Rock-socketed steel dock structure and construction method thereof

A construction method and technology of steel frame, which can be applied in basic structure engineering, underwater structures, artificial islands, etc., can solve the problems of high wharf surface, large horizontal displacement of structure, and influence of water flow state under mooring conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

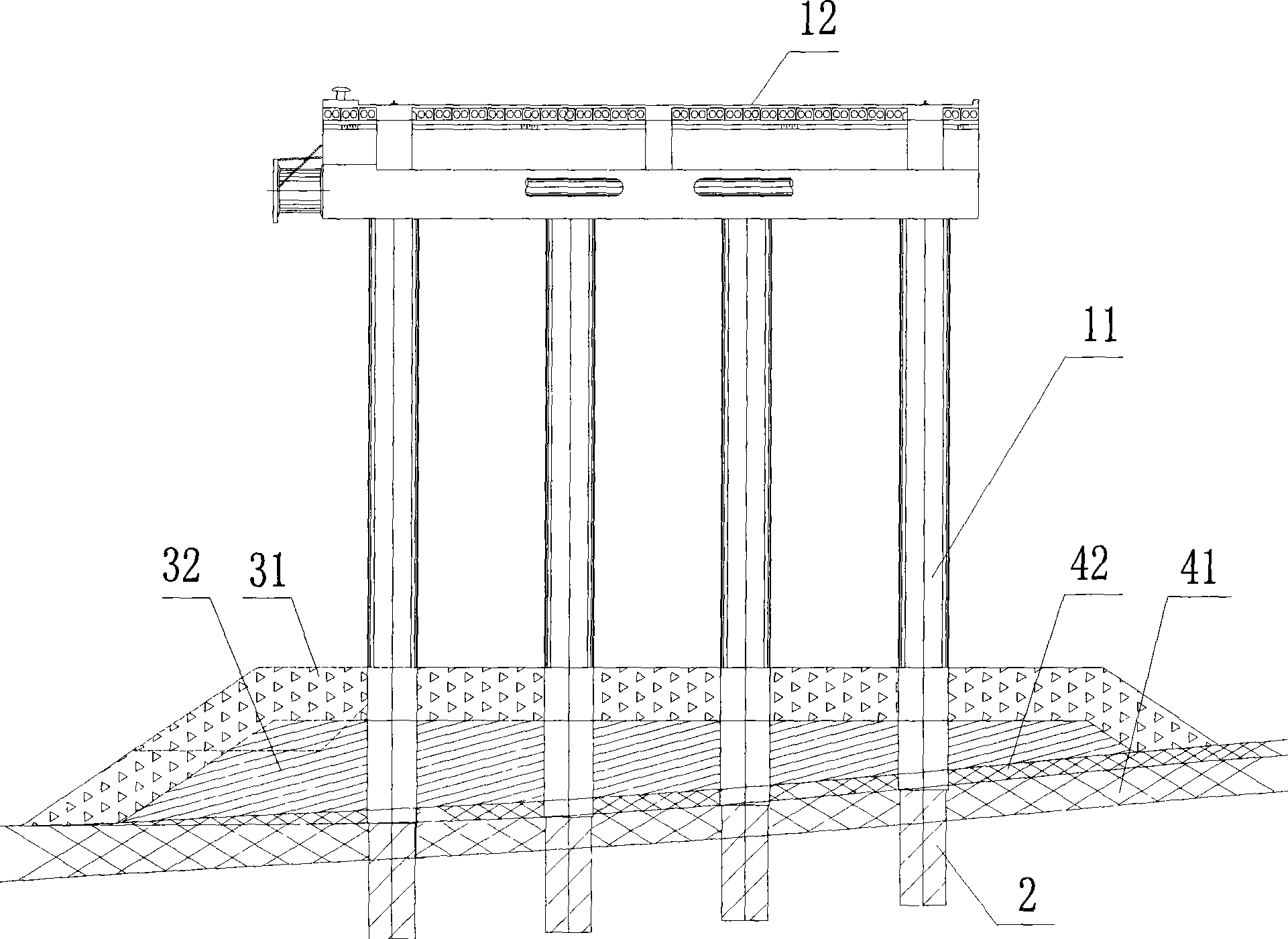

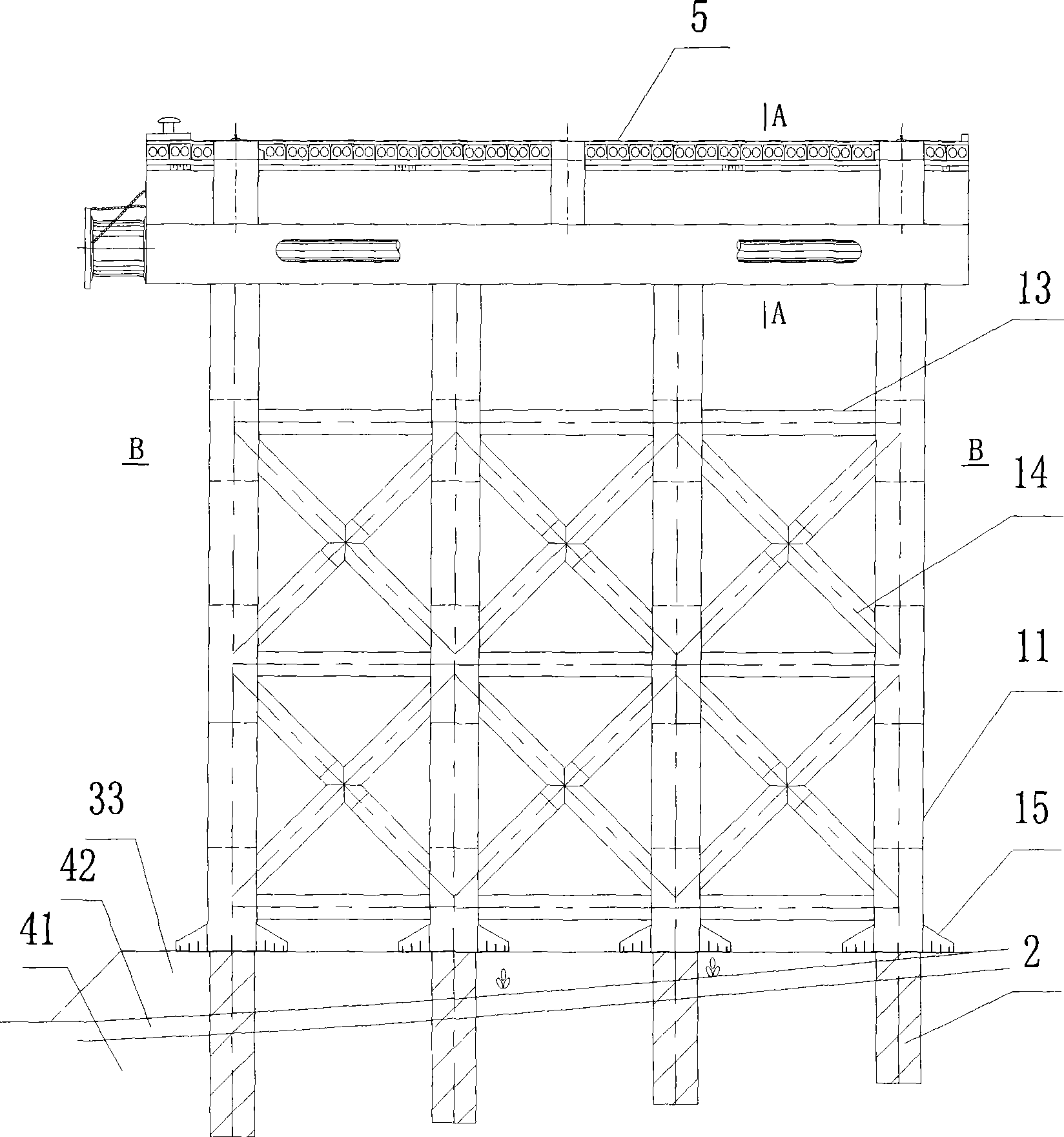

[0031] The rock-socketed steel frame wharf structure of the present invention includes the following structures, which will be described in detail below with reference to the accompanying drawings.

[0032] The invention relates to a rock-socketed pile 2 foundation bed stabilizing technology for deep-water exposed bedrock or a shallow bedrock covering layer, which is suitable for large-scale high-rise buildings constructed on shallow-covered rock foundations or exposed rock foundations in open waters in open seas. Pile dock or bridge.

[0033] Such as figure 2 As shown, the horizontal support 13 and the oblique support 14 are added on the column 11 to reduce the free length of the column 11, enhance the horizontal stiffness and integrity of the structure, and make the structural force more reasonable. The horizontal support 13 and the oblique support 14 adopt steel pipes, and the steel pipes are connected and fixed by welding.

[0034] The steel frame structure unit is made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com