Damage-controllable energy dissipator

An energy-consuming and energy-consuming technology, applied in the field of energy-consuming devices, can solve the problems of affecting the shock absorption effect, damage, early energy consumption of friction dampers, etc., and achieve the effect of improving low-cycle fatigue performance and sufficient energy-consuming capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the embodiments are not intended to limit the present invention.

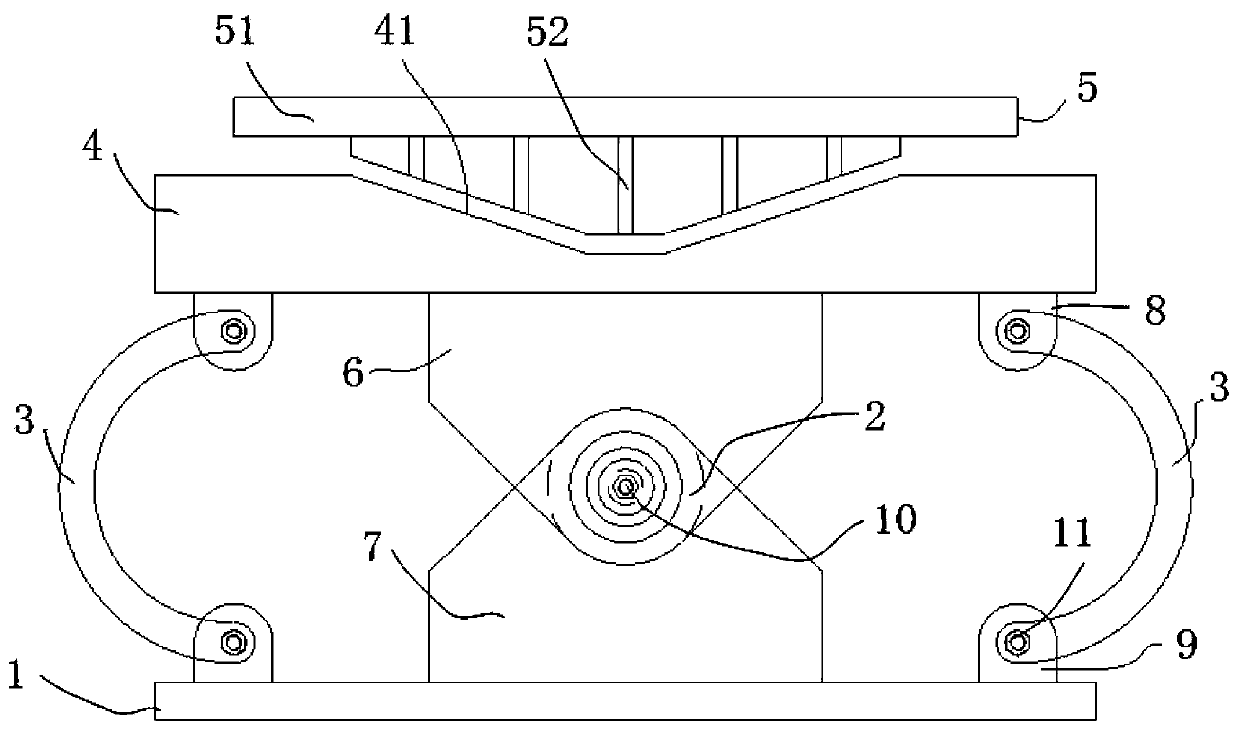

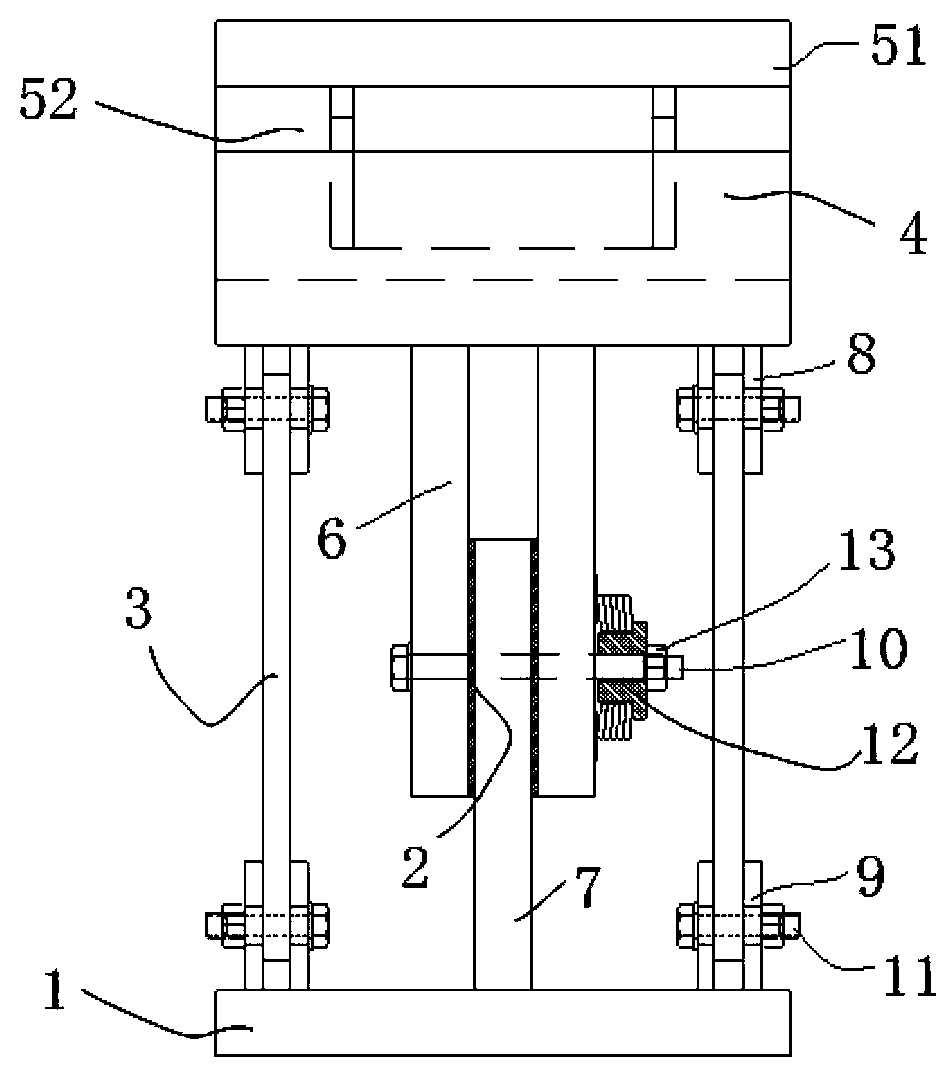

[0018] like Figure 1-Figure 2 As shown in the figure, this embodiment discloses a damage-controllable energy dissipator, which includes an extrusion rotating member 4, a deformable connecting rod 3, a frictional energy dissipation sheet 2 and a bottom plate 1. The upper part of the extrusion rotating member 4 is provided with a sliding The sliding groove 41 is connected with a sliding member 5. The sliding member 5 can slide along the inner wall of the sliding groove 41 and can slide out when the rotating member 4 is squeezed and rotated to a set angle. The grooves 41 are moved to control the damage of the energy dissipator, so as to prevent the deformable link 3 from being damaged by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com