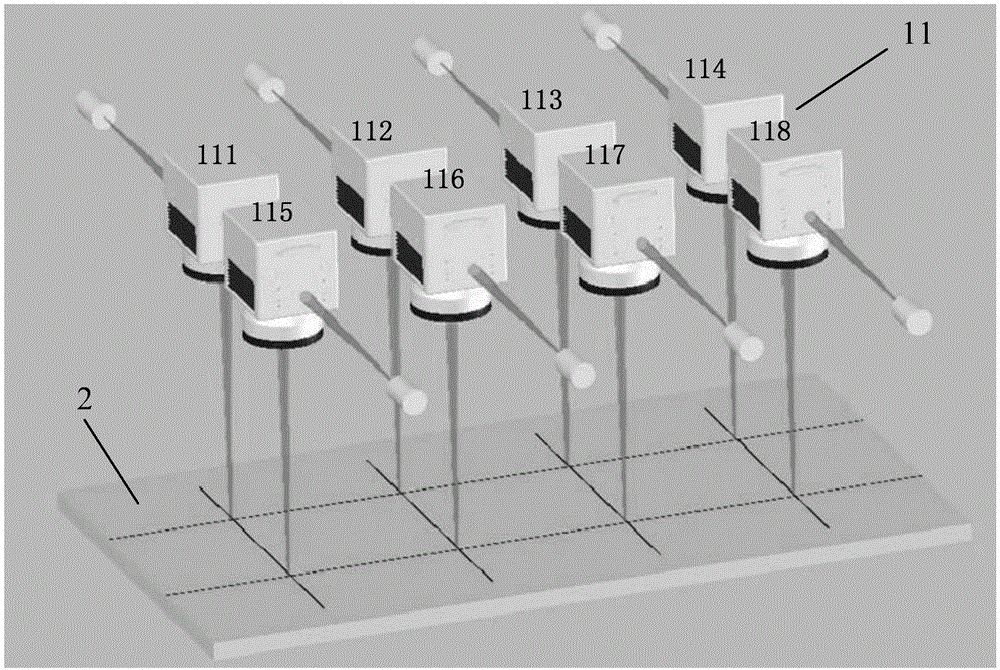

[0026] figure 1 It is a schematic block diagram of the laser device of the present invention. figure 2 It is a structural representation of the laser equipment of the present invention. Figure 3A It is a structural representation of the scanning galvanometer array in the laser equipment of the present invention, Figure 3B It is a structural representation of the correction device in the laser equipment of the present invention. Such as Figures 1 to 3B As shown, the present invention proposes a laser device, which generally includes a scanning galvanometer array 11 and a calibration device 12 matched with the scanning galvanometer array 11 . In this embodiment, the scanning galvanometer array 11 has a 2×4 structure, including a first scanning galvanometer 111, a second scanning galvanometer 112, a third scanning galvanometer 113, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com