Two-way allowance-variable milling method for blade

A blade and allowance technology, applied in milling machine equipment, details of milling machine equipment, metal processing equipment, etc., can solve problems such as poor accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

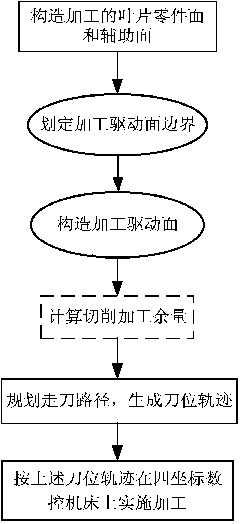

[0030] The following examples refer to Figure 1-6 .

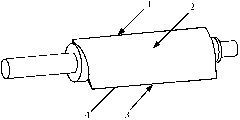

[0031] Taking the thin-walled guide blade of an aero-engine as an example, the size of the blade is 60mm×25mm×1.5mm, and the diameter of the tool is 6mm. First construct the part surface and auxiliary surface of the processed blade, then delineate the boundary of the machining driving surface, construct the machining driving surface, calculate the cutting machining allowance, plan the tool path, and generate the tool position trajectory. Finally, according to the above tool position trajectory in four Machining is performed on a coordinate CNC machine tool. The blade is processed by a four-axis CNC machining center. The axial direction of the blade coincides with the X-axis of the machine tool and can rotate 360° around the X-axis. Specific steps are as follows:

[0032] Step 1: Construct the 3D model of the blade in the 3D modeling software UG according to the blade design data given by the design department; The pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com