Steel-ladle diffusion ring gas-permeable upper nozzle seat brick and argon blowing metallurgy method thereof

A nozzle seat brick and dispersion ring technology, applied in metal processing equipment, electrical program control, program control in sequence/logic controller, etc., can solve problems affecting the cleanliness of molten steel, lack of full-process argon blowing metallurgical function, and residual pouring of molten steel Quantity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

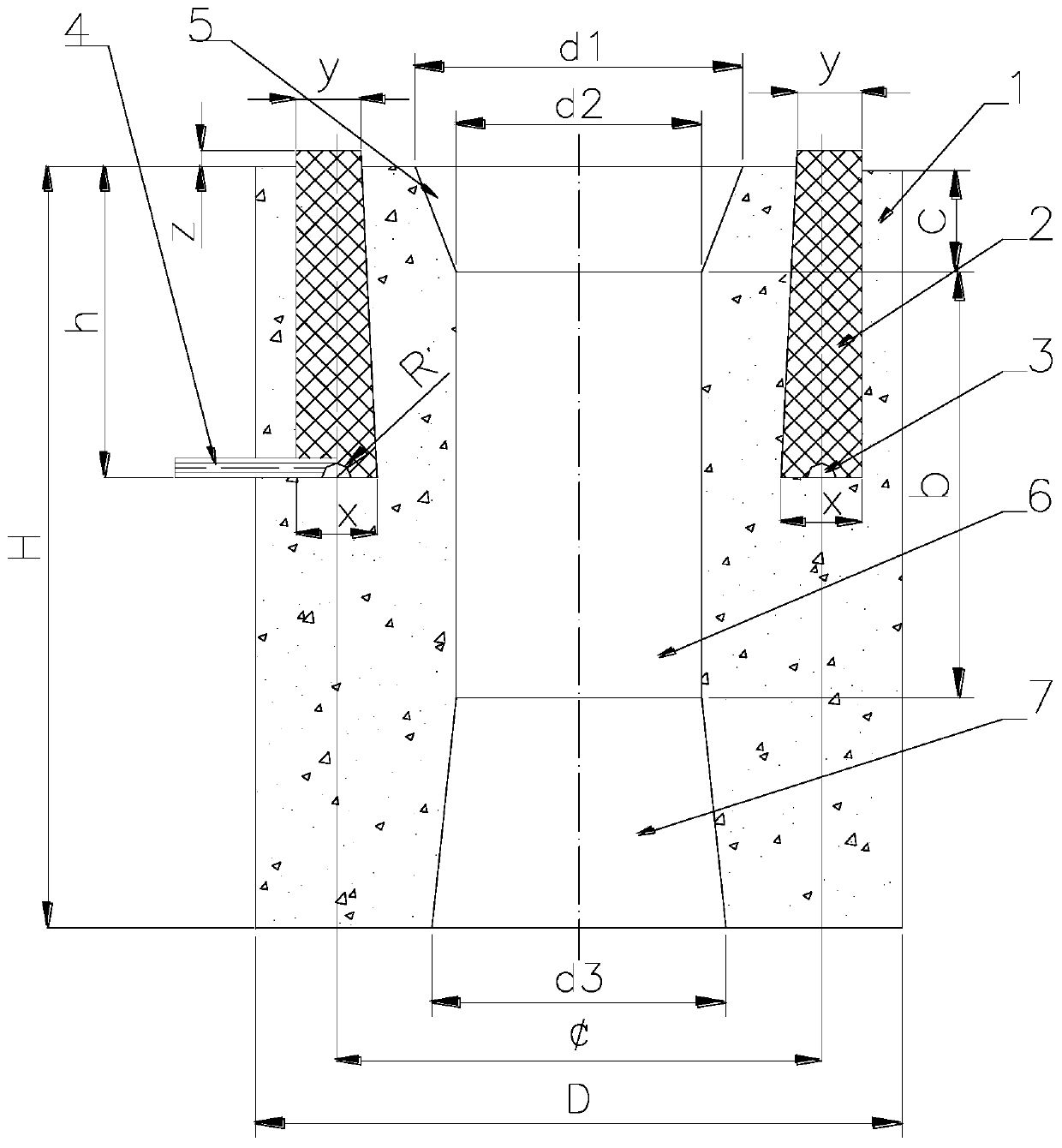

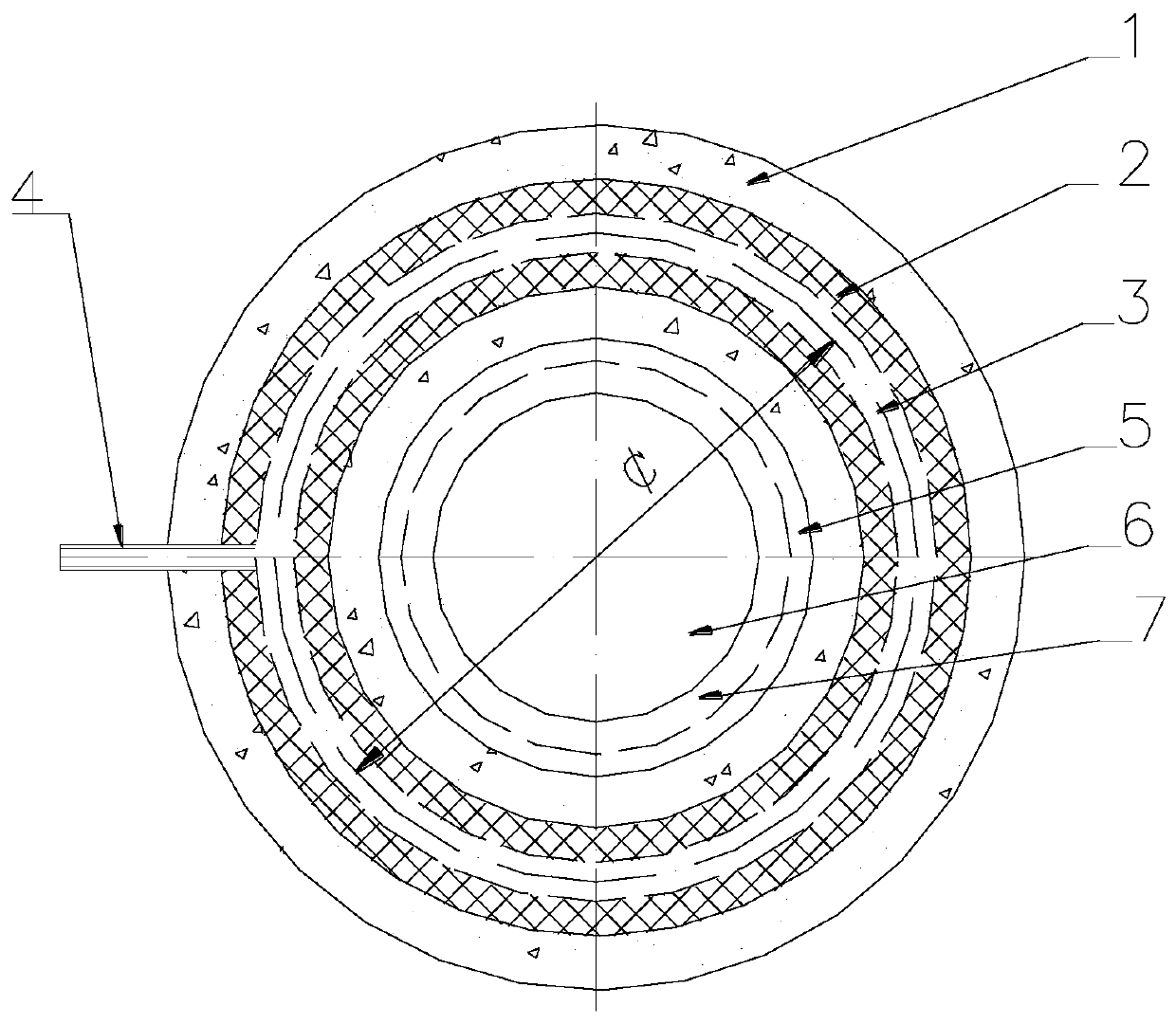

[0042] A ladle diffuser ring breathable upper nozzle seat brick, such as Figure 1-Figure 3As shown, it includes the ladle upper nozzle block body 1, the diffused breathable ring 2, the air chamber 3, and the air intake pipe 4. The middle part of the ladle upper nozzle block body is provided with a flow steel hole 5, a connecting hole 6, and an upper nozzle. Mounting hole 7, said ladle upper nozzle block body 1 is provided with a diffused breathable ring 2 and an air chamber 3 from top to bottom, the upper part of the diffused breathable ring protrudes from the upper surface of the nozzle block body 1, and the air chamber 3 passes through Embedded tire molds are formed at the bottom of the diffused air-permeable ring at one time, and the side of the air chamber 3 is connected with an air intake pipe 4. One end of the air intake pipe communicates with the air chamber, and the other end protrudes from the side of the air curtain retaining wall body 1. It is characterized in that...

Embodiment 2

[0065] As described in Example 1, the ladle diffusion ring breathable upper nozzle seat brick differs in that:

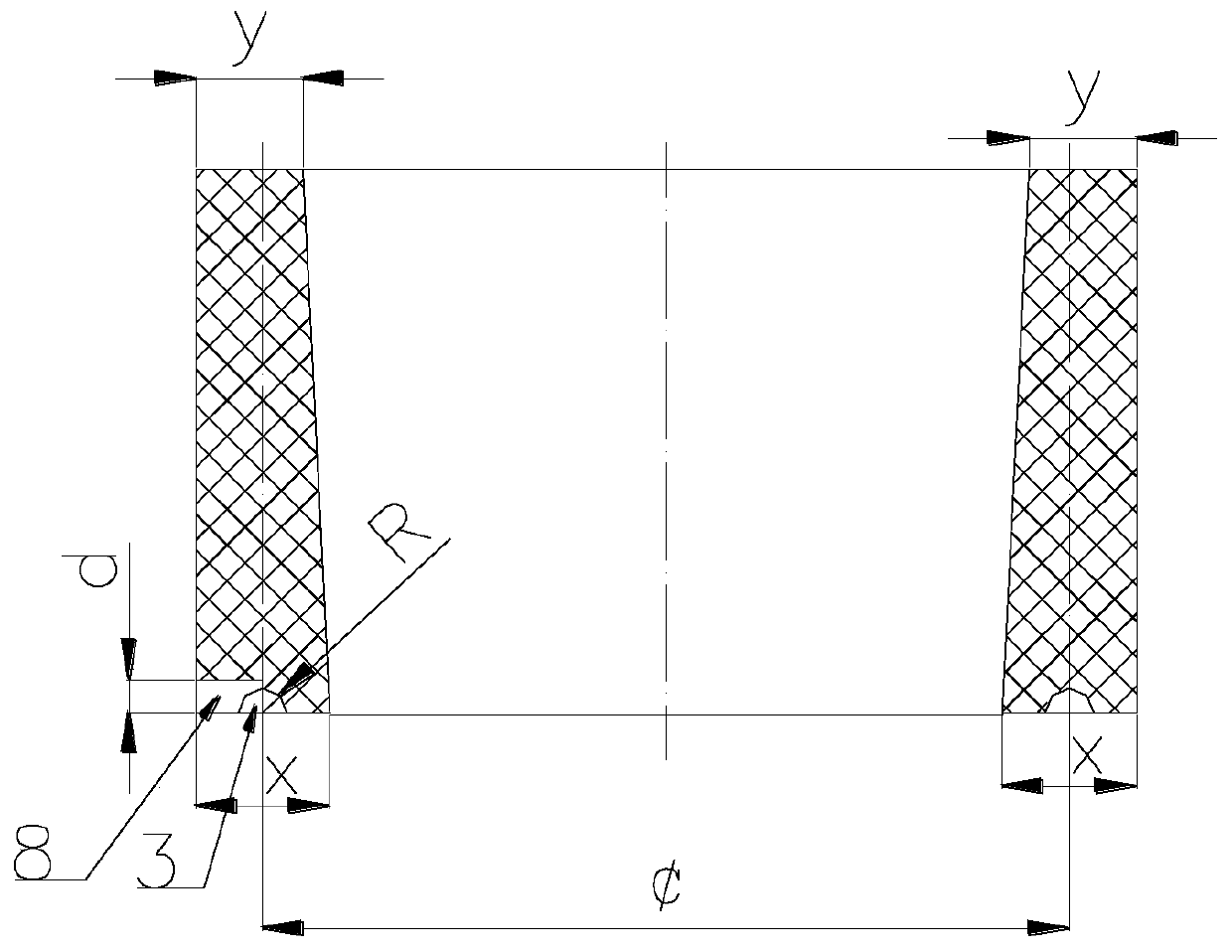

[0066] The diffused air-permeable ring 2 has a circular cross-section and a right-angled trapezoidal longitudinal section. The lower width x of the ring is 60 mm, the upper width y is 56 mm, and the height h is 220 mm.

[0067] The air chamber 3 is in the shape of a ring as a whole, the diameter of the central circle of the ring is 330mm, the longitudinal section of the air chamber is semicircular, and its radius R is 10mm.

[0068] The height Z that the upper end of the diffusion-type breathable ring 2 protrudes from the upper surface of the ladle upper nozzle block body 1 is 10mm.

[0069] Described flow steel hole 5 is circular truncated, and the upper port diameter d1 of circular truncated is 210mm, and the lower port diameter d2 is 160mm, and the height c of circular truncated is 78mm, and described connection hole is cylindrical channel, and the diameter of cy...

Embodiment 3

[0073] As described in Example 1, the ladle diffusion ring breathable upper nozzle seat brick differs in that:

[0074] The diffused air-permeable ring 2 has a circular cross-section and a right-angled trapezoidal longitudinal section. The lower width x of the ring is 50 mm, the upper width y is 46 mm, and the height h is 120 mm.

[0075] The air chamber 3 is circular as a whole, the diameter of the central circle of the ring is 300mm, the longitudinal section of the air chamber is semicircular, and its radius R is 9mm.

[0076] The height Z that the upper end of the diffusion-type breathable ring 2 protrudes from the upper surface of the ladle upper nozzle block body 1 is 5mm.

[0077] Described flow steel hole 5 is circular truncated, and the upper port diameter d1 of circular truncated is 190mm, and the lower port diameter d2 is 140mm, and the height c of circular truncated is 55mm, and described connection hole is cylindrical channel, and the diameter of cylindrical channe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Upper width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com