Sedimentation improving method for ballastless track based on rope saw cutting

A ballastless track and wire saw technology is applied in the directions of track, track laying, track maintenance, etc., which can solve the problems of high labor intensity, poor continuity of the ballast bed and inverted arch filling layer, and low construction efficiency, and reduce labor intensity. , avoid the risk of driving along the point, the effect of simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

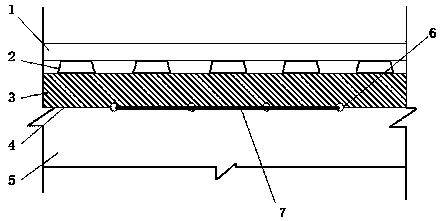

[0029] The settlement control method of the ballastless track in the subgrade section of the Duanjia District includes the following contents:

[0030] (1) Measure the initial data of the geometric state of the ballastless track before construction, divide the cutting unit according to 0.65m, check the lift at each sleeper position of the ballastless track, and establish a data joint control network. The design lift of each sleeper in the remediation section is shown in Table 1.

[0031] Table 1 Design lift of ballastless track

[0032]

[0033] (2) Reinforcement and anchorage of the roadbed slabs at both ends of the treatment section, the anchorage length of the rebar is 15m, and the schematic diagram of the anchorage of the rebar is as follows Figure 4 As shown, five planting holes are arranged in each row perpendicular to the line direction, and the distance between two adjacent rows is 1.5m.

[0034] (3) Drill a wire saw operation hole at the interface between the ba...

Embodiment 2

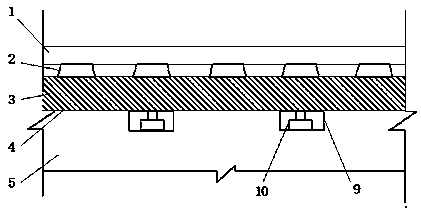

[0040] The settlement control method of ballastless track in the bridge section includes the following contents:

[0041] (1) Measure the initial data of the geometric state of the ballastless track before construction, divide the cutting unit according to 1.3m, and check the lift of each sleeper on the track bed, and establish a data joint control network. The designed uplift of each sleeper in the remediation section is shown in Table 2.

[0042]Table 2 Design lift of ballastless track

[0043]

[0044] (2) Reinforcement and anchorage of the road slabs at both ends of the remediation section, the anchorage length of the rebar is 5m, and the schematic diagram of the anchorage of the rebar is as follows Figure 4 As shown, two planting holes are set in each row perpendicular to the line direction, and the distance between two adjacent rows is 0.3m.

[0045] (3) Drill a wire saw operation hole across the ballastless track at the interface between the ballastless track bed ...

Embodiment 3

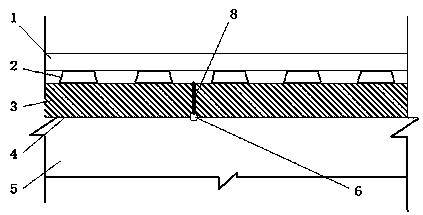

[0051] The subgrade section ballastless track settlement control methods include the following:

[0052] (1) Measure the initial data of the geometric state of the ballastless track before construction, divide the cutting unit according to 4m, and check the lift at each sleeper position of the ballast bed slab, and establish a data joint control network. The design lift of each sleeper in the remediation section is shown in Table 3.

[0053] Table 3 Design lift of ballastless track

[0054]

[0055] (2) For the anchorage of the ballast slab in the tunnel, the anchorage length of the reinforcement is 10m, and the schematic diagram of the anchorage of the reinforcement is as follows image 3 As shown, 4 planting holes are arranged in each row perpendicular to the line direction, and the distance between two adjacent rows is 1.3m.

[0056] (3) Drill a wire saw operation hole across the ballastless track at the interface between the ballastless track bed and the supporting st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com