High-strength non-quenched and tempered steel connecting rod for heavy-duty car and manufacturing method thereof

A heavy-duty vehicle, non-quenched and tempered steel technology, applied in engine components, mechanical equipment, etc., can solve the problems of complex processing procedures, high steel consumption, easy bending, etc. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: A non-quenched and tempered steel connecting rod for high-strength heavy-duty vehicles, the following components are by weight percentage C0.39%, Si 0.56%, Mn 1.40%, P 0.014%, S 0.034%, Cr0.17%, V : 0.1%, Nb: 0.03%, C segregation content is 15%, S segregation content is 25%; its plastic index is 5% for transverse sample A5, Z is 10%, and the connecting rods produced adopt medium frequency induction heating furnace Heating, the heating temperature of the material section is 1160°C, the production cycle is 30S, and the die forging is carried out on the 3150t hot die forging press - descaling - hugging (trimming + correction), and then the hanging line controls the cooling, and the shot blasting is carried out after the off-line Descaled, its mechanical properties are R P0.2 600MPa, R m : 900MPa,A 5 is 12%, and the impact energy is 7J.

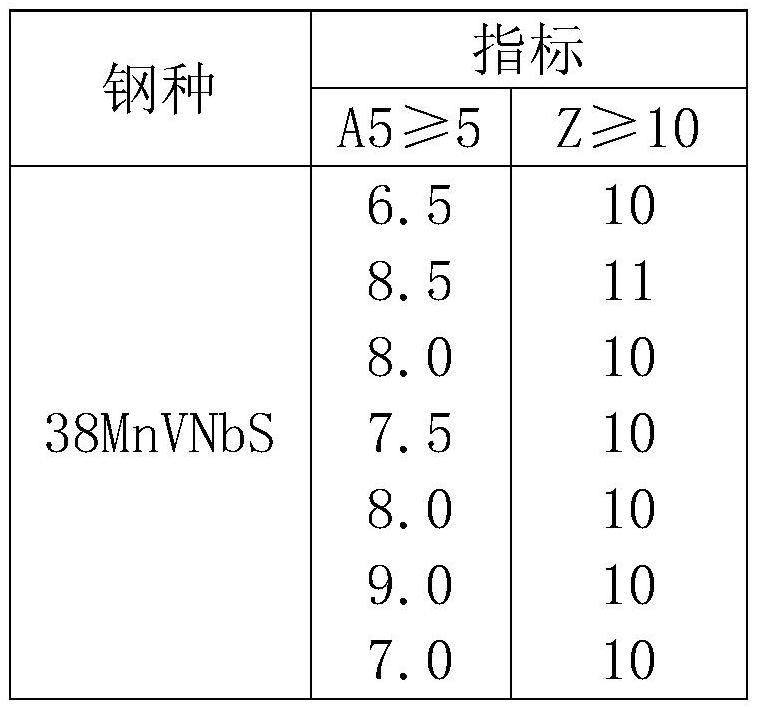

[0016] The plastic index of raw materials is shown in Table 1, the C segregation content is 2.24%, and the S segregation...

Embodiment 2

[0025] Embodiment 2: A non-quenched and tempered steel connecting rod for high-strength heavy-duty vehicles, the following components are by weight percentage C0.30%, Si 0.40%, Mn 1.10%, P 0.035%, S 0.030%, Cr0.10%, V : 0.05%, Nb: 0.015%, C segregation content is 10%, S segregation content is 20%; its plasticity index is 6.5% for transverse sample A5, Z is 11%, and the connecting rod is produced by medium frequency induction heating furnace Heating, the heating temperature of the material section is 1160 ℃, the production cycle is 30S, and the die forging is carried out on the 3150t hot die forging press - descaling - hugging (trimming + correction), and then the hanging line controls the cooling, and the shot blasting is carried out after the off-line Descaled, its mechanical properties are R P0.2 is 717MPa, R m : 1014MPa,A 5 = 13%, impact energy = 7J.

Embodiment 3

[0026] Embodiment 3: A non-quenched and tempered steel connecting rod for high-strength heavy-duty vehicles, the following components are by weight percentage C0.50%, Si 0.70%, Mn 1.50%, P 0.030%, S 0.050%, Cr0.30%, V : 0.15%, Nb: 0.040%, C segregation content is 12%, S segregation content is 23%; its plasticity index is 7% for transverse sample A5, Z position 11%, and the connecting rod produced adopts medium frequency induction heating furnace Heating, the heating temperature of the material section is 1160 ℃, the production cycle is 30S, and the die forging is carried out on the 3150t hot die forging press - descaling - hugging (trimming + correction), and then the hanging line controls the cooling, and the shot blasting is carried out after the off-line Descaled, its mechanical properties are R P0.2 Bit 703MPa, R m : 1011MPa,A 5 = 15.5%, impact energy = 8J.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com