Hydraulic system with priority function

A technology of hydraulic system and function, applied in the field of hydraulic system with priority function, to achieve the effect of improving performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

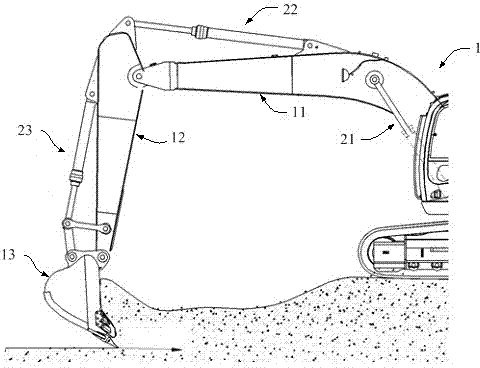

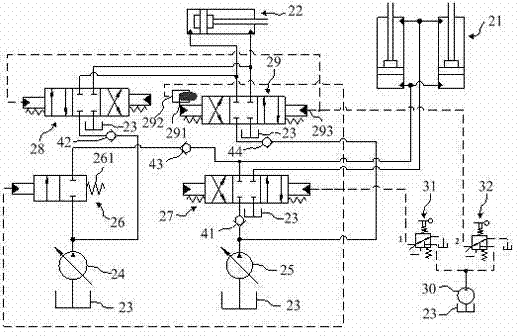

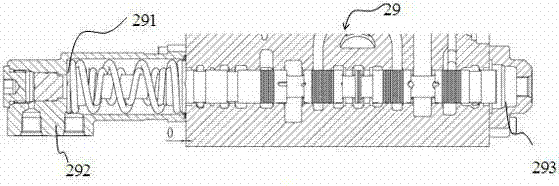

[0016] Such as figure 1 , 2 As shown, the present invention is applied to the machine 1 as a hydraulic excavator, including a first main pump 24, a second main pump 25, a first hydraulic actuator 21, a second hydraulic actuator 22, a first hand pilot hydraulic valve 31, The second hand pilot hydraulic valve 32 and the pilot hydraulic pump 30, the first main pump 24 supplies oil to the second hydraulic actuator 22 or to the first hydraulic actuator 21 through the first main pump switching valve group or to the second hydraulic actuator 21 at the same time. The first hydraulic actuator 21 and the second hydraulic actuator oil supply 22 are switched, and the second main pump 25 supplies oil to the first hydraulic actuator 21 and the second hydraulic actuator 22 through the second main pump switching valve group. switching, the first main pump switching valve group includes a first reversing valve 26 and a third reversing valve 28, the first reversing valve 26 is used to switch b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com