Method for collecting mechanical characteristic parameters of breaker based on high-speed camera

A high-speed camera, mechanical characteristics technology, applied in the testing of mechanical parts, the testing of machine/structural parts, instruments, etc., can solve the problem of no circuit breaker forehead spindle, identification of moving conductive rod transmission parts, etc., to avoid uncommon and Time-consuming, improve test accuracy, and improve the effect of test automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

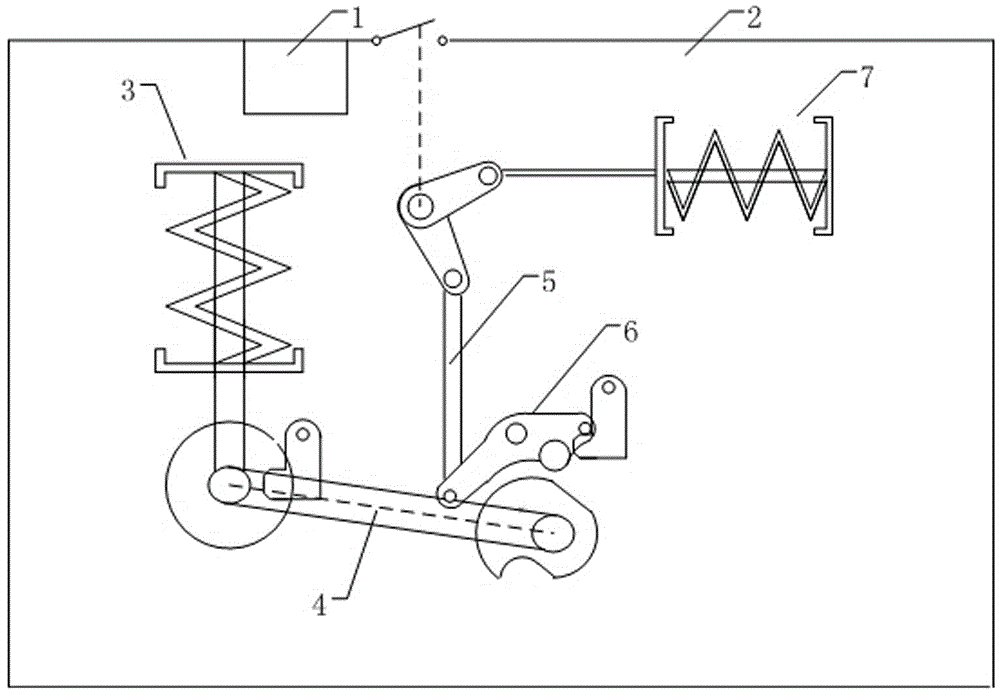

[0017] The method will be further described below in conjunction with the accompanying drawings.

[0018] A method for collecting mechanical characteristic parameters of a circuit breaker based on a high-speed camera, comprising the following steps:

[0019] (A) The image information of the movement of the operating mechanism 2 during the opening and closing process of the circuit breaker is captured by the high-speed camera (CCD image sensor) 1;

[0020] It can be seen from the figure that the operating mechanism 2 includes a closing spring 3 , a main shaft 4 , a metal connecting rod 5 , a main crank arm 6 , and an opening spring 7 . A high-speed camera (CCD image sensor) 1 is used to capture image information such as the rotation of the main shaft 4, the movement of the metal connecting rod 5, the rotation of the main crank arm 6, the compression of the closing spring 3, and the compression of the opening spring 7;

[0021] (B) Input the collected image information into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com