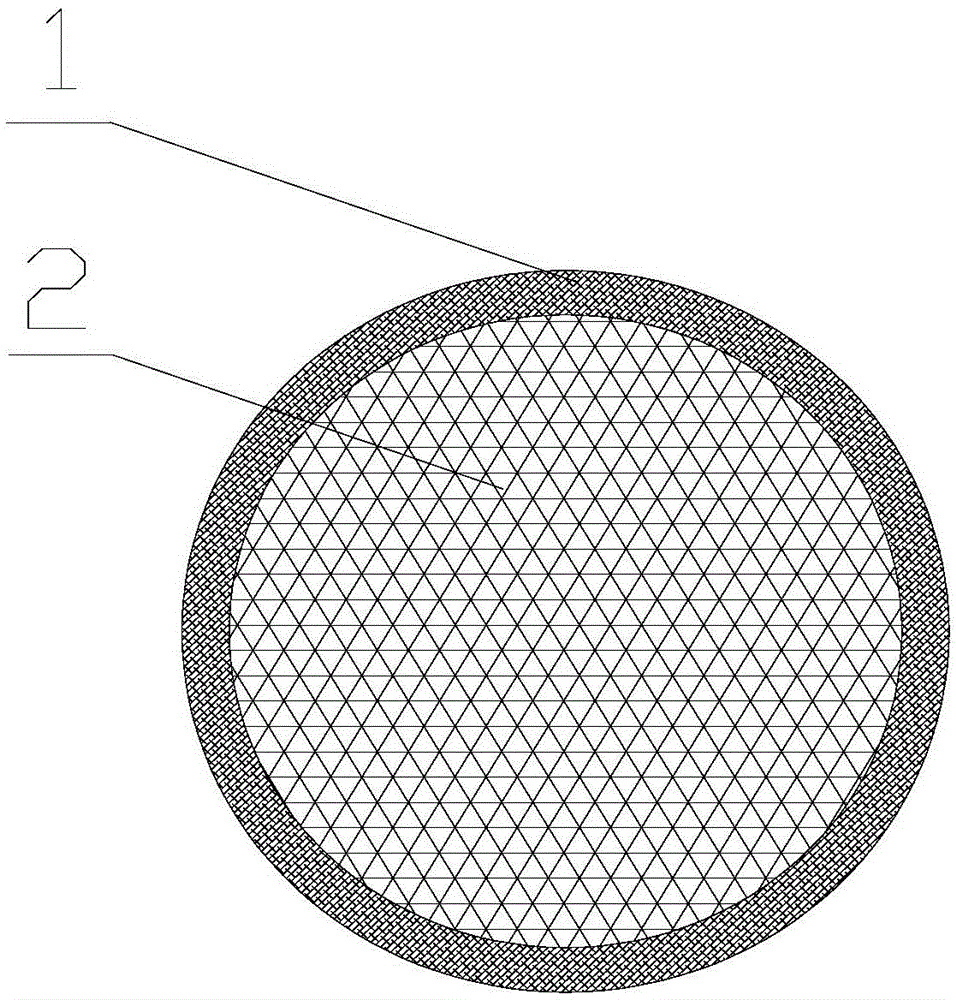

A kind of carbon fiber composite ball and preparation method thereof

A carbon fiber and composite ball technology, applied in the field of carbon fiber composite ball and its preparation, can solve the problems of easy to drop sharp fibers, easy to form agglomerates, difficult to disperse, etc., achieve wide application space, suitable for large-scale continuous production, simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Fiber crushing and mixing: 100 parts of chopped carbon fiber with a length of 3mm, add 10 parts of asphalt powder with a softening point of 280°C, and 7 parts of polyvinyl alcohol fiber with a length of 3mm, crush and mix to obtain a fiber length of 0.06-1.5mm Mixture;

[0034] (2) Spheronization and granulation: take 100 parts of crushed mixture, add 10 parts of liquid binder with a concentration of 5%, spheronize and coat into balls, and sieve to obtain carbon fiber raw material balls with a diameter of 1.7-2.36 mm;

[0035] (3) Secondary spheronization: Take 100 parts of carbon fiber raw material balls and evenly spray 20 parts of thermosetting resin with a concentration of 15%. After the thermosetting resin is completely absorbed, add 5 parts of 200-mesh pitch powder and 10 parts of 200-mesh coke powder accordingly , spheronize and sieve excess powder to obtain carbon fiber secondary processing raw material balls;

[0036] (4) Curing: Curing in air atmosphere a...

Embodiment 2

[0042] (1) Fiber crushing and mixing: 100 parts of 10mm chopped carbon fiber, 10 parts of nitrile rubber powder, 7 parts of 10mm pre-oxidized fiber, crushed and mixed to obtain a crushed mixture with a fiber length of 0.08-2.7mm;

[0043] (2) Spheronization and granulation: take 100 parts of crushed mixture, add 20 parts of liquid binder with a concentration of 10%, spheronize and wrap into balls, and sieve to obtain carbon fiber raw material balls with a diameter of 2-3.35 mm;

[0044] (3) Secondary spheronization: Take 100 parts of carbon fiber raw material balls, evenly spray 45 parts of thermosetting resin with a concentration of 20%, after the thermosetting resin is completely absorbed, add 10 parts of 200 mesh pitch powder accordingly, and add 15 parts of carbon black, Spheronize and sieve excess powder;

[0045] (4) Curing: Curing in air atmosphere at 200°C for 4 hours;

[0046] (5) Carbonization: carbonization in nitrogen atmosphere at 800°C for 30 minutes;

[0047] ...

Embodiment 3

[0051] (1) Fiber crushing and mixing: 100 parts of chopped carbon fibers with a length of 10 mm, 2 parts of phenolic resin powder, 10 parts of polyvinyl alcohol fibers with a length of 3 mm, crushed and mixed to obtain a crushed mixture with a fiber length of 0.05-3 mm;

[0052] (2) Spheronization and granulation: take 100 parts of crushed mixture, add 10 parts of liquid binder with a concentration of 5%, spheronize and coat into balls, and sieve to obtain carbon fiber raw material balls with a diameter of 2.5-3.5 mm;

[0053] (3) Secondary spheronization: Take 10 parts of carbon fiber raw material balls and evenly spray 2 parts of thermosetting resin with a concentration of 5%. Mesh graphite powder, round and sieve excess powder.

[0054] (4) Curing: Curing in air atmosphere at 220°C for 2 hours;

[0055] (5) Carbonization: carbonization in nitrogen atmosphere at 800°C for 30 minutes;

[0056] (6) Graphitization: Graphitization in an argon atmosphere at 2200°C for 30 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com