Multi-stage totally-enclosed mining drilling and dust removal device

A dust removal device and a fully enclosed technology, which is applied in the fields of combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of poor dust capture effect, difficult control of foaming amount, increased energy consumption, etc., so as to reduce the resistance to extraction. , Satisfactory dust removal effect, increase dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

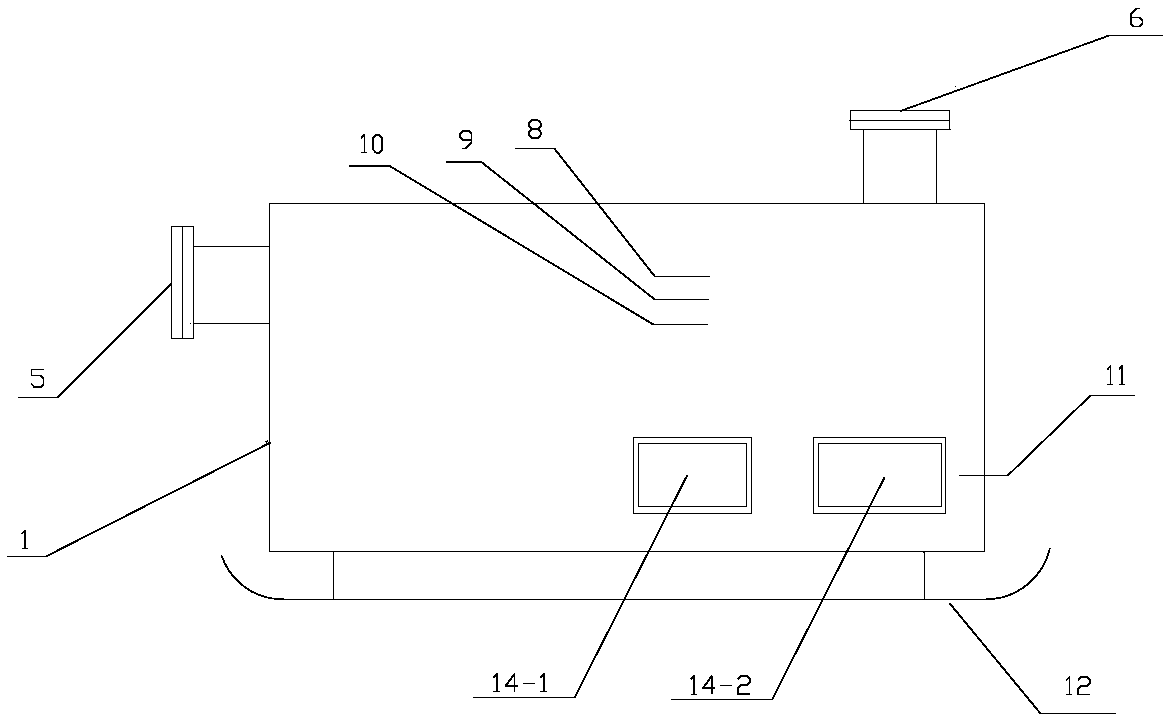

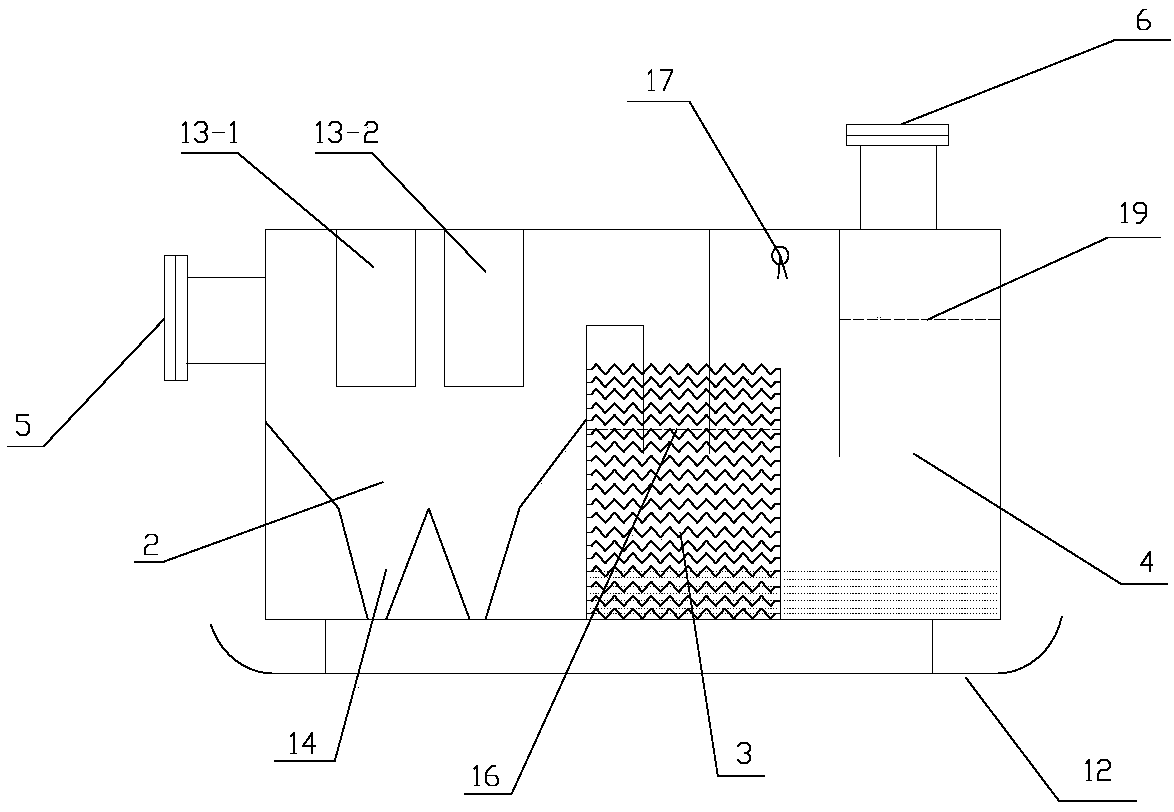

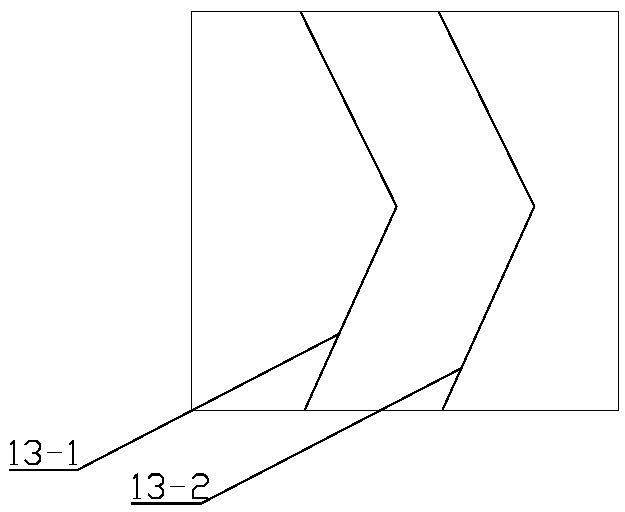

[0019] Such as figure 1 , figure 2 , image 3 As shown, a multi-stage fully enclosed mine drilling dust removal device, the box 1 is provided with a switch for water inlet and spraying, when the water bath dust removal chamber 3 needs water, open the water inlet switch 8 to enter water, when needed When spraying, open the spray switch 9 to spray. And, a water inlet switch 8 and a water inlet valve 10 control the water levels of the two chambers, and the water outlet valve 11 position will be lower than the bottom of the spray dedusting chamber 4 baffle plates. Spray dedusting chamber 4 baffles will be lower than water bath dedusting chamber left baffle, in order to prevent water from entering gravity dedusting chamber 2. When the water inlet switch 8 is turned on, the water level in the water bath dedusting chamber 3 keeps rising. When the water level reaches the height of the baffle, the water flows to the spray dedusting chamber 4, and the water level in the spray dedust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com